How ALD Coating Enhances Photovoltaic Module Durability

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ALD Technology Evolution and Objectives

Atomic Layer Deposition (ALD) technology has evolved significantly since its inception in the 1970s, transforming from a laboratory curiosity to a critical industrial process. Initially developed for semiconductor manufacturing, ALD has undergone remarkable refinement in precision, scalability, and application versatility. The technology's fundamental principle—the sequential self-limiting surface reactions—has remained consistent, while process parameters, precursor chemistry, and equipment design have advanced substantially to meet increasingly demanding industrial requirements.

The evolution of ALD in photovoltaic applications began in the early 2000s when researchers recognized its potential for creating ultra-thin, conformal barrier layers. Early implementations focused primarily on basic moisture protection for conventional silicon solar cells. As photovoltaic technologies diversified to include thin-film, perovskite, and tandem architectures, ALD coating techniques evolved in parallel, developing specialized precursors and process conditions optimized for each photovoltaic material system.

A significant technological milestone occurred around 2010-2015 when spatial ALD techniques emerged, dramatically increasing throughput and reducing manufacturing costs. This development transformed ALD from a niche laboratory technique to a commercially viable process for large-area photovoltaic modules. Subsequent innovations in atmospheric pressure ALD and roll-to-roll processing further enhanced industrial applicability, particularly for flexible photovoltaic technologies.

The primary objective of ALD coating in photovoltaic applications is to enhance module durability without compromising optical and electrical performance. This involves creating nanoscale barrier layers that prevent moisture ingress, oxygen penetration, and ion migration while maintaining high transparency in the solar spectrum. Secondary objectives include improving interface properties between different functional layers, reducing recombination losses, and enabling novel device architectures that would otherwise be unstable under operational conditions.

Current research objectives focus on developing ALD processes that can be seamlessly integrated into existing photovoltaic manufacturing lines with minimal disruption and capital investment. This includes optimizing deposition temperatures to accommodate temperature-sensitive substrates, reducing cycle times to match production throughput requirements, and developing precursors that balance performance, cost, and environmental considerations.

Looking forward, the technology roadmap for ALD in photovoltaics aims to achieve sub-nanometer precision in multi-component films, enable selective area deposition for advanced device architectures, and develop in-line quality control methods for high-volume manufacturing. These advancements are expected to extend photovoltaic module lifetimes beyond 30 years while maintaining high performance, ultimately reducing the levelized cost of solar electricity and accelerating global renewable energy adoption.

The evolution of ALD in photovoltaic applications began in the early 2000s when researchers recognized its potential for creating ultra-thin, conformal barrier layers. Early implementations focused primarily on basic moisture protection for conventional silicon solar cells. As photovoltaic technologies diversified to include thin-film, perovskite, and tandem architectures, ALD coating techniques evolved in parallel, developing specialized precursors and process conditions optimized for each photovoltaic material system.

A significant technological milestone occurred around 2010-2015 when spatial ALD techniques emerged, dramatically increasing throughput and reducing manufacturing costs. This development transformed ALD from a niche laboratory technique to a commercially viable process for large-area photovoltaic modules. Subsequent innovations in atmospheric pressure ALD and roll-to-roll processing further enhanced industrial applicability, particularly for flexible photovoltaic technologies.

The primary objective of ALD coating in photovoltaic applications is to enhance module durability without compromising optical and electrical performance. This involves creating nanoscale barrier layers that prevent moisture ingress, oxygen penetration, and ion migration while maintaining high transparency in the solar spectrum. Secondary objectives include improving interface properties between different functional layers, reducing recombination losses, and enabling novel device architectures that would otherwise be unstable under operational conditions.

Current research objectives focus on developing ALD processes that can be seamlessly integrated into existing photovoltaic manufacturing lines with minimal disruption and capital investment. This includes optimizing deposition temperatures to accommodate temperature-sensitive substrates, reducing cycle times to match production throughput requirements, and developing precursors that balance performance, cost, and environmental considerations.

Looking forward, the technology roadmap for ALD in photovoltaics aims to achieve sub-nanometer precision in multi-component films, enable selective area deposition for advanced device architectures, and develop in-line quality control methods for high-volume manufacturing. These advancements are expected to extend photovoltaic module lifetimes beyond 30 years while maintaining high performance, ultimately reducing the levelized cost of solar electricity and accelerating global renewable energy adoption.

Market Analysis for Durable PV Module Solutions

The global photovoltaic (PV) module market continues to experience robust growth, with increasing demand for durable solutions that can withstand harsh environmental conditions while maintaining optimal performance. Current market projections indicate that the global solar PV market will reach approximately 1,000 GW of annual installations by 2030, representing a significant opportunity for advanced durability technologies like Atomic Layer Deposition (ALD) coating.

Market research reveals that durability has become a primary concern for PV system owners and investors, as it directly impacts the long-term return on investment. Surveys of utility-scale solar developers indicate that extending module lifetime from the standard 25-30 years to 35-40 years could reduce levelized cost of electricity (LCOE) by 5-10%, creating substantial competitive advantage in the increasingly cost-sensitive renewable energy market.

The market for durable PV solutions can be segmented into several key application areas. Utility-scale installations represent the largest volume segment, where even marginal improvements in durability translate to significant financial benefits due to scale. Commercial and industrial applications form another substantial segment, particularly in regions with aggressive sustainability targets and favorable incentive structures. The residential market, while smaller in volume, demonstrates higher willingness to pay premiums for durability assurances.

Geographically, regions with extreme climate conditions show the strongest demand for enhanced durability solutions. These include high-humidity tropical environments, coastal areas with salt spray exposure, desert regions with high UV and temperature stress, and areas with frequent hailstorms or sandstorms. The Middle East, Australia, parts of Asia, and certain regions in North America represent particularly promising markets for ALD coating technology.

Market analysis indicates that the competitive landscape for durable PV solutions is intensifying. Traditional encapsulation and glass manufacturers are enhancing their offerings, while specialized coating companies are entering the solar market. This competition is driving innovation in materials science and manufacturing processes, with ALD coating emerging as a premium solution for high-value applications.

Pricing sensitivity varies significantly across market segments. While utility-scale developers remain highly cost-conscious, they increasingly recognize the value proposition of durability enhancements that extend asset life. Premium residential and commercial installers have demonstrated willingness to absorb 3-7% cost increases for modules with proven durability advantages, particularly when backed by extended performance warranties.

The regulatory landscape is evolving favorably for durable PV solutions, with several countries implementing quality standards that reward longer-lasting modules. Additionally, financial institutions and insurance companies are beginning to offer preferential terms for PV systems utilizing proven durability-enhancing technologies, creating another market driver for solutions like ALD coating.

Market research reveals that durability has become a primary concern for PV system owners and investors, as it directly impacts the long-term return on investment. Surveys of utility-scale solar developers indicate that extending module lifetime from the standard 25-30 years to 35-40 years could reduce levelized cost of electricity (LCOE) by 5-10%, creating substantial competitive advantage in the increasingly cost-sensitive renewable energy market.

The market for durable PV solutions can be segmented into several key application areas. Utility-scale installations represent the largest volume segment, where even marginal improvements in durability translate to significant financial benefits due to scale. Commercial and industrial applications form another substantial segment, particularly in regions with aggressive sustainability targets and favorable incentive structures. The residential market, while smaller in volume, demonstrates higher willingness to pay premiums for durability assurances.

Geographically, regions with extreme climate conditions show the strongest demand for enhanced durability solutions. These include high-humidity tropical environments, coastal areas with salt spray exposure, desert regions with high UV and temperature stress, and areas with frequent hailstorms or sandstorms. The Middle East, Australia, parts of Asia, and certain regions in North America represent particularly promising markets for ALD coating technology.

Market analysis indicates that the competitive landscape for durable PV solutions is intensifying. Traditional encapsulation and glass manufacturers are enhancing their offerings, while specialized coating companies are entering the solar market. This competition is driving innovation in materials science and manufacturing processes, with ALD coating emerging as a premium solution for high-value applications.

Pricing sensitivity varies significantly across market segments. While utility-scale developers remain highly cost-conscious, they increasingly recognize the value proposition of durability enhancements that extend asset life. Premium residential and commercial installers have demonstrated willingness to absorb 3-7% cost increases for modules with proven durability advantages, particularly when backed by extended performance warranties.

The regulatory landscape is evolving favorably for durable PV solutions, with several countries implementing quality standards that reward longer-lasting modules. Additionally, financial institutions and insurance companies are beginning to offer preferential terms for PV systems utilizing proven durability-enhancing technologies, creating another market driver for solutions like ALD coating.

Current ALD Coating Challenges in Photovoltaics

Despite the promising advantages of Atomic Layer Deposition (ALD) coating for enhancing photovoltaic module durability, several significant challenges currently impede its widespread adoption in commercial solar applications. The primary technical obstacle remains the scaling of ALD processes for large-area photovoltaic modules. While ALD excels at depositing uniform, conformal nanoscale films on small substrates in laboratory settings, translating this precision to industrial-scale production lines presents considerable difficulties.

The inherently slow deposition rate of traditional ALD processes creates a substantial throughput bottleneck. Conventional ALD typically achieves growth rates of only 0.1-1.0 nm per minute, making it prohibitively time-consuming for high-volume manufacturing environments where production efficiency is paramount. This slow processing speed directly impacts manufacturing costs and limits commercial viability.

Material selection poses another critical challenge. While ALD can theoretically deposit various materials, identifying optimal precursors that balance reactivity, stability, and cost-effectiveness remains problematic. Many high-performance precursors are expensive, have limited shelf life, or present handling hazards, complicating their integration into production environments.

Process parameter optimization represents a significant hurdle. The complex interplay between deposition temperature, precursor pulse/purge times, and reactor pressure must be precisely controlled to achieve desired film properties. This optimization becomes exponentially more difficult when scaling to larger substrates, where maintaining uniform temperature and precursor distribution across the entire surface is challenging.

Interface engineering between the ALD coating and underlying photovoltaic materials presents additional complications. Ensuring strong adhesion, minimizing interfacial defects, and preventing undesired chemical reactions during deposition requires sophisticated surface preparation techniques that are difficult to implement consistently at scale.

Cost considerations remain perhaps the most significant barrier to widespread adoption. The high capital expenditure for ALD equipment, combined with operational expenses (precursors, maintenance, energy consumption), results in a substantially higher cost-per-watt compared to conventional encapsulation methods. This cost differential must be justified by proportional improvements in module lifetime and performance.

Environmental and safety concerns also merit attention. Some ALD precursors are toxic, pyrophoric, or environmentally harmful, necessitating sophisticated handling systems and waste management protocols that add complexity and cost to manufacturing operations.

Addressing these interconnected challenges requires coordinated research efforts across materials science, chemical engineering, and manufacturing technology to realize the full potential of ALD coatings in enhancing photovoltaic module durability at commercially viable scales.

The inherently slow deposition rate of traditional ALD processes creates a substantial throughput bottleneck. Conventional ALD typically achieves growth rates of only 0.1-1.0 nm per minute, making it prohibitively time-consuming for high-volume manufacturing environments where production efficiency is paramount. This slow processing speed directly impacts manufacturing costs and limits commercial viability.

Material selection poses another critical challenge. While ALD can theoretically deposit various materials, identifying optimal precursors that balance reactivity, stability, and cost-effectiveness remains problematic. Many high-performance precursors are expensive, have limited shelf life, or present handling hazards, complicating their integration into production environments.

Process parameter optimization represents a significant hurdle. The complex interplay between deposition temperature, precursor pulse/purge times, and reactor pressure must be precisely controlled to achieve desired film properties. This optimization becomes exponentially more difficult when scaling to larger substrates, where maintaining uniform temperature and precursor distribution across the entire surface is challenging.

Interface engineering between the ALD coating and underlying photovoltaic materials presents additional complications. Ensuring strong adhesion, minimizing interfacial defects, and preventing undesired chemical reactions during deposition requires sophisticated surface preparation techniques that are difficult to implement consistently at scale.

Cost considerations remain perhaps the most significant barrier to widespread adoption. The high capital expenditure for ALD equipment, combined with operational expenses (precursors, maintenance, energy consumption), results in a substantially higher cost-per-watt compared to conventional encapsulation methods. This cost differential must be justified by proportional improvements in module lifetime and performance.

Environmental and safety concerns also merit attention. Some ALD precursors are toxic, pyrophoric, or environmentally harmful, necessitating sophisticated handling systems and waste management protocols that add complexity and cost to manufacturing operations.

Addressing these interconnected challenges requires coordinated research efforts across materials science, chemical engineering, and manufacturing technology to realize the full potential of ALD coatings in enhancing photovoltaic module durability at commercially viable scales.

Existing ALD Implementation Strategies for PV Modules

01 ALD coating composition for enhanced durability

Specific material compositions can significantly enhance the durability of ALD coatings. These include metal oxides, nitrides, and composite materials that provide superior resistance to mechanical wear, chemical corrosion, and environmental degradation. The selection of precursors and dopants during the ALD process can create coatings with optimized hardness, adhesion, and structural integrity, resulting in extended service life under demanding conditions.- ALD coating process optimization for enhanced durability: Optimizing the atomic layer deposition (ALD) process parameters can significantly improve coating durability. This includes controlling temperature, pressure, precursor exposure time, and purge cycles to ensure uniform film growth and strong adhesion to substrates. Proper process optimization leads to denser films with fewer defects, resulting in coatings that can withstand mechanical stress, thermal cycling, and environmental exposure for extended periods.

- Protective barrier layers for ALD coatings: Incorporating protective barrier layers in ALD coating systems can enhance overall durability. These barrier layers protect the underlying functional coatings from environmental factors such as moisture, oxygen, and corrosive substances. Multi-layer structures with specifically designed barrier properties can significantly extend the lifetime of ALD coatings in harsh operating conditions, while maintaining the desired functional properties of the coating system.

- Material selection for durable ALD coatings: The choice of materials used in ALD coatings significantly impacts durability. Metal oxides like aluminum oxide, titanium dioxide, and zirconium oxide offer excellent resistance to wear, corrosion, and thermal degradation. Nitrides and carbides provide hardness and chemical stability. Selecting appropriate precursors and understanding material compatibility with substrates ensures coatings with superior mechanical properties, chemical resistance, and thermal stability for long-term performance.

- Post-deposition treatments to enhance ALD coating durability: Post-deposition treatments can significantly improve the durability of ALD coatings. Thermal annealing processes help densify the coating structure and improve crystallinity, while plasma treatments can enhance adhesion and surface properties. Other post-processing techniques include surface passivation, chemical treatments, and laser processing. These treatments can eliminate defects, reduce internal stresses, and strengthen interfacial bonding, resulting in more durable coatings with improved resistance to environmental degradation.

- Testing and characterization methods for ALD coating durability: Various testing and characterization methods are essential for evaluating and improving ALD coating durability. Accelerated aging tests simulate long-term environmental exposure, while mechanical testing assesses resistance to wear, scratch, and impact damage. Chemical resistance tests evaluate performance against corrosive substances, and thermal cycling tests determine stability under temperature fluctuations. Advanced analytical techniques like electron microscopy, spectroscopy, and nanoindentation provide insights into coating structure, composition, and failure mechanisms, enabling targeted improvements in durability.

02 Process parameters optimization for durable ALD coatings

The durability of ALD coatings can be significantly improved by optimizing process parameters such as deposition temperature, pulse/purge times, and layer thickness. Controlled growth rates and precise cycle sequences ensure uniform film formation with minimal defects. Post-deposition treatments including annealing and surface modification can further enhance coating adhesion, density, and resistance to environmental factors, resulting in superior long-term performance.Expand Specific Solutions03 Multilayer and nanolaminate ALD structures for improved durability

Multilayer and nanolaminate structures created through ALD offer enhanced durability compared to single-layer coatings. By alternating different materials at the nanoscale, these structures can combine complementary properties such as hardness, flexibility, and chemical resistance. The interfaces between layers can effectively block crack propagation and provide stress relief, while the overall architecture can be designed to withstand specific environmental challenges including thermal cycling, mechanical stress, and corrosive conditions.Expand Specific Solutions04 Surface preparation techniques for durable ALD coating adhesion

Proper surface preparation is critical for ensuring the durability of ALD coatings. Techniques such as plasma treatment, chemical cleaning, and surface functionalization create optimal conditions for coating adhesion by removing contaminants and creating reactive sites. The surface roughness, chemistry, and morphology can be engineered to maximize the interfacial bonding between the substrate and the ALD film, preventing delamination and enhancing the coating's resistance to mechanical and environmental stresses.Expand Specific Solutions05 Testing and characterization methods for ALD coating durability

Various testing and characterization methods are employed to evaluate and predict the durability of ALD coatings. These include accelerated weathering tests, scratch resistance measurements, adhesion tests, and chemical exposure studies. Advanced analytical techniques such as nanoindentation, atomic force microscopy, and electron microscopy provide insights into coating microstructure and failure mechanisms. Computational modeling and simulation approaches can also be used to design more durable coatings by predicting performance under various conditions before physical implementation.Expand Specific Solutions

Leading Companies in ALD Coating for PV Industry

The atomic layer deposition (ALD) coating market for photovoltaic module durability is currently in a growth phase, with increasing adoption across the solar industry. The global market is expanding rapidly as manufacturers seek enhanced module longevity and performance, particularly in harsh environments. Technologically, ALD coating has reached moderate maturity with established players like Applied Materials, Beneq Group, and Forge Nano leading innovation through proprietary processes. Emerging competitors including Jiangsu Leadmicro Nano Technology and LONGi Green Energy are accelerating development in the photovoltaic-specific applications. Research institutions such as North Carolina State University and CEA are advancing next-generation solutions, while semiconductor equipment manufacturers like Lam Research and ASM International are leveraging their expertise to enter this growing market segment, creating a competitive landscape balanced between established equipment providers and specialized coating technology developers.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced ALD technology specifically for enhancing photovoltaic module durability through their Precision Materials Engineering solutions. Their SunFab ALD system enables the deposition of ultra-thin, uniform barrier layers on solar cells that protect against moisture ingress and corrosion. The company's technology can deposit various materials including Al2O3, TiO2, and SiO2 with precise thickness control down to the angstrom level. Applied Materials' ALD process creates conformal coatings that follow the complex topography of textured solar cells, ensuring complete protection even on high-aspect-ratio features. Their systems integrate seamlessly into high-volume manufacturing lines, with throughput optimization that makes ALD economically viable for mass production of durable PV modules. The company has demonstrated that their ALD coatings can extend solar module lifetime by up to 25% in accelerated aging tests, particularly in harsh environmental conditions with high humidity and temperature fluctuations. Applied Materials also offers multi-layer ALD solutions that combine different materials to provide comprehensive protection against multiple degradation mechanisms simultaneously.

Strengths: Extensive experience in semiconductor manufacturing equipment that transfers to PV applications; high-throughput solutions suitable for mass production; comprehensive material science expertise for optimizing coating compositions; global service and support infrastructure. Weaknesses: Higher capital equipment costs compared to traditional coating methods; complex integration requirements for existing production lines; optimization process can be time-consuming for new materials or cell architectures.

Forge Nano, Inc.

Technical Solution: Forge Nano has developed a proprietary Atomic Layer Deposition (ALD) technology called Particle ALD (PALD) specifically designed for enhancing photovoltaic module durability. Their system enables precise nanoscale coatings on solar cell components, creating ultra-thin protective barriers against moisture, oxygen, and other environmental factors that typically degrade PV performance. The PALD process applies uniform coatings as thin as 1-100 nanometers with atomic-level precision, allowing for complete coverage of complex geometries and high-aspect-ratio features found in solar cells. Forge Nano's technology can deposit various materials including Al2O3, TiO2, and SiO2, each offering specific protective properties for different PV components. Their industrial-scale ALD systems can process large volumes of materials continuously, making the technology commercially viable for mass production of solar modules with enhanced durability.

Strengths: Superior uniformity and conformality of coatings even on complex surfaces; precise thickness control at atomic scale; excellent barrier properties against moisture and oxygen; scalable to industrial production levels. Weaknesses: Higher initial capital investment compared to conventional coating methods; potentially slower throughput than some competing technologies; requires specialized expertise for implementation and optimization.

Key ALD Coating Mechanisms for Enhanced Durability

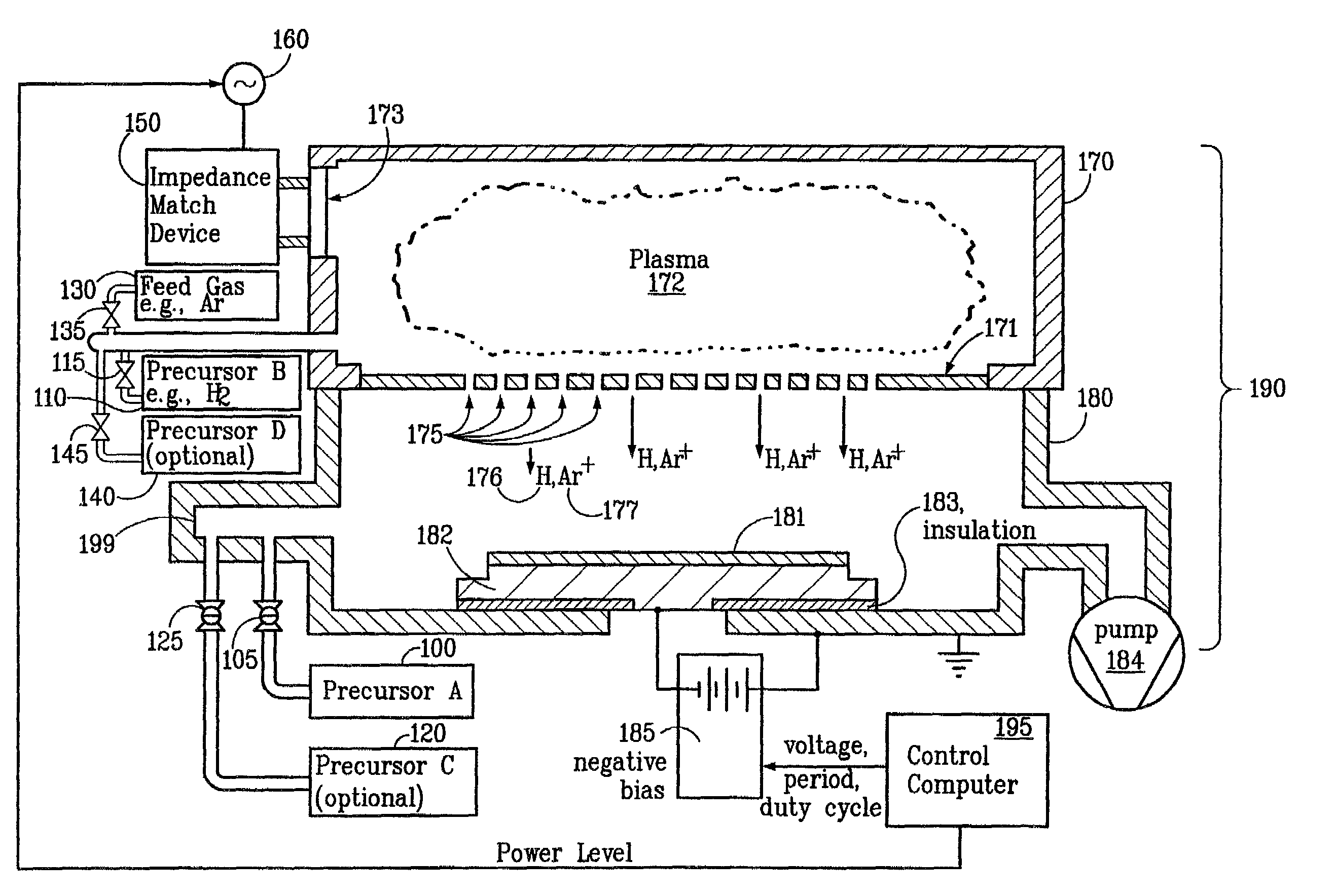

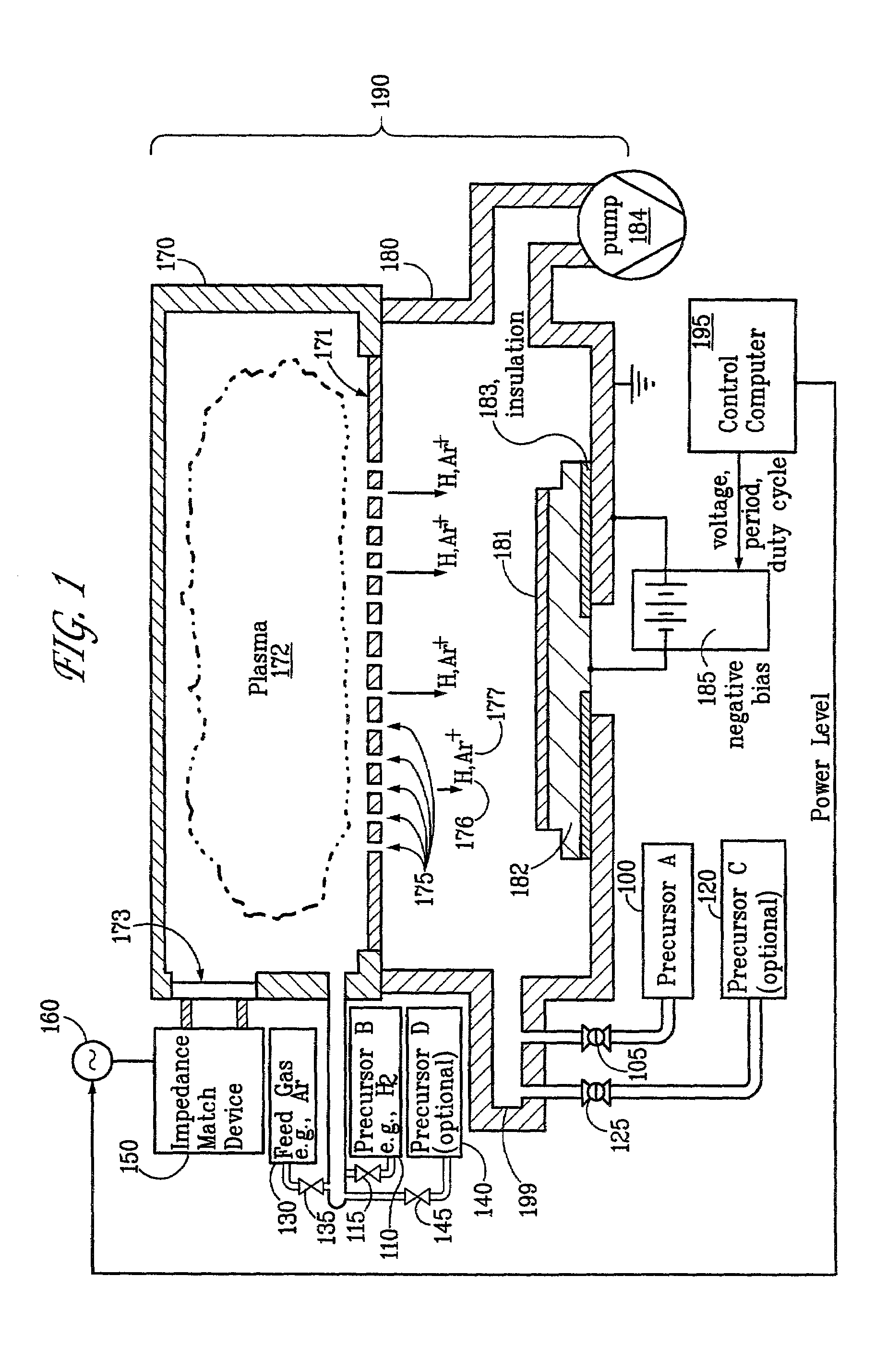

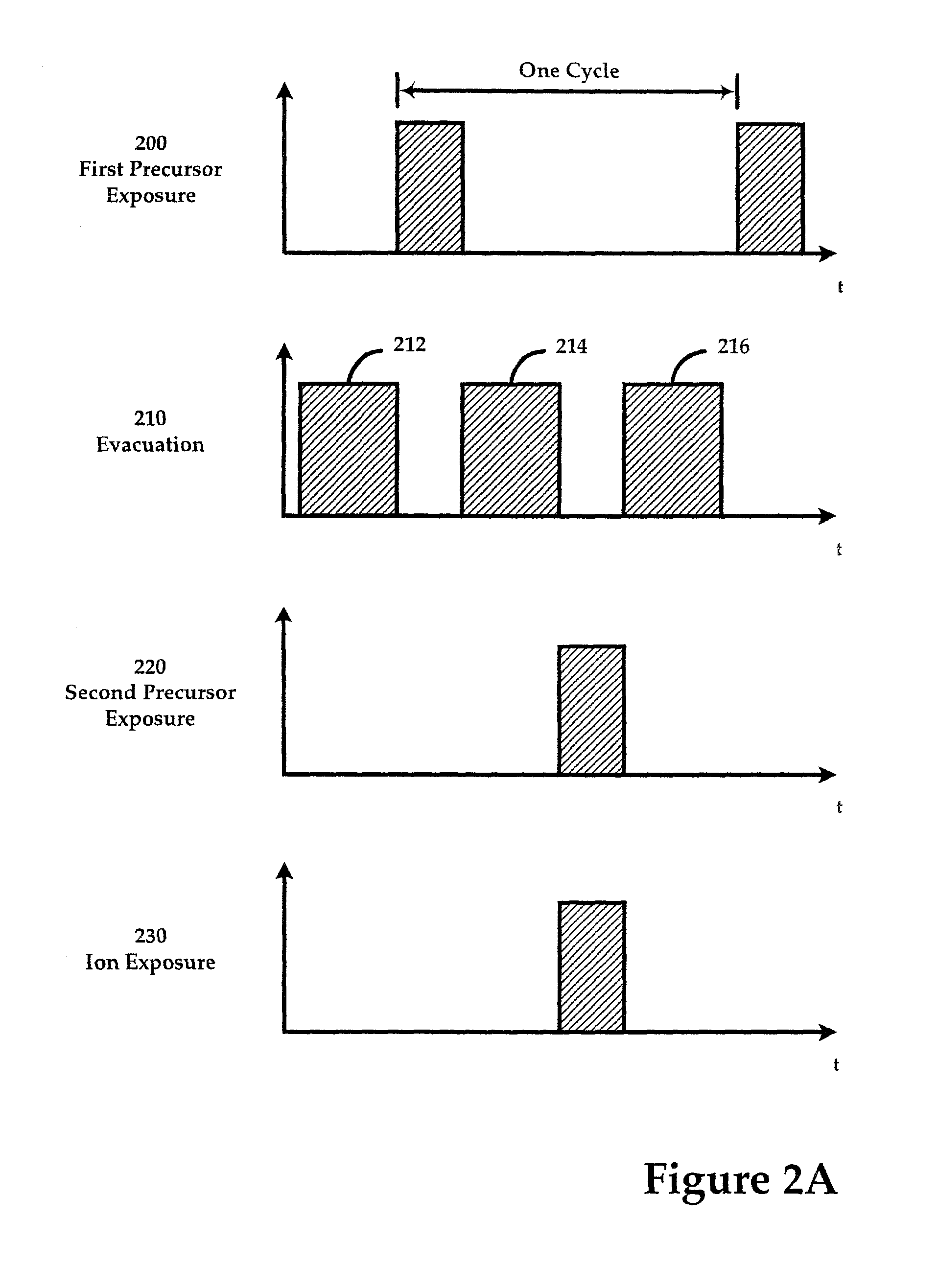

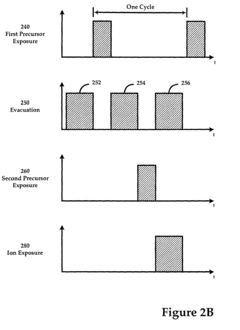

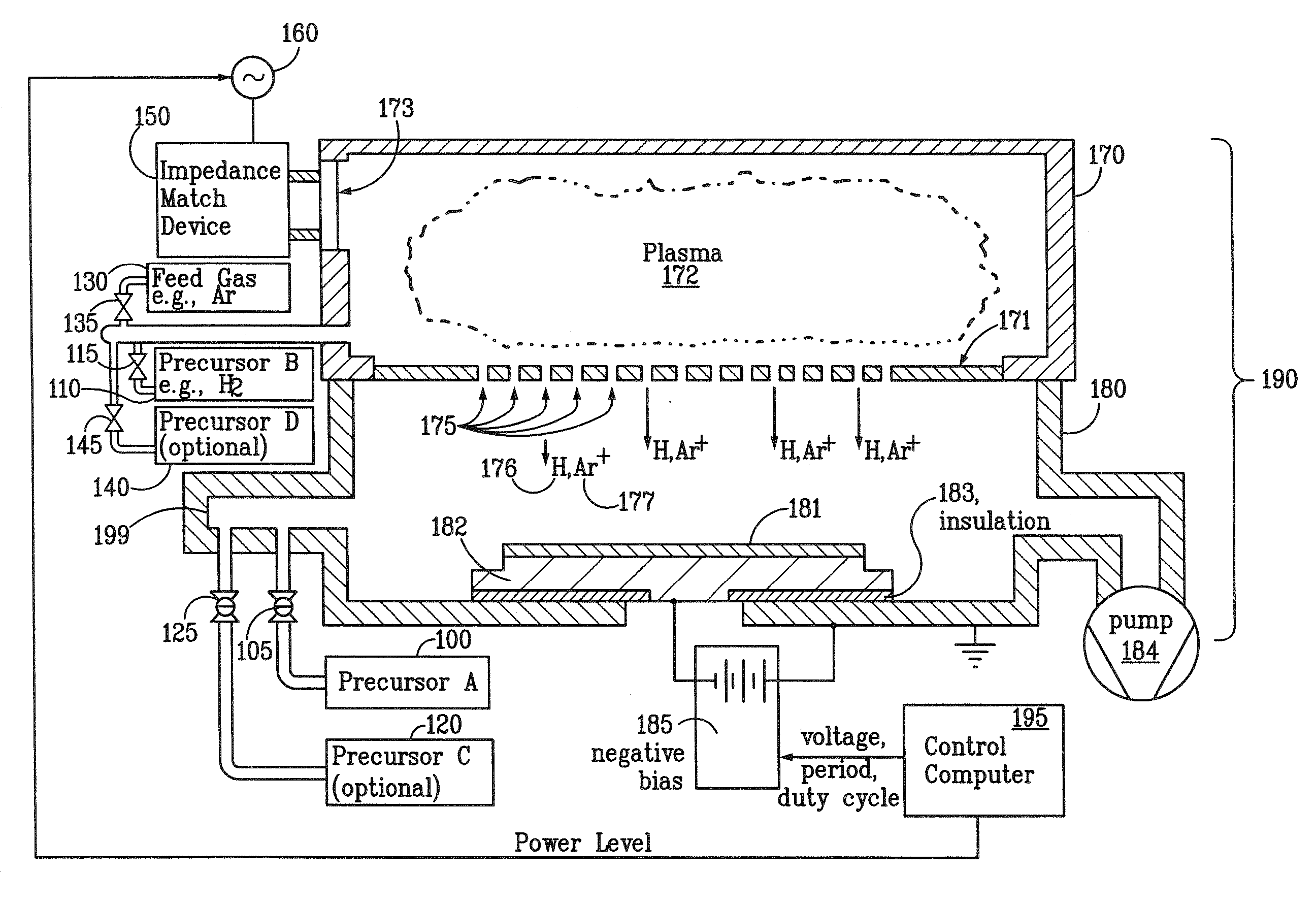

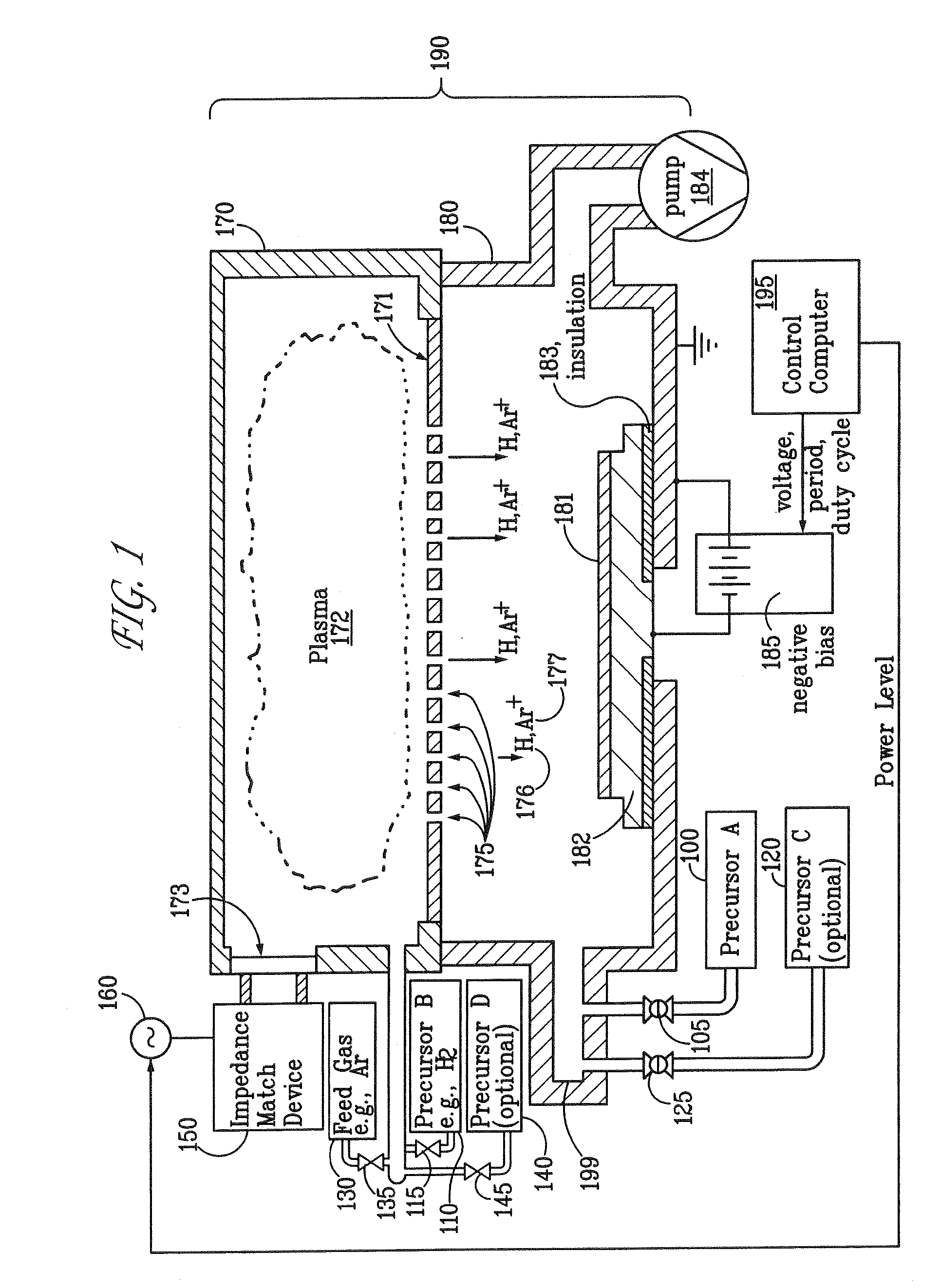

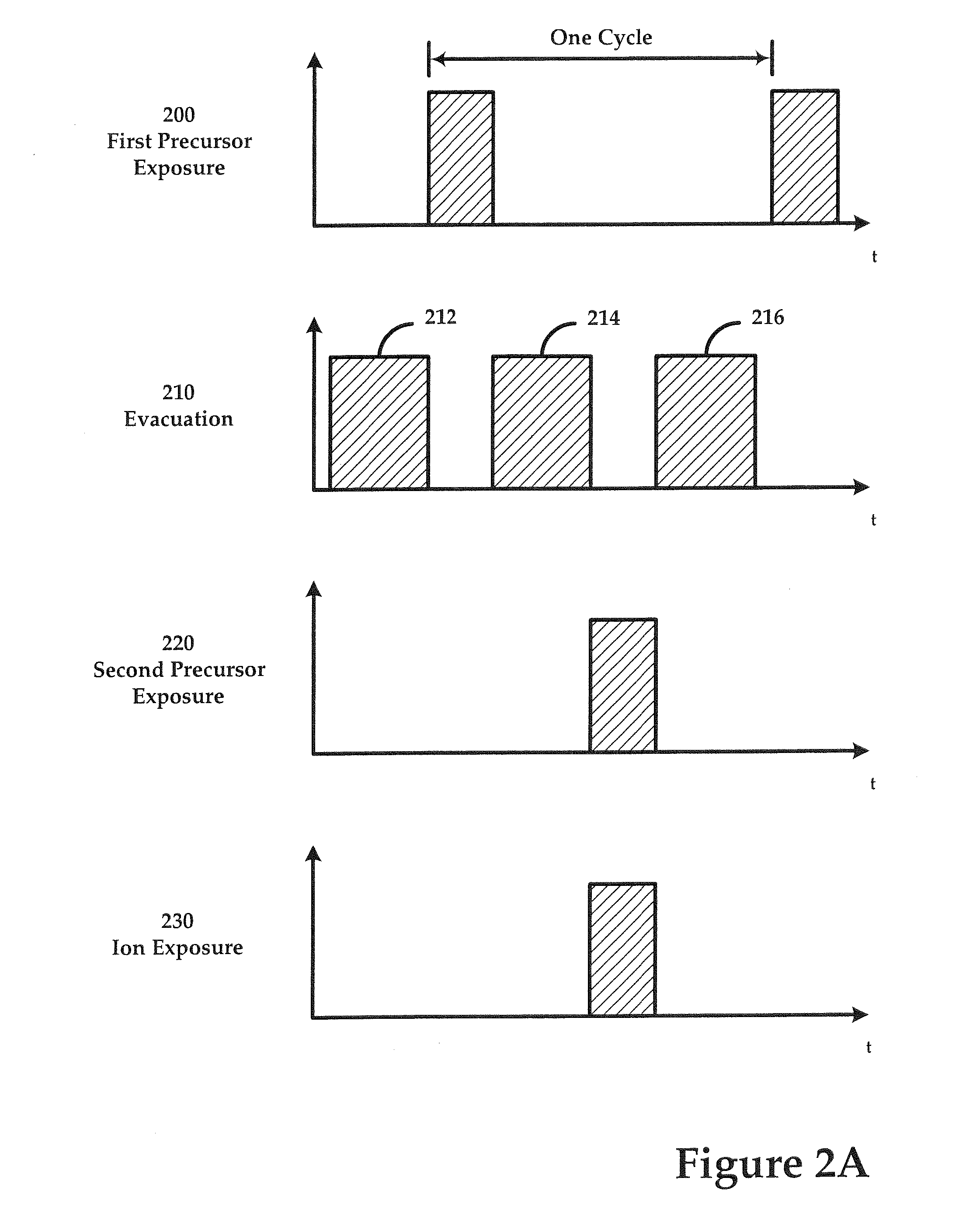

Continuous method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

PatentInactiveUS7348042B2

Innovation

- Modulated ion-induced atomic layer deposition (MII-ALD) uses ion bombardment as a non-thermal activation source to drive the deposition reaction, employing a microwave-generated plasma to generate ions and radicals within the main chamber, allowing for precise control of ion flux and energy to achieve higher density and purity films at lower temperatures, and enabling faster deposition processes.

System for Depositing a Film by Modulated Ion-Induced Atomic Layer Deposition (MII-ALD)

PatentInactiveUS20110017139A1

Innovation

- The modulated ion-induced atomic layer deposition (MII-ALD) method uses ion bombardment as a non-thermal activation source to drive the deposition reaction, employing a microwave-generated plasma to generate ions and radicals efficiently, allowing for lower substrate temperatures and faster deposition rates, while maintaining high film purity and adhesion properties.

Environmental Impact Assessment of ALD Processes

The environmental impact of Atomic Layer Deposition (ALD) processes used for enhancing photovoltaic module durability requires comprehensive assessment across multiple dimensions. When evaluating ALD coating technologies, it is essential to consider both direct and indirect environmental effects throughout the entire lifecycle of photovoltaic modules.

ALD processes generally utilize significantly lower quantities of precursor chemicals compared to traditional coating methods such as Chemical Vapor Deposition (CVD) or Physical Vapor Deposition (PVD). This reduction in material consumption represents a notable environmental advantage, particularly when considering the extraction and processing impacts of rare or toxic materials often used in semiconductor manufacturing.

Energy consumption during ALD processing presents a complex environmental consideration. While ALD operates at lower temperatures than many alternative coating technologies (typically 150-350°C versus 400-800°C for CVD), the sequential nature of the process can extend processing times. Recent advancements in spatial ALD and batch processing have substantially improved energy efficiency, reducing the carbon footprint associated with protective coating application for photovoltaic modules.

Precursor chemicals used in ALD processes for photovoltaic applications, such as trimethylaluminum (TMA) for aluminum oxide coatings, require careful environmental management. These compounds are often pyrophoric and reactive, necessitating specialized handling and disposal protocols. However, the precise monolayer control characteristic of ALD results in minimal waste generation compared to alternative coating technologies, with utilization efficiencies often exceeding 90%.

Water consumption in ALD processes varies significantly depending on the specific chemistry employed. Water-based ALD reactions for metal oxide deposition typically require less water than wet chemical processes, though cooling systems for vacuum equipment may increase overall water usage. Closed-loop cooling systems have been implemented in modern ALD equipment to minimize this environmental impact.

The extended lifetime of photovoltaic modules achieved through ALD protective coatings delivers substantial environmental benefits through reduced manufacturing frequency. Studies indicate that appropriate ALD barrier layers can extend module operational lifetimes by 25-40%, significantly improving the lifecycle environmental profile of solar energy systems and reducing electronic waste generation.

Emissions from ALD processes primarily consist of reaction byproducts such as methane or other hydrocarbons when using metal-organic precursors. Modern ALD systems incorporate abatement technologies including thermal oxidizers and scrubbers that can reduce harmful emissions by over 99%, minimizing atmospheric pollution potential while ensuring regulatory compliance across global manufacturing locations.

ALD processes generally utilize significantly lower quantities of precursor chemicals compared to traditional coating methods such as Chemical Vapor Deposition (CVD) or Physical Vapor Deposition (PVD). This reduction in material consumption represents a notable environmental advantage, particularly when considering the extraction and processing impacts of rare or toxic materials often used in semiconductor manufacturing.

Energy consumption during ALD processing presents a complex environmental consideration. While ALD operates at lower temperatures than many alternative coating technologies (typically 150-350°C versus 400-800°C for CVD), the sequential nature of the process can extend processing times. Recent advancements in spatial ALD and batch processing have substantially improved energy efficiency, reducing the carbon footprint associated with protective coating application for photovoltaic modules.

Precursor chemicals used in ALD processes for photovoltaic applications, such as trimethylaluminum (TMA) for aluminum oxide coatings, require careful environmental management. These compounds are often pyrophoric and reactive, necessitating specialized handling and disposal protocols. However, the precise monolayer control characteristic of ALD results in minimal waste generation compared to alternative coating technologies, with utilization efficiencies often exceeding 90%.

Water consumption in ALD processes varies significantly depending on the specific chemistry employed. Water-based ALD reactions for metal oxide deposition typically require less water than wet chemical processes, though cooling systems for vacuum equipment may increase overall water usage. Closed-loop cooling systems have been implemented in modern ALD equipment to minimize this environmental impact.

The extended lifetime of photovoltaic modules achieved through ALD protective coatings delivers substantial environmental benefits through reduced manufacturing frequency. Studies indicate that appropriate ALD barrier layers can extend module operational lifetimes by 25-40%, significantly improving the lifecycle environmental profile of solar energy systems and reducing electronic waste generation.

Emissions from ALD processes primarily consist of reaction byproducts such as methane or other hydrocarbons when using metal-organic precursors. Modern ALD systems incorporate abatement technologies including thermal oxidizers and scrubbers that can reduce harmful emissions by over 99%, minimizing atmospheric pollution potential while ensuring regulatory compliance across global manufacturing locations.

Cost-Benefit Analysis of ALD Implementation

Implementing Atomic Layer Deposition (ALD) coating technology for photovoltaic modules requires careful financial analysis to determine its economic viability. Initial capital expenditure for ALD equipment represents a significant investment, with industrial-scale systems ranging from $500,000 to $2 million depending on throughput capacity and technical specifications. Additionally, facility modifications to accommodate these systems may cost between $100,000 and $300,000, including clean room environments and specialized utilities.

Operational expenses must also be considered, including precursor chemicals which typically cost $5,000-$15,000 per month depending on production volume. Energy consumption for ALD processes adds approximately $2,000-$4,000 monthly to utility bills, while specialized maintenance contracts range from $30,000-$60,000 annually to ensure optimal equipment performance.

Against these costs, substantial benefits emerge when evaluating long-term returns. Field studies demonstrate that ALD-coated photovoltaic modules exhibit 15-25% longer operational lifespans compared to uncoated counterparts, extending from the standard 25 years to potentially 30+ years. This extension directly increases the lifetime energy generation capacity and improves return on investment calculations.

Performance degradation rates show marked improvement, with annual degradation reduced from the industry standard of 0.5-1% to approximately 0.3-0.5% for ALD-coated modules. This preservation of conversion efficiency translates to approximately 5-10% more cumulative energy generation over the module lifetime, representing significant additional revenue.

Warranty claim reductions constitute another financial benefit, with manufacturers reporting 30-40% fewer claims for modules featuring ALD protective coatings. This reduction in replacement and service costs can save manufacturers $15-25 per kilowatt of installed capacity annually.

The payback period for ALD implementation varies by production scale. Small manufacturers (under 50MW annual capacity) typically achieve return on investment in 3-4 years, while large-scale producers (over 200MW) may see payback in 1.5-2 years due to economies of scale. This timeline makes ALD financially attractive for established manufacturers with stable market positions.

Market premium potential also enhances the value proposition, as modules with documented enhanced durability can command price premiums of 5-8% in premium markets focused on long-term reliability, particularly in utility-scale projects where performance guarantees carry significant value.

Operational expenses must also be considered, including precursor chemicals which typically cost $5,000-$15,000 per month depending on production volume. Energy consumption for ALD processes adds approximately $2,000-$4,000 monthly to utility bills, while specialized maintenance contracts range from $30,000-$60,000 annually to ensure optimal equipment performance.

Against these costs, substantial benefits emerge when evaluating long-term returns. Field studies demonstrate that ALD-coated photovoltaic modules exhibit 15-25% longer operational lifespans compared to uncoated counterparts, extending from the standard 25 years to potentially 30+ years. This extension directly increases the lifetime energy generation capacity and improves return on investment calculations.

Performance degradation rates show marked improvement, with annual degradation reduced from the industry standard of 0.5-1% to approximately 0.3-0.5% for ALD-coated modules. This preservation of conversion efficiency translates to approximately 5-10% more cumulative energy generation over the module lifetime, representing significant additional revenue.

Warranty claim reductions constitute another financial benefit, with manufacturers reporting 30-40% fewer claims for modules featuring ALD protective coatings. This reduction in replacement and service costs can save manufacturers $15-25 per kilowatt of installed capacity annually.

The payback period for ALD implementation varies by production scale. Small manufacturers (under 50MW annual capacity) typically achieve return on investment in 3-4 years, while large-scale producers (over 200MW) may see payback in 1.5-2 years due to economies of scale. This timeline makes ALD financially attractive for established manufacturers with stable market positions.

Market premium potential also enhances the value proposition, as modules with documented enhanced durability can command price premiums of 5-8% in premium markets focused on long-term reliability, particularly in utility-scale projects where performance guarantees carry significant value.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!