Advances in Solid Oxide Electrolytic Cells for Hydrogen Production

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SOEC Technology Evolution

Solid Oxide Electrolytic Cells (SOECs) for hydrogen production have undergone significant technological evolution since their inception. The development trajectory of SOECs can be traced through several key phases, each marked by notable advancements in materials, design, and performance.

In the early stages of SOEC development, research focused primarily on proof-of-concept and basic operational principles. Scientists and engineers worked to demonstrate the feasibility of using solid oxide cells for electrolysis, building upon knowledge gained from solid oxide fuel cells. This phase was characterized by low efficiency and limited durability, with cells operating at extremely high temperatures exceeding 1000°C.

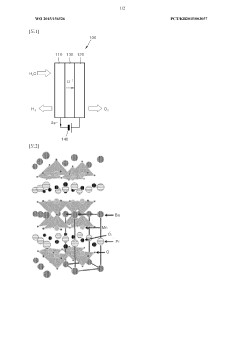

The next phase saw a shift towards more practical implementations, with efforts concentrated on reducing operating temperatures and improving cell stability. Researchers explored alternative materials for electrodes and electrolytes, seeking compounds that could maintain high ionic conductivity at lower temperatures. This period witnessed the introduction of yttria-stabilized zirconia (YSZ) as a standard electrolyte material, marking a significant milestone in SOEC technology.

As the field progressed, attention turned to enhancing cell performance and longevity. Scientists developed new electrode materials and architectures to increase active surface area and catalytic activity. The introduction of mixed ionic-electronic conducting materials for electrodes represented a major breakthrough, significantly improving electrode kinetics and overall cell efficiency.

Recent years have seen a focus on scalability and integration of SOECs into larger systems. Researchers have made strides in stack design, addressing issues related to thermal management, gas distribution, and electrical connections. This phase has been crucial in bridging the gap between laboratory-scale demonstrations and industrial-scale applications.

Concurrent with these developments, there has been a continuous effort to reduce material costs and improve manufacturing processes. Advanced fabrication techniques, such as tape casting and screen printing, have been refined to produce more consistent and cost-effective cells. Additionally, the exploration of novel materials, including proton-conducting ceramics, has opened new avenues for SOEC technology, potentially enabling operation at even lower temperatures.

The most recent phase of SOEC evolution has been characterized by a holistic approach to system optimization. This includes the integration of SOECs with renewable energy sources, the development of reversible solid oxide cells capable of both fuel cell and electrolysis operation, and the exploration of co-electrolysis processes for simultaneous production of hydrogen and carbon monoxide. These advancements are paving the way for SOECs to play a crucial role in future energy systems and the hydrogen economy.

In the early stages of SOEC development, research focused primarily on proof-of-concept and basic operational principles. Scientists and engineers worked to demonstrate the feasibility of using solid oxide cells for electrolysis, building upon knowledge gained from solid oxide fuel cells. This phase was characterized by low efficiency and limited durability, with cells operating at extremely high temperatures exceeding 1000°C.

The next phase saw a shift towards more practical implementations, with efforts concentrated on reducing operating temperatures and improving cell stability. Researchers explored alternative materials for electrodes and electrolytes, seeking compounds that could maintain high ionic conductivity at lower temperatures. This period witnessed the introduction of yttria-stabilized zirconia (YSZ) as a standard electrolyte material, marking a significant milestone in SOEC technology.

As the field progressed, attention turned to enhancing cell performance and longevity. Scientists developed new electrode materials and architectures to increase active surface area and catalytic activity. The introduction of mixed ionic-electronic conducting materials for electrodes represented a major breakthrough, significantly improving electrode kinetics and overall cell efficiency.

Recent years have seen a focus on scalability and integration of SOECs into larger systems. Researchers have made strides in stack design, addressing issues related to thermal management, gas distribution, and electrical connections. This phase has been crucial in bridging the gap between laboratory-scale demonstrations and industrial-scale applications.

Concurrent with these developments, there has been a continuous effort to reduce material costs and improve manufacturing processes. Advanced fabrication techniques, such as tape casting and screen printing, have been refined to produce more consistent and cost-effective cells. Additionally, the exploration of novel materials, including proton-conducting ceramics, has opened new avenues for SOEC technology, potentially enabling operation at even lower temperatures.

The most recent phase of SOEC evolution has been characterized by a holistic approach to system optimization. This includes the integration of SOECs with renewable energy sources, the development of reversible solid oxide cells capable of both fuel cell and electrolysis operation, and the exploration of co-electrolysis processes for simultaneous production of hydrogen and carbon monoxide. These advancements are paving the way for SOECs to play a crucial role in future energy systems and the hydrogen economy.

Hydrogen Market Analysis

The hydrogen market has been experiencing significant growth in recent years, driven by the increasing focus on clean energy solutions and the global push towards decarbonization. As a key component in the transition to a low-carbon economy, hydrogen is gaining traction across various sectors, including transportation, industry, and power generation.

The global hydrogen market size was valued at approximately $130 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of over 9% from 2021 to 2028. This growth is primarily attributed to the rising demand for clean energy sources and the implementation of stringent environmental regulations worldwide.

In the transportation sector, hydrogen fuel cell vehicles are emerging as a promising alternative to traditional internal combustion engines. Major automotive manufacturers are investing heavily in hydrogen technology, with several countries setting ambitious targets for hydrogen vehicle adoption. The industrial sector, particularly in steel production and chemical manufacturing, is also exploring hydrogen as a means to reduce carbon emissions and improve energy efficiency.

The power generation sector is another key driver of hydrogen market growth. As countries strive to integrate more renewable energy sources into their grids, hydrogen is being considered as a potential energy storage solution to address the intermittency issues associated with wind and solar power. This has led to increased interest in power-to-gas technologies and large-scale hydrogen storage projects.

Geographically, Asia-Pacific is expected to dominate the hydrogen market, with countries like Japan, South Korea, and China leading the way in hydrogen technology development and adoption. Europe is also making significant strides, with the European Union's Hydrogen Strategy aiming to install at least 40 gigawatts of renewable hydrogen electrolyzers by 2030.

However, the hydrogen market faces several challenges, including high production costs, limited infrastructure, and technological barriers. The cost of producing green hydrogen, which is generated using renewable energy sources, remains significantly higher than that of conventional hydrogen production methods. Addressing these challenges will be crucial for the widespread adoption of hydrogen technologies and the realization of its full market potential.

Despite these obstacles, the hydrogen market is poised for substantial growth in the coming years. Government support, technological advancements, and increasing private sector investments are expected to drive innovation and cost reductions in hydrogen production, storage, and distribution. As the world continues to prioritize sustainable energy solutions, the hydrogen market is likely to play an increasingly important role in the global energy landscape.

The global hydrogen market size was valued at approximately $130 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of over 9% from 2021 to 2028. This growth is primarily attributed to the rising demand for clean energy sources and the implementation of stringent environmental regulations worldwide.

In the transportation sector, hydrogen fuel cell vehicles are emerging as a promising alternative to traditional internal combustion engines. Major automotive manufacturers are investing heavily in hydrogen technology, with several countries setting ambitious targets for hydrogen vehicle adoption. The industrial sector, particularly in steel production and chemical manufacturing, is also exploring hydrogen as a means to reduce carbon emissions and improve energy efficiency.

The power generation sector is another key driver of hydrogen market growth. As countries strive to integrate more renewable energy sources into their grids, hydrogen is being considered as a potential energy storage solution to address the intermittency issues associated with wind and solar power. This has led to increased interest in power-to-gas technologies and large-scale hydrogen storage projects.

Geographically, Asia-Pacific is expected to dominate the hydrogen market, with countries like Japan, South Korea, and China leading the way in hydrogen technology development and adoption. Europe is also making significant strides, with the European Union's Hydrogen Strategy aiming to install at least 40 gigawatts of renewable hydrogen electrolyzers by 2030.

However, the hydrogen market faces several challenges, including high production costs, limited infrastructure, and technological barriers. The cost of producing green hydrogen, which is generated using renewable energy sources, remains significantly higher than that of conventional hydrogen production methods. Addressing these challenges will be crucial for the widespread adoption of hydrogen technologies and the realization of its full market potential.

Despite these obstacles, the hydrogen market is poised for substantial growth in the coming years. Government support, technological advancements, and increasing private sector investments are expected to drive innovation and cost reductions in hydrogen production, storage, and distribution. As the world continues to prioritize sustainable energy solutions, the hydrogen market is likely to play an increasingly important role in the global energy landscape.

SOEC Technical Challenges

Solid Oxide Electrolytic Cells (SOECs) for hydrogen production face several significant technical challenges that hinder their widespread adoption and commercialization. One of the primary issues is the high operating temperature, typically ranging from 600°C to 1000°C. This extreme heat puts substantial stress on cell materials, leading to degradation and reduced lifespan. The thermal cycling during start-up and shutdown processes further exacerbates this problem, causing thermal shock and potential cell failure.

Material selection and durability present another major challenge. The harsh operating conditions require materials that can withstand high temperatures, resist corrosion, and maintain structural integrity over extended periods. Finding cost-effective materials that meet these criteria while also exhibiting excellent ionic and electronic conductivity remains a significant hurdle. Chromium poisoning, particularly at the cathode, is a persistent issue that affects cell performance and longevity.

Sealing technology is crucial for maintaining gas separation and preventing leakage in SOECs. Developing reliable, long-lasting seals that can withstand high temperatures and thermal cycling is an ongoing challenge. Current sealing materials often degrade over time, leading to decreased efficiency and potential safety hazards.

Scale-up and manufacturing processes pose significant obstacles to SOEC commercialization. Producing large-area cells with consistent performance and minimal defects is technically demanding. Additionally, the integration of individual cells into stacks while maintaining uniform gas distribution and electrical contact presents complex engineering challenges.

Energy efficiency is another critical area for improvement. While SOECs offer high theoretical efficiency, practical systems often fall short due to various losses, including ohmic, activation, and concentration polarizations. Reducing these losses without compromising other aspects of cell performance requires innovative electrode designs and optimized cell architectures.

Lastly, the cost of SOEC systems remains a significant barrier to widespread adoption. The expensive materials, complex manufacturing processes, and high operating temperatures contribute to elevated capital and operational costs. Developing more cost-effective production methods and materials while maintaining or improving performance is essential for the technology's commercial viability.

Addressing these technical challenges requires a multidisciplinary approach, combining advances in materials science, electrochemistry, and process engineering. Ongoing research efforts focus on developing novel materials, improving cell designs, and optimizing operating conditions to overcome these hurdles and realize the full potential of SOECs for efficient hydrogen production.

Material selection and durability present another major challenge. The harsh operating conditions require materials that can withstand high temperatures, resist corrosion, and maintain structural integrity over extended periods. Finding cost-effective materials that meet these criteria while also exhibiting excellent ionic and electronic conductivity remains a significant hurdle. Chromium poisoning, particularly at the cathode, is a persistent issue that affects cell performance and longevity.

Sealing technology is crucial for maintaining gas separation and preventing leakage in SOECs. Developing reliable, long-lasting seals that can withstand high temperatures and thermal cycling is an ongoing challenge. Current sealing materials often degrade over time, leading to decreased efficiency and potential safety hazards.

Scale-up and manufacturing processes pose significant obstacles to SOEC commercialization. Producing large-area cells with consistent performance and minimal defects is technically demanding. Additionally, the integration of individual cells into stacks while maintaining uniform gas distribution and electrical contact presents complex engineering challenges.

Energy efficiency is another critical area for improvement. While SOECs offer high theoretical efficiency, practical systems often fall short due to various losses, including ohmic, activation, and concentration polarizations. Reducing these losses without compromising other aspects of cell performance requires innovative electrode designs and optimized cell architectures.

Lastly, the cost of SOEC systems remains a significant barrier to widespread adoption. The expensive materials, complex manufacturing processes, and high operating temperatures contribute to elevated capital and operational costs. Developing more cost-effective production methods and materials while maintaining or improving performance is essential for the technology's commercial viability.

Addressing these technical challenges requires a multidisciplinary approach, combining advances in materials science, electrochemistry, and process engineering. Ongoing research efforts focus on developing novel materials, improving cell designs, and optimizing operating conditions to overcome these hurdles and realize the full potential of SOECs for efficient hydrogen production.

Current SOEC Solutions

01 Electrode materials and structures

Improving the efficiency of solid oxide electrolytic cells through advanced electrode materials and structures. This includes developing novel cathode and anode compositions, optimizing electrode microstructures, and enhancing the interface between electrodes and electrolytes to reduce polarization losses and improve overall cell performance.- Electrode materials and structures: Improving electrode materials and structures is crucial for enhancing solid oxide electrolytic cell efficiency. This includes developing novel electrode compositions, optimizing porosity and thickness, and creating advanced microstructures to facilitate better ion transport and electrochemical reactions.

- Electrolyte optimization: Enhancing the electrolyte properties is essential for improving cell efficiency. This involves developing thin, dense electrolyte layers with high ionic conductivity, exploring new electrolyte materials, and optimizing the interface between the electrolyte and electrodes to reduce resistance and improve overall performance.

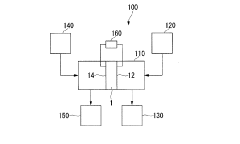

- Operating conditions and control: Optimizing operating conditions and implementing advanced control strategies can significantly impact cell efficiency. This includes managing temperature distribution, controlling gas flow rates, and developing intelligent control systems to maintain optimal performance under varying conditions.

- Cell design and stack configuration: Innovative cell designs and stack configurations can lead to improved efficiency. This involves optimizing cell geometry, developing novel interconnect materials, and creating advanced sealing techniques to minimize losses and enhance overall system performance.

- Integration of advanced materials: Incorporating advanced materials, such as nanostructured components or composite materials, can enhance cell efficiency. This includes developing novel catalysts, exploring the use of protective coatings, and integrating functional layers to improve durability and performance of solid oxide electrolytic cells.

02 Electrolyte optimization

Enhancing the efficiency of solid oxide electrolytic cells by optimizing the electrolyte material and design. This involves developing thin-film electrolytes with high ionic conductivity, improving the mechanical stability of the electrolyte, and reducing ohmic losses across the cell to increase overall energy conversion efficiency.Expand Specific Solutions03 Operating conditions and thermal management

Improving the efficiency of solid oxide electrolytic cells through optimized operating conditions and thermal management strategies. This includes developing advanced temperature control systems, optimizing gas flow patterns, and implementing efficient heat recovery mechanisms to maximize overall system efficiency and durability.Expand Specific Solutions04 Cell stack design and configuration

Enhancing the efficiency of solid oxide electrolytic cells through innovative cell stack designs and configurations. This involves optimizing the interconnect materials, improving sealing technologies, and developing novel stack architectures to minimize internal resistance and maximize power output.Expand Specific Solutions05 Integration of advanced materials and nanotechnology

Improving the efficiency of solid oxide electrolytic cells by incorporating advanced materials and nanotechnology. This includes developing nanostructured electrodes, implementing novel catalyst materials, and utilizing composite electrolytes to enhance electrochemical performance and reduce degradation rates over time.Expand Specific Solutions

Key SOEC Industry Players

The competitive landscape for advances in Solid Oxide Electrolytic Cells (SOECs) for hydrogen production is characterized by a mix of academic institutions, energy companies, and technology firms. The industry is in a growth phase, with increasing market size driven by the global push for clean energy solutions. The technology is maturing but still evolving, with key players like Tsinghua University, Toshiba Corp., and China Petroleum & Chemical Corp. leading research efforts. Other significant contributors include Haldor Topsøe A/S, Northwestern University, and Hyundai Motor Co., indicating a diverse international interest. The involvement of both established energy giants and innovative startups suggests a competitive and dynamic field with potential for further technological breakthroughs and market expansion.

Dalian Institute of Chemical Physics Chinese Academy of Sci

Technical Solution: Dalian Institute of Chemical Physics (DICP) has made significant advances in Solid Oxide Electrolytic Cells (SOECs) for hydrogen production. They have developed a novel electrode material combining praseodymium-doped ceria (PDC) and strontium-doped lanthanum manganite (LSM), which demonstrates excellent performance and stability[1]. This composite electrode shows reduced polarization resistance and enhanced electrocatalytic activity for oxygen evolution reactions. DICP has also pioneered the use of proton-conducting electrolytes in SOECs, which allows for lower operating temperatures (500-700°C) compared to traditional oxygen-ion conducting SOECs (700-1000°C)[2]. Their research has led to the development of SOECs with higher efficiency and longer lifespans, capable of producing hydrogen at rates of up to 10 mL/cm²·min at 700°C[3].

Strengths: Advanced materials research, lower operating temperatures, improved efficiency and lifespan. Weaknesses: Potential challenges in scaling up laboratory results to industrial production, higher costs associated with novel materials.

Haldor Topsøe A/S

Technical Solution: Haldor Topsøe has developed a proprietary SOEC technology called eCOs™ for efficient hydrogen production. Their system operates at high temperatures (700-850°C) and utilizes a unique cell design with a zirconia-based electrolyte and specialized nickel-based electrodes[4]. The eCOs™ technology achieves remarkable electrical efficiency of up to 96% in steam electrolysis mode[5]. Haldor Topsøe's SOECs can operate in reversible mode, allowing for both hydrogen production and fuel cell operation. They have demonstrated long-term stability with degradation rates as low as 0.5% per 1000 hours of operation[6]. The company has also integrated their SOEC technology with renewable energy sources, enabling green hydrogen production at scale.

Strengths: High electrical efficiency, reversible operation capability, proven long-term stability. Weaknesses: High operating temperatures may lead to increased material degradation over time, potentially higher system costs due to specialized materials.

SOEC Core Innovations

Solid oxide electrolysis cell, electrolysis system, and method of producing carbon monoxide and hydrogen

PatentActiveJP2019218578A

Innovation

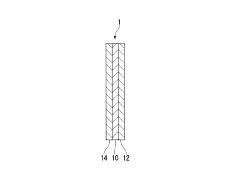

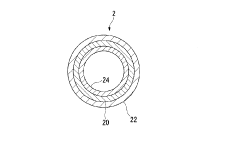

- A solid oxide electrolysis cell with a cathode electrode composed of a spinel structure solid oxide, such as CuFe2O4, is used, along with an anode electrode and an electrolyte layer, to enhance stability and maintain catalytic activity.

Solid oxide water electrolysis cell for producing hydrogen and oxygen

PatentWO2015156526A1

Innovation

- A solid oxide water electrolysis cell with a cathode composed of a double-layer perovskite structure compound, such as RET2O5+δ, operating between 600 °C to 800 °C, using an anode like La0.8Sr0.2Fe-YSZ and an electrolyte like yttria stabilized zirconia, avoiding nickel and enabling efficient hydrogen and oxygen production at lower temperatures.

Energy Policy Implications

The advancement of Solid Oxide Electrolytic Cells (SOECs) for hydrogen production has significant implications for energy policies worldwide. As countries strive to reduce carbon emissions and transition to cleaner energy sources, SOECs offer a promising solution for large-scale, efficient hydrogen production.

Policymakers are increasingly recognizing the potential of SOECs in achieving national and international climate goals. Many governments are implementing supportive policies to accelerate SOEC research, development, and deployment. These policies often include funding for research institutions, tax incentives for companies investing in SOEC technology, and grants for pilot projects.

The integration of SOECs into existing energy infrastructure presents both challenges and opportunities for policymakers. As SOECs can operate at high temperatures, they can be coupled with industrial processes or nuclear power plants to utilize waste heat, improving overall system efficiency. This synergy requires careful consideration in energy policy planning to maximize the benefits of SOEC implementation.

Energy security is another critical aspect influenced by SOEC technology. By enabling domestic hydrogen production from various feedstocks, including water and renewable electricity, SOECs can reduce dependence on imported fossil fuels. This potential for increased energy independence is driving many nations to incorporate SOECs into their long-term energy strategies.

The economic implications of SOEC technology are also shaping energy policies. As the cost of renewable electricity continues to decline, the production of green hydrogen through SOECs becomes increasingly competitive. Policymakers are developing frameworks to support the growth of a hydrogen economy, including infrastructure development and market mechanisms to encourage adoption.

Environmental regulations play a crucial role in the adoption of SOEC technology. Stricter emissions standards and carbon pricing mechanisms are indirectly promoting the use of SOECs by making traditional hydrogen production methods less economically viable. Policymakers are also considering lifecycle assessments of SOEC systems to ensure their environmental benefits are fully realized.

International cooperation in SOEC development is emerging as a key policy focus. Collaborative research initiatives and technology transfer agreements are being established to accelerate progress and share best practices. These partnerships are essential for addressing global challenges and creating a harmonized approach to SOEC implementation.

As SOEC technology matures, energy policies are evolving to address new challenges, such as the need for skilled workforce development and the establishment of safety standards for large-scale hydrogen production and storage. Policymakers are working closely with industry stakeholders to create comprehensive regulatory frameworks that ensure the safe and efficient deployment of SOEC systems.

Policymakers are increasingly recognizing the potential of SOECs in achieving national and international climate goals. Many governments are implementing supportive policies to accelerate SOEC research, development, and deployment. These policies often include funding for research institutions, tax incentives for companies investing in SOEC technology, and grants for pilot projects.

The integration of SOECs into existing energy infrastructure presents both challenges and opportunities for policymakers. As SOECs can operate at high temperatures, they can be coupled with industrial processes or nuclear power plants to utilize waste heat, improving overall system efficiency. This synergy requires careful consideration in energy policy planning to maximize the benefits of SOEC implementation.

Energy security is another critical aspect influenced by SOEC technology. By enabling domestic hydrogen production from various feedstocks, including water and renewable electricity, SOECs can reduce dependence on imported fossil fuels. This potential for increased energy independence is driving many nations to incorporate SOECs into their long-term energy strategies.

The economic implications of SOEC technology are also shaping energy policies. As the cost of renewable electricity continues to decline, the production of green hydrogen through SOECs becomes increasingly competitive. Policymakers are developing frameworks to support the growth of a hydrogen economy, including infrastructure development and market mechanisms to encourage adoption.

Environmental regulations play a crucial role in the adoption of SOEC technology. Stricter emissions standards and carbon pricing mechanisms are indirectly promoting the use of SOECs by making traditional hydrogen production methods less economically viable. Policymakers are also considering lifecycle assessments of SOEC systems to ensure their environmental benefits are fully realized.

International cooperation in SOEC development is emerging as a key policy focus. Collaborative research initiatives and technology transfer agreements are being established to accelerate progress and share best practices. These partnerships are essential for addressing global challenges and creating a harmonized approach to SOEC implementation.

As SOEC technology matures, energy policies are evolving to address new challenges, such as the need for skilled workforce development and the establishment of safety standards for large-scale hydrogen production and storage. Policymakers are working closely with industry stakeholders to create comprehensive regulatory frameworks that ensure the safe and efficient deployment of SOEC systems.

SOEC Scalability Issues

Scaling up Solid Oxide Electrolytic Cells (SOECs) for large-scale hydrogen production presents several significant challenges. One of the primary issues is maintaining uniform temperature distribution across larger cell areas. As the cell size increases, it becomes increasingly difficult to ensure consistent heating and cooling, which can lead to thermal gradients and mechanical stress. These thermal imbalances can cause performance degradation and reduce the overall efficiency of the system.

Another critical scalability issue is the management of gas flow distribution. In larger SOEC systems, achieving uniform gas distribution across the entire active area becomes more complex. Uneven gas flow can result in localized areas of high or low reactant concentration, leading to inefficient operation and potential degradation of cell components. Engineers must develop advanced flow field designs and manifold systems to address this challenge effectively.

The mechanical integrity of larger SOEC stacks also poses a significant hurdle. As the number of cells in a stack increases, the cumulative thermal expansion and contraction during operation cycles can cause mechanical stress and potential failure. This issue is exacerbated by the brittle nature of ceramic materials commonly used in SOECs. Developing robust sealing solutions and interconnect designs that can withstand these stresses while maintaining electrical conductivity is crucial for successful scaling.

Electrical current collection and distribution become more challenging in larger SOEC systems. The increased distance that electrons must travel in scaled-up cells can lead to higher ohmic losses and reduced overall efficiency. Innovative current collector designs and materials are necessary to minimize these losses and ensure uniform current distribution across the entire active area.

Manufacturing processes must also evolve to accommodate larger cell sizes and higher production volumes. Techniques such as tape casting and screen printing, which are commonly used for smaller-scale production, may need to be adapted or replaced with more scalable methods. Ensuring consistent quality and performance across a larger number of cells produced at industrial scales is a significant challenge that requires advanced quality control measures and potentially new manufacturing technologies.

Lastly, the economic viability of scaled-up SOEC systems is a critical consideration. While larger systems may offer economies of scale, the increased complexity and material requirements can offset these gains. Balancing performance improvements with cost-effective manufacturing and operation is essential for the successful commercialization of large-scale SOEC hydrogen production systems.

Another critical scalability issue is the management of gas flow distribution. In larger SOEC systems, achieving uniform gas distribution across the entire active area becomes more complex. Uneven gas flow can result in localized areas of high or low reactant concentration, leading to inefficient operation and potential degradation of cell components. Engineers must develop advanced flow field designs and manifold systems to address this challenge effectively.

The mechanical integrity of larger SOEC stacks also poses a significant hurdle. As the number of cells in a stack increases, the cumulative thermal expansion and contraction during operation cycles can cause mechanical stress and potential failure. This issue is exacerbated by the brittle nature of ceramic materials commonly used in SOECs. Developing robust sealing solutions and interconnect designs that can withstand these stresses while maintaining electrical conductivity is crucial for successful scaling.

Electrical current collection and distribution become more challenging in larger SOEC systems. The increased distance that electrons must travel in scaled-up cells can lead to higher ohmic losses and reduced overall efficiency. Innovative current collector designs and materials are necessary to minimize these losses and ensure uniform current distribution across the entire active area.

Manufacturing processes must also evolve to accommodate larger cell sizes and higher production volumes. Techniques such as tape casting and screen printing, which are commonly used for smaller-scale production, may need to be adapted or replaced with more scalable methods. Ensuring consistent quality and performance across a larger number of cells produced at industrial scales is a significant challenge that requires advanced quality control measures and potentially new manufacturing technologies.

Lastly, the economic viability of scaled-up SOEC systems is a critical consideration. While larger systems may offer economies of scale, the increased complexity and material requirements can offset these gains. Balancing performance improvements with cost-effective manufacturing and operation is essential for the successful commercialization of large-scale SOEC hydrogen production systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!