Impact of valve stem design on torque requirement in large gate valves

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Valve Stem Design Evolution and Objectives

The evolution of valve stem design in large gate valves has been driven by the continuous pursuit of improved performance, reliability, and efficiency. Over the years, engineers and researchers have focused on optimizing the stem design to reduce torque requirements, enhance durability, and minimize maintenance needs.

In the early stages of valve development, stem designs were relatively simple, often consisting of a single piece of metal with basic threading. These designs, while functional, often required significant torque to operate, especially in large gate valves. The high torque requirements not only made valve operation more challenging but also led to increased wear and tear on the valve components.

As industrial applications became more demanding, the need for more sophisticated valve stem designs became apparent. The objectives shifted towards creating stems that could withstand higher pressures, operate more smoothly, and require less torque to actuate. This led to the introduction of multi-start threads, which allowed for faster valve opening and closing while distributing the load more evenly across the stem.

Another significant development in valve stem design was the incorporation of advanced materials. The use of high-strength alloys and corrosion-resistant materials helped to reduce friction, improve wear resistance, and extend the operational life of the valve stems. These material innovations played a crucial role in reducing the torque requirements for large gate valves.

The introduction of computer-aided design (CAD) and finite element analysis (FEA) in the valve industry marked a turning point in stem design evolution. These tools allowed engineers to simulate and optimize stem geometries, thread profiles, and stress distributions before physical prototyping. This led to more efficient designs that could better handle the forces involved in valve operation while minimizing torque requirements.

Recent advancements have focused on the integration of smart technologies into valve stem designs. Sensors and monitoring systems embedded in the stem can now provide real-time data on valve performance, torque levels, and wear patterns. This information allows for predictive maintenance and further optimization of valve operation, contributing to reduced torque requirements and improved overall efficiency.

The current objectives in valve stem design for large gate valves center around further reducing torque requirements while maintaining or improving valve performance and longevity. This includes exploring novel materials, such as composites and ceramics, that offer superior strength-to-weight ratios and self-lubricating properties. Additionally, there is a growing emphasis on developing stem designs that are more adaptable to different operating conditions and can be easily customized for specific applications.

In the early stages of valve development, stem designs were relatively simple, often consisting of a single piece of metal with basic threading. These designs, while functional, often required significant torque to operate, especially in large gate valves. The high torque requirements not only made valve operation more challenging but also led to increased wear and tear on the valve components.

As industrial applications became more demanding, the need for more sophisticated valve stem designs became apparent. The objectives shifted towards creating stems that could withstand higher pressures, operate more smoothly, and require less torque to actuate. This led to the introduction of multi-start threads, which allowed for faster valve opening and closing while distributing the load more evenly across the stem.

Another significant development in valve stem design was the incorporation of advanced materials. The use of high-strength alloys and corrosion-resistant materials helped to reduce friction, improve wear resistance, and extend the operational life of the valve stems. These material innovations played a crucial role in reducing the torque requirements for large gate valves.

The introduction of computer-aided design (CAD) and finite element analysis (FEA) in the valve industry marked a turning point in stem design evolution. These tools allowed engineers to simulate and optimize stem geometries, thread profiles, and stress distributions before physical prototyping. This led to more efficient designs that could better handle the forces involved in valve operation while minimizing torque requirements.

Recent advancements have focused on the integration of smart technologies into valve stem designs. Sensors and monitoring systems embedded in the stem can now provide real-time data on valve performance, torque levels, and wear patterns. This information allows for predictive maintenance and further optimization of valve operation, contributing to reduced torque requirements and improved overall efficiency.

The current objectives in valve stem design for large gate valves center around further reducing torque requirements while maintaining or improving valve performance and longevity. This includes exploring novel materials, such as composites and ceramics, that offer superior strength-to-weight ratios and self-lubricating properties. Additionally, there is a growing emphasis on developing stem designs that are more adaptable to different operating conditions and can be easily customized for specific applications.

Market Demand for Efficient Large Gate Valves

The market demand for efficient large gate valves has been steadily increasing across various industries, driven by the need for improved operational efficiency, reduced maintenance costs, and enhanced safety in fluid control systems. Industries such as oil and gas, water treatment, power generation, and chemical processing are particularly interested in advanced gate valve technologies that can minimize torque requirements while maintaining reliable performance.

In the oil and gas sector, the exploration and production of unconventional resources have led to a surge in demand for high-performance gate valves capable of withstanding extreme pressures and temperatures. These valves must operate efficiently in harsh environments, making low-torque designs crucial for reducing the strain on actuators and extending equipment lifespan.

The water treatment industry is experiencing growth due to urbanization and increasing water scarcity concerns. Municipalities and water management companies are seeking large gate valves with optimized stem designs to improve flow control and reduce energy consumption in distribution networks. The ability to operate these valves with lower torque requirements translates directly into cost savings and improved system reliability.

Power generation plants, particularly those transitioning to more flexible operations to accommodate renewable energy integration, require gate valves that can handle frequent cycling and rapid adjustments. Efficient valve stem designs that reduce torque requirements are essential for these applications, as they enable quicker response times and minimize wear on valve components.

The chemical processing industry is another significant market for efficient large gate valves. As chemical manufacturers strive to improve process efficiency and reduce downtime, there is a growing demand for valves that offer precise control with minimal effort. Low-torque gate valves contribute to smoother operations and reduced maintenance intervals, which are critical in continuous production environments.

Market analysts project that the global industrial valve market, including large gate valves, will continue to grow at a compound annual growth rate of around 5% over the next five years. This growth is partly attributed to the increasing adoption of smart valve technologies and the ongoing modernization of industrial infrastructure worldwide.

Manufacturers are responding to this market demand by investing in research and development to create innovative valve stem designs. These efforts focus on optimizing the geometry of valve stems, exploring new materials with lower friction coefficients, and incorporating advanced coatings to reduce wear and improve performance. The goal is to produce large gate valves that require significantly less torque to operate, thereby enhancing overall system efficiency and reducing operational costs for end-users.

In the oil and gas sector, the exploration and production of unconventional resources have led to a surge in demand for high-performance gate valves capable of withstanding extreme pressures and temperatures. These valves must operate efficiently in harsh environments, making low-torque designs crucial for reducing the strain on actuators and extending equipment lifespan.

The water treatment industry is experiencing growth due to urbanization and increasing water scarcity concerns. Municipalities and water management companies are seeking large gate valves with optimized stem designs to improve flow control and reduce energy consumption in distribution networks. The ability to operate these valves with lower torque requirements translates directly into cost savings and improved system reliability.

Power generation plants, particularly those transitioning to more flexible operations to accommodate renewable energy integration, require gate valves that can handle frequent cycling and rapid adjustments. Efficient valve stem designs that reduce torque requirements are essential for these applications, as they enable quicker response times and minimize wear on valve components.

The chemical processing industry is another significant market for efficient large gate valves. As chemical manufacturers strive to improve process efficiency and reduce downtime, there is a growing demand for valves that offer precise control with minimal effort. Low-torque gate valves contribute to smoother operations and reduced maintenance intervals, which are critical in continuous production environments.

Market analysts project that the global industrial valve market, including large gate valves, will continue to grow at a compound annual growth rate of around 5% over the next five years. This growth is partly attributed to the increasing adoption of smart valve technologies and the ongoing modernization of industrial infrastructure worldwide.

Manufacturers are responding to this market demand by investing in research and development to create innovative valve stem designs. These efforts focus on optimizing the geometry of valve stems, exploring new materials with lower friction coefficients, and incorporating advanced coatings to reduce wear and improve performance. The goal is to produce large gate valves that require significantly less torque to operate, thereby enhancing overall system efficiency and reducing operational costs for end-users.

Current Challenges in Valve Stem Technology

Valve stem technology in large gate valves faces several significant challenges that impact torque requirements and overall valve performance. One of the primary issues is the increasing demand for larger valve sizes in industrial applications, which necessitates stronger and more durable stem designs. As valve sizes grow, the forces exerted on the stem during operation increase exponentially, leading to potential material fatigue and failure if not properly addressed.

The selection of appropriate materials for valve stems presents another challenge. Traditional materials like stainless steel may not always provide the optimal balance of strength, corrosion resistance, and friction characteristics required for large gate valves. Engineers must consider advanced alloys or composite materials that can withstand high stresses while maintaining low friction coefficients to minimize torque requirements.

Friction reduction between the stem and other valve components is a critical area of focus. The interface between the stem and packing, as well as the stem and stem nut, can significantly influence the torque needed to operate the valve. Developing new surface treatments, coatings, or lubricants that can reduce friction without compromising sealing performance or longevity is an ongoing challenge in the industry.

The design of stem threads is another area that demands attention. The thread profile, pitch, and manufacturing precision all play crucial roles in determining the efficiency of force transmission and the overall torque requirement. Optimizing these parameters while ensuring ease of manufacture and assembly poses a significant engineering challenge.

Environmental factors also contribute to the complexity of valve stem design. Extreme temperatures, corrosive media, and high-pressure conditions can all affect the performance and lifespan of valve stems. Designing stems that can maintain their integrity and operational efficiency across a wide range of operating conditions remains a persistent challenge for engineers.

Furthermore, the industry faces increasing pressure to develop valve stems that contribute to overall energy efficiency. Reducing the torque required to operate large gate valves not only improves ease of use but also has implications for the power consumption of automated valve systems. This challenge intersects with broader sustainability goals and the push for more environmentally friendly industrial processes.

Lastly, the integration of smart technologies into valve stem design presents both opportunities and challenges. Incorporating sensors or actuators directly into the stem structure could provide valuable data on valve performance and condition. However, this integration must be achieved without compromising the structural integrity or reliability of the stem, which is particularly challenging given the harsh environments in which many large gate valves operate.

The selection of appropriate materials for valve stems presents another challenge. Traditional materials like stainless steel may not always provide the optimal balance of strength, corrosion resistance, and friction characteristics required for large gate valves. Engineers must consider advanced alloys or composite materials that can withstand high stresses while maintaining low friction coefficients to minimize torque requirements.

Friction reduction between the stem and other valve components is a critical area of focus. The interface between the stem and packing, as well as the stem and stem nut, can significantly influence the torque needed to operate the valve. Developing new surface treatments, coatings, or lubricants that can reduce friction without compromising sealing performance or longevity is an ongoing challenge in the industry.

The design of stem threads is another area that demands attention. The thread profile, pitch, and manufacturing precision all play crucial roles in determining the efficiency of force transmission and the overall torque requirement. Optimizing these parameters while ensuring ease of manufacture and assembly poses a significant engineering challenge.

Environmental factors also contribute to the complexity of valve stem design. Extreme temperatures, corrosive media, and high-pressure conditions can all affect the performance and lifespan of valve stems. Designing stems that can maintain their integrity and operational efficiency across a wide range of operating conditions remains a persistent challenge for engineers.

Furthermore, the industry faces increasing pressure to develop valve stems that contribute to overall energy efficiency. Reducing the torque required to operate large gate valves not only improves ease of use but also has implications for the power consumption of automated valve systems. This challenge intersects with broader sustainability goals and the push for more environmentally friendly industrial processes.

Lastly, the integration of smart technologies into valve stem design presents both opportunities and challenges. Incorporating sensors or actuators directly into the stem structure could provide valuable data on valve performance and condition. However, this integration must be achieved without compromising the structural integrity or reliability of the stem, which is particularly challenging given the harsh environments in which many large gate valves operate.

Existing Valve Stem Design Solutions

01 Torque control mechanisms for valve stems

Various mechanisms are employed to control and regulate the torque applied to valve stems. These include specialized tools, adjustable torque limiters, and precision torque-measuring devices. Such mechanisms ensure proper tightening of valve stems without over-torquing, which could lead to damage or failure.- Torque specifications for valve stem installation: Valve stem torque requirements are critical for proper installation and sealing. Specific torque values are determined based on factors such as valve size, material, and application. Proper torque ensures a secure fit without damaging the valve or stem, preventing leaks and maintaining system integrity.

- Tools and methods for applying correct torque: Specialized tools and techniques are used to apply the correct torque to valve stems. These may include torque wrenches, calibrated tools, and automated torque application systems. Proper use of these tools ensures consistent and accurate torque application, reducing the risk of over-tightening or under-tightening.

- Material considerations for valve stems and torque requirements: The material of the valve stem and associated components influences torque requirements. Different materials may require specific torque values to achieve optimal sealing and performance. Considerations include thermal expansion, corrosion resistance, and mechanical properties of the materials used in valve construction.

- Torque monitoring and quality control in valve assembly: Implementing torque monitoring systems and quality control measures during valve assembly ensures consistent and accurate torque application. This may involve electronic torque sensors, data logging, and automated assembly processes to maintain precise torque specifications and improve overall product reliability.

- Maintenance and re-torquing procedures: Periodic maintenance and re-torquing of valve stems may be necessary to maintain proper sealing and performance. This involves procedures for safely loosening and re-tightening valve stems to the correct torque specifications, taking into account factors such as thermal cycling, vibration, and wear over time.

02 Material selection for valve stems to meet torque requirements

The choice of materials for valve stems is crucial in meeting torque requirements. High-strength alloys, corrosion-resistant materials, and composites are often used to withstand the applied torque while maintaining durability and performance under various operating conditions.Expand Specific Solutions03 Design considerations for valve stem torque optimization

Valve stem designs incorporate features to optimize torque requirements. These may include thread profiles, stem diameters, and surface treatments that reduce friction and improve torque transmission. Proper design ensures efficient operation and longevity of the valve assembly.Expand Specific Solutions04 Torque measurement and monitoring systems for valve stems

Advanced systems are developed to measure and monitor the torque applied to valve stems during installation and operation. These systems may use sensors, digital readouts, and data logging capabilities to ensure compliance with torque specifications and detect potential issues.Expand Specific Solutions05 Automated torque application methods for valve stems

Automated systems are employed to apply precise torque to valve stems. These may include robotic arms, pneumatic or hydraulic torque wrenches, and computer-controlled tightening systems. Such methods ensure consistency and accuracy in meeting torque requirements across multiple valve installations.Expand Specific Solutions

Key Players in Valve Manufacturing Industry

The impact of valve stem design on torque requirements in large gate valves represents a critical area of focus in the mature valve industry. The market for large gate valves is substantial, driven by demand from oil and gas, water treatment, and power generation sectors. Companies like FMC Tech Ltd., SUFA Technology, and Worldwide Oilfield Machine are at the forefront of innovation in this space. The technology is well-established, but ongoing research aims to optimize performance and efficiency. Key players such as NOK Corp. and AVK Holding are investing in advanced materials and design techniques to reduce torque requirements, improve reliability, and extend valve lifespan, reflecting the industry's focus on continuous improvement and cost-effectiveness.

FMC Corp.

Technical Solution: FMC Corp. has developed an innovative valve stem design for large gate valves that significantly reduces torque requirements. Their approach involves using a multi-start thread design on the valve stem, which increases the lead angle and reduces friction[1]. This design allows for smoother operation and less force needed to open and close the valve. Additionally, FMC has implemented a specialized coating on the stem threads, further reducing friction and improving corrosion resistance[3]. The company has also optimized the stem material selection, using high-strength alloys that maintain structural integrity while allowing for a reduced stem diameter, thus decreasing the overall torque needed for valve operation[5].

Strengths: Reduced operational force, improved efficiency, and extended valve lifespan. Weaknesses: Potentially higher initial manufacturing costs and more complex maintenance procedures.

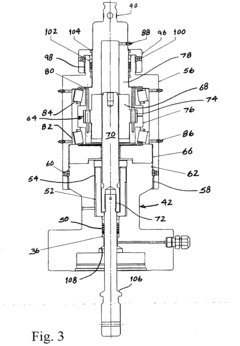

Emerson Process Management Valve Automation, Inc.

Technical Solution: Emerson has developed a patented "Flex-Stem" technology for large gate valves, which incorporates a flexible section in the valve stem design. This innovation allows for slight bending of the stem during operation, reducing side loading and friction between the stem and packing[2]. The company has also implemented advanced surface treatments on the stem, such as nitriding or hard chrome plating, to further reduce friction and improve wear resistance[4]. Emerson's design includes optimized thread profiles that distribute load more evenly, reducing stress concentrations and lowering overall torque requirements[6]. Additionally, they have integrated smart sensors into their valve stems to monitor torque in real-time, allowing for predictive maintenance and optimized valve operation[8].

Strengths: Reduced friction, improved load distribution, and smart monitoring capabilities. Weaknesses: Higher complexity in stem design and potential for increased manufacturing costs.

Innovative Stem Materials and Coatings

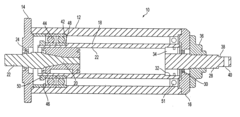

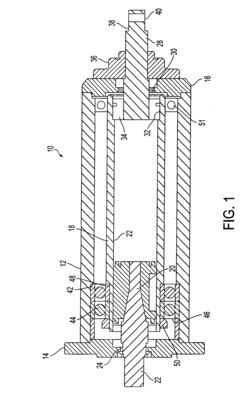

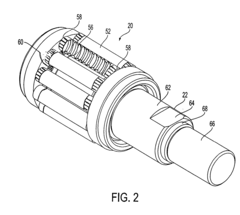

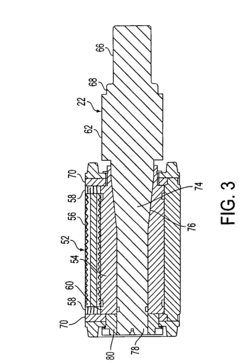

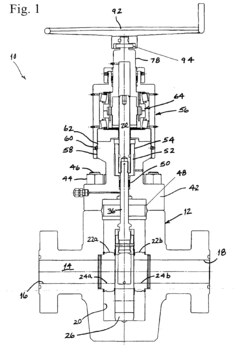

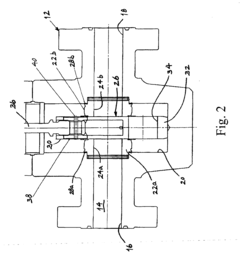

High thrust valve operator

PatentInactiveUS20040244515A1

Innovation

- A high thrust valve operator employing an inverted satellite roller screw with a bearing housing and cylinder, featuring a threaded internal surface and a roller screw assembly that reduces operator length and torque requirements through coordinated rotation and alignment of satellite rollers.

Reduced torque gate valve with roller screw

PatentInactiveEP1419334B1

Innovation

- A gate valve with a roller screw assembly that converts handwheel rotation into axial translation of the valve stem, providing a mechanical advantage to reduce required torque and accelerate valve opening, while maintaining a standard gate configuration to minimize erosion and facilitate maintenance.

Environmental Impact of Valve Stem Materials

The environmental impact of valve stem materials is a critical consideration in the design and operation of large gate valves. The choice of materials for valve stems can significantly influence the overall environmental footprint of the valve system throughout its lifecycle. Traditional valve stem materials, such as stainless steel and carbon steel, have been widely used due to their durability and strength. However, these materials often require energy-intensive production processes and can contribute to increased carbon emissions during manufacturing.

In recent years, there has been a growing interest in exploring alternative materials that offer improved environmental performance without compromising the valve's functionality. Advanced composites and engineered plastics have emerged as potential candidates for valve stem applications. These materials often require less energy to produce and can be lighter in weight, potentially reducing transportation-related emissions. Additionally, some composite materials exhibit superior corrosion resistance, which can extend the valve's lifespan and reduce the need for frequent replacements, thereby minimizing waste generation.

The use of recycled or recyclable materials in valve stem production is another avenue being explored to reduce environmental impact. By incorporating recycled content or designing valve stems for easy disassembly and recycling at the end of their life cycle, manufacturers can contribute to a more circular economy approach in the valve industry. This strategy not only reduces the demand for virgin materials but also helps in minimizing landfill waste.

Surface treatments and coatings applied to valve stems can also play a role in their environmental impact. While some coatings may enhance the stem's performance and longevity, they may introduce additional chemicals or processes that have environmental implications. It is crucial to assess the full lifecycle impact of these treatments, including their production, application, and potential for leaching or degradation during use.

The environmental impact of valve stem materials extends beyond their production and use phases. The disposal or recycling of these components at the end of their service life is an important consideration. Materials that can be easily recycled or safely disposed of without causing environmental harm are increasingly preferred. This aspect becomes particularly significant when dealing with large gate valves, as the volume of material involved can be substantial.

In conclusion, the selection of valve stem materials for large gate valves requires a careful balance between performance requirements and environmental considerations. As the industry moves towards more sustainable practices, ongoing research and development efforts are focused on identifying and implementing materials and processes that minimize environmental impact while maintaining or improving valve functionality and reliability.

In recent years, there has been a growing interest in exploring alternative materials that offer improved environmental performance without compromising the valve's functionality. Advanced composites and engineered plastics have emerged as potential candidates for valve stem applications. These materials often require less energy to produce and can be lighter in weight, potentially reducing transportation-related emissions. Additionally, some composite materials exhibit superior corrosion resistance, which can extend the valve's lifespan and reduce the need for frequent replacements, thereby minimizing waste generation.

The use of recycled or recyclable materials in valve stem production is another avenue being explored to reduce environmental impact. By incorporating recycled content or designing valve stems for easy disassembly and recycling at the end of their life cycle, manufacturers can contribute to a more circular economy approach in the valve industry. This strategy not only reduces the demand for virgin materials but also helps in minimizing landfill waste.

Surface treatments and coatings applied to valve stems can also play a role in their environmental impact. While some coatings may enhance the stem's performance and longevity, they may introduce additional chemicals or processes that have environmental implications. It is crucial to assess the full lifecycle impact of these treatments, including their production, application, and potential for leaching or degradation during use.

The environmental impact of valve stem materials extends beyond their production and use phases. The disposal or recycling of these components at the end of their service life is an important consideration. Materials that can be easily recycled or safely disposed of without causing environmental harm are increasingly preferred. This aspect becomes particularly significant when dealing with large gate valves, as the volume of material involved can be substantial.

In conclusion, the selection of valve stem materials for large gate valves requires a careful balance between performance requirements and environmental considerations. As the industry moves towards more sustainable practices, ongoing research and development efforts are focused on identifying and implementing materials and processes that minimize environmental impact while maintaining or improving valve functionality and reliability.

Regulatory Standards for Industrial Valves

Regulatory standards play a crucial role in ensuring the safety, reliability, and performance of industrial valves, including large gate valves. These standards are established by various international and national organizations to provide guidelines for design, manufacturing, testing, and maintenance of valves used in different industries.

The International Organization for Standardization (ISO) has developed several standards relevant to industrial valves. ISO 5208 specifies the pressure testing requirements for valves, while ISO 10434 covers bolted bonnet steel gate valves for petroleum, petrochemical, and allied industries. These standards address aspects such as material selection, design criteria, and testing procedures, which directly impact valve stem design and torque requirements.

In the United States, the American Petroleum Institute (API) has established standards specifically for the oil and gas industry. API 600 covers steel gate valves, flanged and butt-welding ends, while API 6D focuses on pipeline valves. These standards provide detailed specifications for valve stem design, including material requirements, dimensional tolerances, and performance criteria that influence torque requirements.

The American Society of Mechanical Engineers (ASME) has developed the ASME B16 series of standards, which cover various aspects of valves, including dimensions, tolerances, and pressure ratings. ASME B16.34 specifically addresses valves for flanged, threaded, and welding end connections, providing guidelines that impact valve stem design and torque considerations.

European standards, such as those developed by the European Committee for Standardization (CEN), also play a significant role in regulating industrial valves. EN 12516 covers the strength of valve bodies, while EN 19 specifies marking requirements for industrial valves. These standards ensure that valve designs, including stem configurations, meet specific safety and performance criteria.

Regulatory bodies in different countries may adopt or adapt these international standards or develop their own. For instance, the China Valve Industry Association (CVIA) has established standards specific to the Chinese market, which may have implications for valve stem design and torque requirements in large gate valves manufactured or used in China.

Compliance with these regulatory standards is essential for valve manufacturers and end-users. The standards not only ensure safety and reliability but also facilitate international trade by providing a common framework for valve specifications. As technology advances and industry requirements evolve, these standards are periodically reviewed and updated to reflect the latest best practices and technological developments in valve design and performance.

The International Organization for Standardization (ISO) has developed several standards relevant to industrial valves. ISO 5208 specifies the pressure testing requirements for valves, while ISO 10434 covers bolted bonnet steel gate valves for petroleum, petrochemical, and allied industries. These standards address aspects such as material selection, design criteria, and testing procedures, which directly impact valve stem design and torque requirements.

In the United States, the American Petroleum Institute (API) has established standards specifically for the oil and gas industry. API 600 covers steel gate valves, flanged and butt-welding ends, while API 6D focuses on pipeline valves. These standards provide detailed specifications for valve stem design, including material requirements, dimensional tolerances, and performance criteria that influence torque requirements.

The American Society of Mechanical Engineers (ASME) has developed the ASME B16 series of standards, which cover various aspects of valves, including dimensions, tolerances, and pressure ratings. ASME B16.34 specifically addresses valves for flanged, threaded, and welding end connections, providing guidelines that impact valve stem design and torque considerations.

European standards, such as those developed by the European Committee for Standardization (CEN), also play a significant role in regulating industrial valves. EN 12516 covers the strength of valve bodies, while EN 19 specifies marking requirements for industrial valves. These standards ensure that valve designs, including stem configurations, meet specific safety and performance criteria.

Regulatory bodies in different countries may adopt or adapt these international standards or develop their own. For instance, the China Valve Industry Association (CVIA) has established standards specific to the Chinese market, which may have implications for valve stem design and torque requirements in large gate valves manufactured or used in China.

Compliance with these regulatory standards is essential for valve manufacturers and end-users. The standards not only ensure safety and reliability but also facilitate international trade by providing a common framework for valve specifications. As technology advances and industry requirements evolve, these standards are periodically reviewed and updated to reflect the latest best practices and technological developments in valve design and performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!