Comparative friction analysis in high-viscosity fluid gate valves

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Valve Friction Analysis Background and Objectives

Valve friction analysis in high-viscosity fluid environments has become a critical area of study in the field of fluid dynamics and mechanical engineering. The evolution of this technology can be traced back to the early 20th century when the first gate valves were introduced in industrial applications. Over the years, the complexity of fluid systems and the demand for more efficient valve operations have driven continuous advancements in friction analysis techniques.

The primary objective of comparative friction analysis in high-viscosity fluid gate valves is to optimize valve performance, enhance operational efficiency, and extend the lifespan of valve components. This research aims to develop a comprehensive understanding of the friction mechanisms at play within gate valves when handling high-viscosity fluids, such as heavy crude oil, polymer solutions, or certain chemical compounds.

As industrial processes become more sophisticated, the need for precise control and manipulation of high-viscosity fluids has grown exponentially. This has led to an increased focus on minimizing friction-related energy losses and wear in valve systems. The comparative aspect of this analysis is crucial, as it allows engineers and researchers to evaluate different valve designs, materials, and operational parameters under standardized conditions.

The technological trend in this field is moving towards more advanced modeling techniques, incorporating computational fluid dynamics (CFD) and machine learning algorithms to predict and analyze friction behavior. These cutting-edge approaches are complemented by improvements in experimental methods, including high-precision sensors and real-time monitoring systems.

One of the key challenges in this area is the complex nature of high-viscosity fluid behavior, which often exhibits non-Newtonian characteristics. This complexity necessitates a multidisciplinary approach, combining principles from tribology, rheology, and materials science. Researchers are increasingly focusing on developing novel surface treatments and coatings to reduce friction and enhance the durability of valve components.

The expected outcomes of this research include the development of more efficient gate valve designs, improved predictive models for friction behavior, and the establishment of industry standards for friction analysis in high-viscosity fluid applications. These advancements are anticipated to have far-reaching implications across various sectors, including oil and gas, chemical processing, and food manufacturing.

In conclusion, the comparative friction analysis in high-viscosity fluid gate valves represents a critical area of technological development with significant potential for improving industrial processes. By addressing the challenges associated with friction in these demanding environments, researchers and engineers are paving the way for more efficient, reliable, and sustainable fluid handling systems in the future.

The primary objective of comparative friction analysis in high-viscosity fluid gate valves is to optimize valve performance, enhance operational efficiency, and extend the lifespan of valve components. This research aims to develop a comprehensive understanding of the friction mechanisms at play within gate valves when handling high-viscosity fluids, such as heavy crude oil, polymer solutions, or certain chemical compounds.

As industrial processes become more sophisticated, the need for precise control and manipulation of high-viscosity fluids has grown exponentially. This has led to an increased focus on minimizing friction-related energy losses and wear in valve systems. The comparative aspect of this analysis is crucial, as it allows engineers and researchers to evaluate different valve designs, materials, and operational parameters under standardized conditions.

The technological trend in this field is moving towards more advanced modeling techniques, incorporating computational fluid dynamics (CFD) and machine learning algorithms to predict and analyze friction behavior. These cutting-edge approaches are complemented by improvements in experimental methods, including high-precision sensors and real-time monitoring systems.

One of the key challenges in this area is the complex nature of high-viscosity fluid behavior, which often exhibits non-Newtonian characteristics. This complexity necessitates a multidisciplinary approach, combining principles from tribology, rheology, and materials science. Researchers are increasingly focusing on developing novel surface treatments and coatings to reduce friction and enhance the durability of valve components.

The expected outcomes of this research include the development of more efficient gate valve designs, improved predictive models for friction behavior, and the establishment of industry standards for friction analysis in high-viscosity fluid applications. These advancements are anticipated to have far-reaching implications across various sectors, including oil and gas, chemical processing, and food manufacturing.

In conclusion, the comparative friction analysis in high-viscosity fluid gate valves represents a critical area of technological development with significant potential for improving industrial processes. By addressing the challenges associated with friction in these demanding environments, researchers and engineers are paving the way for more efficient, reliable, and sustainable fluid handling systems in the future.

Market Demand for High-Viscosity Fluid Valves

The market demand for high-viscosity fluid gate valves has been steadily increasing across various industries, driven by the growing need for efficient and reliable fluid control systems in challenging operational environments. Industries such as oil and gas, chemical processing, and wastewater treatment are particularly reliant on these specialized valves due to their ability to handle viscous fluids effectively.

In the oil and gas sector, the exploration and production of heavy crude oil have significantly contributed to the demand for high-viscosity fluid gate valves. As global energy demands continue to rise, oil companies are increasingly tapping into heavy oil reserves, which require specialized equipment to extract and process. These valves play a crucial role in managing the flow of thick, viscous crude oil through pipelines and processing facilities.

The chemical processing industry has also seen a surge in demand for high-viscosity fluid gate valves. As manufacturers develop more complex and viscous chemical compounds, the need for valves capable of handling these substances has grown. These valves are essential in ensuring precise flow control and preventing leaks, which is critical for maintaining safety standards and operational efficiency in chemical plants.

Wastewater treatment facilities represent another significant market for high-viscosity fluid gate valves. As urbanization increases and environmental regulations become more stringent, the demand for advanced wastewater treatment solutions has risen. These valves are crucial in managing the flow of thick sludge and other high-viscosity waste materials throughout the treatment process.

The food and beverage industry is emerging as a growing market for these specialized valves. With the increasing production of viscous food products such as syrups, pastes, and purees, manufacturers require reliable valve solutions to ensure precise flow control and maintain product quality. High-viscosity fluid gate valves are well-suited for these applications, offering the necessary performance characteristics to handle thick food products.

Market analysts project a compound annual growth rate (CAGR) for the high-viscosity fluid gate valve market in the coming years. This growth is attributed to ongoing industrial expansion in developing economies, increased focus on energy efficiency, and the continuous development of new materials and manufacturing techniques that enhance valve performance.

As industries continue to push the boundaries of fluid handling capabilities, the demand for innovative high-viscosity fluid gate valves is expected to rise. Manufacturers are likely to focus on developing valves with improved sealing technologies, enhanced corrosion resistance, and optimized flow characteristics to meet the evolving needs of various industries dealing with challenging fluid applications.

In the oil and gas sector, the exploration and production of heavy crude oil have significantly contributed to the demand for high-viscosity fluid gate valves. As global energy demands continue to rise, oil companies are increasingly tapping into heavy oil reserves, which require specialized equipment to extract and process. These valves play a crucial role in managing the flow of thick, viscous crude oil through pipelines and processing facilities.

The chemical processing industry has also seen a surge in demand for high-viscosity fluid gate valves. As manufacturers develop more complex and viscous chemical compounds, the need for valves capable of handling these substances has grown. These valves are essential in ensuring precise flow control and preventing leaks, which is critical for maintaining safety standards and operational efficiency in chemical plants.

Wastewater treatment facilities represent another significant market for high-viscosity fluid gate valves. As urbanization increases and environmental regulations become more stringent, the demand for advanced wastewater treatment solutions has risen. These valves are crucial in managing the flow of thick sludge and other high-viscosity waste materials throughout the treatment process.

The food and beverage industry is emerging as a growing market for these specialized valves. With the increasing production of viscous food products such as syrups, pastes, and purees, manufacturers require reliable valve solutions to ensure precise flow control and maintain product quality. High-viscosity fluid gate valves are well-suited for these applications, offering the necessary performance characteristics to handle thick food products.

Market analysts project a compound annual growth rate (CAGR) for the high-viscosity fluid gate valve market in the coming years. This growth is attributed to ongoing industrial expansion in developing economies, increased focus on energy efficiency, and the continuous development of new materials and manufacturing techniques that enhance valve performance.

As industries continue to push the boundaries of fluid handling capabilities, the demand for innovative high-viscosity fluid gate valves is expected to rise. Manufacturers are likely to focus on developing valves with improved sealing technologies, enhanced corrosion resistance, and optimized flow characteristics to meet the evolving needs of various industries dealing with challenging fluid applications.

Current Challenges in Gate Valve Friction

Gate valve friction in high-viscosity fluid environments presents several significant challenges that impact valve performance, reliability, and operational efficiency. One of the primary issues is the increased resistance to motion caused by the viscous nature of the fluid. As the fluid's viscosity rises, the force required to open or close the valve increases substantially, leading to higher actuator demands and potential operational difficulties.

The presence of high-viscosity fluids also exacerbates wear and tear on valve components, particularly the sealing surfaces and stem. The increased friction between these surfaces accelerates material degradation, potentially leading to premature failure and increased maintenance requirements. This wear can compromise the valve's ability to provide an effective seal, resulting in leakage and reduced process efficiency.

Another challenge lies in the unpredictable behavior of high-viscosity fluids under varying operating conditions. Temperature fluctuations, pressure changes, and flow rates can all affect fluid viscosity, making it difficult to maintain consistent valve performance across different operational scenarios. This variability complicates the design and selection of appropriate valve materials and actuators.

The accumulation of high-viscosity fluid residues on valve surfaces poses an additional problem. These deposits can interfere with valve movement, potentially causing sticking or incomplete closure. Over time, this buildup can lead to increased friction, reduced flow capacity, and compromised valve functionality.

Lubrication becomes a critical concern in high-viscosity environments. Traditional lubricants may be ineffective or quickly displaced by the process fluid, leading to increased metal-to-metal contact and accelerated wear. Developing lubricants that can withstand these challenging conditions while maintaining their protective properties is an ongoing area of research and development.

The dynamic sealing of gate valves in high-viscosity applications presents unique challenges. Achieving a balance between tight sealing to prevent leakage and minimizing friction during valve operation is particularly difficult. Conventional sealing materials may not provide the necessary resilience and low-friction properties required in these demanding environments.

Furthermore, the increased friction in high-viscosity fluid gate valves can lead to higher energy consumption during valve actuation. This not only impacts operational costs but also places additional stress on actuators and control systems, potentially reducing their lifespan and reliability.

Addressing these challenges requires a multifaceted approach, combining advanced materials science, innovative design techniques, and sophisticated modeling and simulation tools to optimize valve performance in high-viscosity fluid applications.

The presence of high-viscosity fluids also exacerbates wear and tear on valve components, particularly the sealing surfaces and stem. The increased friction between these surfaces accelerates material degradation, potentially leading to premature failure and increased maintenance requirements. This wear can compromise the valve's ability to provide an effective seal, resulting in leakage and reduced process efficiency.

Another challenge lies in the unpredictable behavior of high-viscosity fluids under varying operating conditions. Temperature fluctuations, pressure changes, and flow rates can all affect fluid viscosity, making it difficult to maintain consistent valve performance across different operational scenarios. This variability complicates the design and selection of appropriate valve materials and actuators.

The accumulation of high-viscosity fluid residues on valve surfaces poses an additional problem. These deposits can interfere with valve movement, potentially causing sticking or incomplete closure. Over time, this buildup can lead to increased friction, reduced flow capacity, and compromised valve functionality.

Lubrication becomes a critical concern in high-viscosity environments. Traditional lubricants may be ineffective or quickly displaced by the process fluid, leading to increased metal-to-metal contact and accelerated wear. Developing lubricants that can withstand these challenging conditions while maintaining their protective properties is an ongoing area of research and development.

The dynamic sealing of gate valves in high-viscosity applications presents unique challenges. Achieving a balance between tight sealing to prevent leakage and minimizing friction during valve operation is particularly difficult. Conventional sealing materials may not provide the necessary resilience and low-friction properties required in these demanding environments.

Furthermore, the increased friction in high-viscosity fluid gate valves can lead to higher energy consumption during valve actuation. This not only impacts operational costs but also places additional stress on actuators and control systems, potentially reducing their lifespan and reliability.

Addressing these challenges requires a multifaceted approach, combining advanced materials science, innovative design techniques, and sophisticated modeling and simulation tools to optimize valve performance in high-viscosity fluid applications.

Existing Friction Reduction Solutions

01 Friction reduction in gate valve sealing surfaces

Various designs and materials are employed to reduce friction between sealing surfaces in gate valves. This includes the use of low-friction coatings, specialized alloys, and optimized surface treatments to minimize wear and improve valve operation.- Friction reduction in gate valve sealing surfaces: Various techniques are employed to reduce friction between sealing surfaces in gate valves. These include using low-friction materials, applying special coatings, and optimizing the design of sealing surfaces to minimize contact area. Such improvements enhance valve performance and longevity.

- Lubrication systems for gate valves: Innovative lubrication systems are developed to minimize friction in gate valves. These systems may include automatic lubricators, grease injection ports, or integrated lubrication channels. Proper lubrication reduces wear, extends valve life, and ensures smooth operation.

- Gate valve stem friction reduction: Specific attention is given to reducing friction in the valve stem area. This may involve using specialized bearings, optimizing thread design, or incorporating anti-friction materials in stem seals. These improvements contribute to easier valve operation and reduced actuation force requirements.

- Material selection for friction reduction: Careful selection of materials plays a crucial role in minimizing friction in gate valves. Advanced polymers, ceramics, and metal alloys with inherent low-friction properties are utilized for various valve components. This approach enhances overall valve performance and durability.

- Friction-induced vibration mitigation in gate valves: Techniques are developed to address friction-induced vibrations in gate valves. These may include damping mechanisms, optimized flow paths, or specialized valve seat designs. Mitigating these vibrations improves valve reliability and reduces noise during operation.

02 Lubrication systems for gate valves

Integrated lubrication systems are incorporated into gate valve designs to reduce friction and wear. These systems may include grease fittings, lubricant channels, or automatic lubrication mechanisms to ensure smooth valve operation and extended service life.Expand Specific Solutions03 Gate valve seat design for friction reduction

Innovative seat designs are developed to minimize friction in gate valves. This includes floating seats, spring-loaded seats, and seats with specialized geometries that optimize contact area and pressure distribution, reducing wear and improving valve performance.Expand Specific Solutions04 Material selection for low-friction gate valve components

Careful selection of materials for gate valve components, such as stems, gates, and seats, is crucial for reducing friction. Advanced materials like ceramics, high-performance polymers, and composite materials are used to enhance durability and minimize friction-related issues.Expand Specific Solutions05 Friction-reducing mechanisms in gate valve actuators

Gate valve actuators incorporate various mechanisms to reduce friction and improve operational efficiency. These may include roller bearings, thrust washers, or specialized gearing systems that minimize friction during valve opening and closing processes.Expand Specific Solutions

Key Players in Valve Manufacturing Industry

The comparative friction analysis in high-viscosity fluid gate valves is currently in a growth phase, with increasing market demand driven by the oil and gas industry's need for more efficient and reliable valve systems. The global market for specialized valves is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, this field is advancing rapidly, with companies like Vetco Gray, AVK Holding, and Endress+Hauser Flowtec leading innovations. These firms are developing advanced materials and designs to reduce friction and improve performance in high-viscosity environments. While the technology is maturing, there's still room for significant improvements, particularly in areas of material science and fluid dynamics modeling.

Vetco Gray, Inc.

Technical Solution: Vetco Gray, Inc. has developed advanced gate valve designs for high-viscosity fluid applications in the oil and gas industry. Their technology incorporates specialized coatings and surface treatments to reduce friction between the valve gate and seats. The company utilizes computational fluid dynamics (CFD) simulations to optimize valve geometry and flow paths, minimizing pressure drops and enhancing overall performance[1]. Additionally, Vetco Gray has implemented a novel sealing system that maintains integrity even under high-pressure, high-temperature (HPHT) conditions often encountered in deepwater operations[2].

Strengths: Expertise in oil and gas applications, advanced simulation capabilities, and HPHT-resistant designs. Weaknesses: Potentially limited to specific industry applications, may require frequent maintenance in harsh environments.

AVK Holding A/S

Technical Solution: AVK Holding A/S has developed a comprehensive approach to friction analysis and reduction in high-viscosity fluid gate valves. Their technology incorporates advanced surface engineering techniques, including nano-textured surfaces that create micro-hydrodynamic effects to reduce friction[7]. AVK has also implemented a unique double-eccentric valve design that minimizes contact area during valve operation, significantly reducing friction and wear. The company utilizes advanced polymer seals with self-lubricating properties, further enhancing valve performance in high-viscosity applications[8]. AVK's valves are equipped with smart actuators that adjust operating forces based on fluid viscosity, ensuring optimal performance across a wide range of conditions.

Strengths: Advanced surface engineering, innovative valve design, and smart actuation technology. Weaknesses: May have higher production costs, potential complexity in maintenance and repair.

Core Innovations in Valve Tribology

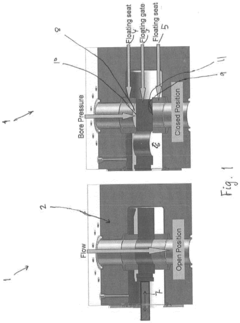

Gate valve

PatentInactiveEP3309277A1

Innovation

- Applying a diamond-like carbon (DLC) top layer coating on sliding surfaces, potentially with hydrogen, to reduce friction, combined with other coatings like carbide or chrome nitride, and using advanced deposition methods like PVD, PACVD, or CVD to ensure effective performance under real-life conditions.

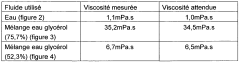

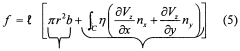

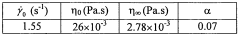

Device and method for measuring the viscosity of a fluid

PatentWO2010043788A1

Innovation

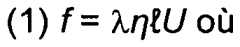

- A method and device that establish a laminar flow in a channel with an elongated element to measure friction force, allowing for precise dynamic viscosity calculation using the relationship f = ληlU, where U is the average flow velocity and λ is a geometric factor, enabling measurements across a wide viscosity range without requiring precise mechanical tolerances or moving parts.

Material Science Advancements for Valve Components

Material science advancements have played a crucial role in enhancing the performance and durability of valve components, particularly in high-viscosity fluid gate valves. Recent developments in this field have focused on improving the friction characteristics and wear resistance of valve materials, leading to significant improvements in valve efficiency and longevity.

One of the key areas of advancement has been in the development of advanced coatings for valve components. These coatings, often based on ceramic or composite materials, provide a low-friction surface that can withstand the harsh operating conditions of high-viscosity fluids. For example, diamond-like carbon (DLC) coatings have shown promising results in reducing friction and wear in valve seats and gates, even under high-pressure and high-temperature conditions.

Nanotechnology has also made significant contributions to material science advancements in valve components. Nanostructured materials and nanocomposites have been developed to enhance the mechanical properties and tribological performance of valve surfaces. These materials offer improved hardness, toughness, and self-lubricating properties, which are essential for reducing friction and extending the service life of valves in high-viscosity fluid applications.

Another area of focus has been the development of advanced polymers and elastomers for valve seals and gaskets. These materials are designed to maintain their mechanical properties and sealing capabilities under extreme conditions, while also providing low friction characteristics. Fluoropolymers, such as PTFE and its derivatives, have been particularly successful in this regard, offering excellent chemical resistance and low friction coefficients.

Surface texturing techniques have also emerged as a promising approach to reducing friction in valve components. By creating micro- or nano-scale patterns on valve surfaces, engineers can control the fluid flow and reduce the contact area between moving parts, thereby minimizing friction and wear. Laser surface texturing and other advanced manufacturing techniques have made it possible to create precise and repeatable surface patterns on a wide range of valve materials.

The integration of smart materials and self-healing technologies into valve components is another exciting area of research. Shape memory alloys and self-healing polymers have the potential to adapt to changing operating conditions and repair minor damage, further extending the lifespan of valve components and reducing maintenance requirements.

These material science advancements have not only improved the performance of high-viscosity fluid gate valves but have also contributed to increased energy efficiency and reduced environmental impact in various industrial applications. As research in this field continues, we can expect further innovations that will push the boundaries of valve technology and enable more efficient and reliable fluid control systems.

One of the key areas of advancement has been in the development of advanced coatings for valve components. These coatings, often based on ceramic or composite materials, provide a low-friction surface that can withstand the harsh operating conditions of high-viscosity fluids. For example, diamond-like carbon (DLC) coatings have shown promising results in reducing friction and wear in valve seats and gates, even under high-pressure and high-temperature conditions.

Nanotechnology has also made significant contributions to material science advancements in valve components. Nanostructured materials and nanocomposites have been developed to enhance the mechanical properties and tribological performance of valve surfaces. These materials offer improved hardness, toughness, and self-lubricating properties, which are essential for reducing friction and extending the service life of valves in high-viscosity fluid applications.

Another area of focus has been the development of advanced polymers and elastomers for valve seals and gaskets. These materials are designed to maintain their mechanical properties and sealing capabilities under extreme conditions, while also providing low friction characteristics. Fluoropolymers, such as PTFE and its derivatives, have been particularly successful in this regard, offering excellent chemical resistance and low friction coefficients.

Surface texturing techniques have also emerged as a promising approach to reducing friction in valve components. By creating micro- or nano-scale patterns on valve surfaces, engineers can control the fluid flow and reduce the contact area between moving parts, thereby minimizing friction and wear. Laser surface texturing and other advanced manufacturing techniques have made it possible to create precise and repeatable surface patterns on a wide range of valve materials.

The integration of smart materials and self-healing technologies into valve components is another exciting area of research. Shape memory alloys and self-healing polymers have the potential to adapt to changing operating conditions and repair minor damage, further extending the lifespan of valve components and reducing maintenance requirements.

These material science advancements have not only improved the performance of high-viscosity fluid gate valves but have also contributed to increased energy efficiency and reduced environmental impact in various industrial applications. As research in this field continues, we can expect further innovations that will push the boundaries of valve technology and enable more efficient and reliable fluid control systems.

Environmental Impact of Valve Friction Reduction

The reduction of friction in high-viscosity fluid gate valves has significant environmental implications, extending beyond operational efficiency to encompass broader ecological considerations. As valve friction decreases, the energy required for valve operation is substantially reduced, leading to lower power consumption in industrial processes. This energy saving translates directly into reduced greenhouse gas emissions, particularly in energy-intensive industries such as oil and gas, chemical processing, and power generation.

Moreover, the minimization of friction in gate valves contributes to extended equipment lifespan. This longevity reduces the frequency of valve replacements, thereby decreasing the demand for raw materials and energy associated with manufacturing new components. The resultant reduction in industrial waste and the conservation of resources align with sustainable manufacturing practices and circular economy principles.

Improved valve performance through friction reduction also mitigates the risk of leaks and fugitive emissions. High-viscosity fluids often contain volatile organic compounds (VOCs) or other environmentally harmful substances. By enhancing seal integrity and reducing wear, low-friction valves minimize the potential for these substances to escape into the environment, thus preventing air and soil pollution.

Furthermore, the optimization of fluid flow achieved through reduced valve friction can lead to more efficient use of process fluids. This efficiency gain potentially reduces the overall consumption of chemicals and raw materials in industrial processes, contributing to resource conservation and minimizing the environmental footprint of operations.

In the context of water management systems, friction reduction in gate valves can improve the energy efficiency of pumping stations and distribution networks. This enhancement is particularly crucial in regions facing water scarcity, as it allows for more effective water resource management and reduces the energy intensity of water supply systems.

Lastly, the environmental benefits of friction reduction extend to noise pollution. Lower friction levels in valve operation typically result in quieter mechanical processes, contributing to improved working conditions and reduced noise emissions from industrial facilities. This aspect is especially relevant in urban or ecologically sensitive areas where noise pollution can have detrimental effects on local ecosystems and human well-being.

Moreover, the minimization of friction in gate valves contributes to extended equipment lifespan. This longevity reduces the frequency of valve replacements, thereby decreasing the demand for raw materials and energy associated with manufacturing new components. The resultant reduction in industrial waste and the conservation of resources align with sustainable manufacturing practices and circular economy principles.

Improved valve performance through friction reduction also mitigates the risk of leaks and fugitive emissions. High-viscosity fluids often contain volatile organic compounds (VOCs) or other environmentally harmful substances. By enhancing seal integrity and reducing wear, low-friction valves minimize the potential for these substances to escape into the environment, thus preventing air and soil pollution.

Furthermore, the optimization of fluid flow achieved through reduced valve friction can lead to more efficient use of process fluids. This efficiency gain potentially reduces the overall consumption of chemicals and raw materials in industrial processes, contributing to resource conservation and minimizing the environmental footprint of operations.

In the context of water management systems, friction reduction in gate valves can improve the energy efficiency of pumping stations and distribution networks. This enhancement is particularly crucial in regions facing water scarcity, as it allows for more effective water resource management and reduces the energy intensity of water supply systems.

Lastly, the environmental benefits of friction reduction extend to noise pollution. Lower friction levels in valve operation typically result in quieter mechanical processes, contributing to improved working conditions and reduced noise emissions from industrial facilities. This aspect is especially relevant in urban or ecologically sensitive areas where noise pollution can have detrimental effects on local ecosystems and human well-being.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!