ALD Coating: Critical Mechanisms in Thermal Barrier Coatings

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ALD Coating Evolution and Objectives

Atomic Layer Deposition (ALD) coating technology has evolved significantly since its inception in the 1970s, originally developed as Atomic Layer Epitaxy (ALE) by Dr. Tuomo Suntola in Finland. The technology was initially applied to thin-film electroluminescent displays before expanding into semiconductor manufacturing in the 1990s. This evolution marked a pivotal shift from conventional Chemical Vapor Deposition (CVD) methods to the more precise, atomic-level control offered by ALD, enabling the creation of ultra-thin, conformal coatings with unprecedented uniformity.

The fundamental principle of ALD—sequential, self-limiting surface reactions—has remained consistent throughout its development, but significant advancements have occurred in precursor chemistry, reactor design, and process optimization. These improvements have progressively enhanced deposition rates, film quality, and compatibility with various substrate materials, particularly in high-temperature applications such as thermal barrier coatings (TBCs).

In the context of TBCs, ALD technology has undergone specialized development to address the unique challenges of protecting components in extreme thermal environments. Traditional plasma spray and electron beam physical vapor deposition (EB-PVD) techniques have dominated the TBC landscape for decades, but their limitations in producing nanoscale, defect-free coatings have created opportunities for ALD implementation.

The primary technical objective in applying ALD to thermal barrier coatings is to develop multi-functional protective layers that simultaneously provide thermal insulation, oxidation resistance, and mechanical stability under extreme temperature cycling conditions. This requires precise control over coating composition, microstructure, and interfacial properties at the nanoscale—capabilities uniquely suited to ALD technology.

Secondary objectives include extending component lifetimes in high-temperature applications, reducing thermal conductivity while maintaining structural integrity, and enabling more efficient operation of gas turbines, jet engines, and other high-temperature systems. These goals align with broader industry trends toward improved energy efficiency, reduced emissions, and extended maintenance intervals.

Recent technological trends indicate a growing focus on hybrid coating approaches that combine ALD with other deposition techniques to leverage complementary advantages. Additionally, there is increasing interest in developing ALD processes compatible with complex 3D geometries typical in turbine components, as well as in-situ monitoring capabilities to ensure coating quality and consistency during the deposition process.

The evolution trajectory suggests that future ALD developments for TBCs will likely focus on multi-material architectures, graded compositions, and self-healing capabilities to further enhance performance under extreme thermal and mechanical stresses. These advancements will be critical for next-generation energy systems operating at increasingly higher temperatures for improved efficiency.

The fundamental principle of ALD—sequential, self-limiting surface reactions—has remained consistent throughout its development, but significant advancements have occurred in precursor chemistry, reactor design, and process optimization. These improvements have progressively enhanced deposition rates, film quality, and compatibility with various substrate materials, particularly in high-temperature applications such as thermal barrier coatings (TBCs).

In the context of TBCs, ALD technology has undergone specialized development to address the unique challenges of protecting components in extreme thermal environments. Traditional plasma spray and electron beam physical vapor deposition (EB-PVD) techniques have dominated the TBC landscape for decades, but their limitations in producing nanoscale, defect-free coatings have created opportunities for ALD implementation.

The primary technical objective in applying ALD to thermal barrier coatings is to develop multi-functional protective layers that simultaneously provide thermal insulation, oxidation resistance, and mechanical stability under extreme temperature cycling conditions. This requires precise control over coating composition, microstructure, and interfacial properties at the nanoscale—capabilities uniquely suited to ALD technology.

Secondary objectives include extending component lifetimes in high-temperature applications, reducing thermal conductivity while maintaining structural integrity, and enabling more efficient operation of gas turbines, jet engines, and other high-temperature systems. These goals align with broader industry trends toward improved energy efficiency, reduced emissions, and extended maintenance intervals.

Recent technological trends indicate a growing focus on hybrid coating approaches that combine ALD with other deposition techniques to leverage complementary advantages. Additionally, there is increasing interest in developing ALD processes compatible with complex 3D geometries typical in turbine components, as well as in-situ monitoring capabilities to ensure coating quality and consistency during the deposition process.

The evolution trajectory suggests that future ALD developments for TBCs will likely focus on multi-material architectures, graded compositions, and self-healing capabilities to further enhance performance under extreme thermal and mechanical stresses. These advancements will be critical for next-generation energy systems operating at increasingly higher temperatures for improved efficiency.

Market Analysis for Thermal Barrier Coatings

The global thermal barrier coatings (TBC) market has been experiencing significant growth, driven by increasing demand across various high-temperature applications. Currently valued at approximately 1.5 billion USD, the market is projected to reach 2.3 billion USD by 2028, representing a compound annual growth rate (CAGR) of 6.8%. This growth trajectory is primarily fueled by expanding applications in aerospace, power generation, and automotive industries.

The aerospace sector remains the dominant consumer of thermal barrier coatings, accounting for nearly 40% of the total market share. This dominance stems from the critical need for high-performance materials in aircraft engines that can withstand extreme operating temperatures while maintaining structural integrity. The continuous push for fuel efficiency and reduced emissions in aviation has further accelerated the adoption of advanced TBC solutions.

Power generation represents the second-largest application segment, constituting approximately 30% of the market. As global energy demands rise and efficiency standards become more stringent, gas turbines equipped with thermal barrier coatings have become increasingly prevalent. The ability of TBCs to enhance turbine efficiency by allowing higher operating temperatures while protecting underlying components has made them indispensable in modern power plants.

Regional analysis reveals that North America and Europe currently lead the market with combined shares exceeding 60%. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India at the forefront. This regional shift is attributed to rapid industrialization, increasing defense spending, and the expansion of aerospace manufacturing capabilities in these economies.

From a technological perspective, the market is witnessing a transition from conventional plasma-sprayed coatings toward advanced deposition techniques, particularly ALD (Atomic Layer Deposition). The superior precision, uniformity, and performance characteristics of ALD-based thermal barrier coatings are driving their adoption despite higher initial costs. Market data indicates that ALD-based TBCs are growing at nearly twice the rate of traditional coating technologies.

Customer requirements are evolving toward coatings with longer lifespans, enhanced thermal resistance, and improved resistance to environmental degradation. This shift is creating new market opportunities for specialized coating solutions tailored to specific operating conditions. Additionally, there is growing demand for environmentally friendly coating processes that reduce hazardous waste and energy consumption during application.

The competitive landscape features both established players and innovative startups. Major companies like General Electric, Praxair Surface Technologies, and Oerlikon Metco control significant market share, while specialized firms focusing exclusively on ALD technology are gaining traction through technological differentiation and strategic partnerships with end-users.

The aerospace sector remains the dominant consumer of thermal barrier coatings, accounting for nearly 40% of the total market share. This dominance stems from the critical need for high-performance materials in aircraft engines that can withstand extreme operating temperatures while maintaining structural integrity. The continuous push for fuel efficiency and reduced emissions in aviation has further accelerated the adoption of advanced TBC solutions.

Power generation represents the second-largest application segment, constituting approximately 30% of the market. As global energy demands rise and efficiency standards become more stringent, gas turbines equipped with thermal barrier coatings have become increasingly prevalent. The ability of TBCs to enhance turbine efficiency by allowing higher operating temperatures while protecting underlying components has made them indispensable in modern power plants.

Regional analysis reveals that North America and Europe currently lead the market with combined shares exceeding 60%. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India at the forefront. This regional shift is attributed to rapid industrialization, increasing defense spending, and the expansion of aerospace manufacturing capabilities in these economies.

From a technological perspective, the market is witnessing a transition from conventional plasma-sprayed coatings toward advanced deposition techniques, particularly ALD (Atomic Layer Deposition). The superior precision, uniformity, and performance characteristics of ALD-based thermal barrier coatings are driving their adoption despite higher initial costs. Market data indicates that ALD-based TBCs are growing at nearly twice the rate of traditional coating technologies.

Customer requirements are evolving toward coatings with longer lifespans, enhanced thermal resistance, and improved resistance to environmental degradation. This shift is creating new market opportunities for specialized coating solutions tailored to specific operating conditions. Additionally, there is growing demand for environmentally friendly coating processes that reduce hazardous waste and energy consumption during application.

The competitive landscape features both established players and innovative startups. Major companies like General Electric, Praxair Surface Technologies, and Oerlikon Metco control significant market share, while specialized firms focusing exclusively on ALD technology are gaining traction through technological differentiation and strategic partnerships with end-users.

Current ALD Technology Landscape and Barriers

Atomic Layer Deposition (ALD) technology has evolved significantly over the past two decades, transitioning from a niche laboratory technique to a mainstream industrial process. Currently, ALD coating for thermal barrier applications represents a sophisticated segment of thin film deposition technologies, characterized by its ability to create conformal, pinhole-free coatings with atomic-level thickness control. The global ALD equipment market is estimated at approximately $1.8 billion, with a projected CAGR of 12.1% through 2027, indicating substantial industrial adoption.

The contemporary ALD landscape features several technical variants, including thermal ALD, plasma-enhanced ALD (PEALD), spatial ALD, and roll-to-roll ALD systems. Thermal ALD remains the most widely implemented for thermal barrier coatings due to its excellent conformality and relatively straightforward process control. PEALD offers advantages in lower processing temperatures but presents challenges in maintaining uniform plasma exposure across complex geometries typical in turbine components.

Despite its advantages, ALD faces significant barriers in thermal barrier coating applications. Process throughput remains a primary limitation, with typical deposition rates of only 0.1-0.2 nm per cycle. For thermal barrier coatings requiring thicknesses of several micrometers, this translates to prohibitively long processing times in conventional batch systems. This throughput constraint has restricted ALD's application primarily to specialized high-value components rather than widespread implementation.

Material selection presents another substantial challenge. While zirconia-based materials (particularly yttria-stabilized zirconia) demonstrate excellent thermal insulation properties, their implementation via ALD processes requires complex precursor chemistry. The precursors must exhibit sufficient volatility, thermal stability, and reactivity while avoiding premature decomposition or particle formation. Current zirconium and yttrium precursors often demand careful temperature control windows that limit process flexibility.

Adhesion and interface engineering between the ALD coating and substrate materials represent another critical barrier. The thermal expansion coefficient mismatch between ceramic ALD coatings and metallic substrates creates significant stress during thermal cycling, leading to potential delamination or cracking. This issue becomes particularly pronounced in turbine applications where components routinely experience temperature gradients exceeding 500°C.

Scalability to complex geometries typical in turbine components presents additional challenges. While ALD theoretically offers superior conformality compared to other deposition techniques, achieving uniform precursor distribution in high-aspect-ratio features or internal cooling channels remains problematic. Current reactor designs struggle to maintain ideal precursor exposure sequences throughout complex three-dimensional structures.

The contemporary ALD landscape features several technical variants, including thermal ALD, plasma-enhanced ALD (PEALD), spatial ALD, and roll-to-roll ALD systems. Thermal ALD remains the most widely implemented for thermal barrier coatings due to its excellent conformality and relatively straightforward process control. PEALD offers advantages in lower processing temperatures but presents challenges in maintaining uniform plasma exposure across complex geometries typical in turbine components.

Despite its advantages, ALD faces significant barriers in thermal barrier coating applications. Process throughput remains a primary limitation, with typical deposition rates of only 0.1-0.2 nm per cycle. For thermal barrier coatings requiring thicknesses of several micrometers, this translates to prohibitively long processing times in conventional batch systems. This throughput constraint has restricted ALD's application primarily to specialized high-value components rather than widespread implementation.

Material selection presents another substantial challenge. While zirconia-based materials (particularly yttria-stabilized zirconia) demonstrate excellent thermal insulation properties, their implementation via ALD processes requires complex precursor chemistry. The precursors must exhibit sufficient volatility, thermal stability, and reactivity while avoiding premature decomposition or particle formation. Current zirconium and yttrium precursors often demand careful temperature control windows that limit process flexibility.

Adhesion and interface engineering between the ALD coating and substrate materials represent another critical barrier. The thermal expansion coefficient mismatch between ceramic ALD coatings and metallic substrates creates significant stress during thermal cycling, leading to potential delamination or cracking. This issue becomes particularly pronounced in turbine applications where components routinely experience temperature gradients exceeding 500°C.

Scalability to complex geometries typical in turbine components presents additional challenges. While ALD theoretically offers superior conformality compared to other deposition techniques, achieving uniform precursor distribution in high-aspect-ratio features or internal cooling channels remains problematic. Current reactor designs struggle to maintain ideal precursor exposure sequences throughout complex three-dimensional structures.

Contemporary ALD Solutions for Thermal Applications

01 ALD coating methods for thermal barrier applications

Atomic Layer Deposition (ALD) techniques can be used to create thin, uniform thermal barrier coatings with precise thickness control. These methods involve sequential, self-limiting surface reactions that allow for conformal coating on complex geometries. ALD processes typically operate at lower temperatures than conventional coating methods, enabling the coating of temperature-sensitive substrates while maintaining excellent adhesion and thermal barrier properties.- ALD coating methods for thermal barrier applications: Atomic Layer Deposition (ALD) techniques can be used to create thermal barrier coatings with precise thickness control and excellent conformality. These methods involve sequential, self-limiting surface reactions that allow for the deposition of thin films with atomic-level precision. ALD coatings provide effective thermal barriers due to their uniform coverage, even on complex geometries, and can be applied at relatively low temperatures compared to other deposition methods.

- Multi-layer thermal barrier coating systems using ALD: Multi-layered coating systems created using ALD technology can enhance thermal barrier performance through the strategic combination of different materials. These systems typically consist of a bond coat, a thermally grown oxide layer, and a ceramic top coat. The multi-layer approach allows for the optimization of different properties such as adhesion, oxidation resistance, and thermal insulation, resulting in superior thermal barrier performance and extended component life in high-temperature environments.

- Novel materials for ALD thermal barrier coatings: Advanced materials deposited via ALD can significantly improve thermal barrier performance. These materials include yttria-stabilized zirconia (YSZ), rare earth oxides, and various ceramic compositions that offer low thermal conductivity and high temperature stability. The precise control afforded by ALD allows for the incorporation of nanoscale features and compositional gradients that can further enhance thermal resistance properties while maintaining mechanical integrity under thermal cycling conditions.

- ALD coatings for turbine engine components: ALD thermal barrier coatings are particularly valuable for protecting turbine engine components that operate in extreme temperature environments. These coatings can be applied to turbine blades, combustion chambers, and other critical components to increase their durability and efficiency. The thin, uniform nature of ALD coatings allows for precise thermal management without significantly altering component dimensions or adding excessive weight, which is crucial for maintaining aerodynamic performance and fuel efficiency in aerospace applications.

- Environmental protection features of ALD thermal barriers: ALD thermal barrier coatings provide environmental protection beyond thermal insulation. These coatings can offer resistance to oxidation, corrosion, and erosion in harsh operating environments. By creating dense, pinhole-free layers, ALD coatings effectively seal underlying substrates from environmental attack. Additionally, certain ALD coating compositions can be tailored to provide self-healing properties or to act as diffusion barriers against harmful elements, further extending component lifetimes in aggressive thermal and chemical environments.

02 Multi-layer thermal barrier coating structures

Multi-layered coating systems created using ALD techniques can provide enhanced thermal barrier properties. These structures typically consist of alternating layers of different materials, each contributing specific properties to the overall thermal barrier performance. The multi-layer approach allows for customization of thermal conductivity, coefficient of thermal expansion, and mechanical properties, resulting in more effective and durable thermal barrier coatings for high-temperature applications.Expand Specific Solutions03 Ceramic-based ALD thermal barrier coatings

Ceramic materials deposited via ALD processes are widely used for thermal barrier applications due to their excellent high-temperature stability and low thermal conductivity. Materials such as yttria-stabilized zirconia (YSZ), alumina, and rare earth oxides can be precisely deposited to form effective thermal barriers. These ceramic coatings provide protection against thermal cycling, oxidation, and corrosion while maintaining structural integrity at elevated temperatures.Expand Specific Solutions04 ALD thermal barriers for turbine components

ALD thermal barrier coatings are particularly valuable for gas turbine components that operate under extreme temperature conditions. These coatings protect turbine blades, vanes, and combustor components from thermal degradation, extending component life and improving engine efficiency. The conformal nature of ALD coatings ensures uniform coverage of complex turbine geometries, including cooling channels and edges, providing comprehensive thermal protection for these critical components.Expand Specific Solutions05 Advanced ALD materials for enhanced thermal barrier performance

Novel materials and compositions deposited via ALD can significantly improve thermal barrier performance. These advanced materials include nanocomposites, doped oxides, and engineered structures with tailored porosity. By controlling the atomic-level composition and structure, these materials can achieve lower thermal conductivity, better strain tolerance, and improved resistance to sintering and phase transformations at high temperatures, resulting in more effective and longer-lasting thermal barrier coatings.Expand Specific Solutions

Leading Companies and Research Institutions in ALD

The ALD Coating market for Thermal Barrier Coatings is currently in a growth phase, with increasing adoption across aerospace, energy, and semiconductor industries. The global market is expanding at approximately 12-15% annually, driven by demand for high-performance protective coatings in extreme environments. Technologically, the field is advancing from early commercial maturity toward widespread implementation. Leading players include established industrial giants like Applied Materials, 3M Innovative Properties, and Siemens AG, who focus on large-scale applications, while specialized innovators such as Forge Nano and Adiabatics are developing next-generation solutions with enhanced precision and performance. Academic institutions including Shanghai Jiao Tong University and research organizations like Shanghai Institute of Ceramics are advancing fundamental mechanisms, creating a competitive landscape balanced between commercial deployment and continued innovation.

Forge Nano, Inc.

Technical Solution: Forge Nano has pioneered proprietary Atomic Armor™ technology specifically designed for thermal barrier coating applications. Their ALD process enables precise deposition of ultra-thin, conformal ceramic coatings at the atomic scale, creating highly engineered thermal barriers with unprecedented performance characteristics. The company's technology platform utilizes a specialized reaction chamber design that allows for rapid cycling of precursor gases, significantly increasing throughput compared to conventional ALD systems[2]. Forge Nano's process can deposit complex oxide structures including yttria-stabilized zirconia, alumina, and rare-earth-doped ceramics with exceptional uniformity. Their innovation includes the development of high-temperature stable precursors that enable direct deposition onto superalloy substrates at elevated temperatures, improving interfacial properties and coating adhesion[4]. The company has also developed proprietary spatial ALD technology that allows continuous processing for larger components, addressing traditional ALD throughput limitations. Their coatings demonstrate superior resistance to CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration, a common failure mechanism in turbine applications, through engineered nanolaminates with sacrificial layers designed to react with molten CMAS and prevent further penetration.

Strengths: Industry-leading deposition rate through optimized precursor delivery systems; exceptional coating uniformity even on complex geometries; proprietary precursors enabling direct high-temperature deposition; demonstrated scale-up capability for industrial applications. Weaknesses: Higher initial capital investment compared to conventional coating technologies; requires specialized precursor materials that may have limited availability; process optimization needed for each specific substrate material and geometry.

Corning, Inc.

Technical Solution: Corning has developed specialized ALD coating technology for thermal barrier applications that leverages their extensive expertise in materials science and glass ceramics. Their approach focuses on creating multi-functional thermal barrier coatings that combine thermal insulation with additional properties such as chemical resistance and optical functionality. Corning's proprietary ALD process utilizes custom-designed precursors to deposit nanolaminates of aluminum oxide, zirconium oxide, and silicon oxide with precisely controlled stoichiometry and thickness[5]. The company has pioneered the integration of rare-earth elements into ALD thermal barrier coatings to enhance phase stability and thermal cycling resistance. Their process incorporates a gradient composition approach, where the ceramic composition gradually transitions through the coating thickness to minimize thermal expansion mismatch stresses and enhance durability[6]. Corning has also developed specialized surface preparation techniques that enhance coating adhesion on various substrate materials, including metals, ceramics, and glass. Their ALD thermal barrier coatings demonstrate exceptional resistance to thermal shock, with testing showing survival through more than 1000 rapid thermal cycles between room temperature and 1100°C without significant degradation or spallation. The company has successfully scaled their technology to coat components with complex geometries while maintaining uniform thickness distribution.

Strengths: Exceptional thermal cycling resistance due to engineered compositional gradients; superior adhesion on multiple substrate types; ability to create multifunctional coatings combining thermal, chemical, and optical properties; extensive materials science expertise. Weaknesses: Process requires precise control of multiple parameters, increasing complexity; higher cost compared to conventional coating methods; limited thickness capability for single ALD layers requires multiple deposition cycles for thicker coatings.

Key Patents and Innovations in ALD Coating Mechanisms

Atomic layer deposition

PatentWO2013150299A1

Innovation

- Introducing a pause or delay between deposition steps in the ALD process, maintaining constant pressure and temperature, allows for improved electrical properties by disrupting the continuous deposition flow and potentially enhancing film structure and defects, thereby improving the dielectric constant and leakage current of the deposited material.

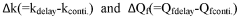

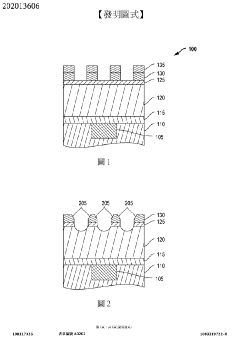

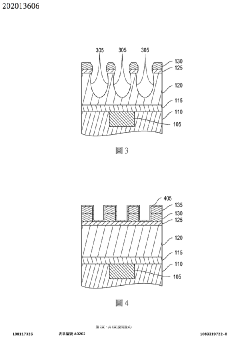

Atomic layer deposition for low-k trench protection during etch

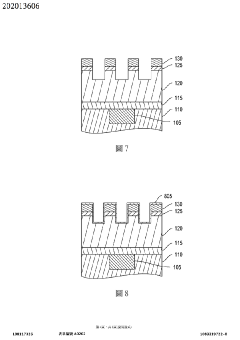

PatentActiveTW202013606A

Innovation

- Incorporating an atomic layer deposition (ALD) technique to form protective layers on hard mask and low-K dielectric sidewalls during the trench etch process, using SiO2 or SiN sacrificial layers to prevent erosion and lateral etching, ensuring better control over trench profiles and critical dimensions.

Environmental Impact and Sustainability of ALD Processes

Atomic Layer Deposition (ALD) coating processes, while offering exceptional precision and control for thermal barrier coatings, present significant environmental considerations that must be addressed as this technology scales. Traditional ALD processes often utilize precursor chemicals that include environmentally problematic compounds such as metal-organic precursors containing volatile organic compounds (VOCs) and reactive gases that may contribute to atmospheric pollution when improperly managed.

The energy consumption profile of ALD processes represents another environmental concern. The need for vacuum conditions and precise temperature control results in substantial energy requirements, particularly for large-scale industrial applications. Current estimates suggest that ALD processes can consume between 5-10 times more energy per unit area coated compared to conventional coating methods, though this is partially offset by the reduced material waste.

Water usage in ALD processes, particularly in purging cycles between precursor exposures, creates additional sustainability challenges. Advanced facilities have begun implementing closed-loop water recycling systems, reducing freshwater consumption by up to 60% compared to earlier generation systems. This represents a significant improvement but indicates room for further optimization.

Recent innovations have focused on developing "green ALD" approaches that address these environmental concerns. Water-based precursors are replacing traditional organometallic compounds, reducing hazardous waste generation by approximately 40%. Additionally, catalyst-enhanced ALD processes have demonstrated the ability to operate at lower temperatures, reducing energy requirements by 25-30% while maintaining coating quality for thermal barrier applications.

Life cycle assessment (LCA) studies comparing ALD thermal barrier coatings to conventional alternatives reveal complex sustainability tradeoffs. While ALD processes may require more energy during manufacturing, the superior performance and longevity of ALD coatings in high-temperature applications can result in net environmental benefits over the product lifecycle. For instance, ALD thermal barrier coatings in turbine applications have demonstrated 15-20% longer service lives, reducing replacement frequency and associated environmental impacts.

Industry leaders are increasingly adopting closed-system approaches that capture and recycle unreacted precursors, significantly reducing emissions and waste. These systems have demonstrated recovery rates of 70-85% for expensive precursor materials, simultaneously addressing both environmental and economic concerns. The development of ambient pressure ALD techniques further promises to reduce energy requirements while maintaining the precision control that makes ALD valuable for thermal barrier coating applications.

The energy consumption profile of ALD processes represents another environmental concern. The need for vacuum conditions and precise temperature control results in substantial energy requirements, particularly for large-scale industrial applications. Current estimates suggest that ALD processes can consume between 5-10 times more energy per unit area coated compared to conventional coating methods, though this is partially offset by the reduced material waste.

Water usage in ALD processes, particularly in purging cycles between precursor exposures, creates additional sustainability challenges. Advanced facilities have begun implementing closed-loop water recycling systems, reducing freshwater consumption by up to 60% compared to earlier generation systems. This represents a significant improvement but indicates room for further optimization.

Recent innovations have focused on developing "green ALD" approaches that address these environmental concerns. Water-based precursors are replacing traditional organometallic compounds, reducing hazardous waste generation by approximately 40%. Additionally, catalyst-enhanced ALD processes have demonstrated the ability to operate at lower temperatures, reducing energy requirements by 25-30% while maintaining coating quality for thermal barrier applications.

Life cycle assessment (LCA) studies comparing ALD thermal barrier coatings to conventional alternatives reveal complex sustainability tradeoffs. While ALD processes may require more energy during manufacturing, the superior performance and longevity of ALD coatings in high-temperature applications can result in net environmental benefits over the product lifecycle. For instance, ALD thermal barrier coatings in turbine applications have demonstrated 15-20% longer service lives, reducing replacement frequency and associated environmental impacts.

Industry leaders are increasingly adopting closed-system approaches that capture and recycle unreacted precursors, significantly reducing emissions and waste. These systems have demonstrated recovery rates of 70-85% for expensive precursor materials, simultaneously addressing both environmental and economic concerns. The development of ambient pressure ALD techniques further promises to reduce energy requirements while maintaining the precision control that makes ALD valuable for thermal barrier coating applications.

Material Science Advancements for Enhanced Thermal Resistance

Recent advancements in material science have significantly enhanced the thermal resistance capabilities of protective coatings, particularly in the realm of Atomic Layer Deposition (ALD) for Thermal Barrier Coatings (TBCs). The evolution of these materials has been driven by the increasing demands of high-temperature applications in aerospace, power generation, and automotive industries.

Ceramic-based materials have emerged as the cornerstone of modern TBCs, with yttria-stabilized zirconia (YSZ) remaining the industry standard due to its exceptional combination of low thermal conductivity and high thermal expansion coefficient. However, research has pushed beyond traditional YSZ formulations to develop next-generation materials with superior performance characteristics.

Rare-earth zirconates (Re₂Zr₂O₇) represent a significant advancement, offering thermal conductivity values approximately 30% lower than conventional YSZ while maintaining stability at temperatures exceeding 1200°C. These materials demonstrate remarkable resistance to sintering and phase transformations that typically compromise coating integrity during thermal cycling.

Nanostructured materials have revolutionized the field by introducing engineered defects and interfaces that effectively scatter phonons, thereby reducing thermal conductivity without compromising mechanical properties. Multi-layered architectures incorporating alternating compositions create thermal boundary resistance at interfaces, further impeding heat transfer through the coating system.

Environmental barrier additions have been integrated into TBC systems to address challenges posed by contaminants such as calcium-magnesium-aluminosilicates (CMAS), which can severely degrade coating performance through infiltration and chemical interaction. These advancements include the incorporation of rare-earth elements that react with molten CMAS to form crystalline phases that arrest further penetration.

Self-healing capabilities represent the frontier of TBC material development, with embedded phases that can flow and seal cracks during high-temperature exposure. This autonomous repair mechanism significantly extends coating lifetime by mitigating the progressive damage that typically leads to spallation failure.

The precision offered by ALD processes has enabled the tailoring of material composition at the atomic scale, allowing for unprecedented control over microstructure and interfacial properties. This has facilitated the development of gradient structures that smoothly transition between different material compositions, eliminating sharp interfaces that often serve as failure initiation sites.

Ceramic-based materials have emerged as the cornerstone of modern TBCs, with yttria-stabilized zirconia (YSZ) remaining the industry standard due to its exceptional combination of low thermal conductivity and high thermal expansion coefficient. However, research has pushed beyond traditional YSZ formulations to develop next-generation materials with superior performance characteristics.

Rare-earth zirconates (Re₂Zr₂O₇) represent a significant advancement, offering thermal conductivity values approximately 30% lower than conventional YSZ while maintaining stability at temperatures exceeding 1200°C. These materials demonstrate remarkable resistance to sintering and phase transformations that typically compromise coating integrity during thermal cycling.

Nanostructured materials have revolutionized the field by introducing engineered defects and interfaces that effectively scatter phonons, thereby reducing thermal conductivity without compromising mechanical properties. Multi-layered architectures incorporating alternating compositions create thermal boundary resistance at interfaces, further impeding heat transfer through the coating system.

Environmental barrier additions have been integrated into TBC systems to address challenges posed by contaminants such as calcium-magnesium-aluminosilicates (CMAS), which can severely degrade coating performance through infiltration and chemical interaction. These advancements include the incorporation of rare-earth elements that react with molten CMAS to form crystalline phases that arrest further penetration.

Self-healing capabilities represent the frontier of TBC material development, with embedded phases that can flow and seal cracks during high-temperature exposure. This autonomous repair mechanism significantly extends coating lifetime by mitigating the progressive damage that typically leads to spallation failure.

The precision offered by ALD processes has enabled the tailoring of material composition at the atomic scale, allowing for unprecedented control over microstructure and interfacial properties. This has facilitated the development of gradient structures that smoothly transition between different material compositions, eliminating sharp interfaces that often serve as failure initiation sites.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!