The Benefits of ALD Coating for Anti-Reflection Applications in Optics

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ALD Anti-Reflection Technology Background and Objectives

Atomic Layer Deposition (ALD) technology has evolved significantly since its inception in the 1970s, transitioning from a niche research technique to a mainstream industrial process. The development trajectory of ALD has been particularly remarkable in optical applications, where precise control of film thickness at the nanometer scale has become increasingly critical. The technology's ability to create uniform, conformal coatings on complex geometries has positioned it as a revolutionary approach for anti-reflection (AR) applications in optics.

The evolution of ALD for optical applications has been driven by growing demands in consumer electronics, precision optics, and photovoltaics industries. Traditional coating methods such as Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) have shown limitations in achieving the uniformity and precision required for next-generation optical devices. ALD emerged as a solution by offering atomic-level control over film thickness and composition, enabling the creation of sophisticated multi-layer structures with tailored optical properties.

The primary technical objective for ALD anti-reflection coatings is to minimize reflection losses across specified wavelength ranges while maintaining excellent durability and environmental stability. This involves developing precise deposition protocols for creating multi-layer structures with carefully controlled refractive indices and thicknesses. The technology aims to achieve reflection reduction from the ultraviolet through visible to infrared wavelengths, depending on the application requirements.

Current technical goals include expanding the material palette available for ALD anti-reflection coatings, reducing deposition temperatures to accommodate temperature-sensitive substrates, and increasing throughput to make the technology more economically viable for mass production. Research is also focused on developing gradient-index coatings that can provide superior anti-reflection properties compared to traditional discrete multi-layer designs.

The trend toward miniaturization in optoelectronics and the increasing complexity of optical systems have created new challenges that ALD is uniquely positioned to address. As devices incorporate more sophisticated optical components in smaller form factors, the need for precise, conformal coatings becomes paramount. Additionally, emerging applications in augmented reality, autonomous vehicles, and advanced sensing systems are driving innovation in anti-reflection technologies.

Looking forward, ALD anti-reflection technology is expected to continue its trajectory of refinement and expansion, with particular emphasis on process optimization, new material development, and integration with other manufacturing techniques. The ultimate goal remains creating optical coatings that maximize light transmission while providing exceptional durability and performance across diverse operating conditions.

The evolution of ALD for optical applications has been driven by growing demands in consumer electronics, precision optics, and photovoltaics industries. Traditional coating methods such as Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) have shown limitations in achieving the uniformity and precision required for next-generation optical devices. ALD emerged as a solution by offering atomic-level control over film thickness and composition, enabling the creation of sophisticated multi-layer structures with tailored optical properties.

The primary technical objective for ALD anti-reflection coatings is to minimize reflection losses across specified wavelength ranges while maintaining excellent durability and environmental stability. This involves developing precise deposition protocols for creating multi-layer structures with carefully controlled refractive indices and thicknesses. The technology aims to achieve reflection reduction from the ultraviolet through visible to infrared wavelengths, depending on the application requirements.

Current technical goals include expanding the material palette available for ALD anti-reflection coatings, reducing deposition temperatures to accommodate temperature-sensitive substrates, and increasing throughput to make the technology more economically viable for mass production. Research is also focused on developing gradient-index coatings that can provide superior anti-reflection properties compared to traditional discrete multi-layer designs.

The trend toward miniaturization in optoelectronics and the increasing complexity of optical systems have created new challenges that ALD is uniquely positioned to address. As devices incorporate more sophisticated optical components in smaller form factors, the need for precise, conformal coatings becomes paramount. Additionally, emerging applications in augmented reality, autonomous vehicles, and advanced sensing systems are driving innovation in anti-reflection technologies.

Looking forward, ALD anti-reflection technology is expected to continue its trajectory of refinement and expansion, with particular emphasis on process optimization, new material development, and integration with other manufacturing techniques. The ultimate goal remains creating optical coatings that maximize light transmission while providing exceptional durability and performance across diverse operating conditions.

Market Analysis for ALD Anti-Reflection Optical Coatings

The global market for ALD anti-reflection optical coatings is experiencing robust growth, driven by increasing demand across multiple industries. The optical coatings market was valued at approximately $13.7 billion in 2022 and is projected to reach $22.4 billion by 2028, with anti-reflection coatings representing a significant segment of this market. ALD-based anti-reflection coatings specifically are growing at a compound annual growth rate of 12.3%, outpacing traditional coating technologies.

Consumer electronics represents the largest application segment, accounting for nearly 38% of the market share. The proliferation of smartphones, tablets, and wearable devices with high-quality displays has created substantial demand for advanced anti-reflection solutions that enhance visual clarity while reducing power consumption. Apple and Samsung have been particularly aggressive in adopting ALD coatings for their premium device displays.

The optical instrumentation sector follows closely, with 27% market share, where precision optics for scientific research, medical diagnostics, and industrial measurement systems benefit significantly from the superior uniformity and precision thickness control offered by ALD coatings. This segment is expected to grow at 14.2% annually through 2027.

Automotive applications are emerging as a rapidly expanding market, particularly with the integration of advanced driver-assistance systems (ADAS) and heads-up displays, which require high-performance optical components. This segment currently represents 15% of the market but is growing at 18.7% annually.

Regionally, Asia-Pacific dominates the market with 42% share, driven by the concentration of electronics manufacturing and display production facilities. North America and Europe follow with 28% and 23% respectively, with particular strength in high-value applications such as aerospace, defense, and medical devices.

Customer requirements are increasingly focused on multifunctional coatings that combine anti-reflection properties with additional benefits such as scratch resistance, hydrophobicity, and antimicrobial properties. This trend is creating premium pricing opportunities for advanced ALD solutions that can deliver these combined benefits.

The competitive landscape features established players like Applied Materials, Beneq, and Veeco Instruments dominating the equipment market, while specialized coating service providers like Materion and Optorun are expanding their ALD capabilities. Recent market consolidation has been evident, with several acquisitions aimed at integrating ALD expertise into broader optical manufacturing capabilities.

Consumer electronics represents the largest application segment, accounting for nearly 38% of the market share. The proliferation of smartphones, tablets, and wearable devices with high-quality displays has created substantial demand for advanced anti-reflection solutions that enhance visual clarity while reducing power consumption. Apple and Samsung have been particularly aggressive in adopting ALD coatings for their premium device displays.

The optical instrumentation sector follows closely, with 27% market share, where precision optics for scientific research, medical diagnostics, and industrial measurement systems benefit significantly from the superior uniformity and precision thickness control offered by ALD coatings. This segment is expected to grow at 14.2% annually through 2027.

Automotive applications are emerging as a rapidly expanding market, particularly with the integration of advanced driver-assistance systems (ADAS) and heads-up displays, which require high-performance optical components. This segment currently represents 15% of the market but is growing at 18.7% annually.

Regionally, Asia-Pacific dominates the market with 42% share, driven by the concentration of electronics manufacturing and display production facilities. North America and Europe follow with 28% and 23% respectively, with particular strength in high-value applications such as aerospace, defense, and medical devices.

Customer requirements are increasingly focused on multifunctional coatings that combine anti-reflection properties with additional benefits such as scratch resistance, hydrophobicity, and antimicrobial properties. This trend is creating premium pricing opportunities for advanced ALD solutions that can deliver these combined benefits.

The competitive landscape features established players like Applied Materials, Beneq, and Veeco Instruments dominating the equipment market, while specialized coating service providers like Materion and Optorun are expanding their ALD capabilities. Recent market consolidation has been evident, with several acquisitions aimed at integrating ALD expertise into broader optical manufacturing capabilities.

Current ALD Technology Challenges in Optical Applications

Despite significant advancements in Atomic Layer Deposition (ALD) technology for anti-reflection applications in optics, several technical challenges persist that limit its widespread industrial adoption. The precise control of film thickness at the nanometer scale remains problematic, particularly when coating complex three-dimensional optical components with high aspect ratios. Current ALD systems struggle to maintain uniform deposition across intricate geometries, resulting in thickness variations that compromise optical performance.

Processing time presents another significant hurdle for commercial implementation. The inherently slow deposition rate of ALD (typically 0.1-0.2 nm per cycle) makes the technology time-consuming for applications requiring thicker films. This slow throughput directly impacts production costs and scalability, especially when compared to competing technologies like physical vapor deposition (PVD) or chemical vapor deposition (CVD).

Precursor chemistry limitations also constrain ALD's application in anti-reflection coatings. The ideal precursors should be highly reactive with surface sites, thermally stable during delivery, and produce non-corrosive, non-toxic byproducts. However, many available precursors fail to meet all these criteria simultaneously. For certain optical materials, suitable precursors either don't exist or have problematic characteristics such as low vapor pressure, decomposition issues, or particle generation that can introduce defects in the optical coating.

Temperature sensitivity represents another technical challenge. Many optical substrates (particularly polymers) cannot withstand the elevated temperatures often required for conventional ALD processes (typically 100-300°C). While low-temperature ALD processes exist, they frequently result in compromised film quality, reduced growth rates, and increased impurity incorporation, all of which can degrade optical performance.

The integration of ALD into existing manufacturing workflows poses additional difficulties. Current optical manufacturing facilities are typically designed around conventional coating technologies, and retrofitting for ALD processes requires significant capital investment and process reengineering. The lack of standardized equipment configurations and process parameters across different manufacturers further complicates industrial adoption.

Cost considerations remain a persistent barrier to widespread implementation. The high initial investment for ALD equipment, combined with relatively low throughput and expensive precursor materials, results in a higher cost-per-coated component compared to traditional methods. This economic disadvantage is particularly pronounced for high-volume, cost-sensitive optical applications where marginal improvements in performance may not justify the additional expense.

Processing time presents another significant hurdle for commercial implementation. The inherently slow deposition rate of ALD (typically 0.1-0.2 nm per cycle) makes the technology time-consuming for applications requiring thicker films. This slow throughput directly impacts production costs and scalability, especially when compared to competing technologies like physical vapor deposition (PVD) or chemical vapor deposition (CVD).

Precursor chemistry limitations also constrain ALD's application in anti-reflection coatings. The ideal precursors should be highly reactive with surface sites, thermally stable during delivery, and produce non-corrosive, non-toxic byproducts. However, many available precursors fail to meet all these criteria simultaneously. For certain optical materials, suitable precursors either don't exist or have problematic characteristics such as low vapor pressure, decomposition issues, or particle generation that can introduce defects in the optical coating.

Temperature sensitivity represents another technical challenge. Many optical substrates (particularly polymers) cannot withstand the elevated temperatures often required for conventional ALD processes (typically 100-300°C). While low-temperature ALD processes exist, they frequently result in compromised film quality, reduced growth rates, and increased impurity incorporation, all of which can degrade optical performance.

The integration of ALD into existing manufacturing workflows poses additional difficulties. Current optical manufacturing facilities are typically designed around conventional coating technologies, and retrofitting for ALD processes requires significant capital investment and process reengineering. The lack of standardized equipment configurations and process parameters across different manufacturers further complicates industrial adoption.

Cost considerations remain a persistent barrier to widespread implementation. The high initial investment for ALD equipment, combined with relatively low throughput and expensive precursor materials, results in a higher cost-per-coated component compared to traditional methods. This economic disadvantage is particularly pronounced for high-volume, cost-sensitive optical applications where marginal improvements in performance may not justify the additional expense.

Current ALD Anti-Reflection Implementation Solutions

01 ALD deposition of anti-reflective coatings on optical surfaces

Atomic Layer Deposition (ALD) can be used to create precise anti-reflective coatings on optical surfaces such as lenses, displays, and windows. The ALD process allows for the deposition of ultra-thin, uniform layers with excellent thickness control at the nanometer scale, which is critical for achieving optimal anti-reflective properties. These coatings typically consist of alternating high and low refractive index materials to create interference effects that minimize reflection across desired wavelength ranges.- ALD deposition of anti-reflective coatings: Atomic Layer Deposition (ALD) is used to create precise anti-reflective coatings with controlled thickness and composition. This technique allows for the deposition of ultra-thin films with excellent uniformity and conformality on various substrates. The ALD process involves sequential self-limiting reactions that enable atomic-level control of film growth, resulting in high-quality anti-reflective coatings with enhanced optical properties.

- Multi-layer anti-reflective structures using ALD: Multi-layer anti-reflective structures can be fabricated using ALD technology to achieve superior optical performance. These structures typically consist of alternating high and low refractive index materials deposited with precise thickness control. By carefully designing the layer sequence and thickness, broadband anti-reflection properties can be achieved across desired wavelength ranges. The multi-layer approach allows for customization of optical properties for specific applications.

- ALD-deposited materials for anti-reflective applications: Various materials can be deposited via ALD for anti-reflective applications, including metal oxides (such as Al2O3, TiO2, SiO2, ZnO), nitrides, and mixed compounds. The selection of materials is based on their refractive indices, transparency, and compatibility with the substrate. ALD enables precise control over material composition and allows for the creation of gradient-index layers or nanocomposites with tailored optical properties for enhanced anti-reflection performance.

- ALD process parameters for optimized anti-reflective coatings: Optimization of ALD process parameters is crucial for achieving high-quality anti-reflective coatings. Key parameters include deposition temperature, precursor selection, pulse and purge times, and reactor pressure. These parameters affect film growth rate, density, crystallinity, and optical properties. By carefully controlling these variables, anti-reflective coatings with minimal defects, high transparency, and precise refractive index can be produced for various optical applications.

- Applications of ALD anti-reflective coatings: ALD-deposited anti-reflective coatings find applications in various optical and electronic devices. These include solar cells (improving light absorption and efficiency), displays (reducing glare and enhancing visibility), optical lenses (improving light transmission), sensors, and semiconductor devices. The precise thickness control and excellent conformality of ALD make it particularly suitable for coating complex geometries and nanostructured surfaces, enabling advanced optical designs with enhanced anti-reflection properties.

02 Multi-layer ALD structures for enhanced anti-reflection performance

Multi-layer structures deposited via ALD can significantly enhance anti-reflection performance by creating gradient refractive index profiles or specific interference patterns. These structures typically consist of alternating layers of materials with different refractive indices, such as Al2O3, TiO2, SiO2, and ZnO. By precisely controlling the thickness and composition of each layer, the anti-reflective coating can be optimized for specific wavelength ranges or incident angles, achieving reflection reduction across the visible spectrum or for specialized applications like solar cells or optical instruments.Expand Specific Solutions03 ALD process parameters for anti-reflective coating optimization

Specific ALD process parameters significantly impact the quality and performance of anti-reflective coatings. Key parameters include deposition temperature, precursor selection, pulse/purge durations, and chamber pressure. Optimizing these parameters allows for precise control over film density, refractive index, and surface roughness. Lower deposition temperatures (typically 50-300°C) often result in smoother films with better optical properties, while proper precursor selection ensures complete reactions and minimal impurities that could otherwise cause light scattering or absorption.Expand Specific Solutions04 ALD anti-reflective coatings for display and electronic device applications

ALD-deposited anti-reflective coatings are particularly valuable for display and electronic device applications, where they improve visibility, contrast, and energy efficiency. These coatings can be applied to smartphone screens, computer monitors, television displays, and touchscreens. The nanometer-scale precision of ALD allows for the creation of coatings that maintain transparency while significantly reducing glare and reflections. Additionally, ALD coatings can be designed to provide additional functionality such as scratch resistance, water repellency, or antimicrobial properties alongside their anti-reflective capabilities.Expand Specific Solutions05 ALD anti-reflective coatings for solar and photovoltaic applications

ALD-deposited anti-reflective coatings significantly enhance the efficiency of solar cells and photovoltaic devices by maximizing light transmission into the active layers. These specialized coatings reduce reflection losses at the air-glass or glass-semiconductor interfaces, allowing more photons to reach the energy-converting materials. The precise thickness control offered by ALD enables the creation of optimized coatings that can increase solar cell efficiency by several percentage points. Additionally, ALD coatings provide excellent durability and environmental stability, maintaining their anti-reflective properties under prolonged exposure to outdoor conditions.Expand Specific Solutions

Core ALD Anti-Reflection Patents and Technical Literature

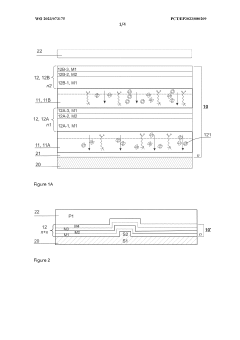

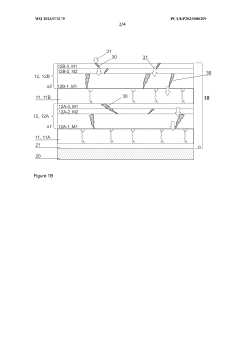

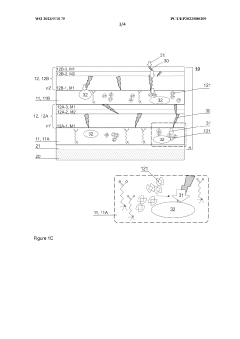

Multifunctional coating, method of manufacturing thereof, related coated items and uses

PatentWO2023073175A1

Innovation

- A self-healing laminate coating is formed using a combination of molecular layer deposition (MLD) and atomic layer deposition (ALD) processes, where a porous bulk material layer interacts with unbound precursors to seal defective sites, and an inorganic film stack composed of materials like Al2O3, TiO2, and SiO2 is deposited to enhance durability and barrier properties.

Environmental Impact of ALD vs Traditional Coating Methods

Atomic Layer Deposition (ALD) coating technology represents a significant advancement in optical coating methods, offering superior environmental benefits compared to traditional coating approaches. The environmental impact assessment of ALD versus conventional coating techniques reveals substantial differences in resource consumption, waste generation, and overall ecological footprint throughout the production lifecycle.

Traditional coating methods such as Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD), and wet chemical processes typically require higher operating temperatures and consume significantly more precursor materials. These conventional approaches often utilize between 60-90% more chemical precursors than ALD, resulting in considerable material waste and increased environmental burden. Additionally, many traditional methods employ environmentally harmful solvents and generate substantial hazardous waste requiring specialized disposal procedures.

ALD technology demonstrates remarkable environmental advantages through its precise atomic-level deposition mechanism. The process operates on a self-limiting reaction principle that ensures nearly 100% precursor utilization efficiency, dramatically reducing chemical waste. Studies indicate that ALD processes can achieve material utilization rates exceeding 90%, compared to 30-50% for conventional PVD methods. This efficiency translates directly to reduced environmental impact from raw material extraction and processing.

Energy consumption metrics further highlight ALD's environmental benefits. While ALD processes require vacuum conditions similar to other deposition methods, the lower operating temperatures (typically 80-300°C versus 400-800°C for CVD) result in approximately 25-40% energy savings. This reduced energy footprint becomes particularly significant in large-scale manufacturing operations where coating processes run continuously.

Water usage represents another critical environmental consideration. Traditional wet chemical coating methods can consume 5-10 gallons of ultra-pure water per square meter of coated surface, while ALD requires minimal or no water for processing. This water conservation aspect becomes increasingly important as manufacturing facilities face growing water scarcity challenges and stricter regulations on wastewater discharge.

Emissions profiles also differ substantially between coating technologies. ALD systems produce minimal airborne particulates and volatile organic compounds (VOCs) compared to spray coating or sol-gel methods. Recent environmental impact assessments indicate that ALD coating facilities typically generate 70-85% fewer air pollutants per unit of production, contributing to improved air quality both within manufacturing environments and surrounding communities.

The longevity of ALD coatings provides additional environmental benefits through extended product lifecycles. Anti-reflection coatings applied via ALD demonstrate superior durability and resistance to environmental degradation, potentially doubling the functional lifespan of optical components compared to conventionally coated alternatives. This durability reduces replacement frequency and associated environmental impacts from manufacturing replacement components.

Traditional coating methods such as Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD), and wet chemical processes typically require higher operating temperatures and consume significantly more precursor materials. These conventional approaches often utilize between 60-90% more chemical precursors than ALD, resulting in considerable material waste and increased environmental burden. Additionally, many traditional methods employ environmentally harmful solvents and generate substantial hazardous waste requiring specialized disposal procedures.

ALD technology demonstrates remarkable environmental advantages through its precise atomic-level deposition mechanism. The process operates on a self-limiting reaction principle that ensures nearly 100% precursor utilization efficiency, dramatically reducing chemical waste. Studies indicate that ALD processes can achieve material utilization rates exceeding 90%, compared to 30-50% for conventional PVD methods. This efficiency translates directly to reduced environmental impact from raw material extraction and processing.

Energy consumption metrics further highlight ALD's environmental benefits. While ALD processes require vacuum conditions similar to other deposition methods, the lower operating temperatures (typically 80-300°C versus 400-800°C for CVD) result in approximately 25-40% energy savings. This reduced energy footprint becomes particularly significant in large-scale manufacturing operations where coating processes run continuously.

Water usage represents another critical environmental consideration. Traditional wet chemical coating methods can consume 5-10 gallons of ultra-pure water per square meter of coated surface, while ALD requires minimal or no water for processing. This water conservation aspect becomes increasingly important as manufacturing facilities face growing water scarcity challenges and stricter regulations on wastewater discharge.

Emissions profiles also differ substantially between coating technologies. ALD systems produce minimal airborne particulates and volatile organic compounds (VOCs) compared to spray coating or sol-gel methods. Recent environmental impact assessments indicate that ALD coating facilities typically generate 70-85% fewer air pollutants per unit of production, contributing to improved air quality both within manufacturing environments and surrounding communities.

The longevity of ALD coatings provides additional environmental benefits through extended product lifecycles. Anti-reflection coatings applied via ALD demonstrate superior durability and resistance to environmental degradation, potentially doubling the functional lifespan of optical components compared to conventionally coated alternatives. This durability reduces replacement frequency and associated environmental impacts from manufacturing replacement components.

Cost-Benefit Analysis of ALD Implementation in Optics

Implementing Atomic Layer Deposition (ALD) technology for anti-reflection applications in optics requires careful financial consideration. The initial capital investment for ALD equipment ranges from $500,000 to $2 million depending on chamber size, automation level, and process capabilities. This represents a significant upfront cost that must be weighed against long-term benefits.

Operational expenses include precursor chemicals ($10,000-30,000 annually), maintenance contracts (typically 8-12% of equipment cost per year), specialized technician salaries ($60,000-90,000), and energy consumption (approximately 30-50 kW during operation). These recurring costs can accumulate to $150,000-250,000 annually for a medium-scale operation.

However, the economic benefits of ALD implementation are substantial. Production efficiency increases through higher yields, with defect rates typically reduced by 30-40% compared to conventional coating methods. The precise thickness control of ALD (±0.1 nm) results in superior optical performance, commanding premium pricing in high-end markets.

The durability of ALD coatings extends product lifecycle by 40-60%, reducing warranty claims and replacement costs. This longevity factor is particularly valuable in harsh environment applications such as aerospace, outdoor optics, and medical devices, where coating failure can lead to significant downstream costs.

Return on investment calculations indicate breakeven periods of 2-4 years for most optical manufacturing operations, with specialty applications achieving ROI in as little as 18 months. The scalability of ALD processes also provides cost advantages as production volumes increase, with per-unit coating costs decreasing by approximately 15-20% at full capacity utilization.

Environmental cost considerations favor ALD implementation as well. The process uses 60-80% less chemical precursors than traditional methods, resulting in reduced waste disposal costs and lower environmental compliance expenses. Many facilities report annual savings of $20,000-40,000 in waste management alone.

When comparing ALD to alternative coating technologies like PVD or sol-gel methods, the total cost of ownership analysis reveals that while ALD has higher initial costs, the 5-year and 10-year financial projections demonstrate superior returns due to quality improvements, reduced material waste, and enhanced production consistency.

Operational expenses include precursor chemicals ($10,000-30,000 annually), maintenance contracts (typically 8-12% of equipment cost per year), specialized technician salaries ($60,000-90,000), and energy consumption (approximately 30-50 kW during operation). These recurring costs can accumulate to $150,000-250,000 annually for a medium-scale operation.

However, the economic benefits of ALD implementation are substantial. Production efficiency increases through higher yields, with defect rates typically reduced by 30-40% compared to conventional coating methods. The precise thickness control of ALD (±0.1 nm) results in superior optical performance, commanding premium pricing in high-end markets.

The durability of ALD coatings extends product lifecycle by 40-60%, reducing warranty claims and replacement costs. This longevity factor is particularly valuable in harsh environment applications such as aerospace, outdoor optics, and medical devices, where coating failure can lead to significant downstream costs.

Return on investment calculations indicate breakeven periods of 2-4 years for most optical manufacturing operations, with specialty applications achieving ROI in as little as 18 months. The scalability of ALD processes also provides cost advantages as production volumes increase, with per-unit coating costs decreasing by approximately 15-20% at full capacity utilization.

Environmental cost considerations favor ALD implementation as well. The process uses 60-80% less chemical precursors than traditional methods, resulting in reduced waste disposal costs and lower environmental compliance expenses. Many facilities report annual savings of $20,000-40,000 in waste management alone.

When comparing ALD to alternative coating technologies like PVD or sol-gel methods, the total cost of ownership analysis reveals that while ALD has higher initial costs, the 5-year and 10-year financial projections demonstrate superior returns due to quality improvements, reduced material waste, and enhanced production consistency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!