Research Trends in ALD Coating for High-Performance Alloys

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ALD Coating Evolution and Objectives

Atomic Layer Deposition (ALD) technology has evolved significantly since its inception in the 1970s, transforming from a laboratory curiosity to a critical industrial process. Initially developed for semiconductor applications, ALD has undergone remarkable expansion into various sectors including energy, aerospace, and medical industries. The precision of ALD in depositing uniform, conformal coatings at the atomic scale has positioned it as a revolutionary technique for surface engineering of high-performance alloys.

The evolution of ALD for high-performance alloy applications can be traced through several distinct phases. The early development period (1970s-1990s) focused primarily on establishing fundamental principles and basic reactor designs. The transition period (2000s) witnessed the expansion beyond semiconductors into broader materials science applications. The current maturation phase (2010s-present) has seen significant advancements in precursor chemistry, process optimization, and industrial-scale implementation specifically tailored for high-temperature alloy protection.

Recent technological breakthroughs have enabled ALD to address critical challenges in high-performance alloy applications. The development of thermal barrier coatings with unprecedented thermal stability, corrosion-resistant layers with exceptional uniformity, and wear-resistant surfaces with nanoscale precision have collectively transformed the performance envelope of advanced alloys in extreme environments. These innovations have been driven by the unique ability of ALD to control film composition and structure at the atomic level.

The primary objectives of current ALD coating research for high-performance alloys center on several key areas. First, enhancing coating durability under extreme thermal cycling conditions remains a critical goal, particularly for aerospace and power generation applications. Second, developing multi-functional coatings that simultaneously address corrosion, wear, and thermal protection represents an important frontier. Third, scaling ALD processes for complex geometries and large components continues to challenge researchers seeking industrial implementation.

Looking forward, the technological trajectory of ALD coatings for high-performance alloys is directed toward several ambitious targets. These include the development of self-healing coating systems, real-time process monitoring capabilities, integration with additive manufacturing workflows, and environmentally sustainable precursor chemistries. The convergence of ALD with complementary technologies such as computational materials design and in-situ characterization methods promises to accelerate innovation in this field.

The ultimate goal remains the creation of next-generation protective systems that can significantly extend component lifetimes, improve energy efficiency, and enable new design possibilities for high-performance alloys in the most demanding applications across aerospace, energy, and advanced manufacturing sectors.

The evolution of ALD for high-performance alloy applications can be traced through several distinct phases. The early development period (1970s-1990s) focused primarily on establishing fundamental principles and basic reactor designs. The transition period (2000s) witnessed the expansion beyond semiconductors into broader materials science applications. The current maturation phase (2010s-present) has seen significant advancements in precursor chemistry, process optimization, and industrial-scale implementation specifically tailored for high-temperature alloy protection.

Recent technological breakthroughs have enabled ALD to address critical challenges in high-performance alloy applications. The development of thermal barrier coatings with unprecedented thermal stability, corrosion-resistant layers with exceptional uniformity, and wear-resistant surfaces with nanoscale precision have collectively transformed the performance envelope of advanced alloys in extreme environments. These innovations have been driven by the unique ability of ALD to control film composition and structure at the atomic level.

The primary objectives of current ALD coating research for high-performance alloys center on several key areas. First, enhancing coating durability under extreme thermal cycling conditions remains a critical goal, particularly for aerospace and power generation applications. Second, developing multi-functional coatings that simultaneously address corrosion, wear, and thermal protection represents an important frontier. Third, scaling ALD processes for complex geometries and large components continues to challenge researchers seeking industrial implementation.

Looking forward, the technological trajectory of ALD coatings for high-performance alloys is directed toward several ambitious targets. These include the development of self-healing coating systems, real-time process monitoring capabilities, integration with additive manufacturing workflows, and environmentally sustainable precursor chemistries. The convergence of ALD with complementary technologies such as computational materials design and in-situ characterization methods promises to accelerate innovation in this field.

The ultimate goal remains the creation of next-generation protective systems that can significantly extend component lifetimes, improve energy efficiency, and enable new design possibilities for high-performance alloys in the most demanding applications across aerospace, energy, and advanced manufacturing sectors.

Market Analysis for ALD-Enhanced Alloys

The global market for ALD-enhanced high-performance alloys is experiencing robust growth, driven by increasing demand across multiple industries. The aerospace sector represents the largest market segment, valuing approximately $2.3 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 8.7% through 2028. This growth is primarily attributed to the superior thermal barrier properties and oxidation resistance that ALD coatings provide to turbine components and structural elements in aircraft.

The automotive industry follows as the second-largest consumer of ALD-coated alloys, particularly for high-performance engine components and electric vehicle battery systems. Market analysis indicates this segment reached $1.8 billion in 2022, with expected acceleration as manufacturers increasingly adopt lightweight, high-strength materials to meet stringent emissions standards and performance requirements.

Energy sector applications, especially in renewable energy and nuclear power generation, constitute a rapidly expanding market for ALD-enhanced alloys. The market size in this sector was valued at approximately $1.2 billion in 2022, with particularly strong growth in solar energy applications where thin-film coatings improve efficiency and durability of components exposed to harsh environmental conditions.

Regional analysis reveals Asia-Pacific as the fastest-growing market for ALD-coated high-performance alloys, with China, Japan, and South Korea leading manufacturing capacity expansion. North America and Europe maintain significant market shares due to their established aerospace and automotive industries, with specialized applications in defense and medical sectors providing premium-priced market segments.

Consumer electronics represents an emerging application area with substantial growth potential, particularly for wear-resistant and corrosion-resistant components in portable devices. This segment, though smaller at $650 million in 2022, demonstrates the highest projected CAGR at 12.3% through 2028.

Market challenges include high initial equipment costs for ALD processing systems and technical complexity in scaling production for larger components. However, these barriers are gradually diminishing as equipment manufacturers develop more cost-effective solutions and process automation advances.

Industry surveys indicate customer willingness to pay premium prices for ALD-enhanced alloys, with 78% of aerospace procurement specialists citing extended component lifespan as the primary value driver. The market demonstrates relatively low price sensitivity in high-performance applications where failure costs significantly outweigh material costs.

The automotive industry follows as the second-largest consumer of ALD-coated alloys, particularly for high-performance engine components and electric vehicle battery systems. Market analysis indicates this segment reached $1.8 billion in 2022, with expected acceleration as manufacturers increasingly adopt lightweight, high-strength materials to meet stringent emissions standards and performance requirements.

Energy sector applications, especially in renewable energy and nuclear power generation, constitute a rapidly expanding market for ALD-enhanced alloys. The market size in this sector was valued at approximately $1.2 billion in 2022, with particularly strong growth in solar energy applications where thin-film coatings improve efficiency and durability of components exposed to harsh environmental conditions.

Regional analysis reveals Asia-Pacific as the fastest-growing market for ALD-coated high-performance alloys, with China, Japan, and South Korea leading manufacturing capacity expansion. North America and Europe maintain significant market shares due to their established aerospace and automotive industries, with specialized applications in defense and medical sectors providing premium-priced market segments.

Consumer electronics represents an emerging application area with substantial growth potential, particularly for wear-resistant and corrosion-resistant components in portable devices. This segment, though smaller at $650 million in 2022, demonstrates the highest projected CAGR at 12.3% through 2028.

Market challenges include high initial equipment costs for ALD processing systems and technical complexity in scaling production for larger components. However, these barriers are gradually diminishing as equipment manufacturers develop more cost-effective solutions and process automation advances.

Industry surveys indicate customer willingness to pay premium prices for ALD-enhanced alloys, with 78% of aerospace procurement specialists citing extended component lifespan as the primary value driver. The market demonstrates relatively low price sensitivity in high-performance applications where failure costs significantly outweigh material costs.

Global ALD Technology Landscape and Barriers

Atomic Layer Deposition (ALD) technology has witnessed significant global adoption across various industries, with particular emphasis on high-performance alloy applications. The current global landscape reveals uneven development patterns, with North America, East Asia, and Europe emerging as dominant hubs for ALD innovation. The United States maintains leadership through substantial research funding and strong university-industry collaborations, while South Korea, Japan, and Taiwan have established robust ecosystems focused on semiconductor applications of ALD. European contributions, particularly from Finland, Germany, and the Netherlands, have been pivotal in advancing fundamental ALD science.

Despite its promising applications, ALD technology faces several critical barriers that impede widespread industrial implementation. The foremost challenge remains the inherently slow deposition rates, which significantly limit throughput in manufacturing environments. While ALD offers unparalleled conformality and thickness control, typical growth rates of 0.1-0.2 nm per cycle translate to extended processing times that prove economically prohibitive for many high-volume applications involving high-performance alloys.

Scale-up challenges present another significant barrier, as processes optimized in laboratory settings often encounter complications when transferred to industrial-scale production. The precise control of precursor delivery, reaction chamber design, and temperature uniformity becomes increasingly difficult at larger scales, affecting coating quality and consistency across high-performance alloy components with complex geometries.

Precursor limitations constitute a technical bottleneck, particularly for coating high-performance alloys that require specific material properties. Many desirable coating materials lack suitable precursors with optimal volatility, thermal stability, and reactivity characteristics. The development of new precursors involves complex chemistry and often requires years of research, creating a lag between identified coating needs and practical implementation capabilities.

Economic considerations further complicate ALD adoption for high-performance alloys. The high capital equipment costs, coupled with relatively low throughput, result in elevated per-unit processing costs compared to alternative coating technologies. This cost structure has confined ALD primarily to high-value applications where performance benefits clearly justify the premium, limiting broader market penetration.

Integration challenges with existing manufacturing workflows represent another significant barrier. ALD processes typically require specific environmental conditions and equipment configurations that may not align with established production lines. Retrofitting existing facilities or developing hybrid approaches that combine ALD with other coating technologies presents both technical and logistical complexities that many manufacturers are hesitant to address.

Despite its promising applications, ALD technology faces several critical barriers that impede widespread industrial implementation. The foremost challenge remains the inherently slow deposition rates, which significantly limit throughput in manufacturing environments. While ALD offers unparalleled conformality and thickness control, typical growth rates of 0.1-0.2 nm per cycle translate to extended processing times that prove economically prohibitive for many high-volume applications involving high-performance alloys.

Scale-up challenges present another significant barrier, as processes optimized in laboratory settings often encounter complications when transferred to industrial-scale production. The precise control of precursor delivery, reaction chamber design, and temperature uniformity becomes increasingly difficult at larger scales, affecting coating quality and consistency across high-performance alloy components with complex geometries.

Precursor limitations constitute a technical bottleneck, particularly for coating high-performance alloys that require specific material properties. Many desirable coating materials lack suitable precursors with optimal volatility, thermal stability, and reactivity characteristics. The development of new precursors involves complex chemistry and often requires years of research, creating a lag between identified coating needs and practical implementation capabilities.

Economic considerations further complicate ALD adoption for high-performance alloys. The high capital equipment costs, coupled with relatively low throughput, result in elevated per-unit processing costs compared to alternative coating technologies. This cost structure has confined ALD primarily to high-value applications where performance benefits clearly justify the premium, limiting broader market penetration.

Integration challenges with existing manufacturing workflows represent another significant barrier. ALD processes typically require specific environmental conditions and equipment configurations that may not align with established production lines. Retrofitting existing facilities or developing hybrid approaches that combine ALD with other coating technologies presents both technical and logistical complexities that many manufacturers are hesitant to address.

Current ALD Methodologies for Alloy Protection

01 ALD coating processes for semiconductor applications

Atomic Layer Deposition (ALD) coating techniques are widely used in semiconductor manufacturing to create ultra-thin, conformal films with precise thickness control. These processes enable the deposition of high-quality barrier layers, dielectric materials, and conductive films for advanced microelectronic devices. The technology allows for atomic-level precision in coating complex 3D structures and high-aspect-ratio features, which is critical for next-generation semiconductor devices.- ALD coating processes for semiconductor applications: Atomic Layer Deposition (ALD) coating techniques are widely used in semiconductor manufacturing to create ultra-thin, conformal films with precise thickness control. These processes enable the deposition of high-quality barrier layers, dielectric materials, and conductive films for advanced microelectronic devices. The technology allows for atomic-level precision in coating complex 3D structures and high-aspect-ratio features, which is critical for next-generation semiconductor devices.

- ALD coating equipment and apparatus design: Specialized equipment and apparatus designs for Atomic Layer Deposition coating processes focus on optimizing precursor delivery, reaction chamber configuration, and temperature control systems. These designs aim to improve coating uniformity, increase throughput, and enhance process reliability. Innovations include multi-chamber systems for sequential deposition, advanced gas flow control mechanisms, and integrated monitoring systems that ensure precise film growth and quality control during the ALD process.

- ALD coating for energy storage and conversion devices: Atomic Layer Deposition coating technology is increasingly applied to energy storage and conversion devices such as batteries, fuel cells, and solar cells. The ultra-thin, conformal coatings provide protective layers, enhance electrode performance, and improve interface properties. These coatings can significantly extend device lifetime, increase energy density, and improve cycling stability by creating uniform protective barriers against degradation mechanisms while maintaining electrical conductivity.

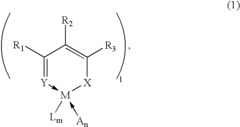

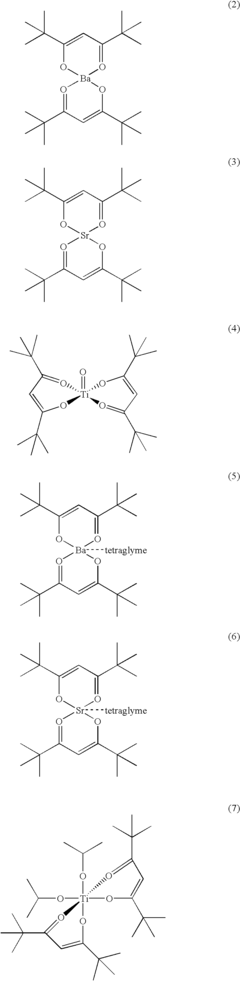

- ALD coating materials and precursors: Development of novel precursor materials and chemistries for Atomic Layer Deposition enables the creation of diverse functional coatings with tailored properties. Research focuses on metal oxides, nitrides, sulfides, and mixed-material systems that can be precisely deposited at low temperatures. Advanced precursor designs improve reactivity, stability, and volatility while reducing impurities in the resulting films, allowing for wider process windows and application-specific coating properties.

- ALD coating for protective and functional surface treatments: Atomic Layer Deposition provides exceptional protective and functional surface treatments for various industrial applications. These coatings offer corrosion resistance, wear protection, and barrier properties against gases and liquids. The technology enables the modification of surface properties such as hydrophobicity, optical characteristics, and catalytic activity. The nanoscale thickness control of ALD allows for preservation of the underlying substrate's features while adding functional properties to components in aerospace, automotive, and consumer electronics industries.

02 ALD coating for energy storage and conversion devices

ALD coating technology is applied to energy storage and conversion devices such as batteries, fuel cells, and solar cells to enhance their performance and durability. The technique enables the deposition of protective layers, ion-conductive films, and catalytic materials with nanometer precision. These coatings can significantly improve the cycle life of batteries, increase the efficiency of solar cells, and enhance the stability of fuel cell components by providing uniform coverage even on complex geometries.Expand Specific Solutions03 Equipment and apparatus for ALD coating

Specialized equipment and apparatus have been developed for implementing ALD coating processes in various industrial applications. These systems include reaction chambers, gas delivery systems, temperature controllers, and automation components designed to achieve precise layer-by-layer deposition. Advanced ALD equipment features innovations such as spatial ALD for higher throughput, multi-chamber configurations for sequential deposition, and in-situ monitoring capabilities to ensure coating quality and consistency.Expand Specific Solutions04 ALD coating for corrosion and wear protection

ALD coating techniques are employed to provide superior corrosion and wear protection for various materials and components. The process allows for the deposition of dense, pinhole-free protective layers that can significantly extend the service life of tools, mechanical parts, and structural components. These protective coatings can be customized in terms of composition and thickness to meet specific environmental challenges and mechanical requirements, offering advantages over traditional coating methods due to their exceptional uniformity and adhesion.Expand Specific Solutions05 Novel materials and precursors for ALD coating

Research and development efforts have focused on creating novel materials and precursors for ALD coating applications. These innovations include new metal-organic compounds, reactive gases, and catalyst materials that enable the deposition of a wider range of functional films with enhanced properties. Advanced precursor chemistry allows for lower deposition temperatures, faster reaction kinetics, and the creation of complex multi-component films and nanolaminate structures with tailored optical, electrical, and mechanical characteristics.Expand Specific Solutions

Industry Leaders in ALD Coating Technology

The Atomic Layer Deposition (ALD) coating market for high-performance alloys is currently in a growth phase, with increasing adoption across aerospace, semiconductor, and energy sectors. The global market is estimated to reach $3-4 billion by 2027, growing at a CAGR of approximately 15%. Technologically, ALD coating has matured significantly, with companies like Applied Materials, Intel, and Forge Nano leading commercial applications. Established equipment manufacturers including Tokyo Electron, Lam Research, and Veeco Instruments have developed advanced ALD systems with enhanced precision and throughput. Research institutions such as North Carolina State University and Industrial Technology Research Institute are advancing next-generation ALD techniques. Meanwhile, specialized players like Beneq Group and SOULBRAIN are focusing on niche applications, creating a competitive landscape balanced between large semiconductor equipment providers and specialized coating technology innovators.

Applied Materials, Inc.

Technical Solution: Applied Materials has pioneered advanced ALD systems specifically designed for high-performance alloy coating applications. Their technology utilizes a multi-chamber approach that allows for sequential deposition of different materials to create tailored protective layers on alloy surfaces. The company's Endura® platform incorporates specialized ALD modules capable of depositing ultra-thin films with exceptional uniformity across large substrate areas. Applied Materials has developed proprietary precursor delivery systems that enable precise control over gas-phase reactions, resulting in highly conformal coatings even on complex alloy geometries. Their process technology allows for low-temperature deposition (typically 150-300°C), which is critical for maintaining the microstructural integrity of advanced alloys. Recent innovations include in-situ plasma enhancement capabilities that improve film adhesion and density without thermal loading of the substrate. The company has also developed specialized pre-treatment processes that optimize the alloy surface for subsequent ALD coating, addressing challenges related to native oxide layers and surface contamination that can affect coating quality.

Strengths: Industry-leading equipment scalability for high-volume manufacturing; extensive material library for diverse coating compositions; advanced process control systems enabling precise thickness and composition control. Weaknesses: Higher equipment footprint and complexity compared to smaller research-scale systems; significant expertise required for process optimization; higher operational costs for maintaining ultra-high vacuum and precursor purity levels.

Forge Nano, Inc.

Technical Solution: Forge Nano has developed a proprietary Atomic Layer Deposition (ALD) technology called Precision Nanocoating that enables ultra-thin, uniform coatings on high-performance alloys. Their approach utilizes a gas-phase deposition process that creates conformal coatings at the atomic level, allowing precise thickness control down to angstrom scale. The technology employs sequential, self-limiting surface reactions that ensure complete coverage even on complex geometries and high-aspect-ratio features of advanced alloys. Forge Nano's system can deposit various materials including oxides, nitrides, and metals at lower temperatures than conventional methods, which is crucial for temperature-sensitive alloy substrates. Their industrial-scale ALD equipment enables high-throughput processing while maintaining coating quality, addressing a key challenge in commercializing ALD for metal alloy applications. Recent advancements include specialized precursor delivery systems and reactor designs optimized specifically for coating high-performance alloys used in aerospace, energy, and automotive sectors.

Strengths: Superior conformality and thickness control at atomic scale; ability to coat complex geometries without compromising alloy properties; scalable to industrial production volumes. Weaknesses: Higher initial capital investment compared to conventional coating methods; process optimization required for each specific alloy composition; longer processing times for thicker coatings compared to traditional methods.

Breakthrough Patents in ALD for High-Performance Alloys

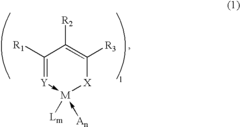

Atomic layer deposition using organometallic complex with beta-diketone ligand

PatentInactiveUS6752869B2

Innovation

- The method involves chemically adsorbing an organometallic complex with a β-diketone ligand onto a substrate and oxidizing it using activated oxygen radicals generated by plasma, which increases the oxidation rate and volatility of the precursor, allowing for high-quality metal oxide film deposition.

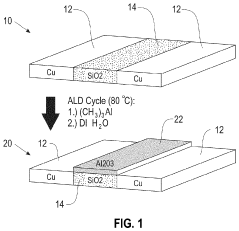

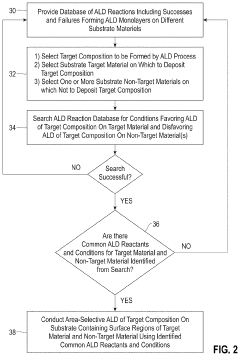

Methods of area-selective atomic layer deposition

PatentInactiveUS20200354834A1

Innovation

- The method involves contacting a substrate with a silicon dioxide surface and a zero-valent metal-containing surface with an organoaluminum compound at low temperatures, followed by exposure to water, to selectively form alumina on silicon dioxide surfaces without depositing on copper surfaces, using a database of ALD reactions to determine optimal conditions for selective deposition.

Materials Compatibility and Interface Engineering

The compatibility between ALD coating materials and high-performance alloy substrates represents a critical factor determining coating performance and durability. When depositing thin films on complex alloy surfaces, the chemical and physical interactions at the interface significantly influence adhesion strength, coating integrity, and long-term stability. Recent research has focused on understanding and optimizing these interfacial phenomena through advanced characterization techniques such as high-resolution transmission electron microscopy (HR-TEM) and X-ray photoelectron spectroscopy (XPS).

Interface engineering has emerged as a specialized discipline within ALD coating technology, with researchers developing tailored approaches for specific alloy compositions. For nickel-based superalloys, pre-treatment protocols involving controlled oxidation have demonstrated enhanced coating adhesion by creating nanoscale anchoring sites. Similarly, for titanium alloys, surface activation through plasma treatments has shown promising results in promoting chemical bonding between the substrate and initial ALD layers.

Thermal expansion coefficient mismatch between coating materials and alloy substrates presents a significant challenge, particularly for applications involving thermal cycling. Research trends indicate growing interest in gradient interface designs, where composition gradually transitions from substrate to coating, thereby distributing thermal stresses and preventing delamination. This approach has proven especially valuable for high-temperature applications where thermal cycling is inevitable.

Diffusion phenomena at the coating-substrate interface represent another critical research area. Studies have revealed that certain elements from high-performance alloys can migrate into the coating during high-temperature service, potentially compromising coating integrity. To address this challenge, researchers have developed diffusion barrier interlayers, often composed of refractory metals or their nitrides, deposited via ALD prior to the main functional coating.

Recent advances in computational modeling have significantly enhanced understanding of interface phenomena. Density functional theory (DFT) calculations now enable prediction of chemical interactions between specific coating materials and alloy surfaces, guiding experimental work toward optimal material combinations. These computational approaches, combined with in-situ characterization techniques, are accelerating the development of tailored interface engineering solutions.

The industry is increasingly adopting a systems engineering approach to materials compatibility, recognizing that successful coating performance depends on holistic consideration of the entire coating-substrate system rather than individual components. This paradigm shift has led to more robust coating solutions with enhanced service life in demanding environments.

Interface engineering has emerged as a specialized discipline within ALD coating technology, with researchers developing tailored approaches for specific alloy compositions. For nickel-based superalloys, pre-treatment protocols involving controlled oxidation have demonstrated enhanced coating adhesion by creating nanoscale anchoring sites. Similarly, for titanium alloys, surface activation through plasma treatments has shown promising results in promoting chemical bonding between the substrate and initial ALD layers.

Thermal expansion coefficient mismatch between coating materials and alloy substrates presents a significant challenge, particularly for applications involving thermal cycling. Research trends indicate growing interest in gradient interface designs, where composition gradually transitions from substrate to coating, thereby distributing thermal stresses and preventing delamination. This approach has proven especially valuable for high-temperature applications where thermal cycling is inevitable.

Diffusion phenomena at the coating-substrate interface represent another critical research area. Studies have revealed that certain elements from high-performance alloys can migrate into the coating during high-temperature service, potentially compromising coating integrity. To address this challenge, researchers have developed diffusion barrier interlayers, often composed of refractory metals or their nitrides, deposited via ALD prior to the main functional coating.

Recent advances in computational modeling have significantly enhanced understanding of interface phenomena. Density functional theory (DFT) calculations now enable prediction of chemical interactions between specific coating materials and alloy surfaces, guiding experimental work toward optimal material combinations. These computational approaches, combined with in-situ characterization techniques, are accelerating the development of tailored interface engineering solutions.

The industry is increasingly adopting a systems engineering approach to materials compatibility, recognizing that successful coating performance depends on holistic consideration of the entire coating-substrate system rather than individual components. This paradigm shift has led to more robust coating solutions with enhanced service life in demanding environments.

Sustainability Aspects of ALD Processes

The sustainability of Atomic Layer Deposition (ALD) processes for high-performance alloy coatings represents a critical dimension in evaluating their industrial viability and environmental impact. ALD demonstrates significant sustainability advantages compared to traditional coating methods, primarily due to its precise material utilization. The atom-by-atom deposition mechanism ensures minimal waste generation, with material efficiency rates typically exceeding 90% compared to 30-60% for conventional physical vapor deposition or chemical vapor deposition techniques.

Energy consumption remains a challenge for ALD sustainability, as many processes require elevated temperatures (150-350°C) and vacuum conditions. However, recent innovations in plasma-enhanced ALD and spatial ALD have reduced energy requirements by 30-40% through lower operating temperatures and atmospheric pressure operation. These advancements significantly improve the carbon footprint of ALD processes when evaluated through life cycle assessment methodologies.

Precursor chemistry presents both opportunities and challenges for ALD sustainability. Traditional ALD processes often utilize organometallic precursors containing environmentally problematic elements. The industry has responded with green chemistry initiatives developing water-based precursors and non-toxic alternatives. For instance, titanium-based precursors have evolved from chloride-based compounds to amino complexes with substantially reduced environmental impact.

Waste management strategies for ALD processes have advanced considerably, with closed-loop systems capturing and recycling unreacted precursors. These systems have demonstrated recovery rates of 50-70% for expensive precursor materials, simultaneously reducing environmental discharge and operational costs. Additionally, end-of-life considerations for ALD-coated alloys show promising recyclability profiles, as the nanometer-scale coatings typically do not interfere with conventional metal recycling processes.

Economic sustainability metrics indicate that while ALD equipment and operation costs exceed conventional coating technologies by 30-50%, the extended service life of high-performance alloys with ALD coatings (typically 2-3 times longer) creates favorable total cost of ownership calculations. Industries such as aerospace and medical implants have already achieved net positive sustainability outcomes through ALD implementation, with reduced material consumption and maintenance requirements offsetting initial investments.

Regulatory frameworks increasingly favor ALD processes as environmental standards tighten globally. The technology's minimal emissions profile and reduced hazardous waste generation align with circular economy principles and emerging extended producer responsibility regulations, positioning ALD as a forward-compatible technology in the evolving sustainability landscape.

Energy consumption remains a challenge for ALD sustainability, as many processes require elevated temperatures (150-350°C) and vacuum conditions. However, recent innovations in plasma-enhanced ALD and spatial ALD have reduced energy requirements by 30-40% through lower operating temperatures and atmospheric pressure operation. These advancements significantly improve the carbon footprint of ALD processes when evaluated through life cycle assessment methodologies.

Precursor chemistry presents both opportunities and challenges for ALD sustainability. Traditional ALD processes often utilize organometallic precursors containing environmentally problematic elements. The industry has responded with green chemistry initiatives developing water-based precursors and non-toxic alternatives. For instance, titanium-based precursors have evolved from chloride-based compounds to amino complexes with substantially reduced environmental impact.

Waste management strategies for ALD processes have advanced considerably, with closed-loop systems capturing and recycling unreacted precursors. These systems have demonstrated recovery rates of 50-70% for expensive precursor materials, simultaneously reducing environmental discharge and operational costs. Additionally, end-of-life considerations for ALD-coated alloys show promising recyclability profiles, as the nanometer-scale coatings typically do not interfere with conventional metal recycling processes.

Economic sustainability metrics indicate that while ALD equipment and operation costs exceed conventional coating technologies by 30-50%, the extended service life of high-performance alloys with ALD coatings (typically 2-3 times longer) creates favorable total cost of ownership calculations. Industries such as aerospace and medical implants have already achieved net positive sustainability outcomes through ALD implementation, with reduced material consumption and maintenance requirements offsetting initial investments.

Regulatory frameworks increasingly favor ALD processes as environmental standards tighten globally. The technology's minimal emissions profile and reduced hazardous waste generation align with circular economy principles and emerging extended producer responsibility regulations, positioning ALD as a forward-compatible technology in the evolving sustainability landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!