Gate valve design considerations for chemical resistance in agriculture

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chemical-Resistant Gate Valve Background and Objectives

Gate valves have been a crucial component in agricultural fluid control systems for decades, evolving alongside the industry's growing demands for efficiency and safety. The development of chemical-resistant gate valves represents a significant milestone in this evolution, addressing the unique challenges posed by the diverse and often corrosive chemicals used in modern agriculture.

The primary objective of chemical-resistant gate valve design is to ensure long-term reliability and performance in environments where exposure to aggressive chemicals is commonplace. This goal encompasses not only the valve's ability to withstand chemical attack but also its capacity to maintain operational integrity under varying pressure and temperature conditions typical in agricultural applications.

Historically, gate valves in agriculture were primarily designed for water management. However, the increasing use of fertilizers, pesticides, and other chemical solutions in farming practices has necessitated a shift towards more resilient materials and innovative designs. This transition has been driven by the need to prevent chemical leakage, reduce maintenance costs, and extend the operational lifespan of valves in chemically harsh environments.

The development of chemical-resistant gate valves has been influenced by advancements in material science, particularly in the realm of corrosion-resistant alloys and engineered plastics. These materials have enabled the creation of valve components that can withstand prolonged exposure to a wide range of agricultural chemicals without degradation or loss of function.

Another key objective in the design of these specialized gate valves is to maintain operational efficiency while incorporating chemical resistance. This includes considerations for smooth actuation, minimal pressure drop, and effective sealing under various chemical and physical conditions. Engineers must balance these performance requirements with the need for chemical compatibility, often leading to innovative design solutions.

The agricultural sector's increasing focus on sustainability and environmental protection has also shaped the objectives of chemical-resistant gate valve design. Modern valves are expected to not only resist chemical attack but also to prevent any leakage that could potentially contaminate soil or water sources. This has led to the development of enhanced sealing technologies and fail-safe mechanisms integrated into valve designs.

As the agricultural industry continues to evolve, the objectives for chemical-resistant gate valves expand to include compatibility with smart farming technologies. This involves incorporating sensors and communication capabilities into valve designs, allowing for remote monitoring and control, which is particularly valuable in large-scale agricultural operations where chemical management is critical.

The primary objective of chemical-resistant gate valve design is to ensure long-term reliability and performance in environments where exposure to aggressive chemicals is commonplace. This goal encompasses not only the valve's ability to withstand chemical attack but also its capacity to maintain operational integrity under varying pressure and temperature conditions typical in agricultural applications.

Historically, gate valves in agriculture were primarily designed for water management. However, the increasing use of fertilizers, pesticides, and other chemical solutions in farming practices has necessitated a shift towards more resilient materials and innovative designs. This transition has been driven by the need to prevent chemical leakage, reduce maintenance costs, and extend the operational lifespan of valves in chemically harsh environments.

The development of chemical-resistant gate valves has been influenced by advancements in material science, particularly in the realm of corrosion-resistant alloys and engineered plastics. These materials have enabled the creation of valve components that can withstand prolonged exposure to a wide range of agricultural chemicals without degradation or loss of function.

Another key objective in the design of these specialized gate valves is to maintain operational efficiency while incorporating chemical resistance. This includes considerations for smooth actuation, minimal pressure drop, and effective sealing under various chemical and physical conditions. Engineers must balance these performance requirements with the need for chemical compatibility, often leading to innovative design solutions.

The agricultural sector's increasing focus on sustainability and environmental protection has also shaped the objectives of chemical-resistant gate valve design. Modern valves are expected to not only resist chemical attack but also to prevent any leakage that could potentially contaminate soil or water sources. This has led to the development of enhanced sealing technologies and fail-safe mechanisms integrated into valve designs.

As the agricultural industry continues to evolve, the objectives for chemical-resistant gate valves expand to include compatibility with smart farming technologies. This involves incorporating sensors and communication capabilities into valve designs, allowing for remote monitoring and control, which is particularly valuable in large-scale agricultural operations where chemical management is critical.

Agricultural Market Demand Analysis

The agricultural sector has witnessed a growing demand for advanced gate valve technologies that can withstand harsh chemical environments. This demand is driven by several factors, including the increasing use of chemical fertilizers, pesticides, and other agrochemicals in modern farming practices. Farmers and agricultural businesses are seeking more durable and reliable valve solutions to handle these corrosive substances efficiently and safely.

Market research indicates that the global agricultural valve market is experiencing steady growth, with a particular emphasis on chemically resistant gate valves. This growth is attributed to the expansion of precision agriculture and the adoption of automated irrigation systems, which require robust valve components capable of withstanding prolonged exposure to various chemicals.

In developing countries, where agriculture remains a significant contributor to the economy, there is a rising awareness of the importance of using high-quality, chemically resistant valves to improve crop yields and reduce maintenance costs. This has led to an increased demand for gate valves specifically designed to handle agricultural chemicals.

The market for chemically resistant gate valves in agriculture is also being driven by stringent environmental regulations and safety standards. Farmers and agricultural businesses are under pressure to minimize chemical leaks and spills, making the selection of appropriate valve technologies crucial for compliance and environmental protection.

Another factor contributing to the market demand is the trend towards sustainable agriculture. As farmers seek to optimize resource use and minimize environmental impact, there is a growing interest in precision application of agrochemicals. This requires gate valves that can accurately control the flow of chemicals, even in small quantities, while resisting corrosion and degradation.

The horticultural and greenhouse sectors represent a significant portion of the demand for chemically resistant gate valves. These controlled environments often involve the use of various nutrients and pH-adjusting chemicals in irrigation systems, necessitating valves that can maintain their integrity over extended periods of exposure.

Furthermore, the aquaculture industry, which is experiencing rapid growth globally, is emerging as a new market segment for chemically resistant gate valves. The need to control water quality and manage chemical treatments in fish farms has created additional demand for specialized valve solutions.

In terms of regional demand, Asia-Pacific is expected to be the fastest-growing market for agricultural gate valves, driven by the modernization of farming practices in countries like China and India. North America and Europe continue to be significant markets, with a focus on replacing aging infrastructure and adopting more efficient and environmentally friendly agricultural technologies.

Market research indicates that the global agricultural valve market is experiencing steady growth, with a particular emphasis on chemically resistant gate valves. This growth is attributed to the expansion of precision agriculture and the adoption of automated irrigation systems, which require robust valve components capable of withstanding prolonged exposure to various chemicals.

In developing countries, where agriculture remains a significant contributor to the economy, there is a rising awareness of the importance of using high-quality, chemically resistant valves to improve crop yields and reduce maintenance costs. This has led to an increased demand for gate valves specifically designed to handle agricultural chemicals.

The market for chemically resistant gate valves in agriculture is also being driven by stringent environmental regulations and safety standards. Farmers and agricultural businesses are under pressure to minimize chemical leaks and spills, making the selection of appropriate valve technologies crucial for compliance and environmental protection.

Another factor contributing to the market demand is the trend towards sustainable agriculture. As farmers seek to optimize resource use and minimize environmental impact, there is a growing interest in precision application of agrochemicals. This requires gate valves that can accurately control the flow of chemicals, even in small quantities, while resisting corrosion and degradation.

The horticultural and greenhouse sectors represent a significant portion of the demand for chemically resistant gate valves. These controlled environments often involve the use of various nutrients and pH-adjusting chemicals in irrigation systems, necessitating valves that can maintain their integrity over extended periods of exposure.

Furthermore, the aquaculture industry, which is experiencing rapid growth globally, is emerging as a new market segment for chemically resistant gate valves. The need to control water quality and manage chemical treatments in fish farms has created additional demand for specialized valve solutions.

In terms of regional demand, Asia-Pacific is expected to be the fastest-growing market for agricultural gate valves, driven by the modernization of farming practices in countries like China and India. North America and Europe continue to be significant markets, with a focus on replacing aging infrastructure and adopting more efficient and environmentally friendly agricultural technologies.

Current Challenges in Gate Valve Design

Gate valve design for agricultural applications faces several significant challenges, particularly in ensuring chemical resistance. The primary concern is the diverse range of corrosive and aggressive chemicals used in modern farming practices, including fertilizers, pesticides, and cleaning agents. These substances can rapidly degrade traditional valve materials, leading to premature failure and potential environmental hazards.

One of the key challenges is selecting appropriate materials that can withstand prolonged exposure to these chemicals while maintaining structural integrity and operational efficiency. Conventional materials like carbon steel or standard stainless steel often prove inadequate in these harsh environments. Engineers must consider advanced alloys or specialized coatings that offer superior chemical resistance without compromising the valve's functionality or increasing costs prohibitively.

Another critical issue is the design of sealing components. The seals in gate valves are particularly vulnerable to chemical attack, and their failure can result in leaks or complete valve malfunction. Developing seals that can withstand aggressive chemicals while maintaining a tight seal over extended periods is a complex engineering task. This challenge is compounded by the need for these seals to perform effectively across a wide range of temperatures and pressures typical in agricultural operations.

The variability of chemical exposure presents an additional design hurdle. Agricultural applications may involve intermittent exposure to different chemicals, requiring valve materials and designs that can resist a broad spectrum of substances rather than being optimized for a single chemical environment. This necessitates extensive material testing and validation under various chemical conditions, a time-consuming and costly process.

Maintenance and cleaning procedures also pose significant challenges in gate valve design for agricultural use. The valves must be designed to allow for easy cleaning and maintenance to prevent chemical buildup and ensure long-term reliability. However, this requirement often conflicts with the need for robust, chemically resistant designs, creating a complex balance between accessibility and durability.

Furthermore, the increasing focus on environmental sustainability in agriculture adds another layer of complexity to valve design. Engineers must now consider the environmental impact of the materials used, as well as the potential for chemical leakage. This includes designing valves that minimize the risk of chemical spills and incorporating materials that are environmentally friendly or recyclable where possible.

One of the key challenges is selecting appropriate materials that can withstand prolonged exposure to these chemicals while maintaining structural integrity and operational efficiency. Conventional materials like carbon steel or standard stainless steel often prove inadequate in these harsh environments. Engineers must consider advanced alloys or specialized coatings that offer superior chemical resistance without compromising the valve's functionality or increasing costs prohibitively.

Another critical issue is the design of sealing components. The seals in gate valves are particularly vulnerable to chemical attack, and their failure can result in leaks or complete valve malfunction. Developing seals that can withstand aggressive chemicals while maintaining a tight seal over extended periods is a complex engineering task. This challenge is compounded by the need for these seals to perform effectively across a wide range of temperatures and pressures typical in agricultural operations.

The variability of chemical exposure presents an additional design hurdle. Agricultural applications may involve intermittent exposure to different chemicals, requiring valve materials and designs that can resist a broad spectrum of substances rather than being optimized for a single chemical environment. This necessitates extensive material testing and validation under various chemical conditions, a time-consuming and costly process.

Maintenance and cleaning procedures also pose significant challenges in gate valve design for agricultural use. The valves must be designed to allow for easy cleaning and maintenance to prevent chemical buildup and ensure long-term reliability. However, this requirement often conflicts with the need for robust, chemically resistant designs, creating a complex balance between accessibility and durability.

Furthermore, the increasing focus on environmental sustainability in agriculture adds another layer of complexity to valve design. Engineers must now consider the environmental impact of the materials used, as well as the potential for chemical leakage. This includes designing valves that minimize the risk of chemical spills and incorporating materials that are environmentally friendly or recyclable where possible.

Existing Chemical-Resistant Gate Valve Solutions

01 Material selection for chemical resistance

Choosing appropriate materials for gate valve construction is crucial for chemical resistance. Materials such as stainless steel, titanium, or specialized alloys are often used to withstand corrosive environments. The selection depends on the specific chemicals the valve will be exposed to and the operating conditions.- Material selection for chemical resistance: Choosing appropriate materials for gate valve construction is crucial for chemical resistance. Materials such as stainless steel, titanium, or specialized alloys are often used to withstand corrosive environments. The selection depends on the specific chemicals the valve will be exposed to and the operating conditions.

- Protective coatings and linings: Applying protective coatings or linings to gate valves can enhance their chemical resistance. These coatings, which may include epoxy, PTFE, or other specialized materials, create a barrier between the valve's base material and the corrosive media, extending the valve's lifespan and maintaining its performance in harsh chemical environments.

- Sealing technology for chemical resistance: Advanced sealing technologies are employed to prevent chemical leakage and ensure the gate valve's integrity. This may include the use of specialized gaskets, O-rings, or metal-to-metal seals designed to withstand aggressive chemicals. The sealing materials and designs are chosen based on their compatibility with the process fluids and operating conditions.

- Valve design optimization for chemical applications: Gate valve designs are optimized for chemical resistance by incorporating features such as streamlined flow paths, minimized crevices, and self-draining configurations. These design elements reduce the potential for chemical trapping and corrosion, improving the valve's overall resistance to aggressive media.

- Testing and certification for chemical resistance: Rigorous testing and certification processes are implemented to ensure gate valves meet chemical resistance requirements. This includes exposure tests, material compatibility analyses, and performance evaluations under simulated operating conditions. Certifications and standards compliance provide assurance of the valve's suitability for specific chemical applications.

02 Protective coatings and linings

Applying protective coatings or linings to gate valves can enhance their chemical resistance. These coatings, which may include epoxy, PTFE, or other chemically resistant materials, provide an additional barrier against corrosive substances and extend the valve's lifespan in harsh chemical environments.Expand Specific Solutions03 Sealing technology for chemical resistance

Advanced sealing technologies are employed to prevent chemical leakage and ensure the integrity of gate valves in corrosive environments. This includes the use of specialized gaskets, O-rings, and packing materials that are resistant to chemical attack and degradation.Expand Specific Solutions04 Design optimization for chemical handling

Gate valve designs are optimized for chemical resistance by minimizing areas where chemicals can accumulate or cause damage. This includes features such as streamlined flow paths, self-draining designs, and the elimination of crevices or dead spaces where corrosive substances might collect.Expand Specific Solutions05 Testing and certification for chemical resistance

Rigorous testing and certification processes are implemented to ensure gate valves meet chemical resistance standards. This includes exposure tests to specific chemicals, accelerated aging tests, and performance evaluations under simulated operating conditions to verify the valve's long-term reliability in corrosive environments.Expand Specific Solutions

Key Players in Agricultural Valve Industry

The gate valve design for chemical resistance in agriculture is in a mature stage of development, with a well-established market and proven technologies. The global market for agricultural valves is substantial, driven by increasing mechanization and precision farming practices. Companies like ITT Engineered Valves, Emerson Process Management, and KSB SE & Co. KGaA are key players, offering advanced solutions that incorporate corrosion-resistant materials and innovative sealing technologies. These firms leverage their extensive experience in industrial valve manufacturing to address the specific challenges of agricultural applications, such as exposure to harsh chemicals and varying environmental conditions. The competitive landscape is characterized by a focus on durability, efficiency, and compliance with stringent agricultural standards.

ITT Engineered Valves LLC

Technical Solution: ITT Engineered Valves LLC has developed advanced gate valve designs specifically for chemical resistance in agricultural applications. Their valves utilize high-performance materials such as duplex stainless steel and specialized elastomers to withstand corrosive chemicals commonly used in agriculture[1]. The company's gate valves incorporate innovative sealing technologies, including their proprietary EnviSeal system, which provides superior fugitive emissions control and extends valve life in harsh chemical environments[2]. ITT's valves also feature optimized flow paths and anti-cavitation trim designs to minimize erosion and maximize efficiency when handling abrasive slurries and fertilizers[3]. Additionally, they have implemented modular designs that allow for easy maintenance and part replacement, reducing downtime in agricultural operations.

Strengths: Specialized materials for chemical resistance, advanced sealing technology, optimized flow design for agricultural fluids. Weaknesses: Potentially higher initial cost compared to basic valve options, may require more frequent maintenance in extremely harsh conditions.

BASF Corp.

Technical Solution: BASF Corp. has developed innovative gate valve solutions tailored for chemical resistance in agricultural applications. Their approach focuses on material science, utilizing advanced polymer compounds and coatings to enhance valve durability. BASF's gate valves incorporate their proprietary Ultramid® polyamide resins, which offer excellent chemical resistance and mechanical strength[4]. These valves feature a multi-layer construction, with an inner lining of fluoropolymers like PTFE for superior chemical inertness. BASF has also implemented their Elastocoat® spray coating technology to provide additional protection against corrosive agricultural chemicals[5]. The company's gate valves are designed with self-lubricating components to reduce maintenance requirements and improve longevity in challenging agricultural environments.

Strengths: Advanced material science, multi-layer protection, self-lubricating components for low maintenance. Weaknesses: May have limitations in extreme temperature conditions, potentially higher cost due to specialized materials.

Core Innovations in Material Science

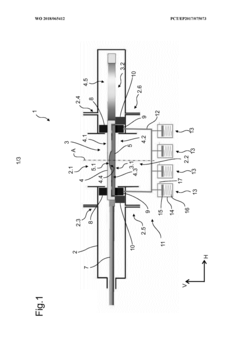

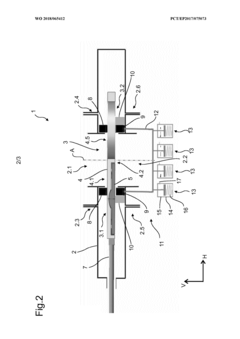

Valve device

PatentWO2008009336A1

Innovation

- A valve device design where the second element with a flow opening is arranged inside the first element, incorporating a movement limiting device to prevent lateral escape of materials, utilizing a latching device and threaded sections for precise control and sealing, ensuring the flow opening remains within the first element during operation.

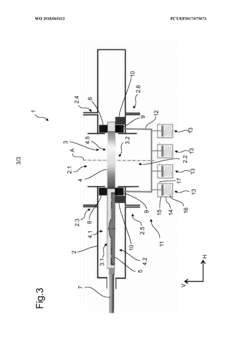

Gate valve for a chemical plant

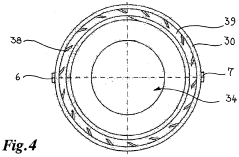

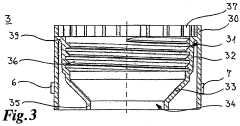

PatentWO2018065412A1

Innovation

- A gate valve design featuring two independently functioning seals, with a fixed upper sealing seat and a moveable lower sealing seat, and a valve gate comprising a first and second plate with a reduced thickness blind recess, allowing for minimal thermal distortion and reduced friction, and utilizing a clamping device for enhanced sealing without continuous pressure.

Environmental Impact and Sustainability

The environmental impact and sustainability considerations of gate valve design for chemical resistance in agriculture are crucial aspects that demand careful attention. These valves play a significant role in controlling the flow of various chemicals used in agricultural processes, and their design directly influences the potential environmental consequences and long-term sustainability of farming practices.

One of the primary environmental concerns is the potential for chemical leakage or spillage. Gate valves designed with superior chemical resistance can significantly reduce the risk of unintended release of agricultural chemicals into the surrounding ecosystem. This is particularly important in areas near water sources, as contamination can have far-reaching effects on aquatic life and water quality. By incorporating materials and sealing mechanisms that withstand corrosive chemicals, gate valve designs can contribute to the prevention of soil and water pollution.

Sustainability in gate valve design extends beyond immediate environmental protection to encompass the longevity and efficiency of the valves themselves. Valves that resist chemical degradation have longer operational lifespans, reducing the frequency of replacement and the associated resource consumption. This durability aspect aligns with sustainable manufacturing principles by minimizing waste generation and the need for raw materials in valve production.

Energy efficiency is another critical factor in the environmental impact of gate valves. Designs that minimize friction and optimize flow characteristics can reduce the energy required for pumping and distribution of agricultural chemicals. This energy reduction translates to lower greenhouse gas emissions associated with power generation, contributing to overall sustainability goals in the agricultural sector.

The choice of materials used in gate valve construction also plays a vital role in their environmental footprint. Sustainable design approaches prioritize the use of recyclable or biodegradable materials where possible, without compromising chemical resistance. Additionally, considering the entire lifecycle of the valve, from production to disposal, can lead to designs that facilitate easier disassembly and recycling at the end of their useful life.

Innovations in gate valve design can also contribute to more precise and efficient application of agricultural chemicals. Valves that allow for better control and metering of chemical flow can help reduce overuse and minimize the environmental impact of excess chemical runoff. This precision not only protects the environment but also improves the economic sustainability of farming operations by optimizing resource use.

In conclusion, the environmental impact and sustainability of gate valve design in agriculture extend far beyond the immediate function of chemical resistance. A holistic approach that considers material selection, energy efficiency, durability, and end-of-life management is essential for developing valve solutions that support sustainable agricultural practices while minimizing environmental harm.

One of the primary environmental concerns is the potential for chemical leakage or spillage. Gate valves designed with superior chemical resistance can significantly reduce the risk of unintended release of agricultural chemicals into the surrounding ecosystem. This is particularly important in areas near water sources, as contamination can have far-reaching effects on aquatic life and water quality. By incorporating materials and sealing mechanisms that withstand corrosive chemicals, gate valve designs can contribute to the prevention of soil and water pollution.

Sustainability in gate valve design extends beyond immediate environmental protection to encompass the longevity and efficiency of the valves themselves. Valves that resist chemical degradation have longer operational lifespans, reducing the frequency of replacement and the associated resource consumption. This durability aspect aligns with sustainable manufacturing principles by minimizing waste generation and the need for raw materials in valve production.

Energy efficiency is another critical factor in the environmental impact of gate valves. Designs that minimize friction and optimize flow characteristics can reduce the energy required for pumping and distribution of agricultural chemicals. This energy reduction translates to lower greenhouse gas emissions associated with power generation, contributing to overall sustainability goals in the agricultural sector.

The choice of materials used in gate valve construction also plays a vital role in their environmental footprint. Sustainable design approaches prioritize the use of recyclable or biodegradable materials where possible, without compromising chemical resistance. Additionally, considering the entire lifecycle of the valve, from production to disposal, can lead to designs that facilitate easier disassembly and recycling at the end of their useful life.

Innovations in gate valve design can also contribute to more precise and efficient application of agricultural chemicals. Valves that allow for better control and metering of chemical flow can help reduce overuse and minimize the environmental impact of excess chemical runoff. This precision not only protects the environment but also improves the economic sustainability of farming operations by optimizing resource use.

In conclusion, the environmental impact and sustainability of gate valve design in agriculture extend far beyond the immediate function of chemical resistance. A holistic approach that considers material selection, energy efficiency, durability, and end-of-life management is essential for developing valve solutions that support sustainable agricultural practices while minimizing environmental harm.

Safety Standards and Compliance

Safety standards and compliance are critical aspects of gate valve design for chemical resistance in agriculture. The agricultural sector deals with a wide range of chemicals, including fertilizers, pesticides, and cleaning agents, which can be corrosive or hazardous. To ensure the safety of workers and the environment, gate valves must adhere to stringent regulations and industry standards.

One of the primary safety standards for agricultural gate valves is the American National Standards Institute (ANSI) B16.34, which specifies pressure-temperature ratings, materials, dimensions, and testing requirements for valves. This standard ensures that gate valves can withstand the pressures and temperatures encountered in agricultural applications while maintaining their chemical resistance properties.

The International Organization for Standardization (ISO) also provides relevant standards, such as ISO 10497 for fire-safe design and testing of valves. This is particularly important in agricultural settings where flammable chemicals may be present, and valve failure could lead to catastrophic consequences.

Chemical resistance in gate valves is further addressed by the ASTM International standards, specifically ASTM F1545, which covers the resistance of plastics to chemical reagents. This standard is crucial for selecting appropriate materials for valve components that come into contact with agricultural chemicals.

Compliance with environmental regulations is another vital consideration. The Environmental Protection Agency (EPA) in the United States sets guidelines for the handling and containment of agricultural chemicals. Gate valves used in these applications must meet EPA requirements to prevent leaks and spills that could contaminate soil or water sources.

The Occupational Safety and Health Administration (OSHA) provides standards for worker safety in agricultural settings. Gate valves must comply with OSHA regulations to minimize the risk of chemical exposure to workers during operation and maintenance.

In the European Union, the ATEX Directive (2014/34/EU) applies to equipment used in potentially explosive atmospheres. Agricultural gate valves that may come into contact with flammable chemicals or dust must be ATEX certified to ensure safe operation in these environments.

Manufacturers of gate valves for agricultural use must also consider the Food and Drug Administration (FDA) regulations, particularly 21 CFR 177, which outlines requirements for materials that come into contact with food products. This is essential for valves used in food processing or handling areas within agricultural facilities.

To demonstrate compliance with these standards, gate valve manufacturers often seek third-party certifications. Organizations such as Underwriters Laboratories (UL) and Factory Mutual (FM) provide testing and certification services that validate the safety and performance of gate valves in various agricultural applications.

One of the primary safety standards for agricultural gate valves is the American National Standards Institute (ANSI) B16.34, which specifies pressure-temperature ratings, materials, dimensions, and testing requirements for valves. This standard ensures that gate valves can withstand the pressures and temperatures encountered in agricultural applications while maintaining their chemical resistance properties.

The International Organization for Standardization (ISO) also provides relevant standards, such as ISO 10497 for fire-safe design and testing of valves. This is particularly important in agricultural settings where flammable chemicals may be present, and valve failure could lead to catastrophic consequences.

Chemical resistance in gate valves is further addressed by the ASTM International standards, specifically ASTM F1545, which covers the resistance of plastics to chemical reagents. This standard is crucial for selecting appropriate materials for valve components that come into contact with agricultural chemicals.

Compliance with environmental regulations is another vital consideration. The Environmental Protection Agency (EPA) in the United States sets guidelines for the handling and containment of agricultural chemicals. Gate valves used in these applications must meet EPA requirements to prevent leaks and spills that could contaminate soil or water sources.

The Occupational Safety and Health Administration (OSHA) provides standards for worker safety in agricultural settings. Gate valves must comply with OSHA regulations to minimize the risk of chemical exposure to workers during operation and maintenance.

In the European Union, the ATEX Directive (2014/34/EU) applies to equipment used in potentially explosive atmospheres. Agricultural gate valves that may come into contact with flammable chemicals or dust must be ATEX certified to ensure safe operation in these environments.

Manufacturers of gate valves for agricultural use must also consider the Food and Drug Administration (FDA) regulations, particularly 21 CFR 177, which outlines requirements for materials that come into contact with food products. This is essential for valves used in food processing or handling areas within agricultural facilities.

To demonstrate compliance with these standards, gate valve manufacturers often seek third-party certifications. Organizations such as Underwriters Laboratories (UL) and Factory Mutual (FM) provide testing and certification services that validate the safety and performance of gate valves in various agricultural applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!