Why ALD Coating is Pivotal for Next-Generation Lithium-ion Batteries

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ALD Coating Technology Evolution and Objectives

Atomic Layer Deposition (ALD) coating technology has evolved significantly since its inception in the 1970s, originally developed for semiconductor manufacturing. The journey began with the pioneering work of Tuomo Suntola, who established the fundamental principles of sequential self-limiting surface reactions that define ALD. This precise deposition method has gradually expanded beyond microelectronics into various fields, with energy storage applications emerging as a particularly promising domain in the early 2000s.

The evolution of ALD for battery applications has been marked by several key milestones. Initially, researchers focused on simple metal oxide coatings for cathode materials, primarily using Al2O3 to enhance thermal stability. By the 2010s, the technology advanced to incorporate more complex compositions and multilayer architectures, enabling tailored interfaces between electrode materials and electrolytes. Recent developments have pushed toward atomic-scale engineering of these interfaces, with precise control over thickness down to sub-nanometer levels.

The current technological trajectory is moving toward industrialization and scaling of ALD processes for mass production of lithium-ion batteries. This transition represents a critical phase in the technology's evolution, as laboratory successes must be translated into economically viable manufacturing processes. Innovations in spatial ALD and roll-to-roll processing are addressing throughput limitations that previously confined ALD to research settings.

The primary objectives of ALD coating technology in next-generation lithium-ion batteries encompass several dimensions. First, enhancing battery safety by creating stable interfaces that prevent unwanted side reactions between electrode materials and electrolytes. Second, extending cycle life by mitigating degradation mechanisms such as transition metal dissolution and structural collapse. Third, enabling higher energy density batteries by allowing the use of high-capacity but otherwise unstable electrode materials.

Another crucial objective is facilitating the adoption of solid-state electrolytes by engineering interfaces that minimize resistance and enhance ion transport. Additionally, ALD coatings aim to improve fast-charging capabilities by stabilizing electrode surfaces under high current densities. The ultimate goal is to develop a versatile platform technology that can be adapted to various battery chemistries and architectures, providing a universal solution to interface-related challenges.

The convergence of these evolutionary trends and objectives positions ALD coating as a transformative technology for next-generation energy storage systems, potentially addressing the most persistent limitations of current lithium-ion batteries while enabling new functionalities and performance levels previously unattainable.

The evolution of ALD for battery applications has been marked by several key milestones. Initially, researchers focused on simple metal oxide coatings for cathode materials, primarily using Al2O3 to enhance thermal stability. By the 2010s, the technology advanced to incorporate more complex compositions and multilayer architectures, enabling tailored interfaces between electrode materials and electrolytes. Recent developments have pushed toward atomic-scale engineering of these interfaces, with precise control over thickness down to sub-nanometer levels.

The current technological trajectory is moving toward industrialization and scaling of ALD processes for mass production of lithium-ion batteries. This transition represents a critical phase in the technology's evolution, as laboratory successes must be translated into economically viable manufacturing processes. Innovations in spatial ALD and roll-to-roll processing are addressing throughput limitations that previously confined ALD to research settings.

The primary objectives of ALD coating technology in next-generation lithium-ion batteries encompass several dimensions. First, enhancing battery safety by creating stable interfaces that prevent unwanted side reactions between electrode materials and electrolytes. Second, extending cycle life by mitigating degradation mechanisms such as transition metal dissolution and structural collapse. Third, enabling higher energy density batteries by allowing the use of high-capacity but otherwise unstable electrode materials.

Another crucial objective is facilitating the adoption of solid-state electrolytes by engineering interfaces that minimize resistance and enhance ion transport. Additionally, ALD coatings aim to improve fast-charging capabilities by stabilizing electrode surfaces under high current densities. The ultimate goal is to develop a versatile platform technology that can be adapted to various battery chemistries and architectures, providing a universal solution to interface-related challenges.

The convergence of these evolutionary trends and objectives positions ALD coating as a transformative technology for next-generation energy storage systems, potentially addressing the most persistent limitations of current lithium-ion batteries while enabling new functionalities and performance levels previously unattainable.

Market Analysis for ALD-Enhanced Battery Solutions

The global market for ALD-enhanced battery solutions is experiencing unprecedented growth, driven by the increasing demand for high-performance energy storage systems across multiple industries. Current market valuations indicate that the ALD coating segment for lithium-ion batteries reached approximately $450 million in 2022, with projections suggesting a compound annual growth rate of 18.7% through 2030. This remarkable expansion is primarily fueled by the electric vehicle sector, which currently consumes nearly 60% of all advanced lithium-ion batteries with protective coatings.

Consumer electronics represents the second-largest market segment, accounting for roughly 25% of the demand for ALD-enhanced batteries. This sector values the extended battery life and improved safety profiles that atomic layer deposition technology provides. The remaining market share is distributed among grid storage applications, aerospace, medical devices, and industrial equipment, all of which benefit from the enhanced performance characteristics of ALD-coated battery components.

Regional analysis reveals that Asia-Pacific dominates the manufacturing landscape, with South Korea, Japan, and China collectively controlling approximately 70% of global ALD equipment and process technology for battery applications. North America and Europe follow with significant research activities and specialized production facilities, particularly focused on high-end applications requiring premium performance specifications.

Market penetration of ALD technology in battery manufacturing remains relatively low at 15-20% of total production volume, indicating substantial room for growth as the technology matures and production costs decrease. Current cost premiums for ALD-enhanced batteries range from 8-12% above conventional alternatives, though this gap is narrowing as economies of scale improve and process efficiencies advance.

Customer demand patterns show increasing willingness to pay premium prices for batteries offering 30-40% longer cycle life and improved safety characteristics. This trend is particularly pronounced in the luxury EV segment and high-performance consumer electronics, where battery performance directly impacts user experience and brand perception.

Supply chain analysis reveals potential bottlenecks in precursor chemical availability and specialized ALD equipment manufacturing capacity. These constraints could temporarily limit market growth if demand accelerates beyond current projections. Several major chemical suppliers have announced capacity expansions specifically targeting battery-grade ALD precursors, suggesting industry awareness of this potential limitation.

Competitive dynamics show increasing consolidation among technology providers, with three major equipment manufacturers controlling approximately 65% of the ALD systems market for battery applications. Parallel to this, battery manufacturers are actively pursuing vertical integration strategies to secure proprietary coating technologies and processes.

Consumer electronics represents the second-largest market segment, accounting for roughly 25% of the demand for ALD-enhanced batteries. This sector values the extended battery life and improved safety profiles that atomic layer deposition technology provides. The remaining market share is distributed among grid storage applications, aerospace, medical devices, and industrial equipment, all of which benefit from the enhanced performance characteristics of ALD-coated battery components.

Regional analysis reveals that Asia-Pacific dominates the manufacturing landscape, with South Korea, Japan, and China collectively controlling approximately 70% of global ALD equipment and process technology for battery applications. North America and Europe follow with significant research activities and specialized production facilities, particularly focused on high-end applications requiring premium performance specifications.

Market penetration of ALD technology in battery manufacturing remains relatively low at 15-20% of total production volume, indicating substantial room for growth as the technology matures and production costs decrease. Current cost premiums for ALD-enhanced batteries range from 8-12% above conventional alternatives, though this gap is narrowing as economies of scale improve and process efficiencies advance.

Customer demand patterns show increasing willingness to pay premium prices for batteries offering 30-40% longer cycle life and improved safety characteristics. This trend is particularly pronounced in the luxury EV segment and high-performance consumer electronics, where battery performance directly impacts user experience and brand perception.

Supply chain analysis reveals potential bottlenecks in precursor chemical availability and specialized ALD equipment manufacturing capacity. These constraints could temporarily limit market growth if demand accelerates beyond current projections. Several major chemical suppliers have announced capacity expansions specifically targeting battery-grade ALD precursors, suggesting industry awareness of this potential limitation.

Competitive dynamics show increasing consolidation among technology providers, with three major equipment manufacturers controlling approximately 65% of the ALD systems market for battery applications. Parallel to this, battery manufacturers are actively pursuing vertical integration strategies to secure proprietary coating technologies and processes.

Current Challenges in Battery Coating Technologies

Despite significant advancements in lithium-ion battery technology, current coating technologies face several critical challenges that limit battery performance, safety, and longevity. Conventional coating methods such as physical vapor deposition (PVD), chemical vapor deposition (CVD), and wet chemical processes struggle to achieve the precision and uniformity required for next-generation battery materials.

One major challenge is thickness control at the nanoscale level. Traditional coating technologies often produce inconsistent layer thicknesses, resulting in uneven protection of electrode materials and suboptimal performance. This variability becomes increasingly problematic as manufacturers push toward thinner electrodes and higher energy densities, where even minor coating imperfections can significantly impact battery performance.

Conformality presents another substantial hurdle. Many existing coating methods fail to provide uniform coverage on complex three-dimensional structures and high-aspect-ratio features that characterize advanced battery electrodes. This leads to exposed areas vulnerable to unwanted side reactions with the electrolyte, accelerating capacity fade and reducing cycle life.

Interface quality between the coating and the underlying electrode material remains problematic with conventional techniques. Poor adhesion, delamination, and the formation of interfacial impurities can create resistance barriers that impede ion transport, ultimately degrading battery performance. Current technologies often require high-temperature processing, which can damage temperature-sensitive electrode materials and trigger undesirable phase transformations.

Scalability and cost-effectiveness represent significant industrial challenges. Many precise coating technologies that work well in laboratory settings prove difficult to scale for mass production without compromising quality or substantially increasing manufacturing costs. This creates a bottleneck in the commercialization pathway for advanced battery technologies.

Environmental and safety concerns also plague traditional coating processes. Many conventional methods rely on toxic precursors, generate hazardous waste, or require environmentally harmful solvents. As sustainability becomes increasingly important in manufacturing, these drawbacks present regulatory and ethical challenges for battery producers.

Finally, current coating technologies often lack the versatility to deposit multiple functional materials in sequence without breaking vacuum or transferring substrates between different deposition systems. This limitation restricts the development of sophisticated multi-layer protective coatings that could address multiple failure mechanisms simultaneously in next-generation batteries.

These challenges collectively highlight the need for advanced coating technologies that can deliver precise, conformal, and high-quality protective layers while remaining economically viable and environmentally sustainable at industrial scales.

One major challenge is thickness control at the nanoscale level. Traditional coating technologies often produce inconsistent layer thicknesses, resulting in uneven protection of electrode materials and suboptimal performance. This variability becomes increasingly problematic as manufacturers push toward thinner electrodes and higher energy densities, where even minor coating imperfections can significantly impact battery performance.

Conformality presents another substantial hurdle. Many existing coating methods fail to provide uniform coverage on complex three-dimensional structures and high-aspect-ratio features that characterize advanced battery electrodes. This leads to exposed areas vulnerable to unwanted side reactions with the electrolyte, accelerating capacity fade and reducing cycle life.

Interface quality between the coating and the underlying electrode material remains problematic with conventional techniques. Poor adhesion, delamination, and the formation of interfacial impurities can create resistance barriers that impede ion transport, ultimately degrading battery performance. Current technologies often require high-temperature processing, which can damage temperature-sensitive electrode materials and trigger undesirable phase transformations.

Scalability and cost-effectiveness represent significant industrial challenges. Many precise coating technologies that work well in laboratory settings prove difficult to scale for mass production without compromising quality or substantially increasing manufacturing costs. This creates a bottleneck in the commercialization pathway for advanced battery technologies.

Environmental and safety concerns also plague traditional coating processes. Many conventional methods rely on toxic precursors, generate hazardous waste, or require environmentally harmful solvents. As sustainability becomes increasingly important in manufacturing, these drawbacks present regulatory and ethical challenges for battery producers.

Finally, current coating technologies often lack the versatility to deposit multiple functional materials in sequence without breaking vacuum or transferring substrates between different deposition systems. This limitation restricts the development of sophisticated multi-layer protective coatings that could address multiple failure mechanisms simultaneously in next-generation batteries.

These challenges collectively highlight the need for advanced coating technologies that can deliver precise, conformal, and high-quality protective layers while remaining economically viable and environmentally sustainable at industrial scales.

State-of-the-Art ALD Coating Methodologies

01 ALD coating on electrode materials

Atomic Layer Deposition (ALD) can be used to apply uniform, conformal coatings on electrode materials such as cathodes and anodes in lithium-ion batteries. These coatings create protective layers that prevent direct contact between electrode materials and electrolytes, reducing unwanted side reactions and electrolyte decomposition. This protection helps maintain electrode integrity during cycling, leading to improved capacity retention and extended battery life.- ALD coating on electrode materials: Atomic Layer Deposition (ALD) can be used to apply uniform, conformal coatings on electrode materials such as cathodes and anodes in lithium-ion batteries. These coatings create protective layers that prevent direct contact between electrode materials and electrolytes, reducing unwanted side reactions and electrolyte decomposition. This protection helps maintain electrode integrity during cycling, leading to improved capacity retention and extended battery life.

- ALD coating for solid electrolyte interfaces: ALD technology enables the formation of artificial solid electrolyte interfaces (SEI) with precisely controlled thickness and composition. These engineered interfaces facilitate lithium-ion transport while minimizing parasitic reactions. By creating stable interfaces between the electrode and electrolyte, ALD coatings reduce impedance growth during cycling, enhance rate capability, and improve the overall electrochemical performance of lithium-ion batteries, particularly at elevated temperatures or under demanding operating conditions.

- Metal oxide ALD coatings for enhanced stability: Metal oxide coatings applied via ALD, such as aluminum oxide (Al2O3), titanium dioxide (TiO2), and zirconium oxide (ZrO2), significantly enhance the thermal and chemical stability of battery components. These nanoscale oxide layers protect electrode materials from degradation mechanisms like transition metal dissolution, structural collapse, and gas generation. The exceptional conformality of ALD allows these protective layers to be applied uniformly even on complex electrode architectures, resulting in improved cycling stability and safety characteristics.

- ALD for silicon and high-capacity anode materials: ALD coatings are particularly beneficial for high-capacity anode materials like silicon, which suffer from significant volume changes during cycling. The conformal coatings accommodate the volume expansion and contraction while maintaining electrical contact and structural integrity. These coatings also prevent excessive SEI formation on anodes, reducing irreversible capacity loss and improving coulombic efficiency. The flexibility and mechanical properties of certain ALD coatings help mitigate pulverization issues associated with high-capacity anode materials.

- Advanced ALD processes and compositions for next-generation batteries: Recent developments in ALD technology include multi-component coatings, doped oxide layers, and gradient compositions that offer tailored properties for specific battery chemistries. These advanced coating strategies combine protective functions with enhanced ionic conductivity and catalytic effects. Innovations in ALD processing, such as spatial ALD and plasma-enhanced ALD, enable faster deposition rates and lower processing temperatures, making the technology more compatible with sensitive battery materials and more feasible for large-scale manufacturing of high-performance lithium-ion batteries.

02 ALD coating for solid electrolyte interfaces

ALD technology enables the formation of artificial solid electrolyte interfaces (SEI) with precisely controlled thickness and composition. These engineered interfaces facilitate efficient lithium-ion transport while blocking unwanted side reactions. By creating stable interfaces between electrodes and electrolytes, ALD coatings can significantly reduce impedance growth during cycling, enhance rate capability, and improve the overall electrochemical performance of lithium-ion batteries.Expand Specific Solutions03 Metal oxide ALD coatings for thermal stability

Metal oxide coatings applied via ALD processes, such as aluminum oxide (Al2O3), titanium dioxide (TiO2), and zirconium oxide (ZrO2), can significantly enhance the thermal stability of lithium-ion battery components. These coatings act as barriers against thermal runaway reactions, improve the battery's safety characteristics, and enable operation across wider temperature ranges. The precise thickness control offered by ALD ensures optimal protection without compromising electrochemical performance.Expand Specific Solutions04 ALD for silicon and high-capacity anode materials

ALD coatings are particularly beneficial for high-capacity anode materials like silicon, which suffer from significant volume changes during cycling. The conformal coatings accommodate the volume expansion and contraction while maintaining electrical contact and structural integrity. This approach helps overcome the pulverization issues common with silicon anodes, leading to improved cycling stability, higher capacity retention, and extended battery lifespan for next-generation high-energy lithium-ion batteries.Expand Specific Solutions05 Multi-layer and doped ALD coatings

Advanced ALD techniques enable the creation of multi-layer and doped coatings with tailored properties for specific battery applications. These sophisticated coating architectures can combine the benefits of different materials, such as mechanical strength from one layer and ionic conductivity from another. Doped ALD coatings can introduce functional elements that enhance specific properties like electronic conductivity or lithium-ion diffusion, resulting in batteries with optimized performance characteristics including faster charging capabilities and improved energy density.Expand Specific Solutions

Leading Companies in ALD Battery Coating Industry

The ALD coating market for next-generation lithium-ion batteries is in a growth phase, with increasing adoption driven by demands for enhanced battery performance and longevity. The market is expanding rapidly as electric vehicle adoption accelerates, with projections suggesting significant growth over the next decade. Technologically, ALD coating has matured from experimental to commercial implementation, with companies like Forge Nano and Coreshell Technologies leading innovation in scalable nanolayer coating solutions. Established players such as ASM International and Beneq provide industrial-scale equipment, while automotive manufacturers including BMW and Volkswagen are integrating these technologies. Research institutions like University of Michigan and Jiangnan University continue advancing fundamental science, while battery manufacturers like LG Energy Solution and Northvolt are implementing ALD technologies to enhance product performance and differentiate in the competitive energy storage market.

Forge Nano, Inc.

Technical Solution: Forge Nano has developed a proprietary Atomic Layer Deposition (ALD) technology called Particle ALD (PALD) specifically designed for battery materials. Their approach enables ultra-thin, conformal coatings on battery electrode particles at industrial scale. The technology creates nanometer-thick protective layers on cathode and anode materials, effectively preventing unwanted side reactions at the electrode-electrolyte interface while maintaining excellent ionic conductivity. Forge Nano's process can be integrated into existing battery manufacturing lines, allowing for high-throughput production with precise thickness control down to the angstrom level. Their ALD coatings have demonstrated significant improvements in battery cycle life (up to 50% longer), capacity retention, and safety characteristics across various lithium-ion chemistries including NMC, NCA, and silicon-based anodes.

Strengths: Scalable industrial implementation with high throughput capabilities; precise thickness control at atomic level; demonstrated performance improvements across multiple battery chemistries. Weaknesses: Potentially higher manufacturing costs compared to conventional coating methods; requires specialized equipment integration into existing production lines.

Beneq Group Oy

Technical Solution: Beneq Group has developed specialized ALD equipment and processes specifically designed for battery material coating applications. Their technology platform, known as Beneq TFS (Thin Film System), enables precise atomic layer deposition on battery particles and electrodes with exceptional uniformity. Beneq's approach utilizes a spatial ALD concept that significantly increases throughput compared to traditional batch ALD processes, making industrial-scale implementation more economically viable. Their systems can deposit various coating materials including Al2O3, ZrO2, TiO2, and LiPON at controlled thicknesses between 1-50nm. Beneq's coating technology has demonstrated particular effectiveness for silicon-based anodes, where their specialized ALD process creates flexible, self-healing coatings that accommodate the substantial volume changes during lithiation/delithiation cycles. Test results show that silicon anodes with their ALD coatings maintain over 80% capacity after 500 cycles, compared to rapid degradation of uncoated materials. Additionally, their equipment design allows for in-line quality monitoring during the coating process.

Strengths: Specialized equipment manufacturer with deep expertise in ALD technology; spatial ALD approach enables higher throughput than conventional methods; flexible coating options for different battery materials. Weaknesses: Primarily focused on equipment rather than direct battery manufacturing; requires significant capital investment for implementation; coating process parameters need optimization for each specific battery chemistry.

Critical Patents and Research in ALD Battery Applications

Atomic layer deposition for continuous, high-speed thin films

PatentActiveUS20190062912A1

Innovation

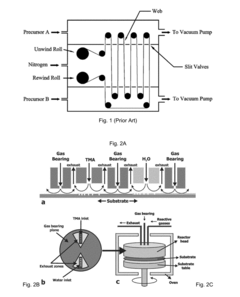

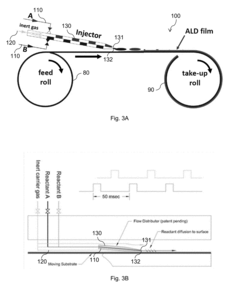

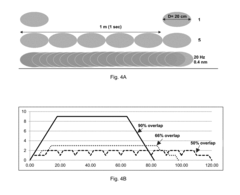

- The implementation of a temporal ALD method using a moving substrate and self-extinguishing precursor pulses within a laminar carrier gas flow, allowing for high-speed deposition without the need for physical separation of precursors and reducing purge requirements, enabling continuous processing.

Environmental Impact of ALD Coating Processes

The environmental implications of Atomic Layer Deposition (ALD) coating processes must be thoroughly evaluated as this technology becomes increasingly central to next-generation lithium-ion battery development. ALD offers remarkable precision in material deposition, but its environmental footprint deserves careful scrutiny across multiple dimensions.

ALD processes typically consume less precursor materials compared to conventional coating methods due to their self-limiting reaction mechanisms. This efficiency translates to reduced chemical waste generation, particularly important given that some ALD precursors contain rare or toxic elements. The precise nature of ALD also minimizes overspray and material loss common in other deposition techniques, further reducing waste streams.

Energy consumption represents a significant environmental consideration for ALD implementation. Traditional ALD processes operate under vacuum conditions and often require elevated temperatures, resulting in substantial energy demands. Recent advancements in atmospheric pressure ALD and room-temperature processes show promise for reducing this energy burden, though these technologies remain in developmental stages for battery applications.

Water usage in ALD processes varies significantly depending on the specific chemistry employed. Water-based ALD reactions generally have lower environmental impact than those utilizing organic solvents or highly reactive compounds. The industry trend toward aqueous-based precursors represents a positive development from an environmental perspective, though challenges remain in achieving equivalent coating performance.

Emissions from ALD processes must also be considered. While generally contained within closed systems, potential fugitive emissions of precursor vapors or reaction byproducts require appropriate abatement technologies. The semiconductor industry has established effective emission control systems for ALD processes that could be adapted for battery manufacturing applications.

Life cycle assessment (LCA) studies comparing ALD to alternative coating technologies for battery applications remain limited but suggest potential environmental benefits when considering the entire battery lifecycle. The improved battery performance and longevity enabled by ALD coatings may offset the environmental impacts of the coating process itself through extended product lifespans and enhanced energy efficiency.

Scaling considerations present additional environmental challenges as ALD moves from laboratory to industrial implementation. While batch processing has been the norm, roll-to-roll and spatial ALD technologies are emerging to enable continuous, higher-throughput production with potentially lower environmental impact per unit of coated material.

ALD processes typically consume less precursor materials compared to conventional coating methods due to their self-limiting reaction mechanisms. This efficiency translates to reduced chemical waste generation, particularly important given that some ALD precursors contain rare or toxic elements. The precise nature of ALD also minimizes overspray and material loss common in other deposition techniques, further reducing waste streams.

Energy consumption represents a significant environmental consideration for ALD implementation. Traditional ALD processes operate under vacuum conditions and often require elevated temperatures, resulting in substantial energy demands. Recent advancements in atmospheric pressure ALD and room-temperature processes show promise for reducing this energy burden, though these technologies remain in developmental stages for battery applications.

Water usage in ALD processes varies significantly depending on the specific chemistry employed. Water-based ALD reactions generally have lower environmental impact than those utilizing organic solvents or highly reactive compounds. The industry trend toward aqueous-based precursors represents a positive development from an environmental perspective, though challenges remain in achieving equivalent coating performance.

Emissions from ALD processes must also be considered. While generally contained within closed systems, potential fugitive emissions of precursor vapors or reaction byproducts require appropriate abatement technologies. The semiconductor industry has established effective emission control systems for ALD processes that could be adapted for battery manufacturing applications.

Life cycle assessment (LCA) studies comparing ALD to alternative coating technologies for battery applications remain limited but suggest potential environmental benefits when considering the entire battery lifecycle. The improved battery performance and longevity enabled by ALD coatings may offset the environmental impacts of the coating process itself through extended product lifespans and enhanced energy efficiency.

Scaling considerations present additional environmental challenges as ALD moves from laboratory to industrial implementation. While batch processing has been the norm, roll-to-roll and spatial ALD technologies are emerging to enable continuous, higher-throughput production with potentially lower environmental impact per unit of coated material.

Scalability and Manufacturing Considerations

The scalability of Atomic Layer Deposition (ALD) coating technology represents a critical factor in determining its commercial viability for next-generation lithium-ion batteries. Current laboratory-scale ALD processes demonstrate exceptional precision in creating uniform, conformal coatings on battery materials, but transitioning to industrial-scale production presents significant challenges. The inherently slow deposition rates of traditional ALD methods—typically measured in angstroms per minute—create a substantial bottleneck for mass production scenarios where throughput requirements are measured in tons per day.

Several innovative approaches are emerging to address these scalability limitations. Spatial ALD technology, which separates precursor gases physically rather than temporally, has demonstrated deposition rates up to 100 times faster than conventional ALD. This breakthrough potentially enables continuous processing lines compatible with existing battery manufacturing infrastructure. Additionally, roll-to-roll ALD systems are being developed specifically for flexible electrode materials, allowing for high-throughput coating of battery components in a continuous process.

Cost considerations remain paramount in scaling ALD technology. The high-purity precursor materials required for ALD processes currently represent a significant expense, with some specialized precursors costing hundreds of dollars per gram. Industry efforts are underway to develop more cost-effective precursor alternatives and recycling systems to reduce this economic barrier. Equipment costs also present challenges, as specialized ALD reactors designed for battery materials can require multi-million dollar investments.

Integration of ALD processes into existing battery manufacturing lines presents another dimension of complexity. Current battery production facilities utilize highly optimized workflows that would require significant modification to accommodate ALD coating steps. The development of modular ALD systems that can be inserted into existing production lines without major disruption represents a promising solution to this integration challenge.

Energy consumption during ALD processing must also be addressed for truly sustainable scaling. The vacuum environments and precise temperature control required by many ALD processes contribute to substantial energy demands. Research into atmospheric pressure ALD and lower-temperature deposition protocols shows promise for reducing these energy requirements while maintaining coating quality.

Quality control and process monitoring systems capable of real-time assessment of nanoscale coatings in high-volume production environments remain underdeveloped. Advanced in-line characterization techniques utilizing spectroscopic methods and machine learning algorithms for process control are emerging as essential components of scalable ALD manufacturing for battery applications.

Several innovative approaches are emerging to address these scalability limitations. Spatial ALD technology, which separates precursor gases physically rather than temporally, has demonstrated deposition rates up to 100 times faster than conventional ALD. This breakthrough potentially enables continuous processing lines compatible with existing battery manufacturing infrastructure. Additionally, roll-to-roll ALD systems are being developed specifically for flexible electrode materials, allowing for high-throughput coating of battery components in a continuous process.

Cost considerations remain paramount in scaling ALD technology. The high-purity precursor materials required for ALD processes currently represent a significant expense, with some specialized precursors costing hundreds of dollars per gram. Industry efforts are underway to develop more cost-effective precursor alternatives and recycling systems to reduce this economic barrier. Equipment costs also present challenges, as specialized ALD reactors designed for battery materials can require multi-million dollar investments.

Integration of ALD processes into existing battery manufacturing lines presents another dimension of complexity. Current battery production facilities utilize highly optimized workflows that would require significant modification to accommodate ALD coating steps. The development of modular ALD systems that can be inserted into existing production lines without major disruption represents a promising solution to this integration challenge.

Energy consumption during ALD processing must also be addressed for truly sustainable scaling. The vacuum environments and precise temperature control required by many ALD processes contribute to substantial energy demands. Research into atmospheric pressure ALD and lower-temperature deposition protocols shows promise for reducing these energy requirements while maintaining coating quality.

Quality control and process monitoring systems capable of real-time assessment of nanoscale coatings in high-volume production environments remain underdeveloped. Advanced in-line characterization techniques utilizing spectroscopic methods and machine learning algorithms for process control are emerging as essential components of scalable ALD manufacturing for battery applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!