Investigating ALD Coating for Corrosion Inhibition in Aggressive Environments

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ALD Coating Technology Background and Objectives

Atomic Layer Deposition (ALD) coating technology has evolved significantly since its inception in the 1970s, transitioning from a laboratory curiosity to a critical industrial process. The technology's development trajectory has been characterized by continuous refinement in precision, scalability, and material compatibility. Initially limited to semiconductor applications, ALD has expanded into diverse sectors including aerospace, biomedical, energy storage, and maritime industries, where corrosion protection is paramount.

The fundamental principle of ALD—sequential, self-limiting surface reactions—enables the formation of conformal, pinhole-free thin films with atomic-level thickness control. This unique capability positions ALD as an ideal candidate for next-generation corrosion inhibition solutions, particularly in aggressive environments where traditional coating methods prove inadequate.

Recent technological advancements have focused on expanding the temperature window of ALD processes, with significant progress in low-temperature deposition techniques that preserve substrate integrity while maintaining coating quality. Concurrently, research has accelerated in developing multi-component and multi-functional ALD films that combine corrosion resistance with additional properties such as wear resistance, hydrophobicity, or catalytic activity.

The primary objective of investigating ALD coating for corrosion inhibition is to develop ultra-thin, highly conformal protective layers that can significantly extend the operational lifespan of critical components exposed to aggressive environments. These environments include high-salinity marine settings, acidic industrial atmospheres, high-temperature processing conditions, and environments with combined mechanical and chemical stressors.

Specific technical goals include achieving uniform coverage on complex geometries with high aspect ratios, enhancing adhesion between coating and substrate across diverse material combinations, and developing cost-effective scaling strategies for industrial implementation. Additionally, research aims to establish standardized testing protocols that accurately predict long-term performance of ALD coatings under real-world corrosive conditions.

The technology roadmap anticipates progression from current laboratory-scale demonstrations to pilot implementations in selected high-value applications, followed by broader industrial adoption. Key milestones include developing multi-layer architectures with self-healing capabilities, establishing in-line quality control methods for industrial-scale processes, and creating computational models that accurately predict coating performance based on deposition parameters.

As global sustainability concerns intensify, an emerging objective is to develop ALD processes that minimize environmental impact through reduced precursor consumption, lower energy requirements, and elimination of hazardous chemicals, aligning technological advancement with ecological responsibility.

The fundamental principle of ALD—sequential, self-limiting surface reactions—enables the formation of conformal, pinhole-free thin films with atomic-level thickness control. This unique capability positions ALD as an ideal candidate for next-generation corrosion inhibition solutions, particularly in aggressive environments where traditional coating methods prove inadequate.

Recent technological advancements have focused on expanding the temperature window of ALD processes, with significant progress in low-temperature deposition techniques that preserve substrate integrity while maintaining coating quality. Concurrently, research has accelerated in developing multi-component and multi-functional ALD films that combine corrosion resistance with additional properties such as wear resistance, hydrophobicity, or catalytic activity.

The primary objective of investigating ALD coating for corrosion inhibition is to develop ultra-thin, highly conformal protective layers that can significantly extend the operational lifespan of critical components exposed to aggressive environments. These environments include high-salinity marine settings, acidic industrial atmospheres, high-temperature processing conditions, and environments with combined mechanical and chemical stressors.

Specific technical goals include achieving uniform coverage on complex geometries with high aspect ratios, enhancing adhesion between coating and substrate across diverse material combinations, and developing cost-effective scaling strategies for industrial implementation. Additionally, research aims to establish standardized testing protocols that accurately predict long-term performance of ALD coatings under real-world corrosive conditions.

The technology roadmap anticipates progression from current laboratory-scale demonstrations to pilot implementations in selected high-value applications, followed by broader industrial adoption. Key milestones include developing multi-layer architectures with self-healing capabilities, establishing in-line quality control methods for industrial-scale processes, and creating computational models that accurately predict coating performance based on deposition parameters.

As global sustainability concerns intensify, an emerging objective is to develop ALD processes that minimize environmental impact through reduced precursor consumption, lower energy requirements, and elimination of hazardous chemicals, aligning technological advancement with ecological responsibility.

Market Demand Analysis for Advanced Corrosion Protection

The global market for advanced corrosion protection solutions is experiencing significant growth, driven primarily by increasing industrial activities in harsh environments and the rising costs associated with corrosion-related damages. Current estimates value the global corrosion inhibitor market at approximately 7.5 billion USD, with projections indicating a compound annual growth rate of 4.3% through 2028. This growth trajectory underscores the substantial economic impact of corrosion, which costs industries worldwide over 2.5 trillion USD annually, representing roughly 3.4% of global GDP.

The demand for atomic layer deposition (ALD) coating technology specifically for corrosion inhibition is emerging as a high-potential segment within this broader market. Industries operating in aggressive environments—including oil and gas, marine, chemical processing, and aerospace—are actively seeking more effective and durable protection solutions than traditional methods can provide. The offshore oil and gas sector alone is expected to invest over 15 billion USD in corrosion protection technologies by 2025, with advanced coating solutions representing a significant portion of this expenditure.

Market research indicates that end-users are increasingly prioritizing total lifecycle cost over initial investment, creating favorable conditions for premium solutions like ALD coatings. A recent industry survey revealed that 78% of maintenance engineers in heavy industries would consider adopting higher-priced coating technologies if they could demonstrate superior performance in aggressive environments and extend maintenance intervals by at least 40%.

Geographically, the North American and European markets currently lead in adoption of advanced corrosion protection technologies, accounting for approximately 60% of global market share. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years, driven by rapid industrialization in China, India, and Southeast Asian countries, along with increasing environmental regulations that necessitate better corrosion management practices.

The market is also being shaped by evolving regulatory frameworks worldwide. Stricter environmental regulations regarding traditional corrosion inhibitors containing heavy metals and other toxic substances are creating market opportunities for environmentally friendly alternatives like certain ALD coating formulations. Industry analysts project that environmentally compliant corrosion protection solutions will capture over 40% of the market by 2026, up from approximately 25% in 2021.

Customer demand is increasingly focused on multi-functional coating solutions that offer not only corrosion resistance but also additional properties such as wear resistance, thermal stability, and chemical inertness. This trend aligns well with the capabilities of advanced ALD coating technologies, which can be engineered to provide multiple protective functions simultaneously.

The demand for atomic layer deposition (ALD) coating technology specifically for corrosion inhibition is emerging as a high-potential segment within this broader market. Industries operating in aggressive environments—including oil and gas, marine, chemical processing, and aerospace—are actively seeking more effective and durable protection solutions than traditional methods can provide. The offshore oil and gas sector alone is expected to invest over 15 billion USD in corrosion protection technologies by 2025, with advanced coating solutions representing a significant portion of this expenditure.

Market research indicates that end-users are increasingly prioritizing total lifecycle cost over initial investment, creating favorable conditions for premium solutions like ALD coatings. A recent industry survey revealed that 78% of maintenance engineers in heavy industries would consider adopting higher-priced coating technologies if they could demonstrate superior performance in aggressive environments and extend maintenance intervals by at least 40%.

Geographically, the North American and European markets currently lead in adoption of advanced corrosion protection technologies, accounting for approximately 60% of global market share. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years, driven by rapid industrialization in China, India, and Southeast Asian countries, along with increasing environmental regulations that necessitate better corrosion management practices.

The market is also being shaped by evolving regulatory frameworks worldwide. Stricter environmental regulations regarding traditional corrosion inhibitors containing heavy metals and other toxic substances are creating market opportunities for environmentally friendly alternatives like certain ALD coating formulations. Industry analysts project that environmentally compliant corrosion protection solutions will capture over 40% of the market by 2026, up from approximately 25% in 2021.

Customer demand is increasingly focused on multi-functional coating solutions that offer not only corrosion resistance but also additional properties such as wear resistance, thermal stability, and chemical inertness. This trend aligns well with the capabilities of advanced ALD coating technologies, which can be engineered to provide multiple protective functions simultaneously.

Current State and Challenges in ALD Corrosion Inhibition

Atomic Layer Deposition (ALD) technology has emerged as a promising solution for corrosion inhibition in aggressive environments, offering unprecedented control over coating thickness and uniformity at the nanoscale. Currently, ALD coatings for corrosion protection are being implemented across various industries including aerospace, maritime, oil and gas, and microelectronics. The global state of ALD technology shows significant advancement in research institutions across North America, Europe, and East Asia, with Finland, the United States, and South Korea leading in patent applications and commercial implementations.

The primary advantage of ALD in corrosion inhibition lies in its ability to create ultra-thin, pinhole-free conformal coatings that can penetrate complex geometries and provide protection even in hard-to-reach areas. Recent developments have demonstrated that ALD-deposited metal oxides such as Al2O3, TiO2, and ZrO2 exhibit excellent barrier properties against corrosive media, with Al2O3 showing particular promise for its chemical stability in acidic environments.

Despite these advancements, several significant challenges remain in the widespread adoption of ALD for corrosion inhibition. The most pressing technical limitation is the relatively slow deposition rate, which restricts industrial scalability for large components. Typical growth rates of 0.1-0.2 nm per cycle translate to extended processing times for coatings of practical thickness (50-200 nm), making the technology economically challenging for high-volume applications.

Another critical challenge is the limited temperature stability of ALD coatings in extreme environments. While effective at moderate temperatures, many ALD films experience degradation or phase transformations above 400°C, compromising their protective properties in high-temperature industrial settings. This limitation is particularly problematic in applications such as gas turbines and chemical processing equipment.

Adhesion issues between ALD films and certain substrate materials present another significant hurdle. Poor interfacial bonding can lead to delamination under thermal cycling or mechanical stress, negating the protective benefits of the coating. Research indicates that surface preparation protocols and interface engineering are crucial but remain inconsistently standardized across the industry.

The cost-effectiveness of ALD implementation also remains a barrier to widespread industrial adoption. The high capital investment for ALD equipment, coupled with relatively low throughput compared to conventional coating methods, results in higher per-unit costs that many industries find difficult to justify despite the superior performance of ALD coatings.

Environmental considerations present additional challenges, as some ALD precursors are toxic, pyrophoric, or environmentally harmful. The development of greener precursor chemistries is ongoing but has not yet reached commercial maturity for all coating compositions needed in corrosion protection applications.

The primary advantage of ALD in corrosion inhibition lies in its ability to create ultra-thin, pinhole-free conformal coatings that can penetrate complex geometries and provide protection even in hard-to-reach areas. Recent developments have demonstrated that ALD-deposited metal oxides such as Al2O3, TiO2, and ZrO2 exhibit excellent barrier properties against corrosive media, with Al2O3 showing particular promise for its chemical stability in acidic environments.

Despite these advancements, several significant challenges remain in the widespread adoption of ALD for corrosion inhibition. The most pressing technical limitation is the relatively slow deposition rate, which restricts industrial scalability for large components. Typical growth rates of 0.1-0.2 nm per cycle translate to extended processing times for coatings of practical thickness (50-200 nm), making the technology economically challenging for high-volume applications.

Another critical challenge is the limited temperature stability of ALD coatings in extreme environments. While effective at moderate temperatures, many ALD films experience degradation or phase transformations above 400°C, compromising their protective properties in high-temperature industrial settings. This limitation is particularly problematic in applications such as gas turbines and chemical processing equipment.

Adhesion issues between ALD films and certain substrate materials present another significant hurdle. Poor interfacial bonding can lead to delamination under thermal cycling or mechanical stress, negating the protective benefits of the coating. Research indicates that surface preparation protocols and interface engineering are crucial but remain inconsistently standardized across the industry.

The cost-effectiveness of ALD implementation also remains a barrier to widespread industrial adoption. The high capital investment for ALD equipment, coupled with relatively low throughput compared to conventional coating methods, results in higher per-unit costs that many industries find difficult to justify despite the superior performance of ALD coatings.

Environmental considerations present additional challenges, as some ALD precursors are toxic, pyrophoric, or environmentally harmful. The development of greener precursor chemistries is ongoing but has not yet reached commercial maturity for all coating compositions needed in corrosion protection applications.

Current ALD Solutions for Aggressive Environment Protection

01 ALD coating materials for corrosion protection

Various materials deposited via Atomic Layer Deposition (ALD) can provide effective corrosion protection for metal substrates. These materials include metal oxides (such as aluminum oxide, titanium oxide, and zirconium oxide), nitrides, and composite layers that form dense, pinhole-free barriers against corrosive agents. The nanoscale thickness control of ALD allows for the creation of uniform protective layers even on complex geometries, significantly enhancing corrosion resistance while maintaining the dimensional properties of the substrate.- ALD coating materials for corrosion protection: Various materials deposited via Atomic Layer Deposition (ALD) can provide effective corrosion protection for metal substrates. These materials include metal oxides (such as aluminum oxide, titanium oxide, and zirconium oxide), nitrides, and composite layers that form dense, pinhole-free barriers against corrosive environments. The nanoscale thickness control of ALD allows for the creation of uniform protective layers even on complex geometries, significantly enhancing corrosion resistance.

- Multi-layer ALD coating structures: Multi-layered ALD coatings can provide enhanced corrosion protection through the combination of different functional layers. These structures typically include a base layer for adhesion, intermediate barrier layers, and a top layer for specific environmental protection. The multi-layer approach allows for the integration of different materials with complementary properties, creating synergistic effects that improve overall corrosion resistance while maintaining thin film characteristics. These structures can be tailored to specific corrosive environments.

- ALD process parameters for corrosion-resistant coatings: Specific ALD process parameters significantly influence the corrosion inhibition properties of the resulting coatings. Parameters such as deposition temperature, precursor selection, pulse/purge times, and number of cycles directly affect film density, crystallinity, and defect concentration. Optimized process conditions can produce coatings with superior barrier properties, enhanced adhesion to substrates, and improved chemical stability, resulting in more effective corrosion protection systems.

- Surface pretreatment methods for ALD corrosion coatings: Surface pretreatment techniques are crucial for enhancing the effectiveness of ALD corrosion-resistant coatings. These methods include chemical cleaning, plasma activation, surface functionalization, and roughness modification. Proper pretreatment ensures optimal adhesion between the substrate and ALD coating, eliminates surface contaminants that could compromise coating integrity, and creates favorable surface chemistry for uniform film nucleation and growth, ultimately improving the corrosion protection performance.

- ALD coatings with self-healing corrosion inhibition properties: Advanced ALD coating systems incorporate self-healing capabilities to provide long-term corrosion protection. These coatings contain active corrosion inhibitors that can be released in response to coating damage or environmental triggers. The controlled release mechanisms are achieved through specially designed layered structures, incorporation of nanocontainers, or stimuli-responsive materials within the ALD films. This approach provides dynamic protection that extends coating lifetime even after initial barrier properties are compromised.

02 Multi-layer ALD coating structures for enhanced corrosion inhibition

Multi-layered ALD coatings can provide superior corrosion protection compared to single-layer coatings. These structures typically consist of alternating layers of different materials, such as metal oxides and nitrides, creating a tortuous path for corrosive species. The combination of hydrophobic and hydrophilic layers can further enhance protection by repelling water while maintaining adhesion to the substrate. These multi-layer systems can be tailored to specific environments and substrates, offering customized corrosion protection solutions.Expand Specific Solutions03 ALD coating process parameters for optimized corrosion resistance

The corrosion inhibition properties of ALD coatings can be significantly influenced by process parameters such as deposition temperature, precursor selection, purge times, and cycle counts. Lower deposition temperatures often result in denser films with fewer defects, while proper precursor selection ensures complete surface reactions and minimizes impurities. Optimized purge times prevent precursor mixing and particle formation, and the number of ALD cycles directly controls coating thickness, which is crucial for balancing corrosion protection with other functional requirements.Expand Specific Solutions04 Surface preparation techniques for improved ALD coating adhesion and corrosion protection

Proper surface preparation is essential for maximizing the corrosion inhibition performance of ALD coatings. Techniques include chemical cleaning to remove organic contaminants, mechanical or chemical etching to increase surface area, plasma treatment to activate surfaces, and the application of adhesion promoters. These preparation methods enhance the bonding between the ALD coating and substrate, reducing the likelihood of coating delamination under corrosive conditions and ensuring long-term protection against environmental degradation.Expand Specific Solutions05 ALD coatings with self-healing capabilities for long-term corrosion inhibition

Advanced ALD coating systems incorporate self-healing mechanisms to provide sustained corrosion protection even after mechanical damage. These systems may include encapsulated corrosion inhibitors that are released upon coating damage, reactive layers that form protective compounds when exposed to corrosive environments, or materials that undergo volume expansion to seal cracks. Some approaches combine ALD with other deposition techniques to create hybrid coatings with both barrier and active protection properties, significantly extending the service life of coated components in aggressive environments.Expand Specific Solutions

Key Industry Players in ALD Coating Development

The Atomic Layer Deposition (ALD) coating market for corrosion inhibition is currently in a growth phase, with increasing adoption across aggressive environment applications. The global market is expanding at approximately 12-15% CAGR, driven by demands from semiconductor, energy storage, and industrial sectors. Technology maturity varies significantly among key players: Applied Materials, Lam Research, and Beneq Group lead with commercial-scale solutions, while Forge Nano and Sundew Technologies offer innovative productivity improvements. Research institutions like Max Planck Society and Naval Research Laboratory continue advancing fundamental science. Emerging players such as BattFlex Technologies and Huawei Digital Power are focusing on specialized applications, particularly in energy storage, indicating the technology's expanding application scope beyond traditional semiconductor markets.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced ALD coating solutions specifically designed for corrosion inhibition in aggressive environments. Their technology utilizes precise atomic layer deposition to create ultra-thin, pinhole-free barrier films that provide exceptional protection against corrosive media. The company's ALD systems can deposit conformal protective layers of materials such as Al2O3, TiO2, and various metal nitrides with thickness control at the angstrom level. Their proprietary process allows for low-temperature deposition (as low as 50°C), making it suitable for temperature-sensitive substrates. Applied Materials' ALD technology incorporates in-situ plasma treatment capabilities that enhance film adhesion and density, resulting in superior corrosion resistance even in highly acidic or alkaline environments. Their systems feature multi-chamber configurations that enable sequential deposition of different materials to create tailored barrier stacks optimized for specific corrosive conditions.

Strengths: Industry-leading precision in film thickness control (±0.1Å); excellent conformality on complex geometries; high throughput for industrial applications. Weaknesses: Higher initial capital investment compared to conventional coating methods; requires specialized expertise for process optimization; some limitations in coating extremely high aspect ratio structures.

Beneq Group Oy

Technical Solution: Beneq has developed specialized ALD coating solutions for corrosion protection in aggressive environments through their industrial-scale TFS (Thin Film Solutions) platform. Their technology enables the deposition of ultra-thin (typically 5-100nm), conformal protective layers on various substrates including metals, ceramics, and polymers. Beneq's approach utilizes both thermal and plasma-enhanced ALD processes to create tailored barrier coatings optimized for specific corrosive conditions. Their proprietary batch ALD systems can process large quantities of components simultaneously, making the technology economically viable for industrial applications. For particularly challenging environments, Beneq has pioneered multi-layer ALD structures combining different materials (such as Al2O3, TiO2, and Ta2O5) to create synergistic protection against multiple corrosion mechanisms. Their nanolaminate structures have demonstrated exceptional resistance to chemical attack, with laboratory tests showing corrosion rate reductions of up to 99% compared to uncoated samples in acidic and saline environments. Beneq's technology has been successfully implemented in applications ranging from offshore equipment protection to electronics in harsh industrial settings.

Strengths: Extensive experience in industrial ALD applications; specialized equipment designed for high-volume manufacturing; proven track record in harsh environment protection. Weaknesses: Higher initial investment costs compared to conventional coating methods; process optimization can be time-consuming for new applications; some limitations in coating extremely complex internal geometries.

Critical Patents and Technical Literature in ALD Corrosion Inhibition

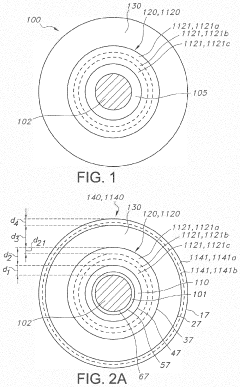

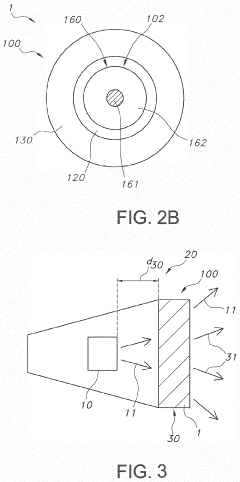

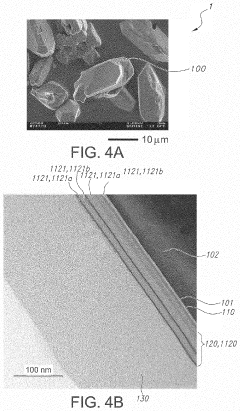

Phosphor particle coating

PatentActiveUS20210403805A1

Innovation

- A hybrid coating method involving a primer layer, a thin atomic layer deposition (ALD) coating, and a thicker sol-gel coating is applied to luminescent particles, providing a moisture barrier and mechanical protection while maintaining light transmissivity and stability.

Environmental Impact and Sustainability of ALD Coatings

The environmental impact of Atomic Layer Deposition (ALD) coatings for corrosion inhibition presents a complex balance of benefits and challenges. ALD technology demonstrates significant sustainability advantages compared to traditional coating methods, primarily due to its precise material deposition capabilities. This precision minimizes waste generation by utilizing precursor chemicals with exceptional efficiency, often achieving utilization rates above 90% compared to conventional methods that may waste 40-60% of materials.

ALD processes typically operate at lower temperatures (50-300°C) than competing technologies like Chemical Vapor Deposition (CVD) or thermal spraying, resulting in reduced energy consumption. The thin, uniform coatings produced by ALD also contribute to resource conservation by requiring substantially less raw material while providing equivalent or superior protection against corrosive environments.

From a lifecycle perspective, ALD coatings extend the operational lifespan of industrial components and infrastructure by providing exceptional corrosion resistance in aggressive environments. This extension directly reduces the environmental burden associated with manufacturing replacement parts and managing premature equipment failure.

However, several environmental challenges remain. Many ALD processes still utilize precursors containing heavy metals or other environmentally problematic substances. While contained during deposition, these materials require careful handling and disposal protocols. The production of certain precursors may involve environmentally intensive processes, creating an upstream environmental footprint that must be considered in comprehensive assessments.

Recent innovations are addressing these concerns through the development of "green ALD" approaches. These include water-based chemistries, non-toxic metal precursors, and processes that eliminate harmful byproducts. Research into bio-inspired precursors derived from renewable resources shows particular promise for reducing the environmental impact of ALD coating technologies.

Regulatory frameworks worldwide are increasingly recognizing ALD's environmental advantages. The European Union's REACH regulations and similar initiatives in North America and Asia have accelerated the transition toward more environmentally benign coating technologies, with ALD well-positioned to meet these evolving standards.

As industries seek sustainable solutions for extending asset lifespans in corrosive environments, ALD coatings offer a compelling combination of performance and reduced environmental impact. The continued development of greener precursors and more energy-efficient deposition systems will further enhance the sustainability profile of this technology in coming years.

ALD processes typically operate at lower temperatures (50-300°C) than competing technologies like Chemical Vapor Deposition (CVD) or thermal spraying, resulting in reduced energy consumption. The thin, uniform coatings produced by ALD also contribute to resource conservation by requiring substantially less raw material while providing equivalent or superior protection against corrosive environments.

From a lifecycle perspective, ALD coatings extend the operational lifespan of industrial components and infrastructure by providing exceptional corrosion resistance in aggressive environments. This extension directly reduces the environmental burden associated with manufacturing replacement parts and managing premature equipment failure.

However, several environmental challenges remain. Many ALD processes still utilize precursors containing heavy metals or other environmentally problematic substances. While contained during deposition, these materials require careful handling and disposal protocols. The production of certain precursors may involve environmentally intensive processes, creating an upstream environmental footprint that must be considered in comprehensive assessments.

Recent innovations are addressing these concerns through the development of "green ALD" approaches. These include water-based chemistries, non-toxic metal precursors, and processes that eliminate harmful byproducts. Research into bio-inspired precursors derived from renewable resources shows particular promise for reducing the environmental impact of ALD coating technologies.

Regulatory frameworks worldwide are increasingly recognizing ALD's environmental advantages. The European Union's REACH regulations and similar initiatives in North America and Asia have accelerated the transition toward more environmentally benign coating technologies, with ALD well-positioned to meet these evolving standards.

As industries seek sustainable solutions for extending asset lifespans in corrosive environments, ALD coatings offer a compelling combination of performance and reduced environmental impact. The continued development of greener precursors and more energy-efficient deposition systems will further enhance the sustainability profile of this technology in coming years.

Cost-Benefit Analysis of ALD Implementation in Various Industries

The implementation of Atomic Layer Deposition (ALD) coating technology for corrosion inhibition requires careful economic evaluation across different industrial sectors. Initial capital investment for ALD equipment ranges from $500,000 to $2 million, depending on chamber size, automation level, and processing capabilities. This substantial upfront cost represents a significant barrier for small to medium enterprises, while larger corporations may find it more financially viable.

Operational expenses include precursor chemicals ($200-500 per cycle), energy consumption (approximately 15-25 kWh per processing hour), and specialized maintenance ($30,000-50,000 annually). Industries with high-value components experiencing frequent corrosion-related failures demonstrate the most favorable return on investment profiles, typically achieving breakeven within 2-3 years.

The aerospace sector shows particularly compelling economics, with ALD-coated components extending service life by 200-300% in salt-spray and high-humidity environments. Cost analysis indicates that despite the 30-40% higher initial component cost, maintenance frequency reduction and extended replacement intervals yield net savings of $1.2-1.8 million annually for a mid-sized fleet operation.

In marine applications, ALD-treated metal structures demonstrate 85% reduction in corrosion rates compared to conventional protective methods. The five-year total cost of ownership analysis reveals 22-28% savings when factoring in reduced maintenance interventions and extended asset lifespan, despite higher initial treatment costs.

For chemical processing industries, where equipment replacement due to corrosion accounts for 15-20% of annual capital expenditure, ALD implementation shows promising economics. Case studies from petrochemical facilities indicate that critical components treated with ALD coatings experienced 4-6 times longer operational life in highly acidic environments, translating to approximately $3.5 million in avoided downtime costs per production line annually.

Scalability considerations significantly impact cost-effectiveness. Batch processing capabilities and coating uniformity on complex geometries determine throughput efficiency. Industries with high-volume, geometrically simple components achieve lower per-unit coating costs (approximately $0.05-0.15 per square centimeter) compared to low-volume, complex components ($0.30-0.60 per square centimeter).

Environmental compliance cost avoidance represents an often-overlooked economic benefit. ALD's minimal waste generation and precise material utilization reduce hazardous waste disposal costs by 60-75% compared to traditional coating methods, translating to annual savings of $50,000-120,000 for medium-sized operations in strictly regulated regions.

Operational expenses include precursor chemicals ($200-500 per cycle), energy consumption (approximately 15-25 kWh per processing hour), and specialized maintenance ($30,000-50,000 annually). Industries with high-value components experiencing frequent corrosion-related failures demonstrate the most favorable return on investment profiles, typically achieving breakeven within 2-3 years.

The aerospace sector shows particularly compelling economics, with ALD-coated components extending service life by 200-300% in salt-spray and high-humidity environments. Cost analysis indicates that despite the 30-40% higher initial component cost, maintenance frequency reduction and extended replacement intervals yield net savings of $1.2-1.8 million annually for a mid-sized fleet operation.

In marine applications, ALD-treated metal structures demonstrate 85% reduction in corrosion rates compared to conventional protective methods. The five-year total cost of ownership analysis reveals 22-28% savings when factoring in reduced maintenance interventions and extended asset lifespan, despite higher initial treatment costs.

For chemical processing industries, where equipment replacement due to corrosion accounts for 15-20% of annual capital expenditure, ALD implementation shows promising economics. Case studies from petrochemical facilities indicate that critical components treated with ALD coatings experienced 4-6 times longer operational life in highly acidic environments, translating to approximately $3.5 million in avoided downtime costs per production line annually.

Scalability considerations significantly impact cost-effectiveness. Batch processing capabilities and coating uniformity on complex geometries determine throughput efficiency. Industries with high-volume, geometrically simple components achieve lower per-unit coating costs (approximately $0.05-0.15 per square centimeter) compared to low-volume, complex components ($0.30-0.60 per square centimeter).

Environmental compliance cost avoidance represents an often-overlooked economic benefit. ALD's minimal waste generation and precise material utilization reduce hazardous waste disposal costs by 60-75% compared to traditional coating methods, translating to annual savings of $50,000-120,000 for medium-sized operations in strictly regulated regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!