ALD Coating Standards and Their Implications for Quality Assurance

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ALD Coating Technology Evolution and Objectives

Atomic Layer Deposition (ALD) technology has evolved significantly since its inception in the 1970s, transitioning from a laboratory curiosity to a critical manufacturing process in semiconductor fabrication and various high-tech industries. The journey began with the pioneering work of Tuomo Suntola in Finland, who developed the first ALD processes for electroluminescent displays. This fundamental technology has since undergone remarkable refinement, particularly in the last two decades, as demands for precise nanoscale coatings have intensified across multiple industries.

The evolution of ALD coating technology has been characterized by several key milestones. Initially limited to simple binary compounds like Al2O3 and ZnS, the material palette has expanded dramatically to include complex oxides, nitrides, metals, and hybrid organic-inorganic materials. Process temperatures have been reduced from high-temperature regimes (>300°C) to room temperature applications, enabling coating of temperature-sensitive substrates including polymers and biological materials.

Equipment design has similarly progressed from basic research tools to sophisticated high-volume manufacturing systems capable of processing multiple wafers simultaneously while maintaining atomic-level precision. This scaling has been crucial for the technology's commercial viability in semiconductor manufacturing, where throughput requirements are stringent.

The primary objective of modern ALD coating technology is to achieve unprecedented control over film thickness, composition, and conformality at the atomic scale. This precision enables the creation of ultra-thin, pinhole-free barrier layers and functional coatings with tailored properties. As devices continue to miniaturize and 3D architectures become more complex, ALD's ability to coat high-aspect-ratio structures uniformly has become increasingly valuable.

Current technological objectives focus on several fronts: expanding the material library to include more complex functional materials, developing selective deposition techniques that enable bottom-up fabrication approaches, increasing throughput without sacrificing quality, and establishing robust standardization protocols for quality assurance across different equipment platforms and manufacturing environments.

The standardization aspect has become particularly critical as ALD applications diversify beyond microelectronics into areas such as medical devices, energy storage, and optical coatings. Each application domain brings unique requirements for coating performance, durability, and safety, necessitating tailored quality assurance frameworks that can reliably verify conformance to specifications while accommodating the atomic-scale precision inherent to the process.

The evolution of ALD coating technology has been characterized by several key milestones. Initially limited to simple binary compounds like Al2O3 and ZnS, the material palette has expanded dramatically to include complex oxides, nitrides, metals, and hybrid organic-inorganic materials. Process temperatures have been reduced from high-temperature regimes (>300°C) to room temperature applications, enabling coating of temperature-sensitive substrates including polymers and biological materials.

Equipment design has similarly progressed from basic research tools to sophisticated high-volume manufacturing systems capable of processing multiple wafers simultaneously while maintaining atomic-level precision. This scaling has been crucial for the technology's commercial viability in semiconductor manufacturing, where throughput requirements are stringent.

The primary objective of modern ALD coating technology is to achieve unprecedented control over film thickness, composition, and conformality at the atomic scale. This precision enables the creation of ultra-thin, pinhole-free barrier layers and functional coatings with tailored properties. As devices continue to miniaturize and 3D architectures become more complex, ALD's ability to coat high-aspect-ratio structures uniformly has become increasingly valuable.

Current technological objectives focus on several fronts: expanding the material library to include more complex functional materials, developing selective deposition techniques that enable bottom-up fabrication approaches, increasing throughput without sacrificing quality, and establishing robust standardization protocols for quality assurance across different equipment platforms and manufacturing environments.

The standardization aspect has become particularly critical as ALD applications diversify beyond microelectronics into areas such as medical devices, energy storage, and optical coatings. Each application domain brings unique requirements for coating performance, durability, and safety, necessitating tailored quality assurance frameworks that can reliably verify conformance to specifications while accommodating the atomic-scale precision inherent to the process.

Market Demand Analysis for ALD Coating Standards

The global market for Atomic Layer Deposition (ALD) coating standards has witnessed significant growth in recent years, driven primarily by the increasing demand for high-precision thin film applications in semiconductor manufacturing, microelectronics, and emerging technologies. Current market analysis indicates that the ALD coating market is expanding at a compound annual growth rate of approximately 15% globally, with particularly strong demand in Asia-Pacific and North American regions.

Industry stakeholders, including semiconductor manufacturers, research institutions, and quality assurance organizations, have expressed growing concerns regarding the lack of standardized protocols for ALD coating processes. This demand for standardization stems from the critical need for consistent quality, reproducibility, and reliability in nanoscale coating applications where even minor variations can significantly impact device performance.

The semiconductor industry represents the largest market segment demanding ALD coating standards, as manufacturers face increasing pressure to achieve atomic-level precision in chip fabrication processes. With transistor dimensions continuing to shrink below 5nm, the tolerance for coating inconsistencies has virtually disappeared, creating urgent market demand for comprehensive quality assurance frameworks.

Medical device manufacturers constitute another rapidly growing market segment seeking standardized ALD coating protocols. The biocompatibility and durability requirements for implantable devices necessitate exceptionally uniform and defect-free coatings, driving demand for rigorous testing and certification standards that can ensure patient safety and regulatory compliance.

Market research indicates that equipment manufacturers and material suppliers are increasingly recognizing standardization as a competitive advantage. Companies that can demonstrate adherence to recognized ALD coating standards command premium pricing and preferred supplier status, particularly in high-reliability applications such as aerospace, defense, and medical technologies.

The energy sector represents an emerging market for ALD coating standards, particularly in battery technology, fuel cells, and photovoltaics. As these technologies advance toward commercial viability, manufacturers require standardized methods to evaluate coating performance, durability, and consistency across production batches.

Customer surveys reveal that end-users are willing to pay a premium of 10-20% for products with certified ALD coatings that meet internationally recognized standards. This price elasticity underscores the significant value that standardization brings to the marketplace and indicates strong economic incentives for the development and adoption of comprehensive ALD coating standards.

Industry stakeholders, including semiconductor manufacturers, research institutions, and quality assurance organizations, have expressed growing concerns regarding the lack of standardized protocols for ALD coating processes. This demand for standardization stems from the critical need for consistent quality, reproducibility, and reliability in nanoscale coating applications where even minor variations can significantly impact device performance.

The semiconductor industry represents the largest market segment demanding ALD coating standards, as manufacturers face increasing pressure to achieve atomic-level precision in chip fabrication processes. With transistor dimensions continuing to shrink below 5nm, the tolerance for coating inconsistencies has virtually disappeared, creating urgent market demand for comprehensive quality assurance frameworks.

Medical device manufacturers constitute another rapidly growing market segment seeking standardized ALD coating protocols. The biocompatibility and durability requirements for implantable devices necessitate exceptionally uniform and defect-free coatings, driving demand for rigorous testing and certification standards that can ensure patient safety and regulatory compliance.

Market research indicates that equipment manufacturers and material suppliers are increasingly recognizing standardization as a competitive advantage. Companies that can demonstrate adherence to recognized ALD coating standards command premium pricing and preferred supplier status, particularly in high-reliability applications such as aerospace, defense, and medical technologies.

The energy sector represents an emerging market for ALD coating standards, particularly in battery technology, fuel cells, and photovoltaics. As these technologies advance toward commercial viability, manufacturers require standardized methods to evaluate coating performance, durability, and consistency across production batches.

Customer surveys reveal that end-users are willing to pay a premium of 10-20% for products with certified ALD coatings that meet internationally recognized standards. This price elasticity underscores the significant value that standardization brings to the marketplace and indicates strong economic incentives for the development and adoption of comprehensive ALD coating standards.

Current Standards Landscape and Technical Challenges

The Atomic Layer Deposition (ALD) coating industry currently faces a fragmented standards landscape, with no unified global framework specifically tailored for ALD processes. Organizations such as ASTM International, ISO, and SEMI have developed adjacent standards that partially address thin film deposition, but comprehensive ALD-specific standards remain limited. This fragmentation creates significant challenges for quality assurance across the supply chain and hinders industry-wide consistency.

Current standards primarily focus on general thin film properties rather than the unique characteristics of ALD processes. ASTM E42 addresses surface analysis techniques applicable to ALD films, while ISO 14644 covers cleanroom environments where ALD equipment operates. However, these standards fail to address the precise process control parameters critical to ALD coating quality, such as precursor purity specifications, pulse/purge timing optimization, and conformality metrics.

A major technical challenge in standardization stems from the diverse application landscape of ALD coatings. The semiconductor industry requires ultra-thin, defect-free films with precise thickness control, while medical implant coatings prioritize biocompatibility and long-term stability. This application diversity makes developing universal standards particularly difficult, as quality metrics vary significantly across sectors.

Process variability presents another substantial challenge. ALD equipment from different manufacturers often employs proprietary designs and control systems, resulting in process variations that complicate standardization efforts. The industry lacks consensus on reference materials and calibration protocols, making cross-platform comparisons problematic and hindering meaningful benchmarking.

Metrology limitations further compound standardization challenges. Current measurement techniques struggle with the ultra-thin films (often <10nm) produced by ALD processes. Techniques like ellipsometry require complex modeling and can produce different results depending on the model assumptions. Standardized measurement protocols that account for these limitations are notably absent in the current landscape.

Emerging applications in areas such as flexible electronics, quantum computing, and energy storage are pushing ALD technology beyond traditional parameters, creating new quality assurance challenges not addressed by existing standards frameworks. These applications often require novel substrate materials and complex 3D geometries that traditional quality metrics cannot adequately evaluate.

The economic implications of this standards gap are significant. Without clear quality benchmarks, manufacturers face increased testing costs, longer development cycles, and potential market barriers. End users struggle to compare products from different suppliers, leading to market inefficiencies and potential reliability issues in critical applications.

Current standards primarily focus on general thin film properties rather than the unique characteristics of ALD processes. ASTM E42 addresses surface analysis techniques applicable to ALD films, while ISO 14644 covers cleanroom environments where ALD equipment operates. However, these standards fail to address the precise process control parameters critical to ALD coating quality, such as precursor purity specifications, pulse/purge timing optimization, and conformality metrics.

A major technical challenge in standardization stems from the diverse application landscape of ALD coatings. The semiconductor industry requires ultra-thin, defect-free films with precise thickness control, while medical implant coatings prioritize biocompatibility and long-term stability. This application diversity makes developing universal standards particularly difficult, as quality metrics vary significantly across sectors.

Process variability presents another substantial challenge. ALD equipment from different manufacturers often employs proprietary designs and control systems, resulting in process variations that complicate standardization efforts. The industry lacks consensus on reference materials and calibration protocols, making cross-platform comparisons problematic and hindering meaningful benchmarking.

Metrology limitations further compound standardization challenges. Current measurement techniques struggle with the ultra-thin films (often <10nm) produced by ALD processes. Techniques like ellipsometry require complex modeling and can produce different results depending on the model assumptions. Standardized measurement protocols that account for these limitations are notably absent in the current landscape.

Emerging applications in areas such as flexible electronics, quantum computing, and energy storage are pushing ALD technology beyond traditional parameters, creating new quality assurance challenges not addressed by existing standards frameworks. These applications often require novel substrate materials and complex 3D geometries that traditional quality metrics cannot adequately evaluate.

The economic implications of this standards gap are significant. Without clear quality benchmarks, manufacturers face increased testing costs, longer development cycles, and potential market barriers. End users struggle to compare products from different suppliers, leading to market inefficiencies and potential reliability issues in critical applications.

Existing Quality Assurance Methodologies for ALD

01 Quality control systems for ALD coating processes

Atomic Layer Deposition (ALD) coating processes require sophisticated quality control systems to ensure consistent film thickness and properties. These systems typically involve real-time monitoring equipment, automated inspection protocols, and statistical process control methods to detect deviations from established standards. Quality assurance for ALD coatings often includes in-line measurement techniques and feedback mechanisms that allow for immediate process adjustments when parameters drift outside acceptable ranges.- Quality control systems for ALD coating processes: Quality assurance systems specifically designed for Atomic Layer Deposition (ALD) coating processes involve automated inspection and monitoring tools that ensure coating uniformity and adherence to specifications. These systems typically include real-time monitoring capabilities, statistical process control methods, and automated defect detection to maintain consistent coating quality across production batches.

- Measurement and testing standards for ALD coatings: Standardized measurement and testing protocols for ALD coatings include thickness measurement techniques, adhesion testing, and compositional analysis. These standards establish consistent methods for evaluating coating quality attributes such as uniformity, conformality, and defect density, enabling reliable quality verification across different manufacturing environments.

- Process automation and control for ALD quality assurance: Advanced process automation and control systems for ALD coating operations incorporate feedback mechanisms that adjust process parameters in real-time based on quality measurements. These systems utilize machine learning algorithms to optimize coating parameters, predict potential defects, and maintain process stability, thereby ensuring consistent coating quality while minimizing manual intervention.

- Documentation and compliance systems for ALD coating standards: Comprehensive documentation and compliance systems for ALD coating processes track all quality-related data throughout the production lifecycle. These systems maintain detailed records of process parameters, test results, and quality certifications, facilitating regulatory compliance and enabling traceability for quality audits and customer verification requirements.

- Thermal management and environmental control for ALD quality: Specialized thermal management and environmental control systems for ALD processes maintain precise temperature, humidity, and contamination control required for high-quality coatings. These systems include advanced temperature monitoring, environmental isolation techniques, and contamination prevention measures that ensure optimal conditions for consistent coating deposition and adherence to quality standards.

02 Standardization and certification of ALD coating processes

Standardization frameworks for ALD coating processes establish industry-wide benchmarks for quality and performance. These standards define acceptable ranges for coating thickness, uniformity, adhesion strength, and other critical parameters. Certification protocols verify that manufacturing facilities meet these standards through regular audits, documentation reviews, and testing procedures. Compliance with international standards ensures that ALD coatings meet specific requirements for various applications, particularly in industries with strict regulatory oversight.Expand Specific Solutions03 Automated inspection and defect detection for ALD coatings

Advanced imaging and sensing technologies enable automated inspection of ALD coatings to detect defects, pinholes, and non-uniformities. These systems employ machine vision algorithms, spectroscopic techniques, and high-resolution microscopy to identify quality issues that might be invisible to the human eye. Automated defect classification systems categorize and track defect types, allowing manufacturers to address systematic problems in their coating processes and improve overall quality assurance procedures.Expand Specific Solutions04 Process monitoring and control systems for ALD

Real-time monitoring systems for ALD processes track critical parameters such as precursor flow rates, chamber pressure, temperature profiles, and plasma characteristics. These systems collect and analyze data to ensure that coating processes remain within specification limits. Advanced control algorithms can automatically adjust process parameters to compensate for drift or equipment aging, maintaining consistent coating quality. Integration with manufacturing execution systems allows for comprehensive tracking of quality metrics across production batches.Expand Specific Solutions05 Testing methodologies for ALD coating performance validation

Comprehensive testing methodologies validate the performance and reliability of ALD coatings against established standards. These include adhesion tests, environmental exposure trials, chemical resistance evaluations, and accelerated aging protocols. Specialized equipment measures coating thickness with nanometer precision, while analytical techniques characterize chemical composition and crystalline structure. Statistical sampling plans ensure that quality testing provides representative data about overall production quality, enabling manufacturers to make data-driven decisions about process improvements.Expand Specific Solutions

Key Industry Players and Standardization Bodies

The ALD coating standards landscape is evolving rapidly as the technology matures from emerging to established status. The market is experiencing significant growth, projected to reach $3-4 billion by 2025, driven by semiconductor, electronics, and medical applications. The competitive environment features established equipment manufacturers like Applied Materials and Lam Research dominating the high-volume production segment, while specialized players such as Beneq, Picosun, and Forge Nano focus on niche applications and innovation. Technical maturity varies across applications, with semiconductor implementations being most advanced. Recent collaborations between industry leaders (Intel, Samsung, Micron) and research institutions (North Carolina State University, University of Oslo) are accelerating standardization efforts, particularly for quality assurance protocols in high-precision manufacturing environments.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed comprehensive ALD coating standards through their Precision Materials Engineering solutions. Their approach integrates in-situ metrology systems that monitor film thickness, uniformity, and composition in real-time during deposition processes. The company's Endura® platform incorporates advanced process control algorithms that automatically adjust deposition parameters based on real-time measurements, ensuring consistent film quality across wafers and production runs. Applied Materials has established a multi-point quality assurance framework that includes pre-deposition surface preparation standards, in-process monitoring protocols, and post-deposition characterization techniques. Their quality standards emphasize the importance of precise precursor delivery systems with controlled temperature zones and optimized purge cycles to prevent cross-contamination and ensure conformal coating integrity. The company also maintains a database of material-specific process recipes that have been validated against industry standards such as SEMI and ASTM specifications for semiconductor manufacturing.

Strengths: Comprehensive integration of metrology with deposition systems enables real-time quality control; extensive experience in semiconductor manufacturing provides deep understanding of precision requirements. Weaknesses: Solutions are primarily optimized for high-volume semiconductor manufacturing environments; implementation costs can be prohibitive for smaller operations.

Beneq Group Oy

Technical Solution: Beneq has pioneered specialized ALD coating standards focused on industrial applications beyond semiconductors. Their technical approach centers on the development of the "Beneq ALD Quality Index" - a proprietary scoring system that evaluates coating quality based on multiple parameters including conformality, pinhole density, and interface quality. Beneq's standards incorporate specialized testing protocols for challenging geometries such as high-aspect-ratio structures and porous substrates, where traditional quality metrics often fail. Their TFS (Thin Film Systems) product line features dedicated quality assurance modules that perform automated optical inspection and electrical characterization of ALD films. Beneq has also developed industry-specific standards for moisture barrier applications, with quantifiable metrics for water vapor transmission rate (WVTR) performance in encapsulation layers. The company maintains a collaborative approach to standards development, working with research institutions to establish reference materials and measurement protocols that can be used across the ALD industry for benchmarking coating performance.

Strengths: Specialized expertise in industrial and challenging applications beyond semiconductors; comprehensive quality metrics specifically designed for ALD processes. Weaknesses: Proprietary standards may limit broader industry adoption; quality assurance systems require significant technical expertise to implement effectively.

Critical Patents and Literature on ALD Standardization

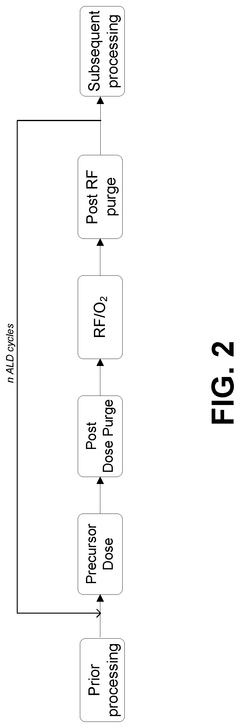

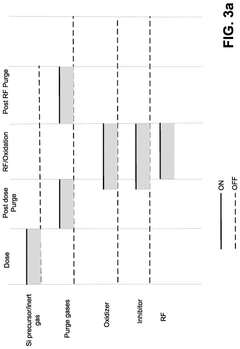

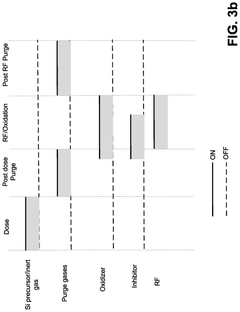

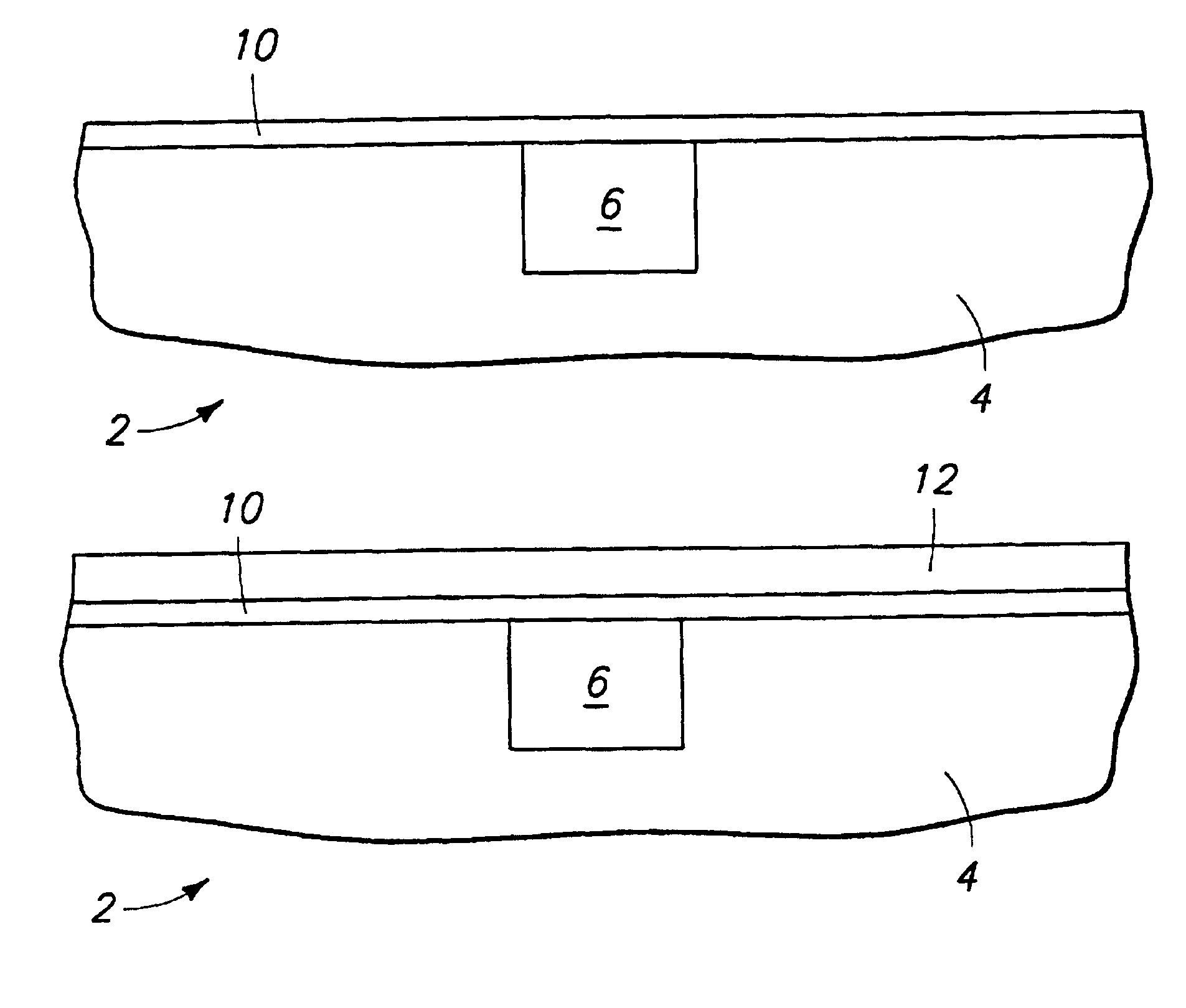

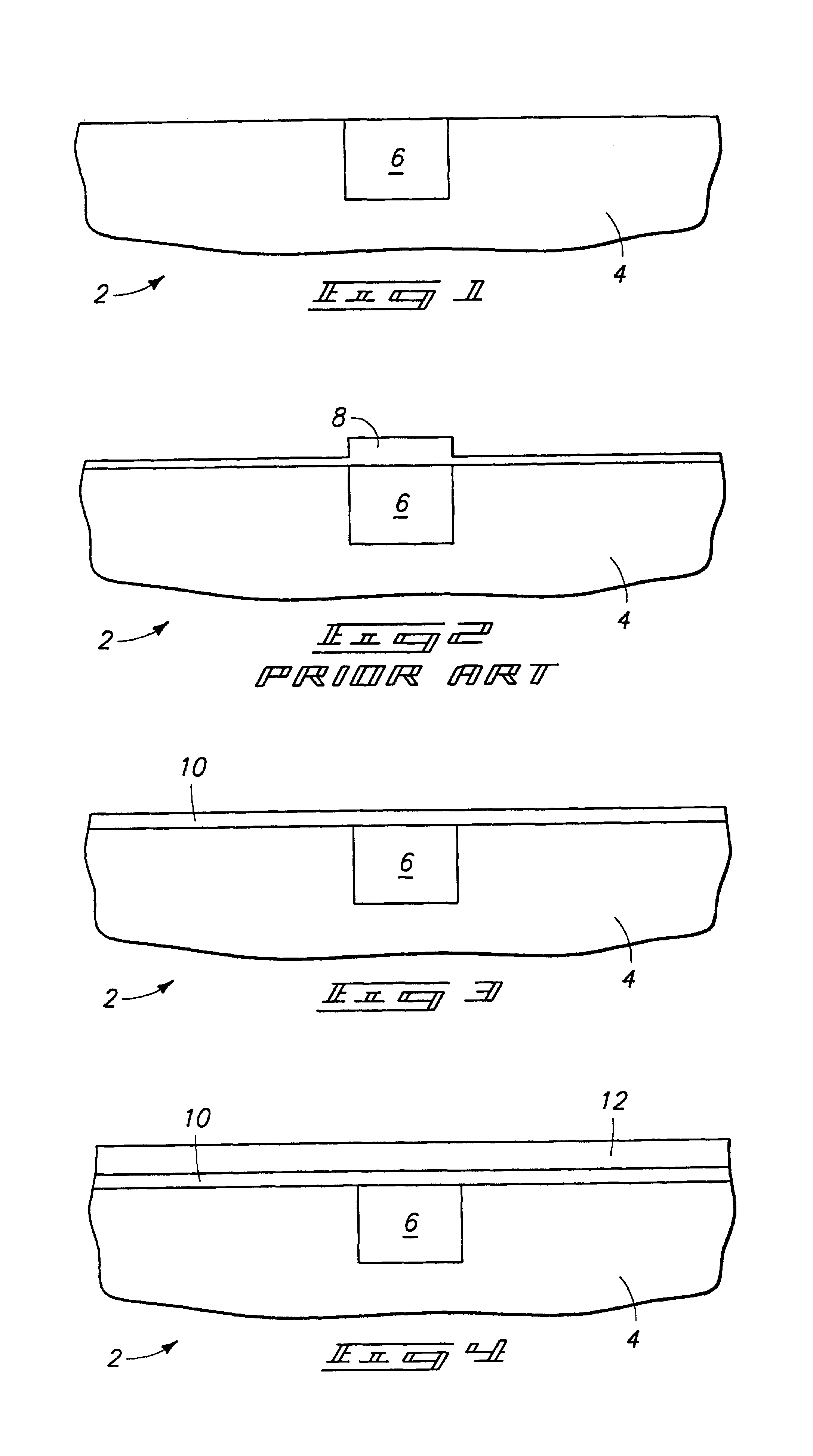

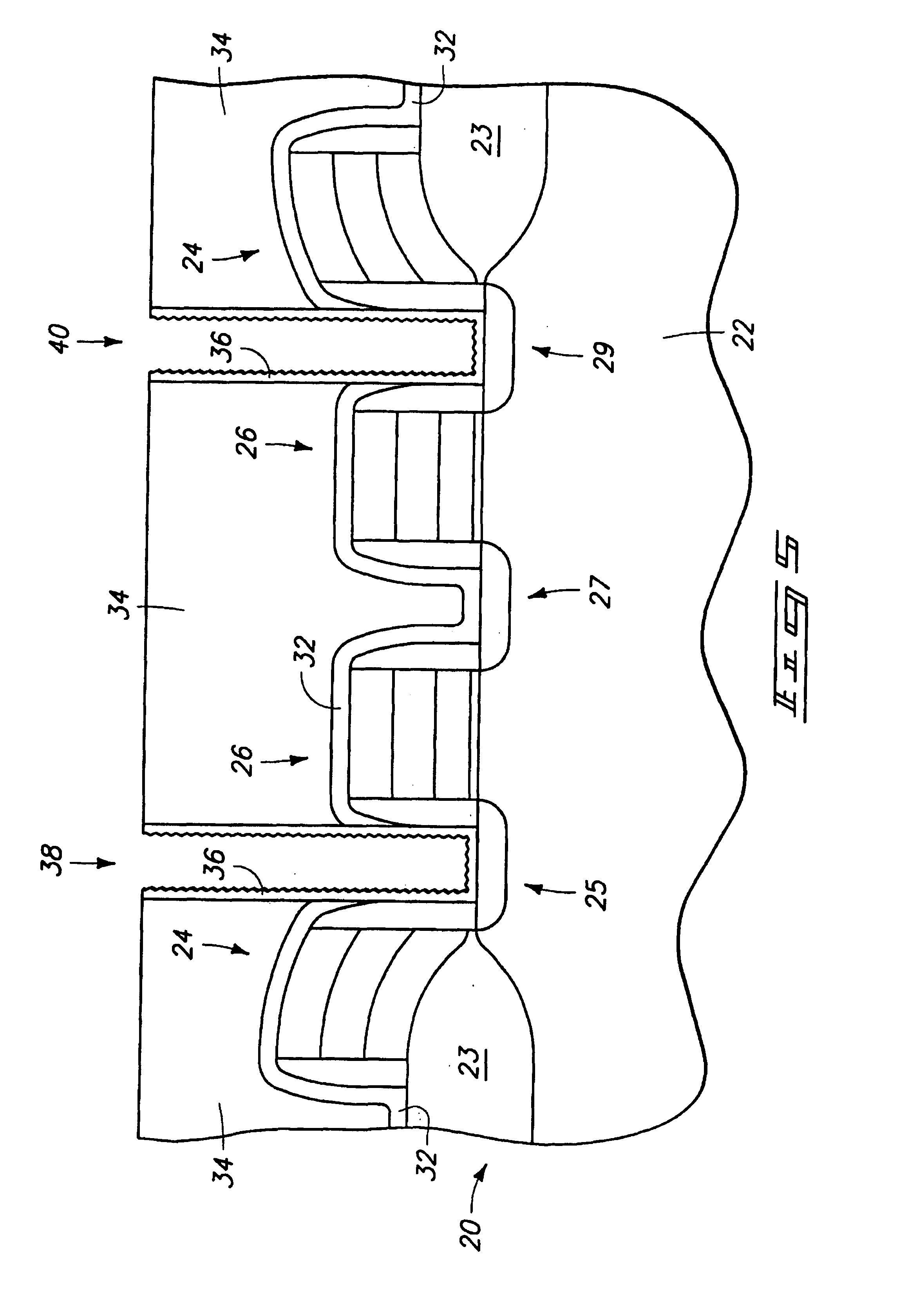

Surface inhibition atomic layer deposition

PatentPendingUS20250179632A1

Innovation

- The use of atomic layer deposition (ALD) processes with a reaction inhibitor, such as nitrogen trifluoride (NF3), is introduced during the plasma operation to inhibit deposition at the top of the gap, allowing for void-free bottom-up gap fill.

Low selectivity deposition methods

PatentInactiveUS7192888B1

Innovation

- The method involves forming a nucleation layer with specific compositions such as silicon nitride, aluminum oxide, or tantalum oxide, which is chemisorbed with a first and second substance to create a uniform surface for subsequent deposition, allowing for non-selective deposition even on surfaces with varying properties, using techniques like ALD or CVD, and maintaining optimal thickness below 20 Angstroms to minimize impact on the final layer.

Regulatory Compliance Framework for ALD Applications

The regulatory landscape for Atomic Layer Deposition (ALD) coating technologies spans multiple industries and jurisdictions, creating a complex compliance environment that manufacturers must navigate. At the international level, organizations such as the International Organization for Standardization (ISO) have established foundational standards that address thin film deposition processes, including ISO 14644 for cleanroom environments where ALD processes typically occur. These standards provide critical guidelines for contamination control and environmental parameters essential for high-quality ALD applications.

In the semiconductor industry, which represents a primary application area for ALD coatings, the SEMI Standards program has developed specific guidelines addressing various aspects of thin film deposition. SEMI Standard F21 specifically addresses the requirements for evaluating and qualifying thin film deposition equipment, providing a framework for quality assurance in ALD processes. Additionally, the International Technology Roadmap for Semiconductors (ITRS) offers guidance on technological requirements that indirectly influence ALD quality standards.

For medical device applications, ALD coatings must comply with FDA regulations in the United States, particularly 21 CFR Part 820 for Quality System Regulation. In Europe, the Medical Device Regulation (MDR 2017/745) imposes stringent requirements for materials used in medical devices, including ALD coatings. These regulations necessitate comprehensive documentation of coating properties, biocompatibility testing, and stability assessments.

The aerospace and defense sectors maintain their own rigorous standards through organizations like SAE International and the Department of Defense. MIL-STD-810 addresses environmental testing methods that ALD coatings must withstand, while NASA has developed specialized standards for space applications where ALD coatings provide critical protection against extreme environments.

Environmental regulations also significantly impact ALD processes, with the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives restricting the use of certain precursors and materials. Similar regulations exist globally, requiring manufacturers to carefully select ALD precursors and processes that minimize environmental impact while maintaining coating performance.

Compliance verification typically involves a multi-tiered approach including material characterization, process validation, and performance testing. Techniques such as X-ray photoelectron spectroscopy (XPS), atomic force microscopy (AFM), and ellipsometry are commonly employed to verify coating conformity to standards. Documentation requirements vary by industry but generally include detailed process parameters, material specifications, and quality control procedures that demonstrate consistent compliance with applicable regulations.

In the semiconductor industry, which represents a primary application area for ALD coatings, the SEMI Standards program has developed specific guidelines addressing various aspects of thin film deposition. SEMI Standard F21 specifically addresses the requirements for evaluating and qualifying thin film deposition equipment, providing a framework for quality assurance in ALD processes. Additionally, the International Technology Roadmap for Semiconductors (ITRS) offers guidance on technological requirements that indirectly influence ALD quality standards.

For medical device applications, ALD coatings must comply with FDA regulations in the United States, particularly 21 CFR Part 820 for Quality System Regulation. In Europe, the Medical Device Regulation (MDR 2017/745) imposes stringent requirements for materials used in medical devices, including ALD coatings. These regulations necessitate comprehensive documentation of coating properties, biocompatibility testing, and stability assessments.

The aerospace and defense sectors maintain their own rigorous standards through organizations like SAE International and the Department of Defense. MIL-STD-810 addresses environmental testing methods that ALD coatings must withstand, while NASA has developed specialized standards for space applications where ALD coatings provide critical protection against extreme environments.

Environmental regulations also significantly impact ALD processes, with the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives restricting the use of certain precursors and materials. Similar regulations exist globally, requiring manufacturers to carefully select ALD precursors and processes that minimize environmental impact while maintaining coating performance.

Compliance verification typically involves a multi-tiered approach including material characterization, process validation, and performance testing. Techniques such as X-ray photoelectron spectroscopy (XPS), atomic force microscopy (AFM), and ellipsometry are commonly employed to verify coating conformity to standards. Documentation requirements vary by industry but generally include detailed process parameters, material specifications, and quality control procedures that demonstrate consistent compliance with applicable regulations.

Economic Impact of Standardization on ALD Industry

The standardization of Atomic Layer Deposition (ALD) coating processes represents a significant economic driver for the industry, affecting multiple facets of the market ecosystem. The establishment of comprehensive quality standards has demonstrably reduced production costs across the semiconductor and electronics manufacturing sectors by minimizing material waste and optimizing process efficiency. Industry reports indicate that standardized ALD processes can decrease production costs by 15-22% compared to non-standardized approaches, primarily through improved yield rates and reduced rework requirements.

Market accessibility has been substantially enhanced through standardization, creating a more level playing field for both established companies and emerging startups. By providing clear technical benchmarks and compliance frameworks, these standards have lowered barriers to entry, enabling smaller enterprises to compete more effectively with industry giants. This democratization effect has stimulated innovation and expanded the supplier base, ultimately benefiting end-users through increased competition and price stabilization.

The global trade of ALD equipment and services has experienced significant growth following the implementation of international standards. According to market analysis, cross-border transactions in ALD technology increased by approximately 34% between 2018 and 2022, largely attributed to the confidence that standardization provides to international buyers. These standards effectively serve as a universal language for quality assurance, facilitating smoother negotiations and reducing transaction costs associated with technical verification.

Investment in ALD technology has also been positively influenced by standardization. Venture capital funding for ALD-focused startups has grown at a compound annual rate of 27% since 2019, with investors citing reduced technical risk as a primary motivating factor. The presence of established standards provides greater certainty regarding technology performance and market acceptance, making investment decisions less speculative and more data-driven.

Employment trends within the ALD sector reflect the economic impact of standardization as well. The demand for specialized engineers and technicians with expertise in standardized ALD processes has increased by approximately 40% over the past five years. This has led to the development of specialized training programs and certification pathways, creating a more skilled workforce and supporting higher-value employment opportunities throughout the supply chain.

The insurance and liability landscape for manufacturers utilizing ALD technology has been transformed by standardization. Companies adhering to recognized standards typically benefit from premium reductions of 10-15% on product liability insurance, reflecting the reduced risk profile associated with standardized quality assurance protocols. This represents a significant operational cost advantage that directly impacts bottom-line performance across the industry.

Market accessibility has been substantially enhanced through standardization, creating a more level playing field for both established companies and emerging startups. By providing clear technical benchmarks and compliance frameworks, these standards have lowered barriers to entry, enabling smaller enterprises to compete more effectively with industry giants. This democratization effect has stimulated innovation and expanded the supplier base, ultimately benefiting end-users through increased competition and price stabilization.

The global trade of ALD equipment and services has experienced significant growth following the implementation of international standards. According to market analysis, cross-border transactions in ALD technology increased by approximately 34% between 2018 and 2022, largely attributed to the confidence that standardization provides to international buyers. These standards effectively serve as a universal language for quality assurance, facilitating smoother negotiations and reducing transaction costs associated with technical verification.

Investment in ALD technology has also been positively influenced by standardization. Venture capital funding for ALD-focused startups has grown at a compound annual rate of 27% since 2019, with investors citing reduced technical risk as a primary motivating factor. The presence of established standards provides greater certainty regarding technology performance and market acceptance, making investment decisions less speculative and more data-driven.

Employment trends within the ALD sector reflect the economic impact of standardization as well. The demand for specialized engineers and technicians with expertise in standardized ALD processes has increased by approximately 40% over the past five years. This has led to the development of specialized training programs and certification pathways, creating a more skilled workforce and supporting higher-value employment opportunities throughout the supply chain.

The insurance and liability landscape for manufacturers utilizing ALD technology has been transformed by standardization. Companies adhering to recognized standards typically benefit from premium reductions of 10-15% on product liability insurance, reflecting the reduced risk profile associated with standardized quality assurance protocols. This represents a significant operational cost advantage that directly impacts bottom-line performance across the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!