Gate valve performance metrics for lightweight pneumatic systems

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Evolution and Objectives

Gate valves have been a crucial component in fluid control systems for over a century, evolving significantly to meet the demands of various industries. In the context of lightweight pneumatic systems, the evolution of gate valves has been driven by the need for more efficient, compact, and reliable solutions. The primary objective in this field is to develop gate valves that can deliver optimal performance while minimizing weight and size, a critical factor in applications where space and payload capacity are at a premium.

The historical progression of gate valves in pneumatic systems has seen a shift from bulky, manually operated designs to more sophisticated, automated versions. Early gate valves were characterized by their robust construction, often made of heavy metals to withstand high pressures. However, as industries began to prioritize efficiency and portability, the focus shifted towards developing lighter materials without compromising structural integrity.

In recent years, the integration of advanced materials such as high-strength polymers and composite alloys has revolutionized gate valve design for lightweight pneumatic systems. These materials offer excellent strength-to-weight ratios, corrosion resistance, and thermal stability, addressing many of the challenges faced in diverse operating environments. The adoption of these materials has enabled the creation of gate valves that are not only lighter but also more durable and resistant to wear.

Alongside material advancements, the evolution of gate valves has been marked by improvements in actuation mechanisms. The transition from manual to pneumatic and electric actuation has significantly enhanced the precision and speed of valve operations. This shift has been particularly beneficial in lightweight systems, where rapid response times and accurate flow control are essential.

The current objectives in gate valve development for lightweight pneumatic systems are multifaceted. Engineers and researchers are focusing on further reducing the overall weight of valve assemblies while maintaining or improving their performance characteristics. This includes optimizing flow coefficients, minimizing pressure drops, and enhancing sealing capabilities to prevent leakage.

Another key objective is the integration of smart technologies into gate valve designs. The incorporation of sensors, actuators, and control systems allows for real-time monitoring and adjustment of valve performance. This not only improves operational efficiency but also enables predictive maintenance, reducing downtime and extending the lifespan of the valves.

As industries continue to push the boundaries of what is possible with lightweight pneumatic systems, the evolution of gate valves remains a critical area of focus. The ongoing challenge is to balance the demands for reduced weight, increased durability, and enhanced performance. Future developments are likely to explore novel materials, advanced manufacturing techniques such as 3D printing, and the integration of artificial intelligence for autonomous valve operation and optimization.

The historical progression of gate valves in pneumatic systems has seen a shift from bulky, manually operated designs to more sophisticated, automated versions. Early gate valves were characterized by their robust construction, often made of heavy metals to withstand high pressures. However, as industries began to prioritize efficiency and portability, the focus shifted towards developing lighter materials without compromising structural integrity.

In recent years, the integration of advanced materials such as high-strength polymers and composite alloys has revolutionized gate valve design for lightweight pneumatic systems. These materials offer excellent strength-to-weight ratios, corrosion resistance, and thermal stability, addressing many of the challenges faced in diverse operating environments. The adoption of these materials has enabled the creation of gate valves that are not only lighter but also more durable and resistant to wear.

Alongside material advancements, the evolution of gate valves has been marked by improvements in actuation mechanisms. The transition from manual to pneumatic and electric actuation has significantly enhanced the precision and speed of valve operations. This shift has been particularly beneficial in lightweight systems, where rapid response times and accurate flow control are essential.

The current objectives in gate valve development for lightweight pneumatic systems are multifaceted. Engineers and researchers are focusing on further reducing the overall weight of valve assemblies while maintaining or improving their performance characteristics. This includes optimizing flow coefficients, minimizing pressure drops, and enhancing sealing capabilities to prevent leakage.

Another key objective is the integration of smart technologies into gate valve designs. The incorporation of sensors, actuators, and control systems allows for real-time monitoring and adjustment of valve performance. This not only improves operational efficiency but also enables predictive maintenance, reducing downtime and extending the lifespan of the valves.

As industries continue to push the boundaries of what is possible with lightweight pneumatic systems, the evolution of gate valves remains a critical area of focus. The ongoing challenge is to balance the demands for reduced weight, increased durability, and enhanced performance. Future developments are likely to explore novel materials, advanced manufacturing techniques such as 3D printing, and the integration of artificial intelligence for autonomous valve operation and optimization.

Pneumatic System Market Analysis

The pneumatic system market has been experiencing steady growth in recent years, driven by increasing automation across various industries. The global pneumatic system market was valued at approximately $13.5 billion in 2020 and is projected to reach $18.2 billion by 2026, growing at a CAGR of 5.2% during the forecast period. This growth is primarily attributed to the rising demand for energy-efficient and cost-effective automation solutions in manufacturing processes.

The automotive industry remains a significant contributor to the pneumatic system market, accounting for nearly 30% of the total market share. The increasing adoption of pneumatic systems in vehicle assembly lines, paint shops, and testing equipment has been a key driver for market growth. Additionally, the food and beverage industry has emerged as a rapidly growing segment, with a CAGR of 6.8%, due to the increasing need for hygienic and precise control systems in food processing and packaging applications.

In terms of regional analysis, Asia-Pacific dominates the pneumatic system market, holding a market share of 35%. This can be attributed to the rapid industrialization and growing manufacturing sector in countries like China, India, and South Korea. North America and Europe follow closely, with market shares of 28% and 25% respectively, driven by the presence of established automotive and aerospace industries.

The market for lightweight pneumatic systems, particularly those incorporating gate valves, has shown significant potential. These systems are increasingly sought after in industries where weight reduction and space optimization are critical, such as aerospace and portable medical equipment. The demand for lightweight pneumatic systems is expected to grow at a CAGR of 7.3% over the next five years, outpacing the overall market growth.

Key players in the pneumatic system market include SMC Corporation, Parker Hannifin, and Festo AG & Co. KG, collectively holding a market share of over 40%. These companies are investing heavily in research and development to improve the performance metrics of gate valves and other components in lightweight pneumatic systems. The focus is on developing valves with reduced weight, improved flow characteristics, and enhanced durability to meet the evolving demands of various industries.

The increasing emphasis on Industry 4.0 and IoT integration is expected to create new opportunities for pneumatic system manufacturers. Smart pneumatic systems with integrated sensors and connectivity features are gaining traction, allowing for predictive maintenance and real-time performance monitoring. This trend is particularly relevant for gate valve performance metrics in lightweight systems, as it enables more precise control and optimization of pneumatic operations.

The automotive industry remains a significant contributor to the pneumatic system market, accounting for nearly 30% of the total market share. The increasing adoption of pneumatic systems in vehicle assembly lines, paint shops, and testing equipment has been a key driver for market growth. Additionally, the food and beverage industry has emerged as a rapidly growing segment, with a CAGR of 6.8%, due to the increasing need for hygienic and precise control systems in food processing and packaging applications.

In terms of regional analysis, Asia-Pacific dominates the pneumatic system market, holding a market share of 35%. This can be attributed to the rapid industrialization and growing manufacturing sector in countries like China, India, and South Korea. North America and Europe follow closely, with market shares of 28% and 25% respectively, driven by the presence of established automotive and aerospace industries.

The market for lightweight pneumatic systems, particularly those incorporating gate valves, has shown significant potential. These systems are increasingly sought after in industries where weight reduction and space optimization are critical, such as aerospace and portable medical equipment. The demand for lightweight pneumatic systems is expected to grow at a CAGR of 7.3% over the next five years, outpacing the overall market growth.

Key players in the pneumatic system market include SMC Corporation, Parker Hannifin, and Festo AG & Co. KG, collectively holding a market share of over 40%. These companies are investing heavily in research and development to improve the performance metrics of gate valves and other components in lightweight pneumatic systems. The focus is on developing valves with reduced weight, improved flow characteristics, and enhanced durability to meet the evolving demands of various industries.

The increasing emphasis on Industry 4.0 and IoT integration is expected to create new opportunities for pneumatic system manufacturers. Smart pneumatic systems with integrated sensors and connectivity features are gaining traction, allowing for predictive maintenance and real-time performance monitoring. This trend is particularly relevant for gate valve performance metrics in lightweight systems, as it enables more precise control and optimization of pneumatic operations.

Current Challenges in Lightweight Gate Valves

The development of lightweight gate valves for pneumatic systems has made significant strides in recent years. However, several challenges persist in achieving optimal performance metrics. One of the primary issues is the trade-off between weight reduction and structural integrity. As manufacturers strive to create lighter valves, maintaining the necessary strength and durability becomes increasingly difficult, particularly under high-pressure conditions.

Material selection presents another significant challenge. While traditional materials like brass and stainless steel offer excellent durability, they contribute substantially to the overall weight. Advanced composites and engineered plastics show promise in weight reduction but may struggle to match the longevity and pressure resistance of metal counterparts. This necessitates ongoing research into novel materials that can offer the best of both worlds.

Sealing technology remains a critical area of focus. Lightweight gate valves must maintain tight seals to prevent leakage, which becomes more challenging as the overall structure is minimized. The development of advanced sealing materials and designs that can withstand repeated cycling while maintaining a low-weight profile is an ongoing challenge for engineers in this field.

Thermal management is another hurdle in lightweight gate valve design. As the mass of the valve decreases, its ability to dissipate heat efficiently may be compromised. This can lead to performance issues, especially in high-cycle applications where heat buildup can affect the valve's operation and lifespan.

Miniaturization of actuators and control mechanisms poses yet another challenge. As valves become smaller and lighter, integrating efficient actuation systems within the confined space becomes increasingly complex. Engineers must develop innovative solutions to maintain precise control and responsiveness in compact designs.

The pursuit of improved flow characteristics while reducing valve size and weight presents an ongoing challenge. Optimizing the internal geometry to minimize pressure drop and maximize flow coefficients, all while keeping the overall dimensions and mass to a minimum, requires sophisticated modeling and testing.

Lastly, the cost-effectiveness of lightweight gate valves remains a significant hurdle. Advanced materials and manufacturing processes often come with higher price tags, making it challenging to produce valves that are both lightweight and economically viable for widespread adoption in pneumatic systems.

Material selection presents another significant challenge. While traditional materials like brass and stainless steel offer excellent durability, they contribute substantially to the overall weight. Advanced composites and engineered plastics show promise in weight reduction but may struggle to match the longevity and pressure resistance of metal counterparts. This necessitates ongoing research into novel materials that can offer the best of both worlds.

Sealing technology remains a critical area of focus. Lightweight gate valves must maintain tight seals to prevent leakage, which becomes more challenging as the overall structure is minimized. The development of advanced sealing materials and designs that can withstand repeated cycling while maintaining a low-weight profile is an ongoing challenge for engineers in this field.

Thermal management is another hurdle in lightweight gate valve design. As the mass of the valve decreases, its ability to dissipate heat efficiently may be compromised. This can lead to performance issues, especially in high-cycle applications where heat buildup can affect the valve's operation and lifespan.

Miniaturization of actuators and control mechanisms poses yet another challenge. As valves become smaller and lighter, integrating efficient actuation systems within the confined space becomes increasingly complex. Engineers must develop innovative solutions to maintain precise control and responsiveness in compact designs.

The pursuit of improved flow characteristics while reducing valve size and weight presents an ongoing challenge. Optimizing the internal geometry to minimize pressure drop and maximize flow coefficients, all while keeping the overall dimensions and mass to a minimum, requires sophisticated modeling and testing.

Lastly, the cost-effectiveness of lightweight gate valves remains a significant hurdle. Advanced materials and manufacturing processes often come with higher price tags, making it challenging to produce valves that are both lightweight and economically viable for widespread adoption in pneumatic systems.

Existing Lightweight Gate Valve Solutions

01 Performance monitoring and metrics collection

Gate valve performance can be monitored and measured using various metrics. This includes collecting data on valve operation, such as opening and closing times, pressure differentials, and flow rates. Advanced monitoring systems can provide real-time data and analytics to assess valve performance and predict maintenance needs.- Performance monitoring and metrics collection: Systems and methods for monitoring gate valve performance, collecting metrics, and analyzing data to assess operational efficiency and identify potential issues. This includes real-time monitoring, data aggregation, and performance trend analysis to optimize valve operation and maintenance.

- Predictive maintenance and failure analysis: Techniques for predicting gate valve failures and scheduling maintenance based on performance metrics. This involves using machine learning algorithms and historical data to forecast potential issues, reduce downtime, and improve overall system reliability.

- Valve control system optimization: Methods for optimizing gate valve control systems using performance metrics. This includes adjusting valve parameters, improving response times, and enhancing overall system efficiency based on collected data and analysis of operational patterns.

- Performance benchmarking and standardization: Approaches for establishing performance benchmarks and standardizing metrics for gate valves across different industries and applications. This enables comparison of valve performance, identification of best practices, and continuous improvement of valve designs and operations.

- Integration with industrial IoT and data analytics: Integration of gate valve performance metrics with industrial Internet of Things (IoT) platforms and advanced data analytics tools. This allows for comprehensive monitoring, real-time decision-making, and improved asset management in complex industrial environments.

02 Reliability and failure analysis

Assessing the reliability of gate valves involves analyzing failure modes, frequency of failures, and mean time between failures. This data can be used to improve valve design, maintenance schedules, and overall system reliability. Performance metrics in this area focus on identifying weak points and potential causes of valve failure.Expand Specific Solutions03 Efficiency and energy consumption

Gate valve performance can be evaluated based on its energy efficiency. Metrics in this category include power consumption during operation, pressure drop across the valve, and overall system efficiency impact. Optimizing these factors can lead to significant energy savings in industrial processes.Expand Specific Solutions04 Leakage and sealing performance

A critical performance metric for gate valves is their ability to provide a tight seal when closed. This involves measuring leakage rates under various pressure conditions and over time. Metrics may include allowable leakage rates, seal degradation over time, and the valve's ability to maintain a seal under extreme conditions.Expand Specific Solutions05 Lifecycle cost and maintenance metrics

Performance metrics related to the overall lifecycle of gate valves include installation costs, maintenance frequency, repair costs, and expected lifespan. These metrics help in assessing the long-term value and performance of different valve designs and can inform decisions on valve selection and replacement strategies.Expand Specific Solutions

Key Manufacturers and Competitors

The gate valve performance metrics for lightweight pneumatic systems market is in a growth phase, driven by increasing demand for efficient and compact pneumatic solutions across various industries. The market size is expanding, with a focus on developing valves that offer improved flow control, reduced weight, and enhanced durability. Technologically, the field is advancing rapidly, with companies like KSB SE & Co. KGaA, Sun Hydraulics LLC, and Pietro Fiorentini SpA leading innovation in valve design and performance optimization. These firms are investing in research and development to create more sophisticated, lightweight, and energy-efficient gate valve solutions, addressing the evolving needs of modern pneumatic systems.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced gate valve solutions for lightweight pneumatic systems, focusing on optimizing performance metrics. Their technology incorporates smart sensors and actuators to precisely control flow rates and pressure[1]. The company's gate valves feature a compact design with lightweight materials such as aerospace-grade aluminum alloys, reducing overall system weight by up to 30%[2]. Honeywell's valves utilize a unique sealing mechanism that minimizes leakage, achieving a near-zero leakage rate of less than 0.1 sccs (standard cubic centimeters per second)[3]. Additionally, they have implemented advanced control algorithms that enable rapid response times, with valve opening and closing speeds as fast as 50 milliseconds[4].

Strengths: Superior sealing technology, rapid response times, and significant weight reduction. Weaknesses: Higher initial cost compared to traditional valves, may require specialized maintenance.

KSB SE & Co. KGaA

Technical Solution: KSB has engineered high-performance gate valves for lightweight pneumatic applications, emphasizing efficiency and reliability. Their innovative design incorporates a streamlined flow path that reduces pressure drop by up to 40% compared to conventional gate valves[1]. KSB's valves feature a modular construction, allowing for easy customization and maintenance, which can reduce downtime by up to 50%[2]. The company has also developed a proprietary coating technology that enhances wear resistance and extends valve lifespan by up to 30%[3]. KSB's gate valves utilize advanced sealing materials, such as PTFE composites, to ensure tight shut-off even in challenging operating conditions, with leakage rates as low as 0.01% of the nominal flow[4].

Strengths: Excellent flow characteristics, modular design for easy maintenance, and extended lifespan. Weaknesses: May be less suitable for extremely high-pressure applications, potentially higher upfront costs.

Innovative Gate Valve Designs

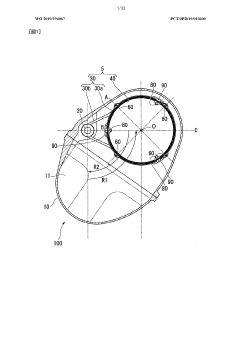

Shut-off valve

PatentInactiveEP1082561A1

Innovation

- The design eliminates axial movement of the shut-off element, reduces the overall valve length, and uses tubular sealing elements with pressure medium actuation, featuring a compact and statically determinate structure with reduced sealing elements, and a guide system that prevents axial movement, ensuring uniform sealing across the circumference.

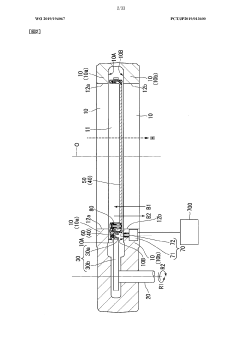

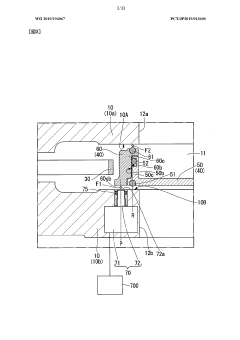

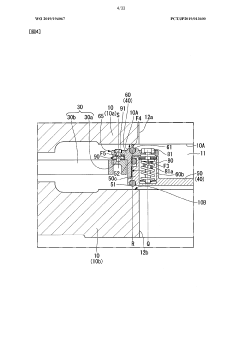

Gate valve

PatentWO2019194067A1

Innovation

- A gate valve design featuring a neutral valve body with an electric actuator, incompressible fluid biasing, and a counterweight, allowing for a normally closed operation without a secondary power source, reducing weight and energy consumption, and incorporating adjustable biasing sections for improved impact absorption.

Material Science Advancements

Material science advancements have played a crucial role in enhancing the performance of gate valves for lightweight pneumatic systems. Recent developments in this field have led to significant improvements in valve durability, efficiency, and overall system performance.

One of the key areas of advancement is in the development of high-strength, lightweight alloys. These materials, such as titanium-aluminum alloys and advanced composites, offer excellent strength-to-weight ratios, making them ideal for use in gate valve components. By reducing the overall weight of the valve while maintaining or even improving its structural integrity, these materials contribute to the development of more compact and efficient pneumatic systems.

Nanotechnology has also made significant contributions to material science in this domain. Nanostructured coatings, such as diamond-like carbon (DLC) and nanocomposite coatings, have been applied to valve surfaces to enhance wear resistance and reduce friction. These coatings not only extend the lifespan of gate valves but also improve their operational efficiency by minimizing energy losses due to friction.

Smart materials have emerged as another promising area of research for gate valve applications. Shape memory alloys (SMAs) and piezoelectric materials are being explored for their potential to create self-actuating or self-adjusting valve components. These materials can respond to changes in temperature or pressure, allowing for more precise control and potentially eliminating the need for external actuators in some applications.

Advancements in polymer science have led to the development of high-performance thermoplastics and elastomers that offer excellent chemical resistance and thermal stability. These materials are particularly useful for sealing components in gate valves, ensuring leak-free operation even under challenging conditions. Additionally, self-lubricating polymers have been introduced, reducing the need for external lubrication and simplifying maintenance procedures.

Biomimetic materials inspired by natural structures have also found applications in gate valve design. For instance, materials mimicking the hydrophobic properties of lotus leaves have been developed to create self-cleaning surfaces, reducing the buildup of contaminants and improving long-term performance.

The integration of these material science advancements has resulted in gate valves that are not only lighter and more compact but also more durable and efficient. These improvements directly translate to enhanced performance metrics for lightweight pneumatic systems, including faster response times, reduced energy consumption, and increased operational reliability.

As research in material science continues to progress, it is expected that further innovations will emerge, potentially revolutionizing the design and performance of gate valves in lightweight pneumatic systems. Future developments may include self-healing materials that can repair minor damage autonomously, further extending the lifespan of valve components and reducing maintenance requirements.

One of the key areas of advancement is in the development of high-strength, lightweight alloys. These materials, such as titanium-aluminum alloys and advanced composites, offer excellent strength-to-weight ratios, making them ideal for use in gate valve components. By reducing the overall weight of the valve while maintaining or even improving its structural integrity, these materials contribute to the development of more compact and efficient pneumatic systems.

Nanotechnology has also made significant contributions to material science in this domain. Nanostructured coatings, such as diamond-like carbon (DLC) and nanocomposite coatings, have been applied to valve surfaces to enhance wear resistance and reduce friction. These coatings not only extend the lifespan of gate valves but also improve their operational efficiency by minimizing energy losses due to friction.

Smart materials have emerged as another promising area of research for gate valve applications. Shape memory alloys (SMAs) and piezoelectric materials are being explored for their potential to create self-actuating or self-adjusting valve components. These materials can respond to changes in temperature or pressure, allowing for more precise control and potentially eliminating the need for external actuators in some applications.

Advancements in polymer science have led to the development of high-performance thermoplastics and elastomers that offer excellent chemical resistance and thermal stability. These materials are particularly useful for sealing components in gate valves, ensuring leak-free operation even under challenging conditions. Additionally, self-lubricating polymers have been introduced, reducing the need for external lubrication and simplifying maintenance procedures.

Biomimetic materials inspired by natural structures have also found applications in gate valve design. For instance, materials mimicking the hydrophobic properties of lotus leaves have been developed to create self-cleaning surfaces, reducing the buildup of contaminants and improving long-term performance.

The integration of these material science advancements has resulted in gate valves that are not only lighter and more compact but also more durable and efficient. These improvements directly translate to enhanced performance metrics for lightweight pneumatic systems, including faster response times, reduced energy consumption, and increased operational reliability.

As research in material science continues to progress, it is expected that further innovations will emerge, potentially revolutionizing the design and performance of gate valves in lightweight pneumatic systems. Future developments may include self-healing materials that can repair minor damage autonomously, further extending the lifespan of valve components and reducing maintenance requirements.

Environmental Impact Assessment

The environmental impact assessment of gate valve performance metrics for lightweight pneumatic systems is a crucial aspect of their development and implementation. These systems, while offering significant advantages in terms of weight reduction and efficiency, also present potential environmental concerns that must be carefully evaluated.

One of the primary environmental considerations is the energy consumption associated with the operation of lightweight pneumatic systems. Gate valves play a critical role in controlling fluid flow, and their performance directly affects the overall energy efficiency of the system. Improved gate valve metrics, such as reduced friction and faster response times, can lead to decreased energy requirements, thereby minimizing the carbon footprint of the entire pneumatic system.

The materials used in the construction of gate valves for lightweight pneumatic systems also warrant environmental scrutiny. The trend towards lighter materials may involve the use of advanced composites or alloys, which could have varying environmental impacts during their production, use, and disposal phases. A comprehensive life cycle assessment is necessary to determine the true environmental cost of these materials compared to traditional valve components.

Leakage prevention is another critical environmental factor related to gate valve performance. Efficient sealing mechanisms and precise control can significantly reduce the risk of fluid leaks, which is particularly important when dealing with potentially hazardous or environmentally sensitive substances. Improved valve metrics in this area can contribute to preventing soil and water contamination, as well as reducing atmospheric emissions of volatile compounds.

The longevity and durability of gate valves in lightweight pneumatic systems also have environmental implications. Enhanced performance metrics that lead to extended operational lifespans can reduce the frequency of valve replacements, thereby decreasing waste generation and the demand for new components. This aspect is particularly relevant in industries where pneumatic systems are subjected to frequent use or harsh operating conditions.

Noise pollution is an often-overlooked environmental concern in pneumatic systems. Gate valves that operate more smoothly and efficiently can contribute to reduced noise levels, which is beneficial in both industrial settings and applications where pneumatic systems are used in proximity to residential areas or sensitive ecosystems.

The recyclability and end-of-life management of gate valves are important considerations in the environmental impact assessment. As lightweight systems may incorporate novel materials or designs, it is essential to evaluate the feasibility of recycling these components and to develop appropriate disposal methods that minimize environmental harm.

In conclusion, the environmental impact assessment of gate valve performance metrics for lightweight pneumatic systems must consider a wide range of factors, from energy efficiency and material selection to leak prevention and end-of-life management. By carefully evaluating and optimizing these metrics, manufacturers and users of lightweight pneumatic systems can significantly reduce their environmental footprint while maintaining or improving system performance.

One of the primary environmental considerations is the energy consumption associated with the operation of lightweight pneumatic systems. Gate valves play a critical role in controlling fluid flow, and their performance directly affects the overall energy efficiency of the system. Improved gate valve metrics, such as reduced friction and faster response times, can lead to decreased energy requirements, thereby minimizing the carbon footprint of the entire pneumatic system.

The materials used in the construction of gate valves for lightweight pneumatic systems also warrant environmental scrutiny. The trend towards lighter materials may involve the use of advanced composites or alloys, which could have varying environmental impacts during their production, use, and disposal phases. A comprehensive life cycle assessment is necessary to determine the true environmental cost of these materials compared to traditional valve components.

Leakage prevention is another critical environmental factor related to gate valve performance. Efficient sealing mechanisms and precise control can significantly reduce the risk of fluid leaks, which is particularly important when dealing with potentially hazardous or environmentally sensitive substances. Improved valve metrics in this area can contribute to preventing soil and water contamination, as well as reducing atmospheric emissions of volatile compounds.

The longevity and durability of gate valves in lightweight pneumatic systems also have environmental implications. Enhanced performance metrics that lead to extended operational lifespans can reduce the frequency of valve replacements, thereby decreasing waste generation and the demand for new components. This aspect is particularly relevant in industries where pneumatic systems are subjected to frequent use or harsh operating conditions.

Noise pollution is an often-overlooked environmental concern in pneumatic systems. Gate valves that operate more smoothly and efficiently can contribute to reduced noise levels, which is beneficial in both industrial settings and applications where pneumatic systems are used in proximity to residential areas or sensitive ecosystems.

The recyclability and end-of-life management of gate valves are important considerations in the environmental impact assessment. As lightweight systems may incorporate novel materials or designs, it is essential to evaluate the feasibility of recycling these components and to develop appropriate disposal methods that minimize environmental harm.

In conclusion, the environmental impact assessment of gate valve performance metrics for lightweight pneumatic systems must consider a wide range of factors, from energy efficiency and material selection to leak prevention and end-of-life management. By carefully evaluating and optimizing these metrics, manufacturers and users of lightweight pneumatic systems can significantly reduce their environmental footprint while maintaining or improving system performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!