AGM Battery Sustainability Initiatives Across Industries

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution

The evolution of Absorbent Glass Mat (AGM) batteries represents a significant advancement in energy storage technology, particularly in the context of sustainability initiatives across various industries. AGM batteries, first developed in the 1970s for military aircraft, have undergone substantial improvements over the decades, adapting to meet the growing demands for more efficient and environmentally friendly power solutions.

In the early stages of AGM battery development, the focus was primarily on creating a maintenance-free alternative to traditional lead-acid batteries. The unique construction of AGM batteries, featuring fiberglass mats saturated with electrolyte, allowed for better electrolyte retention and reduced the risk of spillage. This design not only improved safety but also enabled the batteries to be used in various orientations, expanding their potential applications.

As environmental concerns gained prominence in the 1990s and 2000s, the evolution of AGM batteries shifted towards enhancing their sustainability profile. Manufacturers began to explore ways to increase the recyclability of AGM batteries, recognizing the importance of reducing the environmental impact of battery disposal. This led to improvements in the recycling processes for lead and other components, making AGM batteries more aligned with circular economy principles.

The turn of the millennium saw a surge in demand for renewable energy storage solutions, driving further advancements in AGM battery technology. Engineers focused on increasing the cycle life and depth of discharge capabilities of AGM batteries, making them more suitable for use in solar and wind energy systems. These improvements allowed AGM batteries to play a crucial role in the transition towards cleaner energy sources, supporting the integration of intermittent renewable energy into power grids.

In recent years, the evolution of AGM batteries has been characterized by efforts to enhance their performance in high-demand applications, such as start-stop vehicle systems. This has led to the development of enhanced AGM (eAGM) batteries, which offer improved charge acceptance and faster recharge rates. These advancements have made AGM batteries increasingly competitive with newer battery technologies in automotive and industrial applications.

The ongoing evolution of AGM batteries also includes efforts to reduce their environmental footprint during production. Manufacturers are exploring ways to minimize the use of lead and other potentially harmful materials, as well as implementing more energy-efficient production processes. These initiatives aim to make AGM batteries not only more sustainable in their use but also in their manufacturing.

Looking ahead, the evolution of AGM batteries is likely to continue focusing on sustainability and performance improvements. Research is underway to further extend battery life, increase energy density, and enhance their ability to operate in extreme conditions. Additionally, there is growing interest in integrating smart technology into AGM batteries, enabling better monitoring and management of battery health and performance, which could lead to more efficient use and longer lifespans.

In the early stages of AGM battery development, the focus was primarily on creating a maintenance-free alternative to traditional lead-acid batteries. The unique construction of AGM batteries, featuring fiberglass mats saturated with electrolyte, allowed for better electrolyte retention and reduced the risk of spillage. This design not only improved safety but also enabled the batteries to be used in various orientations, expanding their potential applications.

As environmental concerns gained prominence in the 1990s and 2000s, the evolution of AGM batteries shifted towards enhancing their sustainability profile. Manufacturers began to explore ways to increase the recyclability of AGM batteries, recognizing the importance of reducing the environmental impact of battery disposal. This led to improvements in the recycling processes for lead and other components, making AGM batteries more aligned with circular economy principles.

The turn of the millennium saw a surge in demand for renewable energy storage solutions, driving further advancements in AGM battery technology. Engineers focused on increasing the cycle life and depth of discharge capabilities of AGM batteries, making them more suitable for use in solar and wind energy systems. These improvements allowed AGM batteries to play a crucial role in the transition towards cleaner energy sources, supporting the integration of intermittent renewable energy into power grids.

In recent years, the evolution of AGM batteries has been characterized by efforts to enhance their performance in high-demand applications, such as start-stop vehicle systems. This has led to the development of enhanced AGM (eAGM) batteries, which offer improved charge acceptance and faster recharge rates. These advancements have made AGM batteries increasingly competitive with newer battery technologies in automotive and industrial applications.

The ongoing evolution of AGM batteries also includes efforts to reduce their environmental footprint during production. Manufacturers are exploring ways to minimize the use of lead and other potentially harmful materials, as well as implementing more energy-efficient production processes. These initiatives aim to make AGM batteries not only more sustainable in their use but also in their manufacturing.

Looking ahead, the evolution of AGM batteries is likely to continue focusing on sustainability and performance improvements. Research is underway to further extend battery life, increase energy density, and enhance their ability to operate in extreme conditions. Additionally, there is growing interest in integrating smart technology into AGM batteries, enabling better monitoring and management of battery health and performance, which could lead to more efficient use and longer lifespans.

Market Demand Analysis

The market demand for AGM (Absorbent Glass Mat) batteries has been steadily increasing across various industries due to their superior performance characteristics and sustainability advantages. These batteries are particularly sought after in automotive, renewable energy storage, and telecommunications sectors.

In the automotive industry, the shift towards more advanced electrical systems and start-stop technology has driven the demand for AGM batteries. As vehicles become more electrified and incorporate sophisticated features, the need for reliable and efficient power sources has grown. AGM batteries offer better cycle life, faster charging, and improved resistance to vibration compared to traditional lead-acid batteries, making them ideal for modern vehicles.

The renewable energy sector has also contributed significantly to the market demand for AGM batteries. As solar and wind power installations continue to expand globally, the need for efficient energy storage solutions has increased. AGM batteries are well-suited for off-grid and grid-tied renewable energy systems due to their deep-cycle capabilities and low maintenance requirements.

Telecommunications infrastructure represents another major market for AGM batteries. The rapid expansion of mobile networks, especially in developing regions, has created a substantial demand for reliable backup power solutions. AGM batteries are preferred in this sector due to their long service life, high discharge rate capabilities, and ability to operate in a wide range of temperatures.

The industrial sector, including material handling equipment and uninterruptible power supply (UPS) systems, has also shown growing interest in AGM batteries. These applications require power sources that can withstand frequent cycling and provide consistent performance, attributes that AGM batteries excel in.

Market trends indicate a growing emphasis on sustainability and environmental responsibility across industries. This has further boosted the demand for AGM batteries, as they are sealed, maintenance-free, and have a higher recyclability rate compared to flooded lead-acid batteries. The focus on reducing carbon footprints and adhering to stricter environmental regulations has positioned AGM batteries as a more sustainable choice for many applications.

The global AGM battery market is projected to experience substantial growth in the coming years. Factors such as increasing adoption of electric vehicles, growing renewable energy installations, and the expansion of 5G networks are expected to drive this growth. Additionally, ongoing research and development efforts aimed at improving AGM battery technology are likely to enhance their performance and expand their potential applications, further stimulating market demand.

In the automotive industry, the shift towards more advanced electrical systems and start-stop technology has driven the demand for AGM batteries. As vehicles become more electrified and incorporate sophisticated features, the need for reliable and efficient power sources has grown. AGM batteries offer better cycle life, faster charging, and improved resistance to vibration compared to traditional lead-acid batteries, making them ideal for modern vehicles.

The renewable energy sector has also contributed significantly to the market demand for AGM batteries. As solar and wind power installations continue to expand globally, the need for efficient energy storage solutions has increased. AGM batteries are well-suited for off-grid and grid-tied renewable energy systems due to their deep-cycle capabilities and low maintenance requirements.

Telecommunications infrastructure represents another major market for AGM batteries. The rapid expansion of mobile networks, especially in developing regions, has created a substantial demand for reliable backup power solutions. AGM batteries are preferred in this sector due to their long service life, high discharge rate capabilities, and ability to operate in a wide range of temperatures.

The industrial sector, including material handling equipment and uninterruptible power supply (UPS) systems, has also shown growing interest in AGM batteries. These applications require power sources that can withstand frequent cycling and provide consistent performance, attributes that AGM batteries excel in.

Market trends indicate a growing emphasis on sustainability and environmental responsibility across industries. This has further boosted the demand for AGM batteries, as they are sealed, maintenance-free, and have a higher recyclability rate compared to flooded lead-acid batteries. The focus on reducing carbon footprints and adhering to stricter environmental regulations has positioned AGM batteries as a more sustainable choice for many applications.

The global AGM battery market is projected to experience substantial growth in the coming years. Factors such as increasing adoption of electric vehicles, growing renewable energy installations, and the expansion of 5G networks are expected to drive this growth. Additionally, ongoing research and development efforts aimed at improving AGM battery technology are likely to enhance their performance and expand their potential applications, further stimulating market demand.

Technical Challenges

AGM (Absorbent Glass Mat) battery technology, while offering several advantages over traditional lead-acid batteries, faces significant technical challenges in its pursuit of sustainability across various industries. One of the primary obstacles is the limited recyclability of AGM batteries compared to conventional lead-acid counterparts. The complex structure and materials used in AGM batteries make it more difficult to separate and recover individual components efficiently, leading to increased recycling costs and reduced overall sustainability.

Another major challenge lies in the energy-intensive manufacturing process of AGM batteries. The production of glass mat separators and the assembly of tightly packed cells require substantial energy inputs, contributing to a higher carbon footprint during the manufacturing phase. This energy intensity poses a significant hurdle in achieving true sustainability, particularly when considering the entire lifecycle of the battery.

The use of lead in AGM batteries, although reduced compared to flooded lead-acid batteries, still presents environmental and health concerns. Despite efforts to minimize lead content, the presence of this toxic metal continues to be a point of contention in sustainability initiatives. Developing alternative materials or further reducing lead content without compromising performance remains a critical technical challenge for the industry.

Thermal management is another area of concern for AGM batteries, especially in high-performance applications. The sealed design of AGM batteries, while beneficial for maintenance-free operation, can lead to heat buildup during rapid charging or discharging cycles. This thermal stress can significantly impact the battery's lifespan and performance, necessitating advanced cooling solutions or improved thermal management strategies to enhance long-term sustainability.

The limited cycle life of AGM batteries compared to some newer technologies, such as lithium-ion batteries, presents a sustainability challenge in terms of resource utilization and waste generation. Improving the cycle life of AGM batteries without significantly increasing costs or compromising other performance attributes remains a key technical hurdle for researchers and manufacturers.

Water consumption during the manufacturing process, although reduced compared to flooded lead-acid batteries, still represents a sustainability concern. Developing more water-efficient production methods or exploring alternative manufacturing techniques that minimize water usage is crucial for enhancing the overall environmental profile of AGM batteries.

Lastly, the challenge of balancing performance improvements with sustainability goals is omnipresent. Enhancing energy density, power output, and charge acceptance while simultaneously reducing environmental impact requires innovative approaches to material science, battery design, and manufacturing processes. This delicate balance between performance and sustainability continues to be a driving force behind research and development efforts in the AGM battery industry.

Another major challenge lies in the energy-intensive manufacturing process of AGM batteries. The production of glass mat separators and the assembly of tightly packed cells require substantial energy inputs, contributing to a higher carbon footprint during the manufacturing phase. This energy intensity poses a significant hurdle in achieving true sustainability, particularly when considering the entire lifecycle of the battery.

The use of lead in AGM batteries, although reduced compared to flooded lead-acid batteries, still presents environmental and health concerns. Despite efforts to minimize lead content, the presence of this toxic metal continues to be a point of contention in sustainability initiatives. Developing alternative materials or further reducing lead content without compromising performance remains a critical technical challenge for the industry.

Thermal management is another area of concern for AGM batteries, especially in high-performance applications. The sealed design of AGM batteries, while beneficial for maintenance-free operation, can lead to heat buildup during rapid charging or discharging cycles. This thermal stress can significantly impact the battery's lifespan and performance, necessitating advanced cooling solutions or improved thermal management strategies to enhance long-term sustainability.

The limited cycle life of AGM batteries compared to some newer technologies, such as lithium-ion batteries, presents a sustainability challenge in terms of resource utilization and waste generation. Improving the cycle life of AGM batteries without significantly increasing costs or compromising other performance attributes remains a key technical hurdle for researchers and manufacturers.

Water consumption during the manufacturing process, although reduced compared to flooded lead-acid batteries, still represents a sustainability concern. Developing more water-efficient production methods or exploring alternative manufacturing techniques that minimize water usage is crucial for enhancing the overall environmental profile of AGM batteries.

Lastly, the challenge of balancing performance improvements with sustainability goals is omnipresent. Enhancing energy density, power output, and charge acceptance while simultaneously reducing environmental impact requires innovative approaches to material science, battery design, and manufacturing processes. This delicate balance between performance and sustainability continues to be a driving force behind research and development efforts in the AGM battery industry.

Current Solutions

01 Recycling and reuse of AGM battery components

Developing methods for recycling and reusing components of AGM batteries, such as separators, lead plates, and electrolytes. This approach aims to reduce waste and conserve resources, contributing to the overall sustainability of AGM battery production and disposal.- Recycling and reuse of AGM battery components: Developing methods for recycling and reusing components of AGM batteries, such as lead plates, separators, and electrolytes. This approach aims to reduce waste and environmental impact while conserving resources. Techniques may include chemical treatment, mechanical separation, and refurbishment processes to recover valuable materials and extend battery life.

- Improved AGM battery design for longevity: Enhancing the design of AGM batteries to increase their lifespan and overall sustainability. This may involve optimizing electrode materials, improving electrolyte formulations, and developing advanced separator technologies. The focus is on creating batteries that maintain performance over extended periods, reducing the need for frequent replacements.

- Smart battery management systems: Implementing intelligent battery management systems to optimize AGM battery performance and extend their operational life. These systems may include advanced monitoring, charging algorithms, and predictive maintenance features. By ensuring optimal usage conditions and preventing overcharging or deep discharging, the overall sustainability of AGM batteries can be significantly improved.

- Eco-friendly manufacturing processes: Developing and implementing environmentally friendly manufacturing processes for AGM batteries. This includes reducing energy consumption, minimizing harmful emissions, and using sustainable materials in production. The goal is to decrease the carbon footprint associated with battery manufacturing while maintaining or improving battery performance and quality.

- Integration with renewable energy systems: Designing AGM batteries specifically for integration with renewable energy systems, such as solar and wind power. This approach focuses on optimizing battery performance for intermittent energy sources, improving energy storage efficiency, and enhancing overall system sustainability. It may include developing hybrid systems that combine AGM batteries with other energy storage technologies for optimal performance.

02 Improved manufacturing processes for AGM batteries

Implementing more efficient and environmentally friendly manufacturing processes for AGM batteries. This includes optimizing energy consumption, reducing emissions, and minimizing the use of harmful chemicals during production, thereby enhancing the sustainability of the manufacturing stage.Expand Specific Solutions03 Extended lifespan and performance optimization

Developing technologies to extend the lifespan of AGM batteries and optimize their performance. This involves improving charge-discharge cycles, enhancing thermal management, and implementing advanced monitoring systems to prolong battery life and reduce the need for frequent replacements.Expand Specific Solutions04 Alternative materials for AGM battery components

Researching and implementing alternative, more sustainable materials for AGM battery components. This includes exploring eco-friendly separators, lead-free or reduced-lead plates, and less toxic electrolytes to minimize environmental impact and improve overall sustainability.Expand Specific Solutions05 Smart battery management systems for sustainability

Integrating smart battery management systems to optimize AGM battery usage, charging, and maintenance. These systems can help extend battery life, improve energy efficiency, and reduce waste by providing real-time monitoring and adaptive control of battery parameters.Expand Specific Solutions

Industry Leaders

The AGM battery sustainability market is in a growth phase, driven by increasing demand for eco-friendly energy storage solutions across industries. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, AGM batteries are relatively mature, but ongoing research focuses on improving performance and sustainability. Key players like Contemporary Amperex Technology, LG Energy Solution, and SK On are investing heavily in R&D to enhance AGM battery technology. Companies such as Toyota Motor Corp. and Daimler Truck AG are integrating these batteries into their vehicles, while Johnson Controls and Hoppecke Batterien are developing advanced AGM solutions for various applications. The competitive landscape is characterized by a mix of established battery manufacturers and innovative startups, all striving to capture market share in this evolving sector.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive AGM battery sustainability initiative focusing on circular economy principles. Their approach includes advanced recycling technologies to recover up to 99% of valuable materials from spent batteries[1]. They have also implemented a battery swapping system for electric vehicles, which extends battery life and reduces waste[2]. CATL's research into solid-state batteries aims to increase energy density and reduce reliance on rare earth materials, further enhancing sustainability[3]. Additionally, they have invested in green manufacturing processes, utilizing renewable energy sources in their production facilities to minimize carbon footprint[4].

Strengths: Industry-leading recycling technology, innovative battery swapping system, advanced research in solid-state batteries. Weaknesses: High initial investment costs, potential challenges in scaling up new technologies.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has implemented a multi-faceted approach to AGM battery sustainability. They have developed a closed-loop battery recycling system that recovers up to 95% of key materials[1]. Their "Battery as a Service" model promotes longer battery life cycles and reduces waste[2]. LG has also invested in AI-powered battery management systems to optimize performance and longevity[3]. Furthermore, they are pioneering the use of eco-friendly materials in battery production, including water-based electrode manufacturing processes that reduce harmful emissions[4]. LG's commitment to sustainability extends to their supply chain, where they enforce strict environmental standards for suppliers[5].

Strengths: Advanced recycling capabilities, innovative service models, AI-driven battery management. Weaknesses: Dependency on raw material suppliers, potential regulatory challenges in different markets.

Key Innovations

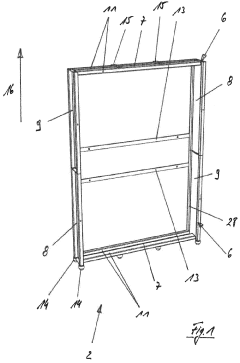

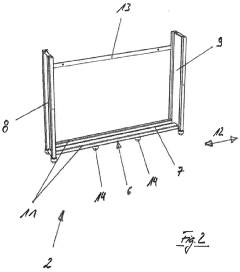

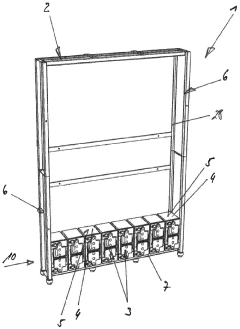

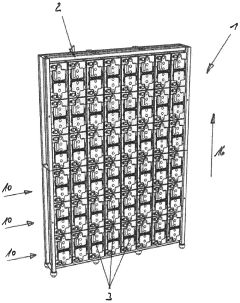

System consisting of a stacking aid and a plurality of AGM batteries

PatentPendingSG11202401655YA

Innovation

- A simplified stacking aid design featuring a U-shaped main body with orthogonal flanges and a support element, where the flanges serve only for lateral protection and not load-bearing, allowing AGM batteries to be stacked with reduced material usage and fewer components, preventing bulging through gravity-induced alignment.

Regulatory Framework

The regulatory framework surrounding AGM (Absorbent Glass Mat) battery sustainability initiatives across industries is evolving rapidly to address environmental concerns and promote responsible resource management. At the international level, the United Nations' Sustainable Development Goals (SDGs) provide a broad framework that influences battery-related regulations, particularly SDG 12 (Responsible Consumption and Production) and SDG 13 (Climate Action).

In the European Union, the proposed Battery Regulation aims to replace the existing Battery Directive, introducing more stringent requirements for battery sustainability. This regulation encompasses the entire battery lifecycle, from raw material sourcing to end-of-life management. It mandates increased recycling targets, carbon footprint declarations, and the use of recycled materials in new batteries. For AGM batteries, these regulations will likely drive innovations in design for recyclability and the development of more efficient recycling processes.

The United States has a patchwork of federal and state-level regulations governing battery sustainability. The Environmental Protection Agency (EPA) oversees the management of spent lead-acid batteries, including AGM batteries, under the Resource Conservation and Recovery Act (RCRA). Several states have implemented their own battery recycling programs and extended producer responsibility (EPR) laws, which place the onus on manufacturers to manage the entire lifecycle of their products.

In Asia, countries like China and Japan are implementing stricter regulations on battery production and recycling. China's Ministry of Industry and Information Technology has issued guidelines for promoting the recycling and reuse of new energy vehicle batteries, which may influence AGM battery regulations in the automotive sector. Japan's Act on Promotion of Recycling of Small Waste Electrical and Electronic Equipment includes provisions for battery recycling, encouraging manufacturers to design for easier disassembly and material recovery.

Emerging economies are also developing regulatory frameworks to address battery sustainability. India's Battery Waste Management Rules 2020 set targets for collection and recycling of different battery types, including AGM batteries. These rules emphasize the responsibility of producers in managing battery waste and promoting circular economy principles.

Industry-specific regulations are also shaping AGM battery sustainability initiatives. In the telecommunications sector, for instance, the European Telecommunications Standards Institute (ETSI) has developed standards for energy efficiency and environmental considerations in network equipment, which include guidelines for battery systems used in telecom infrastructure.

As the regulatory landscape continues to evolve, companies operating across industries must stay informed and proactive in adapting their AGM battery sustainability initiatives. This may involve investing in research and development for more sustainable battery technologies, implementing robust recycling programs, and collaborating with stakeholders across the value chain to ensure compliance with current and future regulations.

In the European Union, the proposed Battery Regulation aims to replace the existing Battery Directive, introducing more stringent requirements for battery sustainability. This regulation encompasses the entire battery lifecycle, from raw material sourcing to end-of-life management. It mandates increased recycling targets, carbon footprint declarations, and the use of recycled materials in new batteries. For AGM batteries, these regulations will likely drive innovations in design for recyclability and the development of more efficient recycling processes.

The United States has a patchwork of federal and state-level regulations governing battery sustainability. The Environmental Protection Agency (EPA) oversees the management of spent lead-acid batteries, including AGM batteries, under the Resource Conservation and Recovery Act (RCRA). Several states have implemented their own battery recycling programs and extended producer responsibility (EPR) laws, which place the onus on manufacturers to manage the entire lifecycle of their products.

In Asia, countries like China and Japan are implementing stricter regulations on battery production and recycling. China's Ministry of Industry and Information Technology has issued guidelines for promoting the recycling and reuse of new energy vehicle batteries, which may influence AGM battery regulations in the automotive sector. Japan's Act on Promotion of Recycling of Small Waste Electrical and Electronic Equipment includes provisions for battery recycling, encouraging manufacturers to design for easier disassembly and material recovery.

Emerging economies are also developing regulatory frameworks to address battery sustainability. India's Battery Waste Management Rules 2020 set targets for collection and recycling of different battery types, including AGM batteries. These rules emphasize the responsibility of producers in managing battery waste and promoting circular economy principles.

Industry-specific regulations are also shaping AGM battery sustainability initiatives. In the telecommunications sector, for instance, the European Telecommunications Standards Institute (ETSI) has developed standards for energy efficiency and environmental considerations in network equipment, which include guidelines for battery systems used in telecom infrastructure.

As the regulatory landscape continues to evolve, companies operating across industries must stay informed and proactive in adapting their AGM battery sustainability initiatives. This may involve investing in research and development for more sustainable battery technologies, implementing robust recycling programs, and collaborating with stakeholders across the value chain to ensure compliance with current and future regulations.

Life Cycle Assessment

Life Cycle Assessment (LCA) plays a crucial role in evaluating the environmental impact of AGM (Absorbent Glass Mat) batteries across their entire lifespan. This comprehensive approach considers all stages of the battery's life, from raw material extraction to manufacturing, use, and end-of-life disposal or recycling.

In the context of AGM battery sustainability initiatives, LCA provides valuable insights into the environmental footprint of these energy storage devices. The assessment typically begins with the extraction and processing of raw materials, including lead, sulfuric acid, and glass fiber mats. This stage accounts for the energy consumption and emissions associated with mining and refining these materials.

The manufacturing phase of AGM batteries is another critical area of focus in LCA. This stage involves the assembly of battery components, including the formation of lead plates, the addition of electrolyte, and the integration of the glass fiber mat. The energy requirements and potential environmental impacts of these processes are carefully evaluated to identify opportunities for improvement.

During the use phase, LCA examines the performance and efficiency of AGM batteries in various applications across industries. This includes assessing factors such as energy density, cycle life, and self-discharge rates. The analysis also considers the potential environmental benefits of AGM batteries in specific applications, such as renewable energy storage or electric vehicles, where they may contribute to reduced carbon emissions.

End-of-life considerations form a significant part of the LCA for AGM batteries. This includes evaluating the recyclability of battery components, the efficiency of recycling processes, and the potential for material recovery. The assessment also examines the environmental impacts of different disposal methods and the potential for second-life applications of used AGM batteries.

By conducting thorough Life Cycle Assessments, industries can identify hotspots in the AGM battery lifecycle where environmental impacts are most significant. This information is invaluable for developing targeted sustainability initiatives aimed at reducing the overall environmental footprint of AGM batteries. Such initiatives may include improving manufacturing processes, enhancing recycling technologies, or exploring alternative materials that offer better environmental performance.

Furthermore, LCA results can guide policy-making and industry standards, promoting more sustainable practices in the production, use, and disposal of AGM batteries across various sectors. This holistic approach to sustainability assessment ensures that efforts to improve the environmental performance of AGM batteries are based on comprehensive, data-driven insights throughout their entire lifecycle.

In the context of AGM battery sustainability initiatives, LCA provides valuable insights into the environmental footprint of these energy storage devices. The assessment typically begins with the extraction and processing of raw materials, including lead, sulfuric acid, and glass fiber mats. This stage accounts for the energy consumption and emissions associated with mining and refining these materials.

The manufacturing phase of AGM batteries is another critical area of focus in LCA. This stage involves the assembly of battery components, including the formation of lead plates, the addition of electrolyte, and the integration of the glass fiber mat. The energy requirements and potential environmental impacts of these processes are carefully evaluated to identify opportunities for improvement.

During the use phase, LCA examines the performance and efficiency of AGM batteries in various applications across industries. This includes assessing factors such as energy density, cycle life, and self-discharge rates. The analysis also considers the potential environmental benefits of AGM batteries in specific applications, such as renewable energy storage or electric vehicles, where they may contribute to reduced carbon emissions.

End-of-life considerations form a significant part of the LCA for AGM batteries. This includes evaluating the recyclability of battery components, the efficiency of recycling processes, and the potential for material recovery. The assessment also examines the environmental impacts of different disposal methods and the potential for second-life applications of used AGM batteries.

By conducting thorough Life Cycle Assessments, industries can identify hotspots in the AGM battery lifecycle where environmental impacts are most significant. This information is invaluable for developing targeted sustainability initiatives aimed at reducing the overall environmental footprint of AGM batteries. Such initiatives may include improving manufacturing processes, enhancing recycling technologies, or exploring alternative materials that offer better environmental performance.

Furthermore, LCA results can guide policy-making and industry standards, promoting more sustainable practices in the production, use, and disposal of AGM batteries across various sectors. This holistic approach to sustainability assessment ensures that efforts to improve the environmental performance of AGM batteries are based on comprehensive, data-driven insights throughout their entire lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!