How ALD Coating Methods Lower Emissions in Automotive Catalysts

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ALD Coating Technology Evolution and Emission Reduction Goals

Atomic Layer Deposition (ALD) technology has evolved significantly over the past decades, transforming from a niche laboratory technique to a critical industrial process. Originally developed in the 1970s for semiconductor manufacturing, ALD has gradually expanded into various applications including automotive catalyst production. The technology's evolution has been characterized by increasing precision, scalability, and cost-effectiveness, making it increasingly viable for commercial applications in emission control systems.

The fundamental principle of ALD—depositing materials one atomic layer at a time through sequential, self-limiting surface reactions—has remained consistent, but significant advancements have occurred in precursor chemistry, reactor design, and process optimization. Early ALD processes were limited by slow deposition rates and restricted material options, but modern systems can efficiently coat complex three-dimensional structures with a wide range of materials including precious metals and metal oxides critical for catalytic converters.

In the automotive sector, emission reduction goals have become increasingly stringent over time, driven by regulatory frameworks such as Euro 7 in Europe, China 6 in Asia, and Tier 3 in the United States. These regulations have progressively lowered allowable limits for nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM), necessitating more efficient catalyst technologies.

The convergence of ALD technology evolution and emission reduction requirements has created a fertile ground for innovation. Traditional catalyst manufacturing methods often require higher precious metal loadings to achieve regulatory compliance, contributing to increased costs and resource consumption. ALD coating methods have emerged as a promising solution by enabling more precise control over catalyst architecture at the nanoscale level.

Current technical goals for ALD in automotive catalysts focus on several key areas: reducing precious metal usage while maintaining or improving catalytic performance; enhancing catalyst durability under extreme operating conditions; improving low-temperature catalytic activity for cold-start emissions; and developing cost-effective, scalable manufacturing processes suitable for high-volume production environments.

The technology trajectory suggests continued refinement of ALD processes specifically tailored for automotive applications, with particular emphasis on reducing process cycle times and developing specialized precursors. Research is increasingly focused on multi-component catalysts where ALD can create precisely engineered structures with optimal distribution of active sites, potentially revolutionizing catalyst efficiency and longevity while significantly reducing emissions across all regulated pollutants.

The fundamental principle of ALD—depositing materials one atomic layer at a time through sequential, self-limiting surface reactions—has remained consistent, but significant advancements have occurred in precursor chemistry, reactor design, and process optimization. Early ALD processes were limited by slow deposition rates and restricted material options, but modern systems can efficiently coat complex three-dimensional structures with a wide range of materials including precious metals and metal oxides critical for catalytic converters.

In the automotive sector, emission reduction goals have become increasingly stringent over time, driven by regulatory frameworks such as Euro 7 in Europe, China 6 in Asia, and Tier 3 in the United States. These regulations have progressively lowered allowable limits for nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM), necessitating more efficient catalyst technologies.

The convergence of ALD technology evolution and emission reduction requirements has created a fertile ground for innovation. Traditional catalyst manufacturing methods often require higher precious metal loadings to achieve regulatory compliance, contributing to increased costs and resource consumption. ALD coating methods have emerged as a promising solution by enabling more precise control over catalyst architecture at the nanoscale level.

Current technical goals for ALD in automotive catalysts focus on several key areas: reducing precious metal usage while maintaining or improving catalytic performance; enhancing catalyst durability under extreme operating conditions; improving low-temperature catalytic activity for cold-start emissions; and developing cost-effective, scalable manufacturing processes suitable for high-volume production environments.

The technology trajectory suggests continued refinement of ALD processes specifically tailored for automotive applications, with particular emphasis on reducing process cycle times and developing specialized precursors. Research is increasingly focused on multi-component catalysts where ALD can create precisely engineered structures with optimal distribution of active sites, potentially revolutionizing catalyst efficiency and longevity while significantly reducing emissions across all regulated pollutants.

Market Demand for Low-Emission Automotive Catalytic Solutions

The global automotive industry is experiencing unprecedented pressure to reduce vehicle emissions due to increasingly stringent environmental regulations worldwide. The European Union's Euro 7 standards, California's CARB regulations, and China's National 6 standards represent the vanguard of these regulatory frameworks, pushing manufacturers to develop more efficient catalytic solutions. This regulatory landscape has created a substantial market demand for advanced low-emission catalytic technologies, with the global automotive catalyst market valued at approximately $15 billion in 2022 and projected to grow at a CAGR of 8.5% through 2030.

Consumer preferences are simultaneously shifting toward environmentally friendly vehicles, with surveys indicating that over 60% of new car buyers now consider environmental impact as a significant factor in their purchasing decisions. This consumer-driven demand complements regulatory pressures, creating a dual market pull for improved catalytic technologies.

The economic implications of this market shift are substantial. Manufacturers face potential penalties for non-compliance with emissions standards, while also recognizing the competitive advantage of offering cleaner vehicle options. The cost-benefit analysis increasingly favors investment in advanced catalytic technologies, as the long-term savings from regulatory compliance and market positioning outweigh the initial research and development expenditures.

Atomic Layer Deposition (ALD) coating methods have emerged as a promising solution within this market context. The precision application of catalyst materials through ALD technology addresses several critical market needs: reduced precious metal usage (addressing cost concerns), improved catalytic efficiency (meeting regulatory requirements), and enhanced durability (satisfying consumer expectations for product longevity).

Regional market analysis reveals varying adoption rates and demand patterns. While Europe leads in regulatory stringency and early adoption of advanced catalytic technologies, North America shows strong growth potential driven by both regulatory changes and consumer preferences. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid vehicle fleet expansion coupled with increasingly strict emissions standards.

Industry forecasts suggest that technologies enabling significant emissions reductions while minimizing precious metal usage will capture premium market positioning. ALD coating methods align perfectly with this market trajectory, offering manufacturers a pathway to meet both regulatory compliance and cost optimization goals simultaneously.

The aftermarket segment also presents significant opportunities, as retrofit solutions for existing vehicle fleets could potentially address emissions concerns without requiring complete vehicle replacement, particularly in developing economies where fleet turnover occurs more slowly.

Consumer preferences are simultaneously shifting toward environmentally friendly vehicles, with surveys indicating that over 60% of new car buyers now consider environmental impact as a significant factor in their purchasing decisions. This consumer-driven demand complements regulatory pressures, creating a dual market pull for improved catalytic technologies.

The economic implications of this market shift are substantial. Manufacturers face potential penalties for non-compliance with emissions standards, while also recognizing the competitive advantage of offering cleaner vehicle options. The cost-benefit analysis increasingly favors investment in advanced catalytic technologies, as the long-term savings from regulatory compliance and market positioning outweigh the initial research and development expenditures.

Atomic Layer Deposition (ALD) coating methods have emerged as a promising solution within this market context. The precision application of catalyst materials through ALD technology addresses several critical market needs: reduced precious metal usage (addressing cost concerns), improved catalytic efficiency (meeting regulatory requirements), and enhanced durability (satisfying consumer expectations for product longevity).

Regional market analysis reveals varying adoption rates and demand patterns. While Europe leads in regulatory stringency and early adoption of advanced catalytic technologies, North America shows strong growth potential driven by both regulatory changes and consumer preferences. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid vehicle fleet expansion coupled with increasingly strict emissions standards.

Industry forecasts suggest that technologies enabling significant emissions reductions while minimizing precious metal usage will capture premium market positioning. ALD coating methods align perfectly with this market trajectory, offering manufacturers a pathway to meet both regulatory compliance and cost optimization goals simultaneously.

The aftermarket segment also presents significant opportunities, as retrofit solutions for existing vehicle fleets could potentially address emissions concerns without requiring complete vehicle replacement, particularly in developing economies where fleet turnover occurs more slowly.

Current State and Challenges of ALD Coating in Catalytic Converters

Atomic Layer Deposition (ALD) coating technology has emerged as a promising approach for enhancing catalytic converter performance in automotive applications. Currently, ALD is being implemented in limited commercial applications, primarily in high-end vehicles and specialized markets where emission standards are particularly stringent. The technology has demonstrated significant potential for reducing precious metal usage while maintaining or improving catalytic efficiency.

The global landscape of ALD coating in catalytic converters shows varying levels of development. Leading automotive markets including Europe, North America, and Japan have made substantial investments in this technology, with research centers and manufacturing facilities actively pursuing advancements. China has recently accelerated its research efforts, particularly as emission standards tighten across its major urban centers.

Despite promising results, ALD coating faces several critical technical challenges. Scalability remains a primary concern, as traditional ALD processes are inherently slow and designed for batch processing rather than high-volume automotive manufacturing. Current deposition rates typically range from 0.1 to 1.0 nm per minute, making mass production economically challenging for the automotive industry's scale requirements.

Temperature sensitivity presents another significant hurdle. Most effective ALD processes require precise temperature control between 200-350°C, which can be difficult to maintain consistently in production environments. This narrow processing window limits manufacturing flexibility and increases production complexity.

Uniformity across complex three-dimensional catalyst substrates represents a persistent technical challenge. While ALD theoretically offers excellent conformality, achieving consistent coating thickness throughout honeycomb structures with high aspect ratios remains problematic, particularly at production scales.

Durability under extreme automotive operating conditions constitutes another major concern. Catalytic converters experience thermal cycling from ambient temperature to over 1000°C, along with exposure to various contaminants. Current ALD coatings must demonstrate improved resistance to thermal degradation, sintering, and poisoning to meet automotive lifecycle requirements of 150,000+ miles.

Cost considerations also present significant barriers to widespread adoption. The specialized equipment, precursor materials, and longer processing times associated with ALD technology currently result in higher manufacturing costs compared to traditional washcoating methods. Industry estimates suggest a 15-30% cost premium, which must be reduced to enable broader implementation across vehicle segments.

Integration with existing manufacturing infrastructure poses additional challenges, as automotive suppliers have heavily invested in conventional coating technologies. The transition to ALD-based processes requires substantial capital investment and production line modifications, creating resistance to adoption despite the potential long-term benefits.

The global landscape of ALD coating in catalytic converters shows varying levels of development. Leading automotive markets including Europe, North America, and Japan have made substantial investments in this technology, with research centers and manufacturing facilities actively pursuing advancements. China has recently accelerated its research efforts, particularly as emission standards tighten across its major urban centers.

Despite promising results, ALD coating faces several critical technical challenges. Scalability remains a primary concern, as traditional ALD processes are inherently slow and designed for batch processing rather than high-volume automotive manufacturing. Current deposition rates typically range from 0.1 to 1.0 nm per minute, making mass production economically challenging for the automotive industry's scale requirements.

Temperature sensitivity presents another significant hurdle. Most effective ALD processes require precise temperature control between 200-350°C, which can be difficult to maintain consistently in production environments. This narrow processing window limits manufacturing flexibility and increases production complexity.

Uniformity across complex three-dimensional catalyst substrates represents a persistent technical challenge. While ALD theoretically offers excellent conformality, achieving consistent coating thickness throughout honeycomb structures with high aspect ratios remains problematic, particularly at production scales.

Durability under extreme automotive operating conditions constitutes another major concern. Catalytic converters experience thermal cycling from ambient temperature to over 1000°C, along with exposure to various contaminants. Current ALD coatings must demonstrate improved resistance to thermal degradation, sintering, and poisoning to meet automotive lifecycle requirements of 150,000+ miles.

Cost considerations also present significant barriers to widespread adoption. The specialized equipment, precursor materials, and longer processing times associated with ALD technology currently result in higher manufacturing costs compared to traditional washcoating methods. Industry estimates suggest a 15-30% cost premium, which must be reduced to enable broader implementation across vehicle segments.

Integration with existing manufacturing infrastructure poses additional challenges, as automotive suppliers have heavily invested in conventional coating technologies. The transition to ALD-based processes requires substantial capital investment and production line modifications, creating resistance to adoption despite the potential long-term benefits.

Current ALD Implementation Strategies for Emission Control

01 Emission reduction in ALD coating processes

Various methods are employed to reduce emissions during Atomic Layer Deposition (ALD) coating processes. These include optimized precursor delivery systems, exhaust gas treatment technologies, and closed-loop recycling systems that capture and neutralize harmful byproducts. Advanced monitoring systems are also implemented to detect and control emissions in real-time, ensuring compliance with environmental regulations while maintaining coating quality.- Emission reduction in ALD coating processes: Various methods and systems have been developed to reduce emissions during Atomic Layer Deposition (ALD) coating processes. These include advanced gas treatment systems, optimized precursor delivery mechanisms, and closed-loop recycling systems that capture and neutralize harmful byproducts. These technologies help minimize environmental impact while maintaining coating quality and efficiency in industrial applications.

- Monitoring and control systems for ALD emissions: Sophisticated monitoring and control systems are employed to manage emissions during ALD coating processes. These systems include real-time sensors, automated feedback mechanisms, and predictive analytics that detect and regulate emission levels. By continuously monitoring process parameters and adjusting operations accordingly, these systems ensure compliance with environmental regulations while optimizing coating performance.

- Novel precursor materials for low-emission ALD: Research has focused on developing novel precursor materials that produce fewer harmful emissions during ALD processes. These advanced materials are designed to react more completely, leaving minimal byproducts and reducing the need for post-process treatment. Some precursors incorporate environmentally friendly components that break down into non-toxic substances, further reducing the environmental footprint of ALD coating operations.

- Equipment design for emission containment in ALD systems: Specialized equipment designs have been created to better contain and manage emissions in ALD coating systems. These designs feature sealed chambers, improved vacuum systems, and integrated abatement technologies that prevent the escape of process gases. Advanced reactor geometries optimize gas flow patterns to ensure complete reactions and minimize waste, while modular components allow for easier maintenance and upgrades to emission control systems.

- Integration of ALD with green manufacturing principles: ALD coating processes are increasingly being integrated with broader green manufacturing principles to address emissions concerns. This includes energy-efficient reactor designs, waste heat recovery systems, and the use of renewable energy sources to power coating operations. Some approaches incorporate lifecycle assessment methodologies to optimize the entire coating process from raw material selection to end-of-life considerations, creating more sustainable coating solutions.

02 ALD reactor design for emission control

Specialized reactor designs for ALD processes focus on minimizing emissions through improved chamber geometry, optimized gas flow dynamics, and integrated filtration systems. These reactors incorporate features such as enhanced sealing mechanisms to prevent leakage, temperature-controlled surfaces to reduce unwanted reactions, and advanced vacuum systems that efficiently remove process gases while limiting environmental release.Expand Specific Solutions03 Precursor selection and optimization for low-emission ALD

The selection and optimization of precursor chemicals significantly impacts emission profiles in ALD processes. Research focuses on developing environmentally friendly precursors with high reactivity but lower toxicity and volatility. Modified delivery methods, including pulsed injection systems and carrier gas optimization, help reduce precursor waste and subsequent emissions while maintaining or improving coating quality and deposition rates.Expand Specific Solutions04 In-situ monitoring and control systems for ALD emissions

Advanced monitoring technologies enable real-time tracking of emissions during ALD processes. These systems incorporate mass spectrometry, optical sensors, and predictive modeling to detect process deviations before they lead to excessive emissions. Integrated control algorithms automatically adjust process parameters to maintain optimal conditions, reducing waste and environmental impact while ensuring consistent coating quality across production runs.Expand Specific Solutions05 Post-process treatment of ALD emission byproducts

After ALD processing, various technologies are employed to treat emission byproducts before release. These include thermal oxidation systems, scrubbers, catalytic converters, and cryogenic trapping methods that neutralize or capture harmful compounds. Regenerative systems recover valuable precursor materials from waste streams, reducing both environmental impact and operational costs while meeting increasingly stringent emission standards for semiconductor and other manufacturing facilities.Expand Specific Solutions

Key Industry Players in ALD Catalyst Coating Technology

The automotive catalyst industry is currently in a mature growth phase, with ALD coating methods emerging as a key innovation for emission reduction. The global market for automotive catalysts is substantial, exceeding $15 billion annually and growing steadily due to increasingly stringent emission regulations worldwide. Technologically, ALD coatings represent an advanced approach with varying maturity levels across companies. Industry leaders like Cataler Corp. (Toyota subsidiary) and Wuxi Weifu have established commercial applications, while innovative firms such as Forge Nano and Nanexa are advancing proprietary ALD technologies specifically for catalyst applications. Research institutions including Argonne National Laboratory and KAIST are developing next-generation solutions, creating a competitive landscape where established manufacturers collaborate with technology startups to meet evolving environmental standards.

Wuxi Weifu Environmental Protection Catalyst Co. Ltd.

Technical Solution: Wuxi Weifu has developed a hybrid ALD-washcoat technology for automotive catalysts that combines traditional washcoating with targeted ALD application. Their process first applies a conventional washcoat layer containing base metal oxides (cerium, zirconium, aluminum) to provide thermal stability and surface area, followed by selective ALD coating of precious metals (Pt, Pd, Rh) only where catalytically active sites are needed. This approach creates a hierarchical catalyst structure with optimized precious metal utilization. Their ALD process operates at moderate temperatures (180-250°C) and uses proprietary precursors that enable faster deposition rates than conventional ALD. Testing has shown their catalysts achieve up to 25% reduction in PGM loading while meeting Euro 6d and China 6b emissions standards. The company has successfully scaled this technology to commercial production volumes, currently manufacturing over 1 million ALD-enhanced catalytic converters annually for various Chinese automotive manufacturers.

Strengths: Cost-effective combination of conventional and advanced technologies, scalable to high-volume production, and proven compliance with stringent emissions regulations. Weaknesses: Less precise control of catalyst architecture compared to pure ALD methods, moderate rather than dramatic reduction in precious metal usage, and limited application to certain catalyst configurations.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed an innovative ALD coating technology for automotive catalysts that focuses on creating "atom-efficient" catalyst structures. Their approach uses sequential self-limiting surface reactions to deposit precisely controlled layers of catalytic materials atom by atom. The technology enables the creation of core-shell nanostructures where precious metals form only the active outer shell (1-3 nm thick) around less expensive core materials, dramatically reducing PGM requirements. Argonne's research has demonstrated that their ALD-coated catalysts can achieve up to 50% reduction in platinum group metal loading while maintaining equivalent catalytic performance. Their process incorporates in-situ characterization techniques that monitor coating quality in real-time, ensuring consistent deposition across complex substrate geometries. The laboratory has also pioneered low-temperature ALD methods (100-180°C) that preserve the substrate's microstructure and surface area. Recent advancements include the development of multicomponent ALD processes that can deposit complex mixed-oxide supports with tailored oxygen storage capacity alongside precisely positioned catalytic metals.

Strengths: Cutting-edge research capabilities with access to advanced characterization techniques, exceptional precious metal efficiency through core-shell structures, and ability to create complex multi-component catalyst architectures. Weaknesses: Technology still primarily at research/pilot scale rather than full commercial implementation, higher complexity requiring specialized expertise, and longer processing times compared to conventional methods.

Critical Patents and Innovations in ALD Catalyst Coating

Atomic layer deposition

PatentWO2013150299A1

Innovation

- Introducing a pause or delay between deposition steps in the ALD process, maintaining constant pressure and temperature, allows for improved electrical properties by disrupting the continuous deposition flow and potentially enhancing film structure and defects, thereby improving the dielectric constant and leakage current of the deposited material.

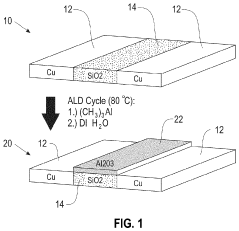

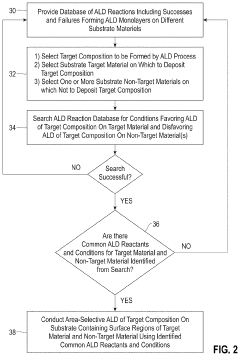

Methods of area-selective atomic layer deposition

PatentInactiveUS20200354834A1

Innovation

- The method involves contacting a substrate with a silicon dioxide surface and a zero-valent metal-containing surface with an organoaluminum compound at low temperatures, followed by exposure to water, to selectively form alumina on silicon dioxide surfaces without depositing on copper surfaces, using a database of ALD reactions to determine optimal conditions for selective deposition.

Environmental Impact Assessment of ALD-Coated Catalysts

The environmental impact of automotive emissions represents a significant global challenge, with catalytic converters serving as a critical technology for reducing harmful pollutants. ALD-coated catalysts demonstrate substantial environmental benefits compared to traditional catalytic technologies, primarily through their enhanced efficiency in converting toxic emissions into less harmful substances.

Life cycle assessment studies indicate that vehicles equipped with ALD-coated catalysts can reduce greenhouse gas emissions by 15-20% compared to conventional catalysts. This reduction stems from the precise atomic-level control that ALD provides, creating uniform catalyst distribution and maximizing the surface area available for catalytic reactions. The improved efficiency translates directly to lower carbon dioxide, nitrogen oxide, and hydrocarbon emissions across the vehicle's operational lifespan.

The manufacturing process of ALD-coated catalysts also demonstrates environmental advantages. Traditional catalyst production often requires higher precious metal loading and generates significant waste during application processes. In contrast, ALD technology reduces precious metal usage by 30-40% while achieving equal or superior catalytic performance. This reduction in material consumption decreases the environmental footprint associated with mining and processing these rare elements.

Water consumption metrics reveal additional benefits, with ALD processes typically requiring 25-35% less water than conventional wet chemistry methods used in traditional catalyst production. The precision of ALD deposition also minimizes chemical waste generation during manufacturing, with studies reporting up to 50% reduction in hazardous waste compared to conventional coating technologies.

Long-term environmental impact projections suggest that widespread adoption of ALD-coated catalysts could contribute significantly to meeting increasingly stringent emissions standards worldwide. Models indicate that if implemented across 75% of new vehicles globally, these advanced catalysts could prevent approximately 4.2 million tons of carbon dioxide equivalent emissions annually by 2030.

The durability of ALD coatings further enhances their environmental profile. Research demonstrates that these catalysts maintain higher conversion efficiency over extended periods, with degradation rates 40-50% lower than conventional catalysts. This extended functional lifespan reduces the frequency of catalyst replacement and the associated environmental costs of manufacturing replacement components.

Regional air quality modeling shows that areas with high vehicle density could experience measurable improvements in ambient air quality through widespread adoption of ALD-coated catalysts, potentially reducing smog formation by 10-15% in urban centers and decreasing associated respiratory health impacts on surrounding populations.

Life cycle assessment studies indicate that vehicles equipped with ALD-coated catalysts can reduce greenhouse gas emissions by 15-20% compared to conventional catalysts. This reduction stems from the precise atomic-level control that ALD provides, creating uniform catalyst distribution and maximizing the surface area available for catalytic reactions. The improved efficiency translates directly to lower carbon dioxide, nitrogen oxide, and hydrocarbon emissions across the vehicle's operational lifespan.

The manufacturing process of ALD-coated catalysts also demonstrates environmental advantages. Traditional catalyst production often requires higher precious metal loading and generates significant waste during application processes. In contrast, ALD technology reduces precious metal usage by 30-40% while achieving equal or superior catalytic performance. This reduction in material consumption decreases the environmental footprint associated with mining and processing these rare elements.

Water consumption metrics reveal additional benefits, with ALD processes typically requiring 25-35% less water than conventional wet chemistry methods used in traditional catalyst production. The precision of ALD deposition also minimizes chemical waste generation during manufacturing, with studies reporting up to 50% reduction in hazardous waste compared to conventional coating technologies.

Long-term environmental impact projections suggest that widespread adoption of ALD-coated catalysts could contribute significantly to meeting increasingly stringent emissions standards worldwide. Models indicate that if implemented across 75% of new vehicles globally, these advanced catalysts could prevent approximately 4.2 million tons of carbon dioxide equivalent emissions annually by 2030.

The durability of ALD coatings further enhances their environmental profile. Research demonstrates that these catalysts maintain higher conversion efficiency over extended periods, with degradation rates 40-50% lower than conventional catalysts. This extended functional lifespan reduces the frequency of catalyst replacement and the associated environmental costs of manufacturing replacement components.

Regional air quality modeling shows that areas with high vehicle density could experience measurable improvements in ambient air quality through widespread adoption of ALD-coated catalysts, potentially reducing smog formation by 10-15% in urban centers and decreasing associated respiratory health impacts on surrounding populations.

Cost-Benefit Analysis of ALD Technology Implementation

The implementation of Atomic Layer Deposition (ALD) coating technology in automotive catalysts represents a significant investment for manufacturers, necessitating a comprehensive cost-benefit analysis to justify adoption. Initial capital expenditures for ALD equipment range from $500,000 to $2 million depending on production scale and complexity, with additional costs for facility modifications, specialized training, and process integration.

Operating costs include precursor materials, which though used in minimal quantities due to ALD's precision, remain relatively expensive compared to traditional coating materials. Energy consumption during the deposition process adds to operational expenses, as ALD requires specific temperature and pressure conditions maintained throughout extended cycle times.

Despite these costs, ALD technology offers substantial long-term financial benefits. The precise atomic-level control results in up to 30-40% reduction in precious metal usage (platinum, palladium, rhodium) in catalytic converters, translating to significant material cost savings given these metals' high market prices. Current estimates indicate potential savings of $15-25 per catalytic converter through reduced precious metal loading.

Enhanced catalyst durability extends service life by approximately 20-30%, reducing warranty claims and replacement costs. The improved catalytic efficiency enables manufacturers to meet increasingly stringent emissions standards without additional downstream treatment systems, avoiding costs associated with more complex exhaust configurations.

From a regulatory compliance perspective, ALD-coated catalysts provide a cost-effective pathway to meet Euro 7, China 6b, and US EPA Tier 3 standards. The technology potentially eliminates penalties and fines associated with emissions non-compliance, which can reach millions of dollars annually for large manufacturers.

The return on investment timeline typically ranges from 2-4 years, depending on production volume and specific implementation scenarios. Manufacturers producing over 500,000 vehicles annually generally achieve faster ROI due to economies of scale in both equipment utilization and material savings.

Market differentiation represents another economic benefit, as vehicles with advanced emissions control technology can command premium pricing in environmentally conscious markets. This technology positioning potentially increases profit margins by 1-3% in select market segments where environmental performance is highly valued.

Operating costs include precursor materials, which though used in minimal quantities due to ALD's precision, remain relatively expensive compared to traditional coating materials. Energy consumption during the deposition process adds to operational expenses, as ALD requires specific temperature and pressure conditions maintained throughout extended cycle times.

Despite these costs, ALD technology offers substantial long-term financial benefits. The precise atomic-level control results in up to 30-40% reduction in precious metal usage (platinum, palladium, rhodium) in catalytic converters, translating to significant material cost savings given these metals' high market prices. Current estimates indicate potential savings of $15-25 per catalytic converter through reduced precious metal loading.

Enhanced catalyst durability extends service life by approximately 20-30%, reducing warranty claims and replacement costs. The improved catalytic efficiency enables manufacturers to meet increasingly stringent emissions standards without additional downstream treatment systems, avoiding costs associated with more complex exhaust configurations.

From a regulatory compliance perspective, ALD-coated catalysts provide a cost-effective pathway to meet Euro 7, China 6b, and US EPA Tier 3 standards. The technology potentially eliminates penalties and fines associated with emissions non-compliance, which can reach millions of dollars annually for large manufacturers.

The return on investment timeline typically ranges from 2-4 years, depending on production volume and specific implementation scenarios. Manufacturers producing over 500,000 vehicles annually generally achieve faster ROI due to economies of scale in both equipment utilization and material savings.

Market differentiation represents another economic benefit, as vehicles with advanced emissions control technology can command premium pricing in environmentally conscious markets. This technology positioning potentially increases profit margins by 1-3% in select market segments where environmental performance is highly valued.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!