Assessing ALD Coating Durability in Harsh Chemical Environments

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ALD Coating Evolution and Research Objectives

Atomic Layer Deposition (ALD) technology has evolved significantly since its inception in the 1970s, transitioning from a laboratory curiosity to a critical industrial process. Initially developed as a variant of Chemical Vapor Deposition (CVD), ALD distinguished itself through its unique self-limiting surface reactions that enable atomic-level precision in thin film deposition. The technology gained substantial momentum in the 1990s when the semiconductor industry recognized its potential for creating ultra-thin, conformal films essential for increasingly miniaturized electronic components.

The evolution of ALD coating technology has been characterized by continuous improvements in precursor chemistry, reactor design, and process control systems. Early ALD processes were limited by slow deposition rates and a narrow range of compatible materials. However, advancements in organometallic chemistry and reactor engineering have dramatically expanded the palette of materials that can be deposited via ALD, including metals, metal oxides, nitrides, and increasingly complex multi-component films.

Recent years have witnessed a paradigm shift in ALD applications beyond microelectronics into diverse fields including energy storage, catalysis, and protective coatings. This expansion has been driven by the development of spatial ALD techniques that increase throughput, roll-to-roll processes for flexible substrates, and plasma-enhanced ALD that enables lower processing temperatures. These innovations have collectively transformed ALD from a specialized technique to a versatile platform technology with broad industrial relevance.

The primary research objective of this investigation is to systematically evaluate the durability and performance of ALD coatings when exposed to harsh chemical environments. Specifically, we aim to quantify the resistance of various ALD film compositions to corrosive acids, strong bases, organic solvents, and oxidizing agents under different temperature and pressure conditions. This assessment will establish fundamental structure-property relationships that govern coating degradation mechanisms.

Additionally, this research seeks to identify optimal ALD process parameters that maximize coating durability while maintaining other critical performance attributes such as adhesion, mechanical stability, and functional properties. By correlating deposition conditions with chemical resistance, we intend to develop predictive models that can guide the design of application-specific protective coatings.

The ultimate goal is to establish design principles for next-generation ALD coatings that can withstand extreme chemical environments in applications ranging from chemical processing equipment to advanced battery technologies and biomedical implants. This research will address the growing industrial demand for nanoscale protective barriers that can significantly extend component lifetimes in aggressive operating conditions while maintaining the dimensional precision that makes ALD uniquely valuable.

The evolution of ALD coating technology has been characterized by continuous improvements in precursor chemistry, reactor design, and process control systems. Early ALD processes were limited by slow deposition rates and a narrow range of compatible materials. However, advancements in organometallic chemistry and reactor engineering have dramatically expanded the palette of materials that can be deposited via ALD, including metals, metal oxides, nitrides, and increasingly complex multi-component films.

Recent years have witnessed a paradigm shift in ALD applications beyond microelectronics into diverse fields including energy storage, catalysis, and protective coatings. This expansion has been driven by the development of spatial ALD techniques that increase throughput, roll-to-roll processes for flexible substrates, and plasma-enhanced ALD that enables lower processing temperatures. These innovations have collectively transformed ALD from a specialized technique to a versatile platform technology with broad industrial relevance.

The primary research objective of this investigation is to systematically evaluate the durability and performance of ALD coatings when exposed to harsh chemical environments. Specifically, we aim to quantify the resistance of various ALD film compositions to corrosive acids, strong bases, organic solvents, and oxidizing agents under different temperature and pressure conditions. This assessment will establish fundamental structure-property relationships that govern coating degradation mechanisms.

Additionally, this research seeks to identify optimal ALD process parameters that maximize coating durability while maintaining other critical performance attributes such as adhesion, mechanical stability, and functional properties. By correlating deposition conditions with chemical resistance, we intend to develop predictive models that can guide the design of application-specific protective coatings.

The ultimate goal is to establish design principles for next-generation ALD coatings that can withstand extreme chemical environments in applications ranging from chemical processing equipment to advanced battery technologies and biomedical implants. This research will address the growing industrial demand for nanoscale protective barriers that can significantly extend component lifetimes in aggressive operating conditions while maintaining the dimensional precision that makes ALD uniquely valuable.

Market Analysis for Chemical-Resistant Coatings

The global market for chemical-resistant coatings has been experiencing robust growth, driven primarily by increasing industrial applications in harsh environments. The market size for specialized protective coatings reached approximately $7.8 billion in 2022, with chemical-resistant variants accounting for roughly 18% of this segment. Projections indicate a compound annual growth rate (CAGR) of 5.3% through 2028, significantly outpacing general industrial coatings.

Atomic Layer Deposition (ALD) coatings represent an emerging high-value subsector within this market. While currently occupying only about 3% of the chemical-resistant coatings market, ALD technology is demonstrating the fastest growth rate at 9.7% annually, reflecting its superior performance characteristics in extreme chemical environments.

Key market drivers include stringent environmental regulations across major economies, particularly in North America and Europe, which mandate improved containment solutions for hazardous chemicals. The semiconductor industry remains the largest consumer of high-performance chemical-resistant coatings, accounting for 34% of market demand, followed by chemical processing (27%), pharmaceutical manufacturing (18%), and energy production (12%).

Regional analysis reveals Asia-Pacific as the dominant market, representing 41% of global consumption, followed by North America (28%) and Europe (23%). China and South Korea have emerged as particularly dynamic markets, with demand growth exceeding 11% annually due to rapid semiconductor industry expansion.

End-user requirements are increasingly focused on coating solutions that can withstand multiple aggressive chemicals simultaneously while maintaining structural integrity over extended periods. Survey data from industrial customers indicates that 76% prioritize long-term durability over initial cost, with 82% willing to pay premium prices for coatings with documented performance in concentrated acids and oxidizing environments.

Price sensitivity varies significantly by application sector. While commodity chemical processing remains highly cost-conscious, semiconductor fabrication and pharmaceutical manufacturing demonstrate minimal price sensitivity when performance specifications are met, particularly regarding particle generation and contamination prevention.

Market penetration barriers for advanced solutions like ALD coatings include high initial implementation costs, limited awareness of performance benefits among potential users, and technical challenges in scaling application processes for large industrial components. However, these barriers are gradually diminishing as demonstration projects validate the superior total cost of ownership for high-performance coatings in critical applications.

Atomic Layer Deposition (ALD) coatings represent an emerging high-value subsector within this market. While currently occupying only about 3% of the chemical-resistant coatings market, ALD technology is demonstrating the fastest growth rate at 9.7% annually, reflecting its superior performance characteristics in extreme chemical environments.

Key market drivers include stringent environmental regulations across major economies, particularly in North America and Europe, which mandate improved containment solutions for hazardous chemicals. The semiconductor industry remains the largest consumer of high-performance chemical-resistant coatings, accounting for 34% of market demand, followed by chemical processing (27%), pharmaceutical manufacturing (18%), and energy production (12%).

Regional analysis reveals Asia-Pacific as the dominant market, representing 41% of global consumption, followed by North America (28%) and Europe (23%). China and South Korea have emerged as particularly dynamic markets, with demand growth exceeding 11% annually due to rapid semiconductor industry expansion.

End-user requirements are increasingly focused on coating solutions that can withstand multiple aggressive chemicals simultaneously while maintaining structural integrity over extended periods. Survey data from industrial customers indicates that 76% prioritize long-term durability over initial cost, with 82% willing to pay premium prices for coatings with documented performance in concentrated acids and oxidizing environments.

Price sensitivity varies significantly by application sector. While commodity chemical processing remains highly cost-conscious, semiconductor fabrication and pharmaceutical manufacturing demonstrate minimal price sensitivity when performance specifications are met, particularly regarding particle generation and contamination prevention.

Market penetration barriers for advanced solutions like ALD coatings include high initial implementation costs, limited awareness of performance benefits among potential users, and technical challenges in scaling application processes for large industrial components. However, these barriers are gradually diminishing as demonstration projects validate the superior total cost of ownership for high-performance coatings in critical applications.

Current ALD Technology Limitations in Harsh Environments

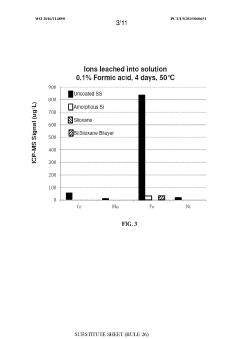

Despite the significant advancements in Atomic Layer Deposition (ALD) technology, several critical limitations persist when applying these coatings in harsh chemical environments. The primary challenge lies in the long-term stability of ALD films when exposed to extreme pH conditions, particularly strong acids and bases that can accelerate degradation through various chemical attack mechanisms. Current ALD coatings often demonstrate insufficient resistance to concentrated acids such as hydrofluoric acid (HF), which can rapidly etch through even high-quality oxide layers.

The thickness constraints of traditional ALD processes present another significant limitation. While ALD excels at producing ultra-thin films with exceptional conformality, these thin layers (typically 10-100 nm) often lack the robustness required for prolonged exposure to corrosive environments. The inherent trade-off between deposition rate and film quality further complicates this issue, as attempts to increase thickness often introduce defects that become vulnerability points for chemical attack.

Interface adhesion represents a persistent challenge, particularly on complex substrate geometries or materials with poor surface compatibility. Current ALD processes struggle to maintain strong adhesion between the coating and substrate under thermal cycling or chemical stress conditions, leading to delamination and subsequent failure of the protective barrier. This adhesion issue becomes particularly problematic when coating polymeric substrates or materials with significant thermal expansion coefficient mismatches.

Pinhole defects and film non-uniformity continue to plague ALD coatings in harsh environment applications. These microscopic imperfections, though rare in well-optimized processes, provide direct pathways for aggressive chemicals to reach and attack the underlying substrate. Current technology lacks reliable in-situ detection methods for these nanoscale defects, making quality control challenging for critical applications.

The limited material selection for harsh environment ALD coatings presents another significant constraint. While certain metal oxides (Al₂O₃, TiO₂, ZrO₂) and nitrides show promising chemical resistance, the precursor chemistry for many potentially superior materials remains underdeveloped. This restricts the ability to tailor coatings specifically for unique chemical exposure scenarios.

Temperature limitations of current ALD processes also impact durability in harsh environments. Many high-performance ceramic-like coatings require elevated deposition temperatures (>300°C) that are incompatible with temperature-sensitive substrates. Conversely, low-temperature ALD processes often produce films with higher impurity levels and lower density, compromising their chemical resistance properties.

Finally, current ALD technology faces significant challenges in scaling production while maintaining coating quality. The inherently slow deposition rates (typically 0.1-2 Å/cycle) create economic barriers for widespread industrial adoption in applications requiring thicker protective layers.

The thickness constraints of traditional ALD processes present another significant limitation. While ALD excels at producing ultra-thin films with exceptional conformality, these thin layers (typically 10-100 nm) often lack the robustness required for prolonged exposure to corrosive environments. The inherent trade-off between deposition rate and film quality further complicates this issue, as attempts to increase thickness often introduce defects that become vulnerability points for chemical attack.

Interface adhesion represents a persistent challenge, particularly on complex substrate geometries or materials with poor surface compatibility. Current ALD processes struggle to maintain strong adhesion between the coating and substrate under thermal cycling or chemical stress conditions, leading to delamination and subsequent failure of the protective barrier. This adhesion issue becomes particularly problematic when coating polymeric substrates or materials with significant thermal expansion coefficient mismatches.

Pinhole defects and film non-uniformity continue to plague ALD coatings in harsh environment applications. These microscopic imperfections, though rare in well-optimized processes, provide direct pathways for aggressive chemicals to reach and attack the underlying substrate. Current technology lacks reliable in-situ detection methods for these nanoscale defects, making quality control challenging for critical applications.

The limited material selection for harsh environment ALD coatings presents another significant constraint. While certain metal oxides (Al₂O₃, TiO₂, ZrO₂) and nitrides show promising chemical resistance, the precursor chemistry for many potentially superior materials remains underdeveloped. This restricts the ability to tailor coatings specifically for unique chemical exposure scenarios.

Temperature limitations of current ALD processes also impact durability in harsh environments. Many high-performance ceramic-like coatings require elevated deposition temperatures (>300°C) that are incompatible with temperature-sensitive substrates. Conversely, low-temperature ALD processes often produce films with higher impurity levels and lower density, compromising their chemical resistance properties.

Finally, current ALD technology faces significant challenges in scaling production while maintaining coating quality. The inherently slow deposition rates (typically 0.1-2 Å/cycle) create economic barriers for widespread industrial adoption in applications requiring thicker protective layers.

Existing Methods for ALD Coating Durability Assessment

01 ALD coating composition for enhanced durability

Specific material compositions can significantly enhance the durability of ALD coatings. These compositions include metal oxides, nitrides, and carbides that provide superior resistance to mechanical wear, chemical corrosion, and environmental degradation. The selection of appropriate precursors and dopants during the ALD process can result in coatings with improved hardness, adhesion, and structural integrity, leading to extended service life in demanding applications.- Enhancement of ALD coating durability through process optimization: Atomic Layer Deposition (ALD) coating durability can be significantly improved through process optimization techniques. These include precise control of deposition parameters such as temperature, pressure, and precursor exposure time. By optimizing these parameters, the resulting films exhibit better adhesion, increased density, and reduced defects, leading to enhanced mechanical stability and longer service life. Advanced process monitoring and real-time adjustments during deposition can further improve coating quality and durability.

- Material selection and multi-layer structures for durable ALD coatings: The selection of appropriate materials and implementation of multi-layer structures significantly impacts ALD coating durability. Combining different materials in alternating layers can create synergistic effects that enhance overall coating performance. These multi-layer structures can provide improved resistance to mechanical stress, thermal cycling, and chemical attack. Strategic material selection based on the specific application environment ensures optimal durability properties, with certain metal oxides, nitrides, and carbides demonstrating superior longevity in harsh conditions.

- Surface preparation techniques for improved ALD coating adhesion: Proper surface preparation is crucial for enhancing the durability of ALD coatings. Techniques such as plasma treatment, chemical cleaning, and surface functionalization create optimal conditions for strong coating adhesion. Removing contaminants, native oxides, and creating uniform surface chemistry ensures consistent nucleation and growth of the ALD film. Enhanced adhesion between the substrate and coating significantly improves mechanical durability, wear resistance, and prevents delamination under stress conditions.

- Post-deposition treatments to enhance ALD coating durability: Various post-deposition treatments can significantly enhance the durability of ALD coatings. Thermal annealing processes promote crystallization, densification, and improved interfacial bonding, resulting in superior mechanical properties. Other treatments include plasma exposure, ion bombardment, and chemical passivation, which can modify the coating structure and composition to increase resistance to environmental degradation. These post-processing techniques effectively reduce defects and enhance the coating's resistance to wear, corrosion, and thermal cycling.

- Testing and characterization methods for ALD coating durability: Advanced testing and characterization methods are essential for evaluating and improving ALD coating durability. Techniques such as nanoindentation, scratch testing, and accelerated environmental exposure provide quantitative data on mechanical properties and failure mechanisms. Spectroscopic and microscopic analyses help identify structural changes and degradation pathways under various conditions. These testing methodologies enable the development of more durable coatings by establishing correlations between processing parameters, microstructure, and performance in real-world applications.

02 Process parameters optimization for durable ALD coatings

Optimizing process parameters such as deposition temperature, pressure, pulse/purge times, and layer thickness is crucial for achieving durable ALD coatings. Precise control of these parameters enables the formation of uniform, defect-free films with excellent adhesion to substrates. Multi-cycle deposition sequences and carefully controlled growth rates can produce coatings with enhanced mechanical properties and resistance to delamination, resulting in significantly improved durability under various operating conditions.Expand Specific Solutions03 Post-deposition treatments for ALD coating durability

Various post-deposition treatments can substantially improve the durability of ALD coatings. These include thermal annealing, plasma treatment, and surface modification techniques that enhance crystallinity, reduce defects, and improve interfacial bonding. Such treatments can transform the microstructure of the coating, increasing its resistance to mechanical stress, thermal cycling, and chemical attack. The optimization of these post-processing steps is essential for maximizing coating longevity in harsh environments.Expand Specific Solutions04 Multi-layer and nanocomposite ALD structures for improved durability

Multi-layer and nanocomposite structures created through ALD offer superior durability compared to single-layer coatings. By alternating different materials or incorporating nanoparticles, these advanced structures can provide enhanced mechanical properties, better stress distribution, and improved resistance to crack propagation. The engineered interfaces between layers can effectively block defect migration and prevent failure mechanisms, resulting in coatings that maintain their protective functions under extreme conditions for extended periods.Expand Specific Solutions05 Testing and characterization methods for ALD coating durability

Advanced testing and characterization methods are essential for evaluating and predicting the durability of ALD coatings. These include accelerated aging tests, mechanical property measurements, chemical resistance evaluations, and microstructural analysis techniques. By employing these methods, researchers can identify failure mechanisms, optimize coating designs, and establish correlations between processing conditions and long-term performance. Comprehensive testing protocols enable the development of more durable ALD coatings tailored for specific application environments.Expand Specific Solutions

Leading Companies and Research Institutions in ALD Field

The ALD coating durability in harsh chemical environments market is in a growth phase, with increasing demand across semiconductor, electronics, and industrial sectors. The market size is expanding as industries seek protective coatings for critical components exposed to corrosive environments. Technologically, ALD is maturing rapidly with key players driving innovation. Companies like Picosun Oy and Beneq Group lead in equipment manufacturing, while Forge Nano and Sundew Technologies focus on high-productivity solutions. Research institutions including Harbin Institute of Technology and University of Oslo collaborate with industrial players like BASF and Lumileds to develop application-specific coatings. Agilent Technologies and 3M contribute materials expertise, while semiconductor equipment manufacturers like Lam Research integrate ALD into broader fabrication processes, creating a competitive ecosystem balancing specialized innovation with industrial-scale implementation.

Picosun Oy

Technical Solution: Picosun has developed advanced ALD coating solutions specifically designed for harsh chemical environments. Their PICOSUN® Sprinter ALD system enables high-volume manufacturing with exceptional film quality and uniformity. The company's proprietary technology focuses on creating ultra-conformal, pinhole-free barrier layers that provide superior protection against corrosive chemicals. Their approach includes multi-layer ALD structures combining different materials (such as Al2O3, TiO2, and Ta2O5) to create synergistic protection mechanisms. Picosun's coatings demonstrate exceptional resistance to acids, bases, and organic solvents, with documented stability in pH ranges from 1-14 and temperatures up to 800°C in aggressive media[1]. Their recent innovations include self-healing ALD films that can repair minor damage through controlled ion migration mechanisms, extending coating lifetime in industrial applications by up to 300% compared to conventional protective layers[3].

Strengths: Industry-leading film uniformity and conformality even on complex 3D structures; scalable processes suitable for industrial production; extensive material library for tailored solutions. Weaknesses: Higher initial investment costs compared to conventional coating methods; some processes require elevated temperatures that may limit substrate compatibility.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed cutting-edge ALD coating technologies specifically designed for extreme chemical environments. Their research focuses on fundamental understanding of degradation mechanisms and designing protective barriers at the atomic level. Argonne's approach utilizes advanced in-situ characterization techniques including synchrotron X-ray analysis to observe coating behavior during chemical exposure in real-time. Their scientists have pioneered novel precursor chemistries that create exceptionally dense, cross-linked films with superior resistance to chemical attack. Argonne has developed specialized nanolaminate structures that combine different materials (including rare earth oxides) to create synergistic protection against multiple degradation mechanisms simultaneously. Their coatings have demonstrated exceptional stability in molten salts, concentrated acids, and high-temperature steam environments relevant to nuclear and energy applications. Testing has shown their advanced ALD films maintain integrity after thousands of hours in environments that would destroy conventional protective layers within minutes[9]. Recent innovations include self-healing coating systems that incorporate sacrificial layers and controlled ion migration to repair damage and extend operational lifetime in extreme environments[10].

Strengths: World-class fundamental research capabilities; access to advanced characterization facilities; development of novel materials beyond commercial availability. Weaknesses: Technologies may require further development for commercial-scale implementation; focus on scientific understanding rather than manufacturing optimization.

Critical Patents and Innovations in Chemical-Resistant ALD

Components with an atomic layer deposition coating and methods of producing the same

PatentWO2016114850A1

Innovation

- The use of atomic layer deposition (ALD) processes to form conformal protective coatings on the interior surfaces of metal components, ensuring uniform thickness and adhesion, even on complex topographies and high aspect ratios, using molecular precursors that react to form inert coatings like Si, Pt, and Ru-based materials.

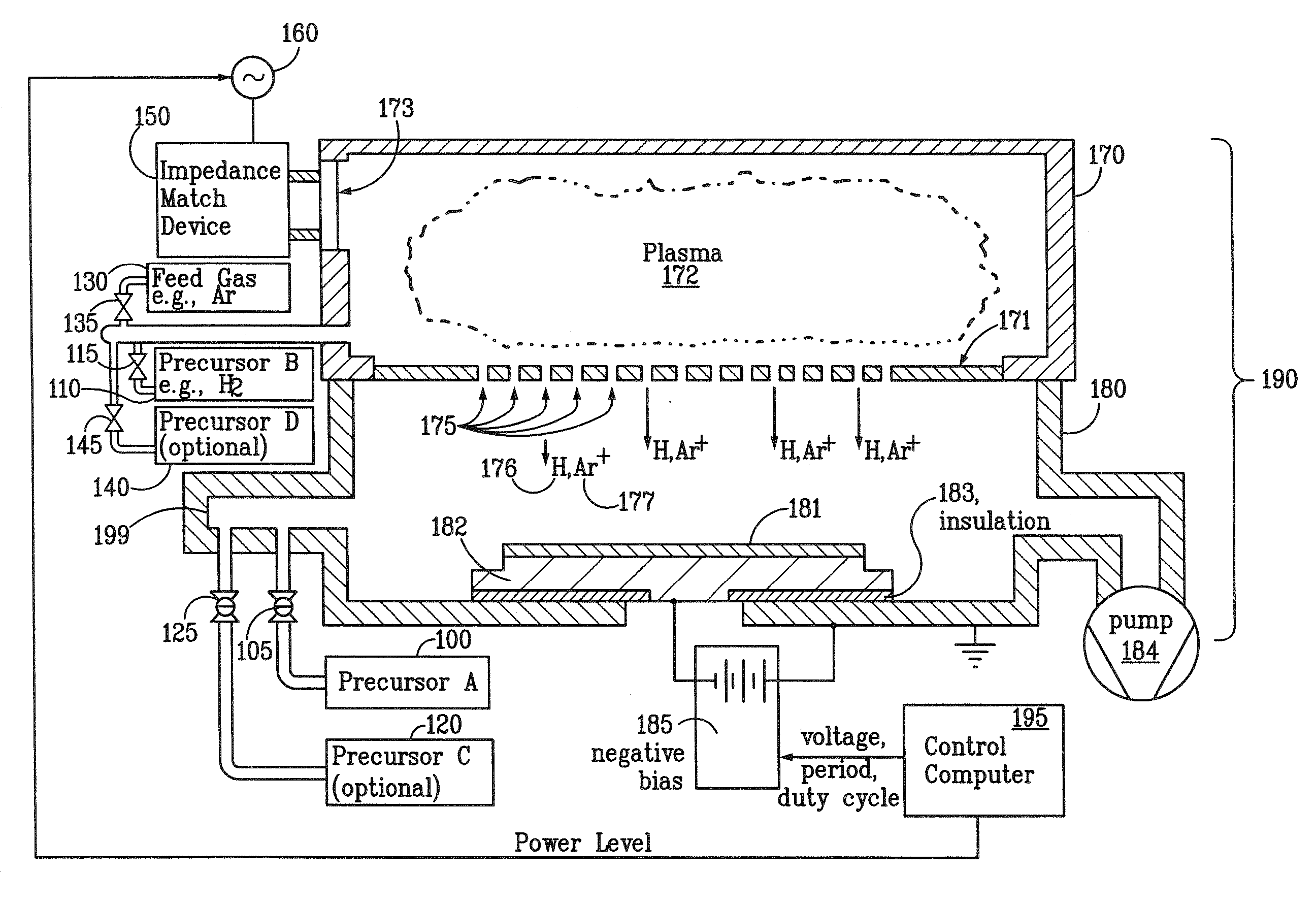

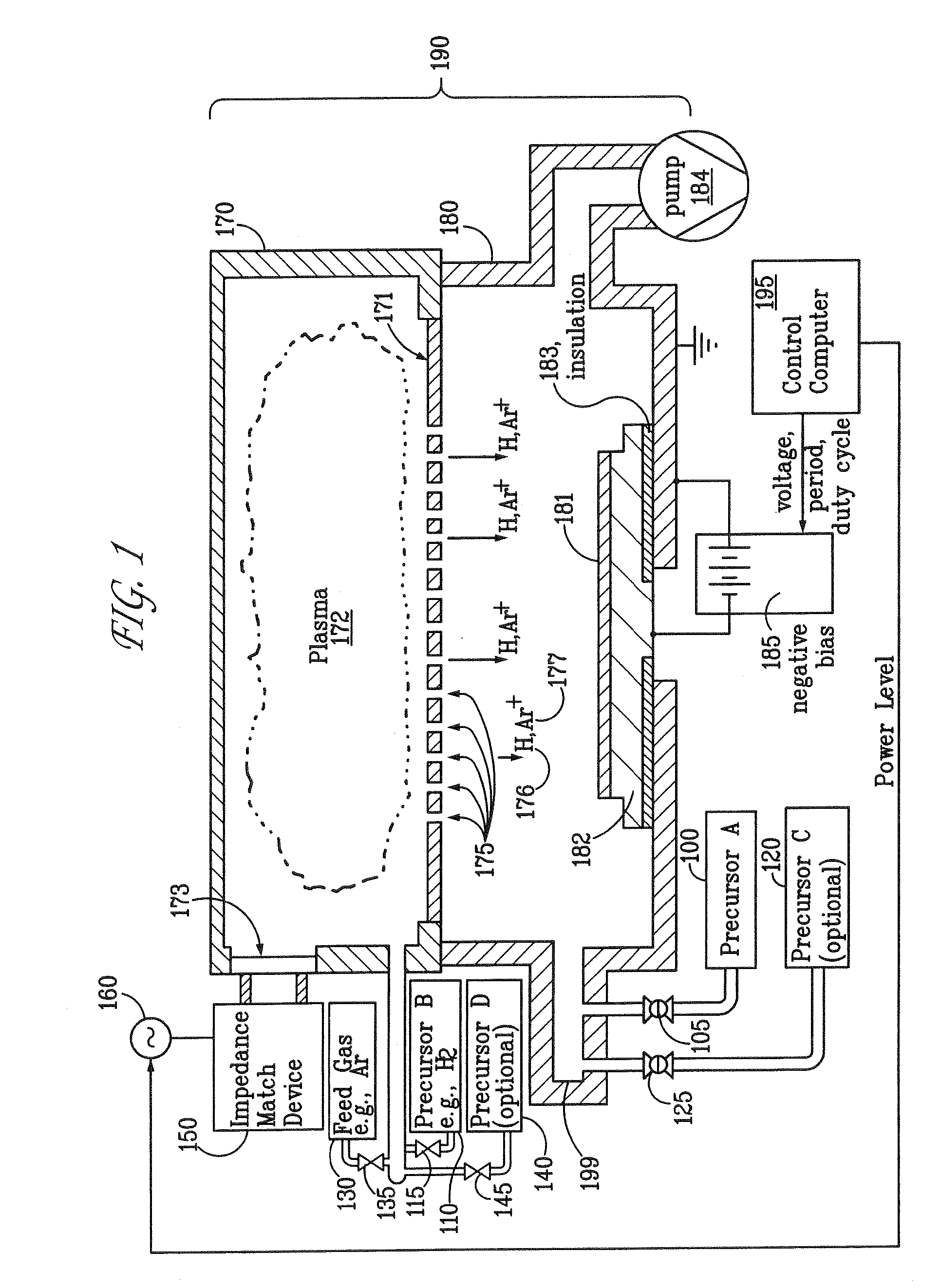

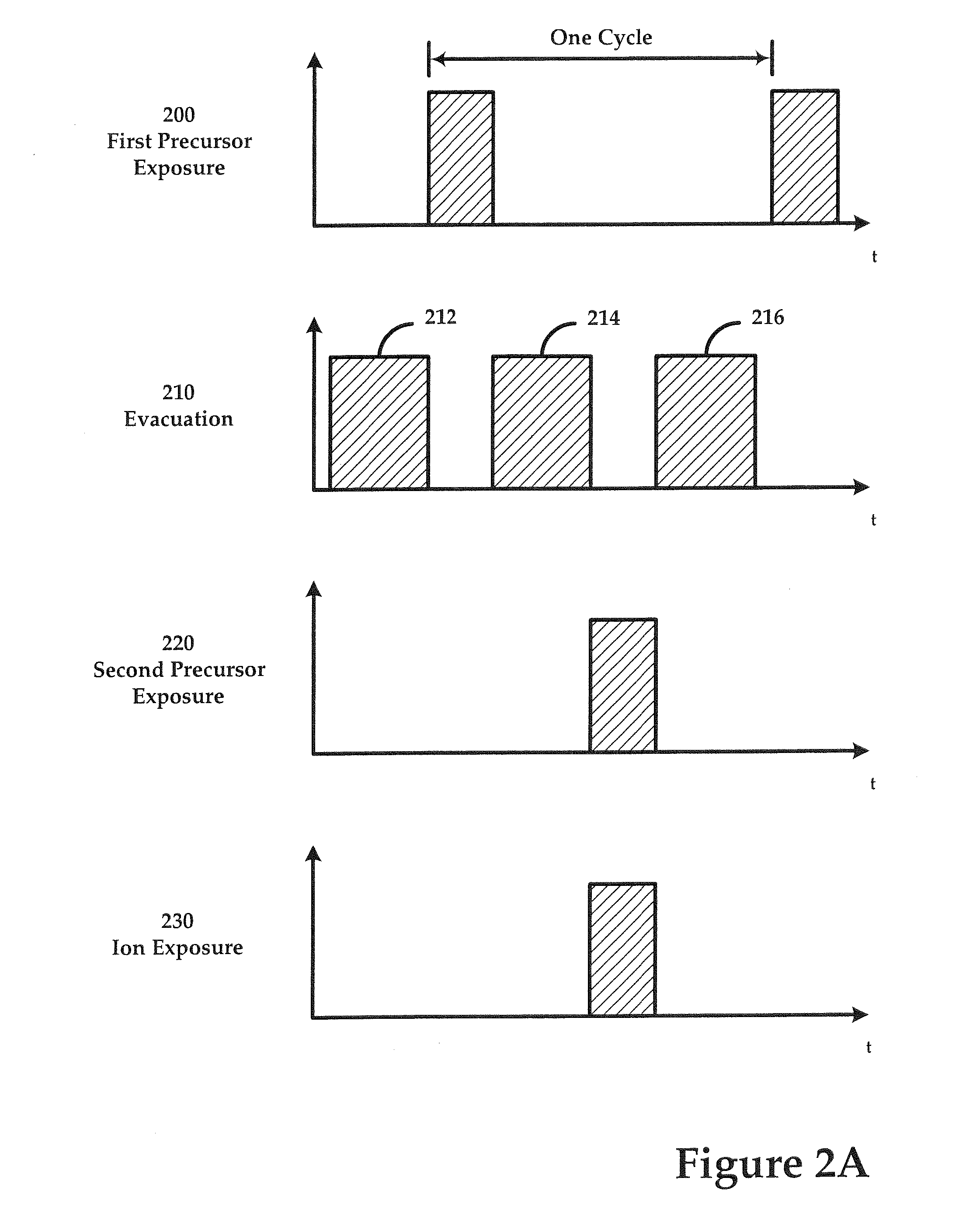

System for Depositing a Film by Modulated Ion-Induced Atomic Layer Deposition (MII-ALD)

PatentInactiveUS20110017139A1

Innovation

- The modulated ion-induced atomic layer deposition (MII-ALD) method uses ion bombardment as a non-thermal activation source to drive the deposition reaction, employing a microwave-generated plasma to generate ions and radicals efficiently, allowing for lower substrate temperatures and faster deposition rates, while maintaining high film purity and adhesion properties.

Environmental Impact and Sustainability Considerations

The environmental impact of Atomic Layer Deposition (ALD) coating processes and their sustainability considerations represent critical dimensions in evaluating this technology's overall viability. ALD processes traditionally consume significant energy due to vacuum requirements and high-temperature operations, typically ranging from 100-350°C. However, recent advancements in plasma-enhanced ALD have reduced operating temperatures, decreasing the overall energy footprint. The environmental assessment must consider this energy consumption alongside the extended product lifecycles that durable ALD coatings enable, potentially offsetting initial environmental costs through reduced replacement frequency.

Chemical precursors used in ALD processes present another environmental concern, as many contain hazardous elements such as heavy metals or reactive organometallics. The environmental persistence of trimethylaluminum (TMA), titanium tetrachloride, and various metal-organic compounds requires careful handling and disposal protocols. Encouragingly, research into green chemistry alternatives has identified several environmentally benign precursors derived from sustainable sources, though their performance in harsh chemical environments often remains inferior to conventional options.

Waste management considerations for ALD processes are particularly relevant when assessing durability in harsh chemical environments. Failed coatings in such applications may release potentially harmful substances into wastewater streams or air emissions. Life cycle assessment (LCA) studies indicate that while ALD processes generate relatively low waste volumes compared to other coating technologies, the toxicity profile of these wastes can be significant, especially when containing unreacted precursors or byproducts from harsh chemical exposure.

The sustainability profile of ALD coatings improves substantially when considering their role in extending equipment lifespans in corrosive environments. By preventing premature material degradation in chemical processing equipment, water treatment systems, and industrial machinery, these coatings reduce resource consumption associated with equipment replacement. Quantitative studies demonstrate that properly engineered ALD coatings can extend component lifespans by 200-300% in aggressive chemical environments, representing significant materials conservation.

Regulatory frameworks increasingly influence ALD coating development, with REACH in Europe and similar regulations worldwide restricting certain precursor chemicals. Forward-looking sustainability strategies for ALD coating development include closed-loop precursor recycling systems, renewable energy integration for process power, and design-for-disassembly approaches that facilitate coating removal and substrate recycling at end-of-life. These considerations are becoming increasingly important as industries adopt more stringent environmental performance metrics and circular economy principles.

Chemical precursors used in ALD processes present another environmental concern, as many contain hazardous elements such as heavy metals or reactive organometallics. The environmental persistence of trimethylaluminum (TMA), titanium tetrachloride, and various metal-organic compounds requires careful handling and disposal protocols. Encouragingly, research into green chemistry alternatives has identified several environmentally benign precursors derived from sustainable sources, though their performance in harsh chemical environments often remains inferior to conventional options.

Waste management considerations for ALD processes are particularly relevant when assessing durability in harsh chemical environments. Failed coatings in such applications may release potentially harmful substances into wastewater streams or air emissions. Life cycle assessment (LCA) studies indicate that while ALD processes generate relatively low waste volumes compared to other coating technologies, the toxicity profile of these wastes can be significant, especially when containing unreacted precursors or byproducts from harsh chemical exposure.

The sustainability profile of ALD coatings improves substantially when considering their role in extending equipment lifespans in corrosive environments. By preventing premature material degradation in chemical processing equipment, water treatment systems, and industrial machinery, these coatings reduce resource consumption associated with equipment replacement. Quantitative studies demonstrate that properly engineered ALD coatings can extend component lifespans by 200-300% in aggressive chemical environments, representing significant materials conservation.

Regulatory frameworks increasingly influence ALD coating development, with REACH in Europe and similar regulations worldwide restricting certain precursor chemicals. Forward-looking sustainability strategies for ALD coating development include closed-loop precursor recycling systems, renewable energy integration for process power, and design-for-disassembly approaches that facilitate coating removal and substrate recycling at end-of-life. These considerations are becoming increasingly important as industries adopt more stringent environmental performance metrics and circular economy principles.

Standardization and Testing Protocols for ALD Coatings

The standardization of testing protocols for ALD coatings represents a critical need in the field of protective surface treatments, particularly when evaluating durability in harsh chemical environments. Current industry practices suffer from significant inconsistencies in methodology, making direct comparisons between different coating solutions challenging and often unreliable. This fragmentation hampers technological advancement and creates barriers to widespread industrial adoption.

A comprehensive standardization framework must address multiple dimensions of chemical durability testing. Exposure parameters including concentration gradients, temperature variations, and time intervals need precise definition to ensure reproducibility across different testing facilities. The chemical resistance evaluation should incorporate both static immersion tests and dynamic flow conditions to simulate real-world operational environments more accurately.

Surface characterization techniques form another essential component of standardized protocols. Pre- and post-exposure analysis should include thickness measurements via ellipsometry, surface morphology examination through AFM/SEM, and chemical composition verification using XPS or FTIR. Quantitative metrics for coating degradation must be clearly defined, such as percentage thickness reduction, surface roughness increase, and chemical composition alterations.

Accelerated aging methodologies represent a particularly valuable approach for predicting long-term performance within reasonable testing timeframes. These protocols should incorporate cyclic exposure to multiple chemical environments, temperature fluctuations, and mechanical stress factors. Statistical validation methods must be integrated to establish confidence intervals for durability predictions and determine minimum sample sizes for reliable results.

Industry-specific test variations need development to address unique environmental challenges across sectors like semiconductor manufacturing, medical devices, and energy storage. For instance, semiconductor applications require protocols focusing on resistance to cleaning chemicals and etching agents, while medical implant coatings demand testing against bodily fluids and sterilization procedures.

Collaborative efforts between standards organizations (ISO, ASTM, NACE), research institutions, and industry stakeholders are essential for developing universally accepted protocols. Recent initiatives like the ALD Durability Consortium have begun addressing these standardization needs, though significant work remains to establish comprehensive industry-wide acceptance and implementation of unified testing methodologies.

The development of reference materials with certified durability characteristics would significantly enhance standardization efforts, providing calibration benchmarks against which new coating technologies can be reliably evaluated and compared across different testing facilities and methodologies.

A comprehensive standardization framework must address multiple dimensions of chemical durability testing. Exposure parameters including concentration gradients, temperature variations, and time intervals need precise definition to ensure reproducibility across different testing facilities. The chemical resistance evaluation should incorporate both static immersion tests and dynamic flow conditions to simulate real-world operational environments more accurately.

Surface characterization techniques form another essential component of standardized protocols. Pre- and post-exposure analysis should include thickness measurements via ellipsometry, surface morphology examination through AFM/SEM, and chemical composition verification using XPS or FTIR. Quantitative metrics for coating degradation must be clearly defined, such as percentage thickness reduction, surface roughness increase, and chemical composition alterations.

Accelerated aging methodologies represent a particularly valuable approach for predicting long-term performance within reasonable testing timeframes. These protocols should incorporate cyclic exposure to multiple chemical environments, temperature fluctuations, and mechanical stress factors. Statistical validation methods must be integrated to establish confidence intervals for durability predictions and determine minimum sample sizes for reliable results.

Industry-specific test variations need development to address unique environmental challenges across sectors like semiconductor manufacturing, medical devices, and energy storage. For instance, semiconductor applications require protocols focusing on resistance to cleaning chemicals and etching agents, while medical implant coatings demand testing against bodily fluids and sterilization procedures.

Collaborative efforts between standards organizations (ISO, ASTM, NACE), research institutions, and industry stakeholders are essential for developing universally accepted protocols. Recent initiatives like the ALD Durability Consortium have begun addressing these standardization needs, though significant work remains to establish comprehensive industry-wide acceptance and implementation of unified testing methodologies.

The development of reference materials with certified durability characteristics would significantly enhance standardization efforts, providing calibration benchmarks against which new coating technologies can be reliably evaluated and compared across different testing facilities and methodologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!