How ALD Coating Enhances Wear Resistance in Aerospace Components

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ALD Technology Evolution and Objectives

Atomic Layer Deposition (ALD) technology has evolved significantly since its inception in the 1970s, transforming from a laboratory curiosity to a critical manufacturing process in advanced industries. Initially developed as a variant of Chemical Vapor Deposition (CVD), ALD distinguished itself through its unique self-limiting surface reactions that enable atomic-level precision in thin film deposition. The technology gained substantial momentum in the 1990s when the semiconductor industry began exploring it for microelectronics applications, particularly for high-k dielectric layers.

The evolution of ALD technology accelerated dramatically in the early 2000s with the development of new precursors and process methodologies that expanded its temperature range and substrate compatibility. This period marked the transition from primarily silicon-based applications to more diverse material systems, including metals, metal oxides, and nitrides. The aerospace industry began showing interest in ALD coatings around 2005-2010, recognizing its potential for creating ultra-thin, conformal protective layers on complex component geometries.

Recent technological advancements have focused on spatial ALD, atmospheric pressure ALD, and roll-to-roll processes, significantly improving throughput and reducing manufacturing costs. These innovations have been crucial in transitioning ALD from a high-value, low-volume process to one suitable for larger aerospace components. The development of plasma-enhanced ALD (PEALD) has further expanded the technology's capabilities, allowing for lower deposition temperatures and enhanced film properties, particularly beneficial for temperature-sensitive aerospace materials.

The primary objective of ALD coating technology in aerospace applications is to create ultra-thin, uniform, and pinhole-free protective layers that significantly enhance wear resistance without altering component dimensions or adding substantial weight. This precision is particularly critical for high-tolerance aerospace components where dimensional stability directly impacts performance and safety. Secondary objectives include improving corrosion resistance, thermal barrier properties, and reducing friction coefficients in moving parts.

Looking forward, the technology trajectory aims to develop multi-material ALD processes capable of creating gradient or multi-layered coatings that can address multiple wear mechanisms simultaneously. Research is also focused on scaling up ALD processes for larger components while maintaining the atomic-level precision that defines the technology. The ultimate goal is to establish ALD as a standard surface engineering solution in aerospace manufacturing, enabling longer component lifespans, reduced maintenance requirements, and improved fuel efficiency through weight reduction and optimized surface properties.

The evolution of ALD technology accelerated dramatically in the early 2000s with the development of new precursors and process methodologies that expanded its temperature range and substrate compatibility. This period marked the transition from primarily silicon-based applications to more diverse material systems, including metals, metal oxides, and nitrides. The aerospace industry began showing interest in ALD coatings around 2005-2010, recognizing its potential for creating ultra-thin, conformal protective layers on complex component geometries.

Recent technological advancements have focused on spatial ALD, atmospheric pressure ALD, and roll-to-roll processes, significantly improving throughput and reducing manufacturing costs. These innovations have been crucial in transitioning ALD from a high-value, low-volume process to one suitable for larger aerospace components. The development of plasma-enhanced ALD (PEALD) has further expanded the technology's capabilities, allowing for lower deposition temperatures and enhanced film properties, particularly beneficial for temperature-sensitive aerospace materials.

The primary objective of ALD coating technology in aerospace applications is to create ultra-thin, uniform, and pinhole-free protective layers that significantly enhance wear resistance without altering component dimensions or adding substantial weight. This precision is particularly critical for high-tolerance aerospace components where dimensional stability directly impacts performance and safety. Secondary objectives include improving corrosion resistance, thermal barrier properties, and reducing friction coefficients in moving parts.

Looking forward, the technology trajectory aims to develop multi-material ALD processes capable of creating gradient or multi-layered coatings that can address multiple wear mechanisms simultaneously. Research is also focused on scaling up ALD processes for larger components while maintaining the atomic-level precision that defines the technology. The ultimate goal is to establish ALD as a standard surface engineering solution in aerospace manufacturing, enabling longer component lifespans, reduced maintenance requirements, and improved fuel efficiency through weight reduction and optimized surface properties.

Aerospace Industry Demand for Advanced Coating Solutions

The aerospace industry faces increasingly demanding operational environments that require components to withstand extreme conditions including high temperatures, corrosive atmospheres, and significant mechanical stress. This has created a substantial and growing demand for advanced coating solutions that can enhance component performance and longevity while reducing maintenance costs and improving safety margins.

Commercial aircraft manufacturers are particularly focused on reducing the weight-to-strength ratio of components while simultaneously extending their service life. With fuel costs representing approximately 30% of airline operating expenses, any technology that can reduce maintenance frequency or extend component replacement intervals translates directly to competitive advantage in the marketplace.

Military aerospace applications present even more stringent requirements, with defense contractors seeking coating technologies that can protect critical components from thermal cycling, oxidation, and wear under combat conditions. The defense sector's willingness to adopt premium solutions for performance enhancement has created a significant market segment for specialized coating technologies.

Space exploration represents another high-value market for advanced coatings, with components requiring protection in the vacuum of space, during atmospheric re-entry, and against micrometeorite impacts. As commercial space activities expand, this segment is experiencing rapid growth and technological innovation.

Market analysis indicates that aerospace manufacturers are increasingly prioritizing coating solutions that offer multifunctional benefits beyond mere wear resistance, including thermal barrier properties, corrosion resistance, and reduced friction coefficients. This trend is driving research toward integrated coating systems rather than single-purpose applications.

The economic implications of component failure in aerospace applications are substantial, with unscheduled maintenance events costing commercial airlines millions in direct repair costs and lost revenue. This creates a compelling value proposition for coating technologies that can demonstrably extend component life cycles and improve reliability metrics.

Regulatory factors are also driving demand, with environmental regulations increasingly restricting traditional coating processes that involve hazardous materials or generate significant waste streams. This regulatory landscape favors technologies like Atomic Layer Deposition (ALD) that offer precise material utilization and minimal environmental impact.

Industry forecasts project the global aerospace coatings market to grow at a compound annual rate exceeding 5% through 2028, with advanced wear-resistant coatings representing one of the fastest-growing segments within this market. This growth is supported by both fleet expansion in commercial aviation and modernization programs in defense aerospace.

Commercial aircraft manufacturers are particularly focused on reducing the weight-to-strength ratio of components while simultaneously extending their service life. With fuel costs representing approximately 30% of airline operating expenses, any technology that can reduce maintenance frequency or extend component replacement intervals translates directly to competitive advantage in the marketplace.

Military aerospace applications present even more stringent requirements, with defense contractors seeking coating technologies that can protect critical components from thermal cycling, oxidation, and wear under combat conditions. The defense sector's willingness to adopt premium solutions for performance enhancement has created a significant market segment for specialized coating technologies.

Space exploration represents another high-value market for advanced coatings, with components requiring protection in the vacuum of space, during atmospheric re-entry, and against micrometeorite impacts. As commercial space activities expand, this segment is experiencing rapid growth and technological innovation.

Market analysis indicates that aerospace manufacturers are increasingly prioritizing coating solutions that offer multifunctional benefits beyond mere wear resistance, including thermal barrier properties, corrosion resistance, and reduced friction coefficients. This trend is driving research toward integrated coating systems rather than single-purpose applications.

The economic implications of component failure in aerospace applications are substantial, with unscheduled maintenance events costing commercial airlines millions in direct repair costs and lost revenue. This creates a compelling value proposition for coating technologies that can demonstrably extend component life cycles and improve reliability metrics.

Regulatory factors are also driving demand, with environmental regulations increasingly restricting traditional coating processes that involve hazardous materials or generate significant waste streams. This regulatory landscape favors technologies like Atomic Layer Deposition (ALD) that offer precise material utilization and minimal environmental impact.

Industry forecasts project the global aerospace coatings market to grow at a compound annual rate exceeding 5% through 2028, with advanced wear-resistant coatings representing one of the fastest-growing segments within this market. This growth is supported by both fleet expansion in commercial aviation and modernization programs in defense aerospace.

Current ALD Coating Challenges in Aerospace Applications

Despite the significant advancements in Atomic Layer Deposition (ALD) coating technology for aerospace applications, several critical challenges continue to impede its widespread implementation and optimal performance. The primary challenge remains the deposition rate limitations inherent to ALD processes. The self-limiting nature of ALD reactions, while ensuring excellent conformality and thickness control, results in extremely slow growth rates typically between 0.05-0.1 nm per cycle. For aerospace components requiring thicker protective layers (>1 μm), this translates to prohibitively long processing times and reduced production throughput.

Temperature constraints present another significant hurdle. Many aerospace substrates, particularly those containing aluminum alloys or polymer composites, cannot withstand the elevated temperatures (200-350°C) often required for conventional ALD processes. While low-temperature ALD variants exist, they frequently compromise film quality, adhesion strength, and wear resistance properties critical for aerospace applications.

Scalability issues persist when applying ALD to complex aerospace geometries. Components with high aspect ratios, internal channels, or intricate surface features present precursor diffusion challenges, leading to non-uniform coating thickness and potential weak points in wear protection. The industry still lacks standardized approaches for ensuring complete coverage on complex three-dimensional structures typical in aerospace engineering.

Cost considerations remain a substantial barrier to broader adoption. The high-purity precursors required for ALD processes, particularly for specialized wear-resistant materials like transition metal nitrides and carbides, carry significant expense. Combined with the aforementioned slow deposition rates, this results in higher per-component processing costs compared to alternative coating technologies like PVD or thermal spray methods.

Adhesion failures between ALD coatings and aerospace substrate materials continue to challenge engineers, particularly under the extreme thermal cycling conditions experienced in aerospace applications. The coefficient of thermal expansion mismatch between ceramic ALD films and metallic substrates can lead to coating delamination during service, compromising wear protection.

Quality control and characterization methodologies for ALD coatings on aerospace components remain underdeveloped. Non-destructive testing techniques capable of detecting nanoscale defects, thickness variations, or adhesion issues across large and complex components are still evolving, creating uncertainty in quality assurance protocols.

Environmental and regulatory challenges are emerging as well. Some traditional ALD precursors contain environmentally hazardous elements or produce toxic byproducts, facing increasing regulatory scrutiny. The aerospace industry must develop greener ALD chemistries that maintain performance standards while meeting stringent environmental regulations.

Temperature constraints present another significant hurdle. Many aerospace substrates, particularly those containing aluminum alloys or polymer composites, cannot withstand the elevated temperatures (200-350°C) often required for conventional ALD processes. While low-temperature ALD variants exist, they frequently compromise film quality, adhesion strength, and wear resistance properties critical for aerospace applications.

Scalability issues persist when applying ALD to complex aerospace geometries. Components with high aspect ratios, internal channels, or intricate surface features present precursor diffusion challenges, leading to non-uniform coating thickness and potential weak points in wear protection. The industry still lacks standardized approaches for ensuring complete coverage on complex three-dimensional structures typical in aerospace engineering.

Cost considerations remain a substantial barrier to broader adoption. The high-purity precursors required for ALD processes, particularly for specialized wear-resistant materials like transition metal nitrides and carbides, carry significant expense. Combined with the aforementioned slow deposition rates, this results in higher per-component processing costs compared to alternative coating technologies like PVD or thermal spray methods.

Adhesion failures between ALD coatings and aerospace substrate materials continue to challenge engineers, particularly under the extreme thermal cycling conditions experienced in aerospace applications. The coefficient of thermal expansion mismatch between ceramic ALD films and metallic substrates can lead to coating delamination during service, compromising wear protection.

Quality control and characterization methodologies for ALD coatings on aerospace components remain underdeveloped. Non-destructive testing techniques capable of detecting nanoscale defects, thickness variations, or adhesion issues across large and complex components are still evolving, creating uncertainty in quality assurance protocols.

Environmental and regulatory challenges are emerging as well. Some traditional ALD precursors contain environmentally hazardous elements or produce toxic byproducts, facing increasing regulatory scrutiny. The aerospace industry must develop greener ALD chemistries that maintain performance standards while meeting stringent environmental regulations.

Existing ALD Implementation Methods for Wear Resistance

01 ALD coating for enhanced wear resistance on metal substrates

Atomic Layer Deposition (ALD) coatings can be applied to metal substrates to significantly improve wear resistance properties. These thin film coatings create a protective barrier that reduces friction and prevents surface degradation during mechanical contact. The nanoscale precision of ALD allows for uniform coverage even on complex geometries, resulting in superior wear protection compared to conventional coating methods.- ALD coating for enhanced wear resistance in mechanical components: Atomic Layer Deposition (ALD) coatings can significantly improve the wear resistance of mechanical components by creating uniform, conformal layers that protect against friction and abrasion. These coatings can be applied to various substrates including metals, ceramics, and polymers to extend component lifetime and maintain performance under harsh operating conditions. The nanoscale precision of ALD allows for optimized coating thickness and composition tailored to specific wear requirements.

- Multi-layer ALD coatings with enhanced hardness properties: Multi-layered ALD coating structures can be designed to provide superior wear resistance through the strategic combination of different materials. By alternating layers with complementary properties, these coatings achieve enhanced hardness, toughness, and adhesion to the substrate. The nanolaminates created through this process can effectively distribute stress and prevent crack propagation, resulting in significantly improved wear performance compared to single-layer coatings.

- ALD coating with metal oxides and nitrides for tribological applications: Metal oxide and nitride ALD coatings, such as aluminum oxide, titanium nitride, and zirconium oxide, offer exceptional wear resistance properties for tribological applications. These materials provide high hardness, chemical stability, and low friction coefficients. The precise control of composition and structure during the ALD process allows for optimization of these coatings for specific wear environments, including high temperature, corrosive conditions, or applications requiring low friction.

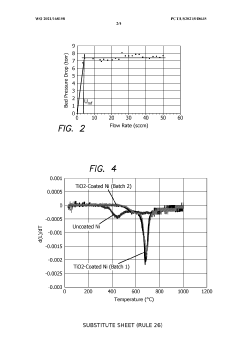

- ALD coating process parameters optimization for wear resistance: The optimization of ALD process parameters significantly impacts the wear resistance properties of the resulting coatings. Factors such as deposition temperature, precursor selection, pulse and purge times, and number of cycles can be tuned to achieve desired coating characteristics. Post-deposition treatments like annealing can further enhance crystallinity and adhesion, resulting in superior wear performance. Advanced process monitoring and control systems enable reproducible production of high-performance wear-resistant coatings.

- ALD coatings for tool and cutting applications: ALD coatings provide exceptional wear resistance for cutting tools, drills, and other machining equipment, significantly extending tool life and maintaining cutting edge performance. The conformal nature of ALD ensures uniform protection even on complex tool geometries and sharp edges. These coatings can be customized with specific compositions to address particular cutting conditions, such as high-speed machining, dry cutting, or processing of abrasive materials, resulting in improved productivity and reduced tool replacement costs.

02 Multi-layer ALD coatings for extreme wear conditions

Multi-layered ALD coating structures can be engineered to withstand extreme wear conditions by combining different materials with complementary properties. These composite coatings typically feature alternating hard and soft layers or gradient compositions that distribute mechanical stress and prevent crack propagation. The multi-layer approach allows for customization of wear resistance properties for specific applications while maintaining the nanoscale precision characteristic of ALD technology.Expand Specific Solutions03 ALD coating with ceramic materials for superior hardness

Ceramic materials deposited via ALD processes can provide exceptional hardness and wear resistance for industrial applications. Materials such as aluminum oxide, titanium nitride, and zirconium oxide can be precisely deposited to create ultra-hard protective layers. These ceramic ALD coatings offer superior protection against abrasive wear while maintaining dimensional precision of the coated components, making them ideal for cutting tools, mechanical parts, and high-stress applications.Expand Specific Solutions04 Temperature-optimized ALD processes for wear-resistant coatings

Optimizing the temperature parameters during the ALD process can significantly enhance the wear resistance properties of the resulting coatings. By carefully controlling deposition temperature, researchers have developed processes that improve coating adhesion, density, and crystallinity, all of which contribute to superior wear performance. These temperature-optimized ALD methods enable the creation of wear-resistant coatings that maintain their protective properties even under thermal cycling conditions.Expand Specific Solutions05 ALD coatings with self-healing properties for prolonged wear resistance

Advanced ALD coating formulations can incorporate self-healing mechanisms that extend wear resistance over time. These innovative coatings contain reactive components that can fill in microscopic damage or wear spots when activated by heat, pressure, or specific environmental conditions. The self-healing capability prevents the progression of wear from minor surface damage to catastrophic failure, significantly extending the service life of coated components in high-wear applications.Expand Specific Solutions

Leading Companies in ALD Coating Technology

The ALD coating market for aerospace wear resistance is in a growth phase, with increasing adoption driven by stringent performance requirements in aerospace applications. The market is expanding as manufacturers seek advanced surface engineering solutions to enhance component durability and efficiency. Technologically, ALD has reached commercial maturity with companies like Applied Materials, Forge Nano, and Sundew Technologies leading innovation in high-productivity ALD processes. Major aerospace players including Rolls Royce and Honeywell are integrating these solutions, while research institutions such as Harbin Institute of Technology and University of California contribute to fundamental advancements. The competitive landscape features specialized ALD providers (Picosun, ALD NanoSolutions) alongside semiconductor equipment giants (Lam Research, TSMC) transferring expertise to aerospace applications, creating a dynamic ecosystem of established players and innovative entrants.

Forge Nano, Inc.

Technical Solution: Forge Nano has developed a proprietary Atomic Layer Deposition (ALD) technology called "Precision Nano" specifically optimized for aerospace component protection. Their system employs a high-throughput reactor design capable of processing complex geometries with exceptional uniformity. The technology deposits ultra-thin (typically 5-100 nm) conformal coatings of various materials including Al2O3, TiO2, and ZrO2 on aerospace components such as turbine blades, bearings, and structural elements[1]. Forge Nano's innovation lies in their proprietary precursor delivery system that enables precise control over coating composition and thickness while maintaining deposition rates up to 5x faster than conventional ALD processes. Their coatings demonstrate exceptional adhesion strength (>80 MPa) to various aerospace alloys and can withstand temperatures exceeding 1000°C without degradation[3]. The company has developed specialized surface preparation protocols that enhance coating-substrate interface quality, resulting in wear resistance improvements of up to 400% in high-temperature, high-stress applications compared to uncoated components. Recent advancements include doped ceramic formulations that provide self-lubricating properties under extreme conditions.

Strengths: Industry-leading throughput capabilities; exceptional coating uniformity even on complex geometries; demonstrated performance in extreme aerospace environments; scalable manufacturing process. Weaknesses: Higher initial capital investment compared to conventional coating technologies; requires specialized expertise for process optimization; limited track record in long-term aerospace applications compared to established players.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced ALD coating solutions specifically engineered for aerospace components subjected to extreme operating conditions. Their proprietary ALD process creates ultra-thin, conformal protective layers of metal oxides and nitrides (typically Al2O3, TiN, and ZrO2) on complex aerospace parts including turbine blades, bearings, and actuator components. The company's technology enables precise thickness control at the nanometer scale (typically 2-10 nm per cycle) while ensuring complete coverage of high-aspect-ratio features and internal surfaces that traditional coating methods cannot reach[1]. Honeywell's ALD process operates at relatively low temperatures (150-300°C) to prevent thermal damage to sensitive aerospace alloys while creating dense, pinhole-free barriers against oxidation, corrosion, and wear. Their multi-layer coating architecture combines different materials to optimize both adhesion and performance properties, resulting in up to 300% improvement in component lifespan under high-temperature, high-stress conditions[3].

Strengths: Superior conformality on complex geometries; excellent thickness uniformity (±2%); enhanced protection against multiple degradation mechanisms; compatibility with existing aerospace materials. Weaknesses: Higher initial implementation costs compared to conventional coatings; longer processing times for thicker coatings; requires specialized equipment and expertise for quality control.

Key Patents and Research in ALD Coating Technology

Components with an atomic layer deposition coating and methods of producing the same

PatentWO2016114850A1

Innovation

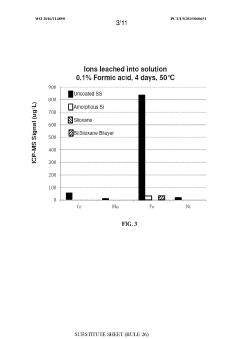

- The use of atomic layer deposition (ALD) processes to form conformal protective coatings on the interior surfaces of metal components, ensuring uniform thickness and adhesion, even on complex topographies and high aspect ratios, using molecular precursors that react to form inert coatings like Si, Pt, and Ru-based materials.

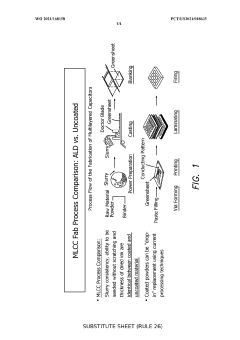

ATOMIC LAYER DEPOSITION (ALD) FOR MULTI-LAYER CERAMIC CAPACITORS (MLCCs)

PatentWO2021168158A2

Innovation

- The application of Atomic Layer Deposition (ALD) techniques to coat metal and ceramic powders with ultra-thin, uniform layers, enabling smaller particle sizes, improved sintering control, and the elimination of sintering retardants, resulting in enhanced capacitance and heat management.

Material Compatibility and Performance Testing

Material compatibility is a critical factor in the successful implementation of ALD coatings for aerospace components. The interaction between substrate materials and coating compounds must be thoroughly evaluated to ensure optimal adhesion, performance, and longevity. Common aerospace materials including titanium alloys, nickel-based superalloys, aluminum alloys, and advanced composites each present unique compatibility challenges with various ALD coating materials such as Al2O3, TiO2, and ZrO2.

Thermal expansion coefficient matching between substrate and coating materials represents a primary concern, as mismatches can lead to coating delamination during thermal cycling experienced in aerospace applications. Research indicates that properly engineered transition layers can mitigate these effects, with gradient compositions showing particular promise in recent studies.

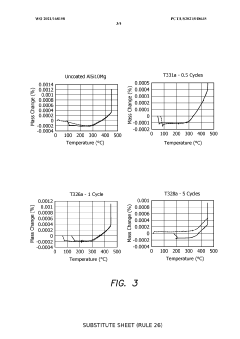

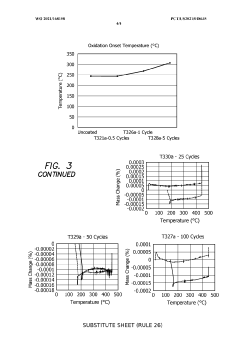

Performance testing protocols for ALD-coated aerospace components must simulate the extreme conditions encountered during service. Standard testing methodologies include pin-on-disk tribological testing, nanoindentation hardness measurements, scratch adhesion testing, and thermal cycling evaluations. These tests provide quantitative data on wear resistance, friction coefficients, and coating durability under various operational conditions.

Salt spray testing and humidity chamber exposure are essential for evaluating corrosion resistance, particularly for components exposed to marine environments or high-altitude moisture conditions. Recent advancements in accelerated testing protocols have enabled more accurate prediction of long-term performance within compressed timeframes, significantly reducing development cycles.

High-temperature performance testing is particularly relevant for engine components, where temperatures can exceed 1000°C. Studies have demonstrated that certain ALD coating compositions maintain structural integrity and wear resistance at these extreme temperatures, with multilayer architectures showing superior performance compared to single-layer alternatives.

Fatigue testing under cyclic loading conditions provides critical data on coating-substrate interface integrity over time. Research indicates that properly applied ALD coatings can actually enhance fatigue resistance of base materials by preventing crack initiation at surface defects. This synergistic effect has been documented in several aerospace alloy systems, particularly in titanium components subject to high-cycle fatigue conditions.

Standardization of testing protocols remains an ongoing challenge in the industry, with efforts underway to establish unified testing methodologies that accurately predict in-service performance across diverse aerospace applications. The development of digital twins and simulation models calibrated with physical test data represents a promising approach to accelerate qualification processes for new coating-substrate combinations.

Thermal expansion coefficient matching between substrate and coating materials represents a primary concern, as mismatches can lead to coating delamination during thermal cycling experienced in aerospace applications. Research indicates that properly engineered transition layers can mitigate these effects, with gradient compositions showing particular promise in recent studies.

Performance testing protocols for ALD-coated aerospace components must simulate the extreme conditions encountered during service. Standard testing methodologies include pin-on-disk tribological testing, nanoindentation hardness measurements, scratch adhesion testing, and thermal cycling evaluations. These tests provide quantitative data on wear resistance, friction coefficients, and coating durability under various operational conditions.

Salt spray testing and humidity chamber exposure are essential for evaluating corrosion resistance, particularly for components exposed to marine environments or high-altitude moisture conditions. Recent advancements in accelerated testing protocols have enabled more accurate prediction of long-term performance within compressed timeframes, significantly reducing development cycles.

High-temperature performance testing is particularly relevant for engine components, where temperatures can exceed 1000°C. Studies have demonstrated that certain ALD coating compositions maintain structural integrity and wear resistance at these extreme temperatures, with multilayer architectures showing superior performance compared to single-layer alternatives.

Fatigue testing under cyclic loading conditions provides critical data on coating-substrate interface integrity over time. Research indicates that properly applied ALD coatings can actually enhance fatigue resistance of base materials by preventing crack initiation at surface defects. This synergistic effect has been documented in several aerospace alloy systems, particularly in titanium components subject to high-cycle fatigue conditions.

Standardization of testing protocols remains an ongoing challenge in the industry, with efforts underway to establish unified testing methodologies that accurately predict in-service performance across diverse aerospace applications. The development of digital twins and simulation models calibrated with physical test data represents a promising approach to accelerate qualification processes for new coating-substrate combinations.

Environmental Impact and Sustainability Considerations

The adoption of Atomic Layer Deposition (ALD) coating technology in aerospace applications presents significant environmental and sustainability implications that merit careful consideration. Traditional coating methods often involve hazardous chemicals, high energy consumption, and substantial waste generation. In contrast, ALD offers several environmental advantages due to its precise nature and efficient material utilization.

ALD processes demonstrate superior material efficiency compared to conventional coating techniques. The atomic-level precision enables the deposition of ultra-thin, uniform layers with minimal material waste. This efficiency translates to reduced consumption of rare and expensive materials often used in aerospace applications, such as precious metals and specialized compounds, contributing to resource conservation and sustainability.

Energy efficiency represents another critical environmental benefit of ALD technology. While initial implementation may require significant energy input, the process typically operates at lower temperatures than competing technologies like Chemical Vapor Deposition (CVD) or Physical Vapor Deposition (PVD). This temperature advantage, combined with precise reaction control, results in lower overall energy consumption throughout the component lifecycle, aligning with aerospace industry sustainability goals.

The chemical processes involved in ALD coating production generally utilize less hazardous precursors compared to traditional methods. However, certain ALD precursors may still pose environmental concerns if not properly managed. The industry has been advancing toward greener chemistry, developing water-based processes and less toxic alternatives that minimize environmental impact while maintaining coating performance for aerospace applications.

Lifecycle assessment of ALD-coated aerospace components reveals substantial sustainability benefits. The enhanced wear resistance and extended service life directly reduce the frequency of component replacement, decreasing the overall material consumption and manufacturing energy requirements. This longevity factor significantly lowers the carbon footprint associated with aerospace operations and maintenance activities.

Waste management considerations for ALD processes are generally favorable. The technology produces minimal byproducts compared to wet chemical processes, and unreacted precursors can often be recovered and recycled. Nevertheless, proper handling and disposal protocols remain essential for any waste materials generated during the coating process to prevent environmental contamination.

Regulatory compliance represents an increasingly important factor in coating technology selection. ALD processes typically align well with stringent environmental regulations, including restrictions on volatile organic compounds (VOCs) and hazardous air pollutants. As global environmental standards continue to tighten, ALD's inherently cleaner process chemistry positions it advantageously for future aerospace applications where sustainability metrics influence technology adoption decisions.

ALD processes demonstrate superior material efficiency compared to conventional coating techniques. The atomic-level precision enables the deposition of ultra-thin, uniform layers with minimal material waste. This efficiency translates to reduced consumption of rare and expensive materials often used in aerospace applications, such as precious metals and specialized compounds, contributing to resource conservation and sustainability.

Energy efficiency represents another critical environmental benefit of ALD technology. While initial implementation may require significant energy input, the process typically operates at lower temperatures than competing technologies like Chemical Vapor Deposition (CVD) or Physical Vapor Deposition (PVD). This temperature advantage, combined with precise reaction control, results in lower overall energy consumption throughout the component lifecycle, aligning with aerospace industry sustainability goals.

The chemical processes involved in ALD coating production generally utilize less hazardous precursors compared to traditional methods. However, certain ALD precursors may still pose environmental concerns if not properly managed. The industry has been advancing toward greener chemistry, developing water-based processes and less toxic alternatives that minimize environmental impact while maintaining coating performance for aerospace applications.

Lifecycle assessment of ALD-coated aerospace components reveals substantial sustainability benefits. The enhanced wear resistance and extended service life directly reduce the frequency of component replacement, decreasing the overall material consumption and manufacturing energy requirements. This longevity factor significantly lowers the carbon footprint associated with aerospace operations and maintenance activities.

Waste management considerations for ALD processes are generally favorable. The technology produces minimal byproducts compared to wet chemical processes, and unreacted precursors can often be recovered and recycled. Nevertheless, proper handling and disposal protocols remain essential for any waste materials generated during the coating process to prevent environmental contamination.

Regulatory compliance represents an increasingly important factor in coating technology selection. ALD processes typically align well with stringent environmental regulations, including restrictions on volatile organic compounds (VOCs) and hazardous air pollutants. As global environmental standards continue to tighten, ALD's inherently cleaner process chemistry positions it advantageously for future aerospace applications where sustainability metrics influence technology adoption decisions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!