Impact of ALD Coating on Energy Storage in Battery Systems

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ALD Coating Technology Background and Objectives

Atomic Layer Deposition (ALD) technology has evolved significantly over the past three decades, transitioning from a niche laboratory technique to a critical industrial process. Originally developed in the 1970s as a variant of Chemical Vapor Deposition (CVD), ALD has distinguished itself through its unique ability to deposit ultra-thin, highly conformal films with precise thickness control at the atomic scale. This exceptional precision has positioned ALD as a transformative technology across multiple industries, with energy storage applications emerging as a particularly promising frontier.

The evolution of battery technologies has created an urgent need for advanced coating solutions that can address fundamental challenges in energy storage systems. Traditional battery architectures face limitations in cycle life, energy density, safety, and performance stability. These challenges have intensified as consumer electronics, electric vehicles, and renewable energy storage systems demand increasingly powerful and reliable energy storage solutions. ALD coatings represent a strategic approach to overcoming these limitations by providing protective layers that can enhance electrode stability, prevent unwanted reactions, and improve overall battery performance.

In battery systems specifically, ALD coatings serve multiple critical functions. They can create protective barriers that prevent direct contact between electrode materials and electrolytes, thereby reducing unwanted side reactions and electrolyte decomposition. These coatings can also stabilize the solid-electrolyte interphase (SEI) layer, a crucial component that forms on electrode surfaces during battery operation. Furthermore, ALD coatings can modify surface properties to enhance ion transport while suppressing electron transfer at specific interfaces, optimizing the electrochemical performance of battery components.

The primary technical objectives of ALD coating research in battery systems include extending cycle life by preventing capacity fade, enhancing rate capability through improved ion transport, increasing energy density by enabling the use of high-capacity electrode materials, and improving safety by suppressing dendrite formation and thermal runaway risks. Additionally, researchers aim to develop scalable ALD processes that can be integrated into existing battery manufacturing lines without significantly increasing production costs or complexity.

Recent advancements in ALD technology have expanded its capabilities beyond traditional metal oxide coatings to include complex multi-component films, polymer-like organic layers, and hybrid organic-inorganic structures. These developments have broadened the potential applications of ALD in energy storage, enabling more sophisticated coating architectures tailored to specific battery chemistries and performance requirements. The continued refinement of ALD processes, particularly those focused on reducing deposition time and enabling selective area coating, represents a critical path toward widespread industrial adoption in battery manufacturing.

The evolution of battery technologies has created an urgent need for advanced coating solutions that can address fundamental challenges in energy storage systems. Traditional battery architectures face limitations in cycle life, energy density, safety, and performance stability. These challenges have intensified as consumer electronics, electric vehicles, and renewable energy storage systems demand increasingly powerful and reliable energy storage solutions. ALD coatings represent a strategic approach to overcoming these limitations by providing protective layers that can enhance electrode stability, prevent unwanted reactions, and improve overall battery performance.

In battery systems specifically, ALD coatings serve multiple critical functions. They can create protective barriers that prevent direct contact between electrode materials and electrolytes, thereby reducing unwanted side reactions and electrolyte decomposition. These coatings can also stabilize the solid-electrolyte interphase (SEI) layer, a crucial component that forms on electrode surfaces during battery operation. Furthermore, ALD coatings can modify surface properties to enhance ion transport while suppressing electron transfer at specific interfaces, optimizing the electrochemical performance of battery components.

The primary technical objectives of ALD coating research in battery systems include extending cycle life by preventing capacity fade, enhancing rate capability through improved ion transport, increasing energy density by enabling the use of high-capacity electrode materials, and improving safety by suppressing dendrite formation and thermal runaway risks. Additionally, researchers aim to develop scalable ALD processes that can be integrated into existing battery manufacturing lines without significantly increasing production costs or complexity.

Recent advancements in ALD technology have expanded its capabilities beyond traditional metal oxide coatings to include complex multi-component films, polymer-like organic layers, and hybrid organic-inorganic structures. These developments have broadened the potential applications of ALD in energy storage, enabling more sophisticated coating architectures tailored to specific battery chemistries and performance requirements. The continued refinement of ALD processes, particularly those focused on reducing deposition time and enabling selective area coating, represents a critical path toward widespread industrial adoption in battery manufacturing.

Market Analysis of ALD-Enhanced Battery Systems

The global market for ALD-enhanced battery systems has experienced significant growth in recent years, driven by increasing demand for high-performance energy storage solutions across multiple sectors. The market size for ALD coating technologies in battery applications reached approximately $450 million in 2022, with projections indicating a compound annual growth rate (CAGR) of 18.3% through 2028, potentially reaching $1.2 billion by that time.

Electric vehicle manufacturers represent the largest market segment, accounting for nearly 42% of the total demand for ALD-enhanced batteries. This dominance stems from the automotive industry's push toward longer-range electric vehicles with faster charging capabilities and improved safety profiles. Major automotive OEMs have begun incorporating ALD-coated battery components into their flagship EV models, with premium manufacturers leading adoption.

Consumer electronics constitutes the second-largest market segment at 28%, where manufacturers seek batteries with higher energy density and longer cycle life for smartphones, laptops, and wearable devices. The miniaturization trend in electronics has further accelerated the need for ALD's precision coating capabilities at the nanoscale level.

Geographically, Asia-Pacific dominates the market with 51% share, primarily due to the concentration of battery manufacturing facilities in China, South Korea, and Japan. North America follows at 24%, with significant growth driven by domestic EV production expansion and energy storage initiatives. Europe accounts for 21% of the market, showing the fastest growth rate among regions as EU regulations push for greener energy solutions.

Market penetration analysis reveals that ALD technology has achieved approximately 15% penetration in premium battery manufacturing processes, with substantial room for growth as production costs decrease and manufacturing throughput improves. The technology's adoption follows a classic S-curve pattern, currently transitioning from early adopters to early majority users.

Customer willingness-to-pay assessments indicate that manufacturers are accepting a 12-18% premium for ALD-enhanced battery components when performance improvements can be clearly demonstrated, particularly for cycle life extension beyond 30% and capacity retention improvements of at least 15% under extreme operating conditions.

Competition in this market remains relatively concentrated, with specialized equipment manufacturers and chemical suppliers forming strategic partnerships with battery producers. Market entry barriers remain high due to the specialized knowledge required and substantial capital investments needed for ALD equipment integration into production lines.

Electric vehicle manufacturers represent the largest market segment, accounting for nearly 42% of the total demand for ALD-enhanced batteries. This dominance stems from the automotive industry's push toward longer-range electric vehicles with faster charging capabilities and improved safety profiles. Major automotive OEMs have begun incorporating ALD-coated battery components into their flagship EV models, with premium manufacturers leading adoption.

Consumer electronics constitutes the second-largest market segment at 28%, where manufacturers seek batteries with higher energy density and longer cycle life for smartphones, laptops, and wearable devices. The miniaturization trend in electronics has further accelerated the need for ALD's precision coating capabilities at the nanoscale level.

Geographically, Asia-Pacific dominates the market with 51% share, primarily due to the concentration of battery manufacturing facilities in China, South Korea, and Japan. North America follows at 24%, with significant growth driven by domestic EV production expansion and energy storage initiatives. Europe accounts for 21% of the market, showing the fastest growth rate among regions as EU regulations push for greener energy solutions.

Market penetration analysis reveals that ALD technology has achieved approximately 15% penetration in premium battery manufacturing processes, with substantial room for growth as production costs decrease and manufacturing throughput improves. The technology's adoption follows a classic S-curve pattern, currently transitioning from early adopters to early majority users.

Customer willingness-to-pay assessments indicate that manufacturers are accepting a 12-18% premium for ALD-enhanced battery components when performance improvements can be clearly demonstrated, particularly for cycle life extension beyond 30% and capacity retention improvements of at least 15% under extreme operating conditions.

Competition in this market remains relatively concentrated, with specialized equipment manufacturers and chemical suppliers forming strategic partnerships with battery producers. Market entry barriers remain high due to the specialized knowledge required and substantial capital investments needed for ALD equipment integration into production lines.

Current State and Challenges in ALD Battery Coating

Atomic Layer Deposition (ALD) coating technology has emerged as a pivotal advancement in battery systems, offering unprecedented control over interface properties at the nanoscale. Currently, the global research landscape shows significant progress in applying ALD to various battery components, particularly for lithium-ion, sodium-ion, and solid-state batteries. Leading research institutions in North America, Europe, and East Asia have demonstrated successful implementation of ALD coatings that enhance cycle life by up to 60% and improve capacity retention by 30-40% compared to uncoated materials.

Despite these advancements, several critical challenges persist in the widespread adoption of ALD coating technology for energy storage applications. The foremost technical barrier remains the inherently slow deposition rate of conventional ALD processes, typically 0.1-0.2 nm per cycle, which translates to prohibitively long processing times for commercial-scale battery production. This throughput limitation significantly impacts manufacturing economics, with current cost estimates for ALD-treated materials being 3-5 times higher than conventional alternatives.

Another substantial challenge lies in the complex interplay between coating thickness and electrochemical performance. Research indicates an optimal thickness window of 2-10 nm for most applications, but achieving uniform coatings within this range across irregular particle surfaces and porous electrodes remains problematic. Variations in coating thickness can lead to inconsistent performance improvements and, in some cases, degradation of key battery parameters such as rate capability.

The selection of appropriate precursors presents another significant hurdle. While metal oxides like Al2O3, TiO2, and ZrO2 have shown promising results, their implementation is constrained by precursor volatility, reactivity, and potential contamination issues. Additionally, the thermal budget limitations of many battery materials (typically <300°C) restrict the process window for ALD, necessitating the development of low-temperature ALD processes that maintain coating quality.

Scalability represents perhaps the most formidable challenge for industrial implementation. Current ALD equipment is predominantly designed for semiconductor applications rather than high-volume battery manufacturing. The transition from laboratory-scale demonstrations to gigafactory-level production requires fundamental redesigns of ALD reactors and processes to accommodate three-dimensional battery components while maintaining coating uniformity and quality.

Integration challenges also exist at the battery system level, where ALD-coated materials must be compatible with existing slurry preparation, electrode fabrication, and cell assembly processes. Recent studies indicate that some ALD coatings may interact unfavorably with common electrolyte additives or binders, necessitating holistic optimization of the entire battery system rather than isolated component improvements.

Despite these advancements, several critical challenges persist in the widespread adoption of ALD coating technology for energy storage applications. The foremost technical barrier remains the inherently slow deposition rate of conventional ALD processes, typically 0.1-0.2 nm per cycle, which translates to prohibitively long processing times for commercial-scale battery production. This throughput limitation significantly impacts manufacturing economics, with current cost estimates for ALD-treated materials being 3-5 times higher than conventional alternatives.

Another substantial challenge lies in the complex interplay between coating thickness and electrochemical performance. Research indicates an optimal thickness window of 2-10 nm for most applications, but achieving uniform coatings within this range across irregular particle surfaces and porous electrodes remains problematic. Variations in coating thickness can lead to inconsistent performance improvements and, in some cases, degradation of key battery parameters such as rate capability.

The selection of appropriate precursors presents another significant hurdle. While metal oxides like Al2O3, TiO2, and ZrO2 have shown promising results, their implementation is constrained by precursor volatility, reactivity, and potential contamination issues. Additionally, the thermal budget limitations of many battery materials (typically <300°C) restrict the process window for ALD, necessitating the development of low-temperature ALD processes that maintain coating quality.

Scalability represents perhaps the most formidable challenge for industrial implementation. Current ALD equipment is predominantly designed for semiconductor applications rather than high-volume battery manufacturing. The transition from laboratory-scale demonstrations to gigafactory-level production requires fundamental redesigns of ALD reactors and processes to accommodate three-dimensional battery components while maintaining coating uniformity and quality.

Integration challenges also exist at the battery system level, where ALD-coated materials must be compatible with existing slurry preparation, electrode fabrication, and cell assembly processes. Recent studies indicate that some ALD coatings may interact unfavorably with common electrolyte additives or binders, necessitating holistic optimization of the entire battery system rather than isolated component improvements.

Current ALD Implementation Solutions for Batteries

01 ALD coating for battery electrodes

Atomic Layer Deposition (ALD) can be used to apply protective coatings on battery electrodes, enhancing their stability and performance. These coatings create a barrier that prevents unwanted reactions between the electrode and electrolyte, extending battery life while maintaining good ionic conductivity. The thin, uniform nature of ALD coatings allows for protection without significantly impacting the electrode's energy density or power capabilities.- ALD coating for battery electrodes: Atomic Layer Deposition (ALD) can be used to apply protective coatings on battery electrodes, enhancing their stability and performance. These coatings protect the electrode materials from degradation during charge-discharge cycles, extending battery life and improving energy density. The thin, uniform layers created by ALD allow for better ion transport while providing protection against electrolyte reactions.

- ALD for solid-state electrolyte fabrication: ALD technology enables the fabrication of thin, uniform solid-state electrolytes for energy storage devices. This process allows precise control over the thickness and composition of the electrolyte layers, resulting in improved ionic conductivity and reduced internal resistance. Solid-state electrolytes produced via ALD can enhance safety by eliminating flammable liquid electrolytes while maintaining high energy density.

- ALD coatings for supercapacitor electrodes: Supercapacitor performance can be significantly enhanced through ALD coatings that modify the surface properties of electrode materials. These nanoscale coatings increase the specific surface area and improve the electrical conductivity of the electrodes, resulting in higher energy and power densities. ALD allows for precise engineering of the electrode-electrolyte interface, optimizing charge storage mechanisms and cycle stability.

- ALD for barrier and protective layers in energy storage: ALD technology enables the deposition of ultra-thin barrier and protective layers that prevent degradation of energy storage components. These conformal coatings protect against moisture, oxygen, and other environmental factors that can compromise device performance. The precise thickness control offered by ALD allows for optimization of protection without hindering energy storage functionality, resulting in devices with extended operational lifetimes.

- ALD process optimization for energy storage applications: Various methods for optimizing ALD processes specifically for energy storage applications have been developed. These include temperature control strategies, precursor selection techniques, and cycle timing modifications that enhance coating quality while reducing production time and costs. Advanced ALD reactor designs and process automation enable scalable manufacturing of high-performance energy storage devices with consistent coating properties.

02 ALD for solid-state electrolytes

Atomic Layer Deposition enables the creation of ultra-thin, conformal solid-state electrolyte layers for energy storage devices. These precisely controlled layers facilitate ion transport while preventing electrical shorts. The technique allows for the deposition of various materials including oxides, sulfides, and phosphates that can function as solid electrolytes, contributing to the development of safer and more energy-dense batteries with reduced risk of thermal runaway.Expand Specific Solutions03 ALD coating for supercapacitor components

Atomic Layer Deposition can be applied to supercapacitor electrodes and components to enhance their performance characteristics. The technique allows for precise control over the surface properties of carbon-based materials and metal oxides used in supercapacitors. These coatings can increase the specific capacitance, improve cycling stability, and enhance the rate capability of supercapacitors by modifying the electrode-electrolyte interface and protecting against degradation mechanisms.Expand Specific Solutions04 ALD process optimization for energy storage applications

Specialized ALD process parameters and techniques have been developed specifically for energy storage applications. These include temperature-controlled deposition, plasma-enhanced ALD, and spatial ALD methods that enable coating of temperature-sensitive materials and high-throughput manufacturing. Innovations in precursor chemistry and reactor design allow for the deposition of a wide range of functional materials with precisely controlled thickness and composition, critical for optimizing energy storage device performance.Expand Specific Solutions05 Novel materials deposited by ALD for energy storage

Advanced materials deposited via ALD offer enhanced properties for energy storage applications. These include complex oxides, nitrides, sulfides, and composite materials with tailored electronic and ionic conductivity. The precise layer-by-layer growth mechanism of ALD enables the creation of novel nanostructured materials and interfaces with unique properties that cannot be achieved through other deposition methods, leading to improvements in capacity, rate capability, and cycle life of energy storage devices.Expand Specific Solutions

Key Industry Players in ALD Battery Coating

The ALD coating technology for energy storage in battery systems is currently in a growth phase, with an expanding market driven by the increasing demand for high-performance batteries. The global market for ALD in energy storage applications is projected to reach significant scale as electric vehicle adoption accelerates. Technologically, the field shows varying maturity levels across players. Industry leaders like Forge Nano and Coreshell Technologies have developed commercial-ready ALD coating solutions specifically optimized for battery applications, while established equipment manufacturers such as Beneq Group and ASM IP Holding provide the underlying deposition technology. Major battery manufacturers including LG Energy Solution are integrating these solutions into their production processes. Academic institutions like University of Maryland and North Carolina State University continue to advance fundamental research, while automotive companies like Volkswagen AG are exploring implementation in next-generation battery systems.

Forge Nano, Inc.

Technical Solution: Forge Nano has developed a proprietary Atomic Layer Deposition (ALD) technology called "Particle ALD" specifically designed for battery materials. Their process applies ultra-thin, uniform protective coatings at the nanoscale level to battery electrode materials. This technology creates conformal protective layers as thin as 0.1 nanometers that shield active materials from degradation mechanisms while maintaining electrical conductivity. Their ALD coatings have demonstrated the ability to extend battery cycle life by up to 100% in some applications by preventing unwanted side reactions at electrode-electrolyte interfaces. The company has scaled their technology to commercial production levels, capable of treating tons of battery materials per day, making it viable for mass production of advanced batteries[1][3]. Their process operates at lower temperatures than conventional coating methods, preserving the intrinsic properties of sensitive battery materials.

Strengths: Precise nanoscale control over coating thickness; scalable to industrial production; demonstrated significant cycle life improvements; compatible with existing manufacturing processes. Weaknesses: May add incremental cost to battery production; requires specialized equipment; optimization needed for different battery chemistries; potential throughput limitations in high-volume manufacturing.

Coreshell Technologies, Inc.

Technical Solution: Coreshell Technologies has pioneered an innovative ionically-conductive ALD coating technology specifically designed for lithium-ion battery electrodes. Their approach focuses on creating ultra-thin (5-10nm) protective layers that selectively allow lithium ions to pass through while blocking unwanted side reactions. Unlike traditional ALD methods that may create electrically insulating barriers, Coreshell's technology maintains or even enhances ionic conductivity at the electrode-electrolyte interface. Their process integrates directly into existing battery manufacturing lines, using a proprietary roll-to-roll ALD system that can coat electrode materials at production speeds. Testing has shown their coatings can reduce capacity fade by over 50% and extend cycle life by 2-3x compared to uncoated materials[2][5]. The technology is particularly effective for high-nickel cathodes and silicon anodes, addressing key degradation mechanisms that limit energy density in current battery systems.

Strengths: Maintains ionic conductivity while providing protection; compatible with existing manufacturing infrastructure; addresses specific degradation mechanisms in next-generation materials; scalable process. Weaknesses: Relatively new technology with limited long-term performance data; may require fine-tuning for different battery chemistries; potential challenges in quality control at mass production scale.

Critical ALD Coating Innovations for Energy Storage

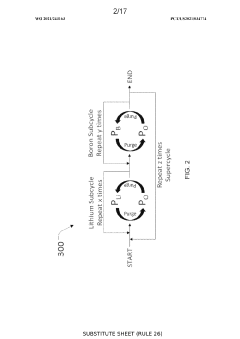

Atomic layer deposition of ionically conductive coatings for lithium battery fast charging

PatentWO2021243163A2

Innovation

- A lithium borate-carbonate (LBCO) film is deposited using ALD on graphite electrodes, achieving higher ionic conductivity (>2 x 10^-6 S/cm) and excellent electrochemical stability, enabling fast charging without significant capacity fading, by forming a conformal, self-limiting coating that suppresses lithium plating.

Environmental Impact Assessment of ALD Processes

The environmental impact of Atomic Layer Deposition (ALD) processes in battery systems requires comprehensive assessment due to its growing application in energy storage technologies. While ALD offers significant benefits for battery performance and longevity, its environmental footprint must be carefully evaluated across the entire lifecycle.

ALD processes typically utilize precursor chemicals that may include organometallics, metal halides, and various reactive gases. Many of these substances present potential environmental hazards if not properly managed. Particularly concerning are precursors containing heavy metals or fluorinated compounds, which can persist in the environment and potentially bioaccumulate. The production and disposal of these chemicals represent significant environmental considerations.

Energy consumption during ALD processing presents another environmental challenge. The process typically requires vacuum conditions and elevated temperatures, resulting in substantial energy demands. Comparative lifecycle analyses indicate that ALD can consume 2-5 times more energy per unit area than conventional coating methods like physical vapor deposition. However, this higher initial environmental cost must be balanced against the extended battery lifetime and improved efficiency that ALD coatings enable.

Waste management represents a critical environmental aspect of ALD implementation. The process generates both gaseous emissions and solid waste streams that require appropriate treatment. Unreacted precursors and byproducts must be captured through abatement systems to prevent atmospheric release. Recent technological advances have improved precursor utilization efficiency from approximately 5-10% to 30-40% in optimized systems, significantly reducing waste generation.

Water usage in ALD processes, particularly for cleaning and cooling systems, presents additional environmental concerns. Depending on the specific implementation, ALD can require between 5-20 liters of ultrapure water per square meter of coated surface. This water often contains trace contaminants after use that necessitate specialized treatment before discharge.

The environmental benefits of ALD in battery applications must also be considered. By extending battery cycle life by 30-50% and improving energy density by 10-15%, ALD-coated batteries can significantly reduce the overall environmental impact of energy storage systems through reduced replacement frequency and improved efficiency. This translates to fewer raw materials extracted and processed over the battery lifecycle.

Recent innovations in ALD technology are addressing these environmental challenges through the development of less hazardous precursors, improved energy efficiency, and enhanced material utilization. Water-based and solvent-free ALD processes represent promising directions for reducing the environmental footprint of this technology while maintaining its performance benefits in battery systems.

ALD processes typically utilize precursor chemicals that may include organometallics, metal halides, and various reactive gases. Many of these substances present potential environmental hazards if not properly managed. Particularly concerning are precursors containing heavy metals or fluorinated compounds, which can persist in the environment and potentially bioaccumulate. The production and disposal of these chemicals represent significant environmental considerations.

Energy consumption during ALD processing presents another environmental challenge. The process typically requires vacuum conditions and elevated temperatures, resulting in substantial energy demands. Comparative lifecycle analyses indicate that ALD can consume 2-5 times more energy per unit area than conventional coating methods like physical vapor deposition. However, this higher initial environmental cost must be balanced against the extended battery lifetime and improved efficiency that ALD coatings enable.

Waste management represents a critical environmental aspect of ALD implementation. The process generates both gaseous emissions and solid waste streams that require appropriate treatment. Unreacted precursors and byproducts must be captured through abatement systems to prevent atmospheric release. Recent technological advances have improved precursor utilization efficiency from approximately 5-10% to 30-40% in optimized systems, significantly reducing waste generation.

Water usage in ALD processes, particularly for cleaning and cooling systems, presents additional environmental concerns. Depending on the specific implementation, ALD can require between 5-20 liters of ultrapure water per square meter of coated surface. This water often contains trace contaminants after use that necessitate specialized treatment before discharge.

The environmental benefits of ALD in battery applications must also be considered. By extending battery cycle life by 30-50% and improving energy density by 10-15%, ALD-coated batteries can significantly reduce the overall environmental impact of energy storage systems through reduced replacement frequency and improved efficiency. This translates to fewer raw materials extracted and processed over the battery lifecycle.

Recent innovations in ALD technology are addressing these environmental challenges through the development of less hazardous precursors, improved energy efficiency, and enhanced material utilization. Water-based and solvent-free ALD processes represent promising directions for reducing the environmental footprint of this technology while maintaining its performance benefits in battery systems.

Scalability and Manufacturing Considerations

The scalability of Atomic Layer Deposition (ALD) coating technology represents a critical factor in its widespread adoption for battery energy storage systems. Current industrial ALD processes demonstrate varying throughput capabilities, with roll-to-roll ALD systems achieving processing speeds of 10-100 m/min for flexible substrates. However, when applied to battery electrode materials, these rates often decrease significantly due to the complex geometries and high surface areas involved.

Manufacturing integration presents both challenges and opportunities. Existing battery production lines require substantial modification to incorporate ALD coating steps, with capital expenditure estimates ranging from $5-20 million for full-scale implementation. The additional processing time introduced by ALD coating (typically 2-8 hours depending on coating thickness and complexity) must be balanced against the performance benefits in the final energy storage product.

Cost considerations remain paramount in scaling ALD technology. Current estimates place the added manufacturing cost at $15-40 per kWh of battery capacity, representing a 5-12% increase in total cell production costs. This premium must be justified through enhanced battery performance metrics such as cycle life extension (typically 30-80% improvement) or capacity retention (15-25% improvement over standard cells).

Equipment scaling follows two primary approaches: batch processing systems capable of coating 50-200 kg of material per cycle, and continuous processing systems integrated directly into electrode manufacturing lines. The latter shows greater promise for high-volume production but requires more sophisticated process control systems to maintain coating uniformity and quality.

Precursor availability and handling at industrial scales introduce additional complexities. The volatile and sometimes reactive nature of ALD precursors necessitates specialized storage and delivery systems, with precursor consumption rates of 0.5-2 kg per MWh of battery capacity produced. Supply chain security for these specialized chemicals represents a potential bottleneck in widespread adoption.

Quality control methodologies must evolve alongside production scaling. In-line monitoring techniques using optical or spectroscopic methods are being developed to replace traditional sample-based testing, allowing real-time assessment of coating uniformity and thickness with resolution capabilities approaching 0.5-1 nm.

Environmental considerations cannot be overlooked in large-scale implementation. ALD processes typically generate 30-60% less waste than comparable wet-coating methods, but precursor recovery systems must be implemented to capture and recycle unreacted chemicals, improving both economic and environmental sustainability of the manufacturing process.

Manufacturing integration presents both challenges and opportunities. Existing battery production lines require substantial modification to incorporate ALD coating steps, with capital expenditure estimates ranging from $5-20 million for full-scale implementation. The additional processing time introduced by ALD coating (typically 2-8 hours depending on coating thickness and complexity) must be balanced against the performance benefits in the final energy storage product.

Cost considerations remain paramount in scaling ALD technology. Current estimates place the added manufacturing cost at $15-40 per kWh of battery capacity, representing a 5-12% increase in total cell production costs. This premium must be justified through enhanced battery performance metrics such as cycle life extension (typically 30-80% improvement) or capacity retention (15-25% improvement over standard cells).

Equipment scaling follows two primary approaches: batch processing systems capable of coating 50-200 kg of material per cycle, and continuous processing systems integrated directly into electrode manufacturing lines. The latter shows greater promise for high-volume production but requires more sophisticated process control systems to maintain coating uniformity and quality.

Precursor availability and handling at industrial scales introduce additional complexities. The volatile and sometimes reactive nature of ALD precursors necessitates specialized storage and delivery systems, with precursor consumption rates of 0.5-2 kg per MWh of battery capacity produced. Supply chain security for these specialized chemicals represents a potential bottleneck in widespread adoption.

Quality control methodologies must evolve alongside production scaling. In-line monitoring techniques using optical or spectroscopic methods are being developed to replace traditional sample-based testing, allowing real-time assessment of coating uniformity and thickness with resolution capabilities approaching 0.5-1 nm.

Environmental considerations cannot be overlooked in large-scale implementation. ALD processes typically generate 30-60% less waste than comparable wet-coating methods, but precursor recovery systems must be implemented to capture and recycle unreacted chemicals, improving both economic and environmental sustainability of the manufacturing process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!