ALD Coating for Improved Thermal Management in LED Technologies

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ALD Coating Technology Evolution and Objectives

Atomic Layer Deposition (ALD) technology has evolved significantly since its inception in the 1970s, transitioning from a laboratory curiosity to a critical industrial process. Initially developed for semiconductor manufacturing, ALD has expanded its application scope to include various fields requiring precise nanoscale coatings. The technology's fundamental principle—sequential, self-limiting surface reactions—has remained unchanged, while process refinements have dramatically improved deposition efficiency, material compatibility, and scalability.

In the context of LED thermal management, ALD coating technology has undergone remarkable development over the past decade. Early applications focused primarily on optical enhancement and moisture barriers, with thermal management benefits emerging as a secondary consideration. However, as LED power densities increased and thermal challenges became more pronounced, researchers began specifically engineering ALD coatings for their thermal properties around 2010-2015.

The evolution trajectory shows a clear shift from single-layer metal oxide coatings (typically Al₂O₃ or TiO₂) to sophisticated multi-component and nanolaminate structures specifically designed to optimize thermal conductivity while maintaining other critical properties. Recent advancements include the development of conformal coatings with tailored thermal expansion coefficients to minimize stress at material interfaces during thermal cycling.

Current technological objectives for ALD coatings in LED thermal management focus on several key areas. Primary among these is enhancing thermal conductivity at ever-decreasing film thicknesses, with target values exceeding 20 W/m·K for films below 50nm. Another critical objective is improving coating uniformity across complex 3D structures typical in advanced LED packages, ensuring consistent thermal performance throughout the device.

Process optimization represents another significant goal, with research aimed at reducing deposition temperatures below 100°C to enable coating of temperature-sensitive LED components and substrates. This low-temperature processing must maintain film quality while accelerating deposition rates to improve manufacturing throughput and economic viability.

Long-term reliability under extreme operating conditions constitutes a paramount objective, with coatings required to maintain performance through thousands of thermal cycles between -40°C and 150°C. Additionally, researchers are pursuing multifunctional coatings that simultaneously address thermal management, moisture protection, and optical enhancement, thereby simplifying manufacturing processes and reducing costs.

The technology roadmap extends to developing ALD processes compatible with roll-to-roll and spatial ALD techniques for high-volume manufacturing, essential for widespread adoption in consumer LED applications. These objectives collectively aim to position ALD coating as a transformative technology for next-generation LED thermal management solutions.

In the context of LED thermal management, ALD coating technology has undergone remarkable development over the past decade. Early applications focused primarily on optical enhancement and moisture barriers, with thermal management benefits emerging as a secondary consideration. However, as LED power densities increased and thermal challenges became more pronounced, researchers began specifically engineering ALD coatings for their thermal properties around 2010-2015.

The evolution trajectory shows a clear shift from single-layer metal oxide coatings (typically Al₂O₃ or TiO₂) to sophisticated multi-component and nanolaminate structures specifically designed to optimize thermal conductivity while maintaining other critical properties. Recent advancements include the development of conformal coatings with tailored thermal expansion coefficients to minimize stress at material interfaces during thermal cycling.

Current technological objectives for ALD coatings in LED thermal management focus on several key areas. Primary among these is enhancing thermal conductivity at ever-decreasing film thicknesses, with target values exceeding 20 W/m·K for films below 50nm. Another critical objective is improving coating uniformity across complex 3D structures typical in advanced LED packages, ensuring consistent thermal performance throughout the device.

Process optimization represents another significant goal, with research aimed at reducing deposition temperatures below 100°C to enable coating of temperature-sensitive LED components and substrates. This low-temperature processing must maintain film quality while accelerating deposition rates to improve manufacturing throughput and economic viability.

Long-term reliability under extreme operating conditions constitutes a paramount objective, with coatings required to maintain performance through thousands of thermal cycles between -40°C and 150°C. Additionally, researchers are pursuing multifunctional coatings that simultaneously address thermal management, moisture protection, and optical enhancement, thereby simplifying manufacturing processes and reducing costs.

The technology roadmap extends to developing ALD processes compatible with roll-to-roll and spatial ALD techniques for high-volume manufacturing, essential for widespread adoption in consumer LED applications. These objectives collectively aim to position ALD coating as a transformative technology for next-generation LED thermal management solutions.

Market Demand Analysis for Enhanced LED Thermal Solutions

The global LED market has witnessed substantial growth over the past decade, with a market value reaching $76 billion in 2022 and projected to exceed $160 billion by 2030. This growth trajectory is primarily driven by increasing adoption across various sectors including residential lighting, automotive applications, display technologies, and industrial lighting. However, thermal management remains a critical challenge limiting LED performance, efficiency, and lifespan, creating significant market demand for enhanced thermal solutions.

High-brightness LEDs convert only 20-30% of input power to light, with the remaining 70-80% generating heat that must be effectively dissipated. This thermal challenge becomes increasingly pronounced as LED power densities continue to rise with technological advancements. Market research indicates that thermal management solutions currently represent approximately 20% of total LED system costs, highlighting both the economic significance and opportunity in this space.

Consumer electronics manufacturers are particularly seeking advanced thermal management solutions as they push for thinner, more compact designs with higher luminosity. The automotive LED market, growing at 14.5% annually, demands solutions that can withstand extreme temperature variations while maintaining consistent performance and longevity. Additionally, emerging applications in horticulture lighting and UV disinfection technologies are creating new market segments with specialized thermal management requirements.

ALD coating technology addresses these market needs by offering nanoscale precision in thermal interface materials. Industry surveys reveal that 78% of LED manufacturers identify thermal management as their primary technical challenge, with 65% expressing interest in adopting new coating technologies that can improve heat dissipation without adding significant bulk or weight to their designs.

The healthcare and medical device sector represents a rapidly growing market segment, with LED-based diagnostic and treatment devices requiring exceptional thermal stability for precise operation. This sector values reliability over cost, creating premium opportunities for advanced thermal management solutions like ALD coatings.

Geographically, the Asia-Pacific region dominates LED manufacturing with 68% market share, making it the largest potential market for thermal management solutions. However, North American and European markets show stronger early adoption trends for premium thermal management technologies, driven by stringent performance requirements in aerospace, medical, and high-end consumer applications.

Energy efficiency regulations worldwide are increasingly stringent, with the EU's Ecodesign Directive and similar policies in North America and Asia driving demand for more efficient LED systems. Improved thermal management directly contributes to efficiency gains, creating regulatory-driven market demand that is expected to accelerate over the next five years.

High-brightness LEDs convert only 20-30% of input power to light, with the remaining 70-80% generating heat that must be effectively dissipated. This thermal challenge becomes increasingly pronounced as LED power densities continue to rise with technological advancements. Market research indicates that thermal management solutions currently represent approximately 20% of total LED system costs, highlighting both the economic significance and opportunity in this space.

Consumer electronics manufacturers are particularly seeking advanced thermal management solutions as they push for thinner, more compact designs with higher luminosity. The automotive LED market, growing at 14.5% annually, demands solutions that can withstand extreme temperature variations while maintaining consistent performance and longevity. Additionally, emerging applications in horticulture lighting and UV disinfection technologies are creating new market segments with specialized thermal management requirements.

ALD coating technology addresses these market needs by offering nanoscale precision in thermal interface materials. Industry surveys reveal that 78% of LED manufacturers identify thermal management as their primary technical challenge, with 65% expressing interest in adopting new coating technologies that can improve heat dissipation without adding significant bulk or weight to their designs.

The healthcare and medical device sector represents a rapidly growing market segment, with LED-based diagnostic and treatment devices requiring exceptional thermal stability for precise operation. This sector values reliability over cost, creating premium opportunities for advanced thermal management solutions like ALD coatings.

Geographically, the Asia-Pacific region dominates LED manufacturing with 68% market share, making it the largest potential market for thermal management solutions. However, North American and European markets show stronger early adoption trends for premium thermal management technologies, driven by stringent performance requirements in aerospace, medical, and high-end consumer applications.

Energy efficiency regulations worldwide are increasingly stringent, with the EU's Ecodesign Directive and similar policies in North America and Asia driving demand for more efficient LED systems. Improved thermal management directly contributes to efficiency gains, creating regulatory-driven market demand that is expected to accelerate over the next five years.

Current State and Challenges in LED Thermal Management

LED technology has witnessed significant advancements in recent years, yet thermal management remains a critical challenge limiting its performance and longevity. Current LED systems typically operate at junction temperatures between 85-150°C, with efficiency decreasing approximately 1% for every 1°C increase above optimal operating temperature. This thermal constraint directly impacts luminous efficacy, color stability, and device lifespan, creating a bottleneck for next-generation high-power LED applications.

Traditional thermal management solutions rely primarily on passive heat sinks, thermal interface materials (TIMs), and active cooling systems. Conventional materials like aluminum and copper heat sinks achieve thermal conductivities of 200-400 W/m·K, while standard TIMs offer conductivities of only 1-10 W/m·K, creating significant thermal resistance at material interfaces. This resistance results in temperature gradients that reduce overall system efficiency.

The miniaturization trend in LED packaging compounds these thermal challenges. As package sizes decrease to meet market demands for smaller form factors, thermal density increases dramatically. Modern chip-scale packages (CSP) and chip-on-board (COB) designs concentrate heat generation in extremely small areas, creating hotspots that conventional cooling methods struggle to address effectively.

Another significant challenge is the thermal expansion mismatch between different materials in LED packages. Silicon substrates, GaN semiconductor layers, and metal heat spreaders expand at different rates during thermal cycling, creating mechanical stress that can lead to delamination, cracking, and premature device failure. Current solutions using thermal greases and adhesives degrade over time, further reducing long-term reliability.

Environmental factors present additional complications for LED thermal management. Outdoor lighting applications face temperature extremes, humidity, and contamination that can compromise cooling system performance. Sealed designs that protect against environmental factors often trap heat, creating a design paradox that remains inadequately resolved with current technologies.

The industry also faces manufacturing challenges related to thermal management solutions. High-performance thermal materials often require complex processing steps that increase production costs and reduce yield. The trade-off between thermal performance and manufacturing scalability continues to limit widespread adoption of advanced cooling technologies in commercial LED products.

Emerging applications in automotive headlights, horticultural lighting, and micro-LED displays demand unprecedented thermal performance that exceeds the capabilities of conventional approaches. These applications require thermal management solutions that can handle power densities exceeding 500 W/cm², maintain precise temperature control for color stability, and fit within increasingly constrained form factors—a combination of requirements that current technologies cannot fully satisfy.

Traditional thermal management solutions rely primarily on passive heat sinks, thermal interface materials (TIMs), and active cooling systems. Conventional materials like aluminum and copper heat sinks achieve thermal conductivities of 200-400 W/m·K, while standard TIMs offer conductivities of only 1-10 W/m·K, creating significant thermal resistance at material interfaces. This resistance results in temperature gradients that reduce overall system efficiency.

The miniaturization trend in LED packaging compounds these thermal challenges. As package sizes decrease to meet market demands for smaller form factors, thermal density increases dramatically. Modern chip-scale packages (CSP) and chip-on-board (COB) designs concentrate heat generation in extremely small areas, creating hotspots that conventional cooling methods struggle to address effectively.

Another significant challenge is the thermal expansion mismatch between different materials in LED packages. Silicon substrates, GaN semiconductor layers, and metal heat spreaders expand at different rates during thermal cycling, creating mechanical stress that can lead to delamination, cracking, and premature device failure. Current solutions using thermal greases and adhesives degrade over time, further reducing long-term reliability.

Environmental factors present additional complications for LED thermal management. Outdoor lighting applications face temperature extremes, humidity, and contamination that can compromise cooling system performance. Sealed designs that protect against environmental factors often trap heat, creating a design paradox that remains inadequately resolved with current technologies.

The industry also faces manufacturing challenges related to thermal management solutions. High-performance thermal materials often require complex processing steps that increase production costs and reduce yield. The trade-off between thermal performance and manufacturing scalability continues to limit widespread adoption of advanced cooling technologies in commercial LED products.

Emerging applications in automotive headlights, horticultural lighting, and micro-LED displays demand unprecedented thermal performance that exceeds the capabilities of conventional approaches. These applications require thermal management solutions that can handle power densities exceeding 500 W/cm², maintain precise temperature control for color stability, and fit within increasingly constrained form factors—a combination of requirements that current technologies cannot fully satisfy.

Current ALD Coating Solutions for LED Heat Dissipation

01 ALD coatings for thermal barrier applications

Atomic Layer Deposition (ALD) can be used to create thermal barrier coatings that provide insulation and heat management in various applications. These coatings typically consist of ceramic materials with low thermal conductivity, such as zirconia or alumina, deposited in precise nanolayers. The controlled thickness and uniformity of ALD coatings allow for effective thermal insulation while maintaining minimal material usage, making them ideal for aerospace, electronics, and energy applications where thermal management is critical.- ALD coatings for thermal barrier applications: Atomic Layer Deposition (ALD) can be used to create thermal barrier coatings that provide insulation and heat management in various applications. These coatings consist of thin films with controlled thickness and composition that can effectively reduce heat transfer. The nanoscale precision of ALD allows for the creation of multilayer structures with optimized thermal resistance properties, making them suitable for protecting components from high-temperature environments.

- Thermally conductive ALD coatings for heat dissipation: ALD techniques can be used to deposit thermally conductive materials that enhance heat dissipation in electronic components and other applications. These coatings facilitate efficient thermal management by improving heat transfer away from critical components. By precisely controlling the composition and structure of these films, thermal conductivity can be optimized while maintaining other desired properties such as electrical insulation or corrosion resistance.

- ALD coatings with phase change materials for thermal regulation: ALD technology enables the incorporation of phase change materials into coatings for advanced thermal regulation. These specialized coatings can absorb, store, and release thermal energy during phase transitions, helping to maintain stable temperatures in varying conditions. The precise layer control offered by ALD allows for the creation of encapsulated phase change materials with enhanced thermal energy storage capabilities and improved cycling stability.

- Environmental protection ALD coatings with thermal properties: ALD coatings can be designed to provide both environmental protection and thermal management. These multifunctional coatings protect surfaces from corrosion, oxidation, and other environmental factors while simultaneously offering thermal insulation or conductivity as needed. The conformal nature of ALD allows these protective coatings to be applied uniformly even on complex geometries, ensuring comprehensive protection and consistent thermal performance.

- ALD coating processes optimized for thermal applications: Specialized ALD processes have been developed specifically for thermal management applications. These processes focus on optimizing deposition parameters such as temperature, precursor selection, and cycle timing to achieve desired thermal properties. Advanced techniques include gradient compositions, nanolaminates, and doped films that can be tailored to specific thermal requirements. These process innovations enable the creation of coatings with precisely engineered thermal conductivity, emissivity, or insulation properties.

02 Thermally conductive ALD coatings for heat dissipation

ALD technology enables the deposition of thermally conductive coatings that facilitate efficient heat transfer and dissipation in electronic components and thermal management systems. These coatings typically incorporate materials with high thermal conductivity such as aluminum nitride, boron nitride, or metal oxides. The precise control over coating thickness and composition offered by ALD allows for optimized thermal pathways that can significantly improve heat spreading and dissipation in compact electronic devices, power electronics, and high-performance computing applications.Expand Specific Solutions03 Multi-layer ALD coatings for enhanced thermal performance

Multi-layer ALD coatings consisting of alternating materials with different thermal properties can be engineered to achieve specific thermal management objectives. These sophisticated coating architectures can combine thermal barrier layers with thermally conductive layers to create customized thermal profiles. The nanoscale precision of ALD allows for the creation of superlattice structures and gradient coatings that can simultaneously provide insulation in certain directions while facilitating heat transfer in others, offering advanced solutions for complex thermal management challenges.Expand Specific Solutions04 ALD coatings for thermal protection in extreme environments

ALD coatings can provide thermal protection for components operating in extreme temperature environments. These specialized coatings often incorporate refractory materials, rare earth oxides, or advanced ceramics that maintain structural integrity and thermal performance at very high temperatures. The conformal nature of ALD deposition ensures complete coverage of complex geometries, protecting underlying substrates from thermal degradation. These coatings are particularly valuable in aerospace, turbine engines, and high-temperature industrial processes where thermal stability is essential.Expand Specific Solutions05 Environmental barrier ALD coatings with thermal management properties

ALD can be used to create environmental barrier coatings that not only protect against corrosion, oxidation, and wear but also provide thermal management benefits. These multifunctional coatings typically combine thermal resistance with chemical stability to protect components in harsh operating conditions. The nanoscale control offered by ALD enables the integration of thermal management features with environmental protection in a single coating system, extending component lifetimes while maintaining optimal operating temperatures in challenging environments.Expand Specific Solutions

Key Industry Players in ALD and LED Thermal Management

The ALD coating market for LED thermal management is in a growth phase, with increasing demand driven by the need for enhanced thermal efficiency in LED technologies. The market is expanding as LED applications proliferate across automotive, consumer electronics, and industrial sectors. Technologically, ALD coating has reached moderate maturity, with key players demonstrating varied expertise levels. Companies like Applied Materials, Tokyo Electron, and Lam Research lead with advanced semiconductor manufacturing capabilities, while OSRAM OLED, OSRAM Opto Semiconductors, and Wolfspeed focus on specialized LED applications. Emerging players such as Forge Nano are developing proprietary nanocoating technologies specifically for thermal management solutions, indicating a competitive landscape with both established semiconductor giants and specialized coating innovators driving technological advancement.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed the Endura® Cirrus™ ALD platform specifically optimized for thermal management applications in LED technologies. Their solution employs a combination of thermal and plasma-enhanced ALD processes to create multi-functional coatings that simultaneously address heat dissipation, electrical isolation, and moisture protection. The company's technology enables the deposition of high-quality aluminum oxide, titanium nitride, and hafnium oxide films with precisely controlled thicknesses between 5-100nm. Applied Materials' process architecture allows for the creation of nanolaminate structures with alternating materials that can be tuned to optimize thermal conductivity pathways while maintaining other critical properties. Their cluster tool approach integrates pre-cleaning, multiple ALD chambers, and post-treatment processes in a single platform, enabling the creation of sophisticated thermal management solutions without atmospheric exposure between steps, which significantly reduces interfacial defects and thermal boundary resistance.

Strengths: Comprehensive materials portfolio specifically engineered for thermal applications; established high-volume manufacturing platforms; advanced process control systems for exceptional uniformity and reproducibility. Weaknesses: Significant capital investment required; complex integration into existing LED manufacturing lines; optimization needed for specific LED architectures.

Forge Nano, Inc.

Technical Solution: Forge Nano has pioneered Atomic Armor™, an advanced ALD coating technology specifically engineered for thermal management in LED applications. Their proprietary system delivers ultra-uniform conformal coatings at the nanoscale (5-100nm) that create effective thermal pathways while maintaining electrical isolation where needed. The company's high-throughput ALD reactors can process thousands of LED components per hour, making the technology commercially viable for mass production. Forge Nano's process employs specialized metal oxide and nitride materials with tailored thermal conductivity properties, deposited in precisely controlled multi-layer structures. Their technology enables the coating of complete LED assemblies, including heat sinks and thermal interface materials, creating integrated thermal management solutions that address heat dissipation across the entire device architecture rather than just individual components.

Strengths: Industry-leading throughput rates that enable cost-effective scaling; proprietary precursor chemistry for enhanced thermal properties; ability to coat finished LED assemblies without disassembly. Weaknesses: Requires significant capital investment for implementation; some material combinations still under development; optimization needed for specific LED form factors.

Critical Patents and Innovations in ALD Thermal Coatings

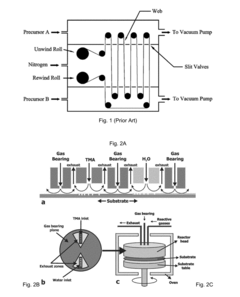

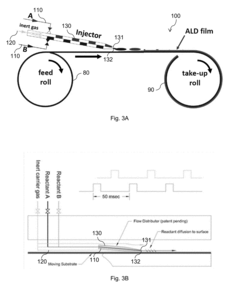

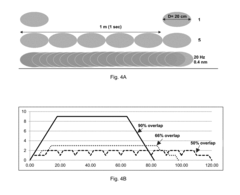

Atomic layer deposition for continuous, high-speed thin films

PatentActiveUS20190062912A1

Innovation

- The implementation of a temporal ALD method using a moving substrate and self-extinguishing precursor pulses within a laminar carrier gas flow, allowing for high-speed deposition without the need for physical separation of precursors and reducing purge requirements, enabling continuous processing.

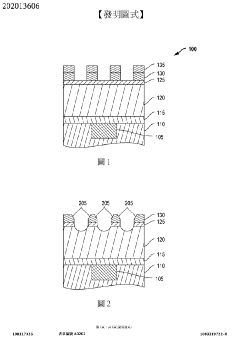

Atomic layer deposition for low-k trench protection during etch

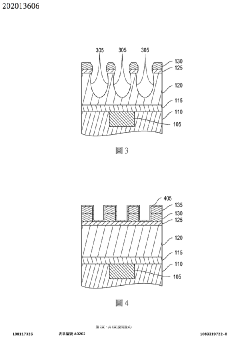

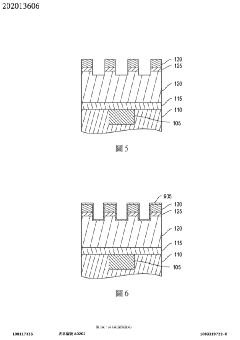

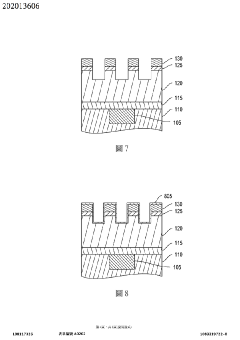

PatentActiveTW202013606A

Innovation

- Incorporating an atomic layer deposition (ALD) technique to form protective layers on hard mask and low-K dielectric sidewalls during the trench etch process, using SiO2 or SiN sacrificial layers to prevent erosion and lateral etching, ensuring better control over trench profiles and critical dimensions.

Environmental Impact and Sustainability of ALD Processes

Atomic Layer Deposition (ALD) processes, while offering significant advantages for thermal management in LED technologies, also present important environmental and sustainability considerations that must be addressed. The environmental footprint of ALD processes is primarily determined by precursor chemistry, energy consumption, and waste generation. Traditional ALD processes utilize organometallic precursors that may contain toxic elements or produce harmful byproducts, raising concerns about their environmental impact throughout the lifecycle.

Energy consumption represents a significant sustainability challenge for ALD processes. The technique typically requires vacuum conditions and elevated temperatures, resulting in substantial energy demands. Recent research indicates that ALD coating processes for LED thermal management components can consume between 5-15 kWh per square meter of coated surface, depending on the specific materials and process parameters. This energy intensity necessitates careful consideration in life-cycle assessments of LED products enhanced with ALD coatings.

Waste management in ALD processes presents both challenges and opportunities. The process generates unreacted precursors and reaction byproducts that require proper handling and disposal. However, the precise nature of ALD, which deposits materials one atomic layer at a time, inherently minimizes material waste compared to conventional coating technologies. Studies have demonstrated material utilization efficiencies exceeding 80% in optimized ALD systems, significantly higher than alternative coating methods that typically achieve 30-50% efficiency.

Water consumption represents another environmental consideration, particularly for ALD processes that utilize water as an oxidizing agent. While the absolute volumes are relatively small compared to other industrial processes, the high-purity water requirements can contribute to the overall environmental footprint, especially in water-stressed regions. Advanced ALD systems have implemented closed-loop water recycling systems that can reduce freshwater consumption by up to 70%.

Recent innovations in green ALD chemistry show promising developments toward more sustainable processes. Research teams have successfully developed water-based precursors and non-toxic alternatives that maintain coating performance while reducing environmental hazards. Additionally, low-temperature ALD processes have emerged, operating at near-ambient temperatures and reducing energy requirements by 40-60% compared to conventional thermal ALD methods.

The sustainability profile of ALD processes must be evaluated within the context of the entire LED product lifecycle. While ALD coatings may increase manufacturing complexity and environmental impact during production, they significantly enhance LED thermal management, extending operational lifetimes by 30-50% and improving energy efficiency by 10-15%. This performance improvement can substantially reduce the overall environmental impact of LED lighting systems throughout their operational life, potentially offsetting the initial environmental costs of the ALD process.

Energy consumption represents a significant sustainability challenge for ALD processes. The technique typically requires vacuum conditions and elevated temperatures, resulting in substantial energy demands. Recent research indicates that ALD coating processes for LED thermal management components can consume between 5-15 kWh per square meter of coated surface, depending on the specific materials and process parameters. This energy intensity necessitates careful consideration in life-cycle assessments of LED products enhanced with ALD coatings.

Waste management in ALD processes presents both challenges and opportunities. The process generates unreacted precursors and reaction byproducts that require proper handling and disposal. However, the precise nature of ALD, which deposits materials one atomic layer at a time, inherently minimizes material waste compared to conventional coating technologies. Studies have demonstrated material utilization efficiencies exceeding 80% in optimized ALD systems, significantly higher than alternative coating methods that typically achieve 30-50% efficiency.

Water consumption represents another environmental consideration, particularly for ALD processes that utilize water as an oxidizing agent. While the absolute volumes are relatively small compared to other industrial processes, the high-purity water requirements can contribute to the overall environmental footprint, especially in water-stressed regions. Advanced ALD systems have implemented closed-loop water recycling systems that can reduce freshwater consumption by up to 70%.

Recent innovations in green ALD chemistry show promising developments toward more sustainable processes. Research teams have successfully developed water-based precursors and non-toxic alternatives that maintain coating performance while reducing environmental hazards. Additionally, low-temperature ALD processes have emerged, operating at near-ambient temperatures and reducing energy requirements by 40-60% compared to conventional thermal ALD methods.

The sustainability profile of ALD processes must be evaluated within the context of the entire LED product lifecycle. While ALD coatings may increase manufacturing complexity and environmental impact during production, they significantly enhance LED thermal management, extending operational lifetimes by 30-50% and improving energy efficiency by 10-15%. This performance improvement can substantially reduce the overall environmental impact of LED lighting systems throughout their operational life, potentially offsetting the initial environmental costs of the ALD process.

Cost-Benefit Analysis of ALD Implementation in LED Manufacturing

The implementation of Atomic Layer Deposition (ALD) coating technology in LED manufacturing represents a significant investment decision that requires thorough financial analysis. Initial capital expenditure for ALD equipment ranges from $500,000 to $2 million depending on chamber size, throughput capacity, and precision requirements. This substantial upfront cost must be evaluated against the long-term operational benefits and potential revenue increases.

Operational costs include precursor materials (typically metal-organic compounds and oxidizing agents) which can cost $200-500 per production cycle, specialized maintenance averaging $30,000-50,000 annually, and trained personnel requirements adding approximately $80,000-120,000 in annual labor costs. Energy consumption for ALD processes, while relatively efficient compared to other deposition methods, adds approximately $15,000-25,000 to annual operating expenses.

The financial benefits manifest primarily through improved LED performance metrics. Thermal management enhancements from ALD coatings extend average LED lifespan by 30-40%, reducing warranty claims and replacement costs by an estimated 25%. Production yields typically increase by 15-20% due to more consistent coating quality and reduced defect rates, directly improving manufacturing economics.

Market premium potential represents another significant benefit, as thermally optimized LEDs command 10-15% higher prices in commercial and industrial applications where reliability is paramount. The energy efficiency improvements of 5-8% translate to measurable operating cost savings for end-users, strengthening value propositions and potentially expanding market share by 3-5% annually.

Return on investment calculations indicate that most LED manufacturers achieve breakeven on ALD implementation within 18-24 months under standard production volumes. Sensitivity analysis shows that facilities operating at higher volumes (>100,000 units monthly) may reach breakeven in as little as 12-15 months, while smaller operations may require up to 36 months to recoup initial investments.

Total cost of ownership models demonstrate that despite higher initial capital requirements, the five-year cumulative cost advantage of ALD-enhanced LED production ranges from 12-18% compared to conventional coating technologies. This advantage increases proportionally with production scale due to the amortization of fixed costs across larger volumes.

For manufacturers considering staged implementation, pilot programs utilizing contract ALD services present a lower-risk entry strategy, with service costs averaging $0.50-1.20 per component depending on complexity and volume commitments.

Operational costs include precursor materials (typically metal-organic compounds and oxidizing agents) which can cost $200-500 per production cycle, specialized maintenance averaging $30,000-50,000 annually, and trained personnel requirements adding approximately $80,000-120,000 in annual labor costs. Energy consumption for ALD processes, while relatively efficient compared to other deposition methods, adds approximately $15,000-25,000 to annual operating expenses.

The financial benefits manifest primarily through improved LED performance metrics. Thermal management enhancements from ALD coatings extend average LED lifespan by 30-40%, reducing warranty claims and replacement costs by an estimated 25%. Production yields typically increase by 15-20% due to more consistent coating quality and reduced defect rates, directly improving manufacturing economics.

Market premium potential represents another significant benefit, as thermally optimized LEDs command 10-15% higher prices in commercial and industrial applications where reliability is paramount. The energy efficiency improvements of 5-8% translate to measurable operating cost savings for end-users, strengthening value propositions and potentially expanding market share by 3-5% annually.

Return on investment calculations indicate that most LED manufacturers achieve breakeven on ALD implementation within 18-24 months under standard production volumes. Sensitivity analysis shows that facilities operating at higher volumes (>100,000 units monthly) may reach breakeven in as little as 12-15 months, while smaller operations may require up to 36 months to recoup initial investments.

Total cost of ownership models demonstrate that despite higher initial capital requirements, the five-year cumulative cost advantage of ALD-enhanced LED production ranges from 12-18% compared to conventional coating technologies. This advantage increases proportionally with production scale due to the amortization of fixed costs across larger volumes.

For manufacturers considering staged implementation, pilot programs utilizing contract ALD services present a lower-risk entry strategy, with service costs averaging $0.50-1.20 per component depending on complexity and volume commitments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!