Comparison of ALD Coating vs. PVD Coating for EV Batteries

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ALD vs PVD Coating Evolution and Objectives

The evolution of battery coating technologies has witnessed significant advancements over the past decades, with Atomic Layer Deposition (ALD) and Physical Vapor Deposition (PVD) emerging as two prominent techniques for enhancing electric vehicle battery performance. The journey began in the early 1990s with rudimentary coating methods that offered minimal protection against electrolyte degradation and electrode corrosion. By the early 2000s, PVD coating had established itself as an industry standard, providing improved barrier properties and extending battery cycle life.

ALD technology, initially developed for semiconductor applications, began its transition into battery applications around 2010, offering unprecedented precision in coating thickness control down to the atomic level. This evolution represents a paradigm shift from the micron-scale coatings of traditional methods to nanoscale precision engineering of electrode surfaces. The technological progression has been driven by the increasing demands for higher energy density, longer cycle life, and enhanced safety in EV batteries.

The current technological landscape shows a clear divergence in application scenarios between these two coating methods. PVD coating continues to dominate high-volume manufacturing environments due to its established infrastructure and relatively high throughput capabilities. Meanwhile, ALD has been gaining traction in premium battery applications where atomic-level precision and uniformity are paramount for performance optimization.

Recent research indicates a convergence trend where hybrid approaches combining the throughput advantages of PVD with the precision of ALD are being explored. This represents the next frontier in coating technology evolution, potentially offering the best of both worlds for next-generation EV batteries. The industry is witnessing increased patent activity in this hybrid space, signaling strong commercial interest.

The primary objectives of modern coating technology development center around five key parameters: coating uniformity, thickness precision, scalability, cost-effectiveness, and environmental impact. ALD excels in the first two parameters, offering unmatched conformality on complex electrode geometries and angstrom-level thickness control. PVD maintains advantages in throughput and established manufacturing integration, though often with compromises in coating uniformity on high-aspect-ratio structures.

Looking forward, the technological roadmap aims to achieve coating solutions that can be seamlessly integrated into gigafactory-scale production while maintaining nanoscale precision. This represents a significant engineering challenge that will likely require innovations in both ALD and PVD technologies, potentially through parallel processing architectures, roll-to-roll adaptation, or novel precursor chemistries that accelerate deposition rates without sacrificing quality.

ALD technology, initially developed for semiconductor applications, began its transition into battery applications around 2010, offering unprecedented precision in coating thickness control down to the atomic level. This evolution represents a paradigm shift from the micron-scale coatings of traditional methods to nanoscale precision engineering of electrode surfaces. The technological progression has been driven by the increasing demands for higher energy density, longer cycle life, and enhanced safety in EV batteries.

The current technological landscape shows a clear divergence in application scenarios between these two coating methods. PVD coating continues to dominate high-volume manufacturing environments due to its established infrastructure and relatively high throughput capabilities. Meanwhile, ALD has been gaining traction in premium battery applications where atomic-level precision and uniformity are paramount for performance optimization.

Recent research indicates a convergence trend where hybrid approaches combining the throughput advantages of PVD with the precision of ALD are being explored. This represents the next frontier in coating technology evolution, potentially offering the best of both worlds for next-generation EV batteries. The industry is witnessing increased patent activity in this hybrid space, signaling strong commercial interest.

The primary objectives of modern coating technology development center around five key parameters: coating uniformity, thickness precision, scalability, cost-effectiveness, and environmental impact. ALD excels in the first two parameters, offering unmatched conformality on complex electrode geometries and angstrom-level thickness control. PVD maintains advantages in throughput and established manufacturing integration, though often with compromises in coating uniformity on high-aspect-ratio structures.

Looking forward, the technological roadmap aims to achieve coating solutions that can be seamlessly integrated into gigafactory-scale production while maintaining nanoscale precision. This represents a significant engineering challenge that will likely require innovations in both ALD and PVD technologies, potentially through parallel processing architectures, roll-to-roll adaptation, or novel precursor chemistries that accelerate deposition rates without sacrificing quality.

EV Battery Market Demand Analysis

The electric vehicle (EV) battery market is experiencing unprecedented growth, driven by the global shift towards sustainable transportation solutions. Current market projections indicate that the global EV battery market will reach approximately $175 billion by 2028, with a compound annual growth rate exceeding 18% from 2023 to 2028. This remarkable expansion is primarily fueled by stringent government regulations on vehicle emissions, declining battery costs, and increasing consumer awareness about environmental sustainability.

Battery coating technologies, particularly ALD (Atomic Layer Deposition) and PVD (Physical Vapor Deposition), are becoming increasingly critical components in this evolving market landscape. The demand for these advanced coating solutions is directly linked to manufacturers' pursuit of batteries with enhanced performance metrics, including longer cycle life, improved safety characteristics, and higher energy density.

Market research reveals that consumers consistently prioritize three key factors when considering EV purchases: driving range, battery longevity, and charging speed. These consumer preferences are directly influencing battery manufacturers' R&D focus, with coating technologies emerging as a vital enabler for addressing these demands. Specifically, the market shows a growing preference for batteries that can maintain 80% capacity after 1000+ charging cycles, which advanced coating technologies can help achieve.

Regional analysis indicates varying market dynamics across different territories. Asia-Pacific, particularly China, South Korea, and Japan, dominates the EV battery production landscape, accounting for over 70% of global manufacturing capacity. These markets are showing increased adoption of advanced coating technologies to maintain competitive advantages. Meanwhile, European and North American markets are rapidly expanding their battery production capabilities, with significant investments in coating technology research to reduce dependency on Asian suppliers.

The commercial vehicle segment represents an emerging opportunity for specialized battery coatings, with fleet operators demanding batteries optimized for high utilization rates and extended service life. This segment is projected to grow at a faster rate than the passenger vehicle segment over the next five years, creating new application scenarios for both ALD and PVD coating technologies.

Battery recycling considerations are also influencing coating technology selection, as regulatory frameworks increasingly emphasize end-of-life management. Coatings that facilitate easier material recovery while maintaining performance during the battery's operational life are gaining market traction, with both environmental and economic benefits driving this trend.

Battery coating technologies, particularly ALD (Atomic Layer Deposition) and PVD (Physical Vapor Deposition), are becoming increasingly critical components in this evolving market landscape. The demand for these advanced coating solutions is directly linked to manufacturers' pursuit of batteries with enhanced performance metrics, including longer cycle life, improved safety characteristics, and higher energy density.

Market research reveals that consumers consistently prioritize three key factors when considering EV purchases: driving range, battery longevity, and charging speed. These consumer preferences are directly influencing battery manufacturers' R&D focus, with coating technologies emerging as a vital enabler for addressing these demands. Specifically, the market shows a growing preference for batteries that can maintain 80% capacity after 1000+ charging cycles, which advanced coating technologies can help achieve.

Regional analysis indicates varying market dynamics across different territories. Asia-Pacific, particularly China, South Korea, and Japan, dominates the EV battery production landscape, accounting for over 70% of global manufacturing capacity. These markets are showing increased adoption of advanced coating technologies to maintain competitive advantages. Meanwhile, European and North American markets are rapidly expanding their battery production capabilities, with significant investments in coating technology research to reduce dependency on Asian suppliers.

The commercial vehicle segment represents an emerging opportunity for specialized battery coatings, with fleet operators demanding batteries optimized for high utilization rates and extended service life. This segment is projected to grow at a faster rate than the passenger vehicle segment over the next five years, creating new application scenarios for both ALD and PVD coating technologies.

Battery recycling considerations are also influencing coating technology selection, as regulatory frameworks increasingly emphasize end-of-life management. Coatings that facilitate easier material recovery while maintaining performance during the battery's operational life are gaining market traction, with both environmental and economic benefits driving this trend.

Current Coating Technologies and Challenges

The current landscape of battery coating technologies for electric vehicles is dominated by two main approaches: Physical Vapor Deposition (PVD) and Atomic Layer Deposition (ALD). These technologies serve critical functions in enhancing battery performance, safety, and longevity by creating protective layers on electrode materials.

PVD coating, the more established technology, involves the physical transfer of material from a target to the substrate through evaporation or sputtering in vacuum conditions. This process typically achieves deposition rates of 10-100 nm per minute, making it relatively efficient for mass production. However, PVD faces significant challenges in achieving uniform coatings on complex three-dimensional battery electrode structures, often resulting in thickness variations that can compromise performance.

ALD technology, while newer in battery applications, offers unprecedented precision through sequential, self-limiting chemical reactions that deposit materials one atomic layer at a time. This approach achieves exceptional conformality even on high-aspect-ratio structures, with thickness control at the angstrom level. The trade-off comes in processing speed, with typical deposition rates of only 0.1-1 nm per minute, presenting significant throughput challenges for high-volume manufacturing environments.

Current industrial implementation reveals that PVD dominates commercial applications due to its cost-effectiveness and established infrastructure, despite its limitations. Major battery manufacturers have optimized PVD processes to mitigate uniformity issues through advanced chamber designs and substrate rotation systems, though fundamental physics constraints remain.

The technical challenges facing both technologies center around scalability, cost-effectiveness, and performance optimization. PVD struggles with coating uniformity on increasingly complex electrode architectures, while ALD faces significant hurdles in processing speed and equipment costs. Both technologies must also address material compatibility issues with next-generation battery chemistries, particularly solid-state electrolytes.

Recent developments show promising hybrid approaches that combine aspects of both technologies. Spatial ALD and high-power impulse magnetron sputtering (HiPIMS) represent attempts to overcome the speed limitations of conventional ALD while maintaining coating quality. Additionally, atmospheric pressure variants of both technologies are being explored to reduce vacuum requirements and associated costs.

The environmental impact of coating processes presents another challenge, with both technologies requiring optimization to reduce energy consumption and minimize waste. PVD typically consumes more energy due to high vacuum and temperature requirements, while ALD often utilizes precursors with environmental concerns.

PVD coating, the more established technology, involves the physical transfer of material from a target to the substrate through evaporation or sputtering in vacuum conditions. This process typically achieves deposition rates of 10-100 nm per minute, making it relatively efficient for mass production. However, PVD faces significant challenges in achieving uniform coatings on complex three-dimensional battery electrode structures, often resulting in thickness variations that can compromise performance.

ALD technology, while newer in battery applications, offers unprecedented precision through sequential, self-limiting chemical reactions that deposit materials one atomic layer at a time. This approach achieves exceptional conformality even on high-aspect-ratio structures, with thickness control at the angstrom level. The trade-off comes in processing speed, with typical deposition rates of only 0.1-1 nm per minute, presenting significant throughput challenges for high-volume manufacturing environments.

Current industrial implementation reveals that PVD dominates commercial applications due to its cost-effectiveness and established infrastructure, despite its limitations. Major battery manufacturers have optimized PVD processes to mitigate uniformity issues through advanced chamber designs and substrate rotation systems, though fundamental physics constraints remain.

The technical challenges facing both technologies center around scalability, cost-effectiveness, and performance optimization. PVD struggles with coating uniformity on increasingly complex electrode architectures, while ALD faces significant hurdles in processing speed and equipment costs. Both technologies must also address material compatibility issues with next-generation battery chemistries, particularly solid-state electrolytes.

Recent developments show promising hybrid approaches that combine aspects of both technologies. Spatial ALD and high-power impulse magnetron sputtering (HiPIMS) represent attempts to overcome the speed limitations of conventional ALD while maintaining coating quality. Additionally, atmospheric pressure variants of both technologies are being explored to reduce vacuum requirements and associated costs.

The environmental impact of coating processes presents another challenge, with both technologies requiring optimization to reduce energy consumption and minimize waste. PVD typically consumes more energy due to high vacuum and temperature requirements, while ALD often utilizes precursors with environmental concerns.

Technical Comparison of ALD and PVD Solutions

01 Process characteristics and deposition mechanisms

ALD (Atomic Layer Deposition) is a chemical vapor deposition technique that creates thin films one atomic layer at a time through sequential, self-limiting surface reactions. This results in highly conformal coatings with precise thickness control at the atomic level. PVD (Physical Vapor Deposition) involves physical processes like sputtering or evaporation to transfer material from a target to a substrate, typically operating at higher deposition rates but with less conformality on complex geometries. ALD works well at lower temperatures and provides superior step coverage for high-aspect-ratio structures compared to PVD.- Deposition process characteristics: Atomic Layer Deposition (ALD) is characterized by sequential, self-limiting surface reactions that create uniform, conformal thin films with precise thickness control at the atomic level. Physical Vapor Deposition (PVD) involves physical processes like evaporation or sputtering to transfer material from a target to a substrate, typically offering higher deposition rates but less conformality on complex geometries. ALD operates at lower temperatures and provides superior step coverage for high-aspect-ratio structures compared to PVD.

- Coating quality and performance characteristics: ALD coatings typically offer superior uniformity, conformality, and pinhole-free coverage even on complex 3D structures. PVD coatings generally provide better mechanical properties, higher density, and improved adhesion for certain applications. ALD excels in producing ultra-thin films with precise thickness control down to angstrom level, while PVD is often preferred for thicker coatings with specific crystalline structures. The coating quality differences impact wear resistance, corrosion protection, and optical properties in various industrial applications.

- Equipment and manufacturing considerations: ALD equipment typically requires more complex gas delivery systems and precise timing control mechanisms compared to PVD systems. PVD equipment often uses magnetron sputtering or electron beam evaporation technologies that require vacuum chambers and power supplies. ALD processes generally have lower throughput but offer better reproducibility and process control, while PVD systems can achieve higher deposition rates suitable for mass production. The choice between technologies often involves trade-offs between initial equipment costs, operating expenses, maintenance requirements, and production volume needs.

- Application-specific advantages: ALD coatings are preferred for semiconductor devices, microelectronics, and nanotechnology applications requiring precise atomic-level control and conformality in high-aspect-ratio structures. PVD coatings excel in applications needing wear resistance, decorative finishes, and optical coatings where thicker films and specific crystalline structures are advantageous. ALD is increasingly used for barrier films in flexible electronics and packaging, while PVD remains dominant for hard coatings on cutting tools and mechanical components. The selection between technologies depends on specific performance requirements, substrate geometry, and operating conditions.

- Hybrid and combined coating approaches: Innovative approaches combine ALD and PVD technologies to leverage the advantages of both methods. These hybrid processes can include sequential deposition where an ALD layer serves as a seed or barrier layer followed by a PVD coating for bulk material properties. Combined systems may integrate both technologies in a single chamber to reduce handling and contamination. These hybrid approaches enable tailored coating architectures with enhanced properties such as improved adhesion, corrosion resistance, and mechanical performance while potentially reducing processing time and costs compared to using either method alone.

02 Film quality and material properties

ALD coatings typically exhibit higher density, better uniformity, and fewer defects compared to PVD coatings. ALD produces pinhole-free films even at extremely thin thicknesses (nanometer scale), while PVD films may contain more impurities and structural defects. However, PVD coatings often have better crystallinity and can achieve higher purity for certain materials. The mechanical properties, such as hardness, wear resistance, and adhesion, differ between the two techniques, with each offering advantages for specific applications based on the desired material characteristics.Expand Specific Solutions03 Equipment and manufacturing considerations

ALD equipment typically requires more complex gas delivery systems and precise timing control compared to PVD systems. PVD processes generally operate at higher vacuum levels and may require higher power inputs. ALD processes tend to be slower with lower throughput but offer better reproducibility and process control. Manufacturing costs differ between the two technologies, with ALD often having higher operational costs but potentially lower material waste. The selection between ALD and PVD equipment depends on factors such as production volume, substrate geometry, and specific coating requirements.Expand Specific Solutions04 Application-specific advantages

ALD is preferred for applications requiring ultrathin, highly conformal coatings on complex 3D structures, such as in semiconductor manufacturing, MEMS devices, and barrier films. PVD excels in applications needing thicker coatings with specific optical, electrical, or decorative properties, including optical coatings, wear-resistant tools, and decorative finishes. The semiconductor industry increasingly uses ALD for high-k dielectrics and metal gates, while PVD remains dominant for metallization layers. In some advanced applications, hybrid approaches combining both technologies are employed to leverage the advantages of each coating method.Expand Specific Solutions05 Environmental and sustainability aspects

ALD and PVD differ in their environmental impact and sustainability profiles. ALD processes often use specialized precursor chemicals that may be expensive, toxic, or environmentally concerning, but typically consume smaller quantities of materials with less waste. PVD processes generally use simpler source materials but may have higher energy consumption and material waste. The selection between these coating technologies increasingly considers factors such as energy efficiency, material utilization, waste generation, and overall environmental footprint, with ongoing research focused on developing more sustainable variants of both processes.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The ALD vs. PVD coating market for EV batteries is currently in a growth phase, with ALD technology gaining momentum due to its superior precision and uniformity advantages. The global market is expanding rapidly, driven by increasing EV adoption and demand for higher-performance batteries. While PVD remains more established, ALD is emerging as the more promising technology for next-generation battery applications. Key players include Applied Materials and Forge Nano leading in ALD innovation, with companies like Coreshell Technologies developing specialized battery coating solutions. Traditional manufacturers like BMW and Apple are investing in these technologies to secure competitive advantages in battery performance and longevity, indicating the strategic importance of advanced coating technologies in the EV ecosystem.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced ALD coating solutions specifically for EV battery applications through their "Precision Materials Engineering" approach. Their EnVision™ ALD system enables conformal ultra-thin coatings on battery electrodes with atomic-level precision at high throughput rates suitable for mass production. The technology creates uniform protective layers (typically 2-50nm thick) on cathode active materials that significantly improve battery cycle life by preventing unwanted side reactions at electrode-electrolyte interfaces. Applied Materials' ALD process operates at lower temperatures (80-150°C) compared to traditional PVD methods, making it compatible with temperature-sensitive battery materials while achieving deposition rates of 1-2nm per minute with excellent thickness uniformity (<2% variation) across large substrates[1][3]. Their system incorporates in-situ monitoring capabilities that ensure precise coating thickness control and composition throughout the manufacturing process.

Strengths: Superior conformality on complex 3D structures; excellent thickness uniformity; lower process temperatures compatible with sensitive battery materials; precise interface engineering capabilities. Weaknesses: Higher initial equipment investment compared to PVD; slightly slower throughput for thicker coatings; requires specialized precursor chemistry management.

Forge Nano, Inc.

Technical Solution: Forge Nano has pioneered proprietary Atomic Armor® technology, a specialized ALD coating solution specifically engineered for EV battery applications. Their platform enables ultra-thin protective nanolayers (typically 2-100nm) on battery materials with atomic-level precision while maintaining industrial-scale throughput rates of up to 30kg/hour for cathode materials. The company's Particle ALD technology can coat individual powder particles with conformal layers before electrode manufacturing, providing comprehensive protection throughout the battery structure. Forge Nano's process operates at moderate temperatures (100-200°C) and creates pinhole-free barriers that effectively prevent electrolyte degradation at interfaces while maintaining electrical conductivity. Their technology has demonstrated 30-50% improvements in battery cycle life and up to 20% increases in energy density when applied to various cathode chemistries including NMC and high-nickel variants[2][4]. The company has scaled their technology to industrial production levels with continuous processing capabilities that maintain coating quality while reducing manufacturing costs.

Strengths: Specialized in particle-level ALD coating before electrode manufacturing; demonstrated significant cycle life improvements; scalable to industrial production volumes; maintains electrical conductivity while providing protection. Weaknesses: Requires integration into existing battery manufacturing processes; optimal coating parameters vary by battery chemistry requiring customization; higher initial implementation costs compared to conventional technologies.

Critical Patents and Innovations in Battery Coating

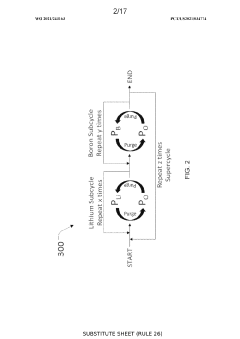

Atomic layer deposition of ionically conductive coatings for lithium battery fast charging

PatentWO2021243163A2

Innovation

- A lithium borate-carbonate (LBCO) film is deposited using ALD on graphite electrodes, achieving higher ionic conductivity (>2 x 10^-6 S/cm) and excellent electrochemical stability, enabling fast charging without significant capacity fading, by forming a conformal, self-limiting coating that suppresses lithium plating.

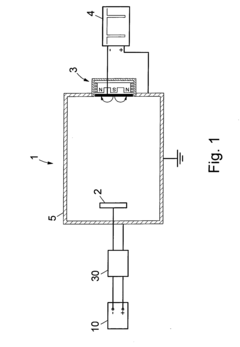

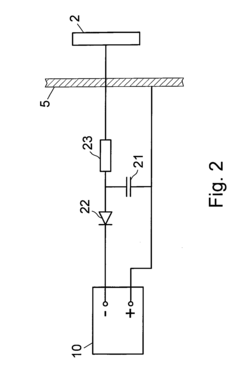

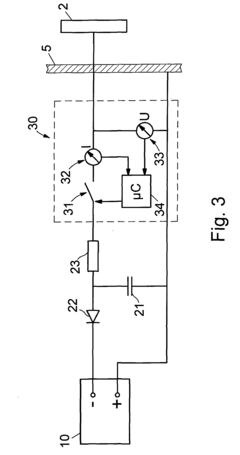

PVD coating with switchable bias voltage

PatentInactiveEP2194159A1

Innovation

- Implementing a galvanic decoupling mechanism for the voltage source during discharges, using a load isolation circuit with an electrically controllable power switch, such as an IGBT or MOSFET, to automatically disconnect and reconnect the bias voltage source when specific conditions are met, ensuring stable operation and maintaining the bias voltage.

Environmental Impact and Sustainability Assessment

The environmental impact of battery coating technologies has become increasingly significant as electric vehicle (EV) production scales globally. When comparing Atomic Layer Deposition (ALD) and Physical Vapor Deposition (PVD) coating methods for EV batteries, several key environmental factors emerge that differentiate these technologies across their lifecycle.

ALD demonstrates superior material efficiency with precise atomic-level deposition that minimizes waste generation. The process typically achieves 90-95% material utilization rates compared to PVD's 30-60%, resulting in substantially reduced raw material consumption and associated extraction impacts. This efficiency translates to lower environmental footprints in upstream supply chains, particularly important for rare or precious metals often used in battery coatings.

Energy consumption patterns differ significantly between these technologies. PVD processes generally require higher vacuum levels and operating temperatures, consuming approximately 15-25 kWh per coating cycle. In contrast, ALD operates at lower temperatures and can achieve comparable coating quality while consuming only 8-12 kWh per cycle. This 40-50% energy reduction directly correlates to lower greenhouse gas emissions when considering grid-dependent manufacturing facilities.

Waste stream analysis reveals ALD produces minimal hazardous byproducts due to its precise chemical reactions. PVD generates more particulate matter and spent target materials requiring specialized disposal protocols. Life cycle assessments indicate ALD coating processes produce approximately 30% less CO2-equivalent emissions per functional unit of coated battery material compared to conventional PVD methods.

Water resource impacts also favor ALD technology, which typically requires 40-60% less process water than comparable PVD systems. This reduction becomes particularly relevant in water-stressed manufacturing regions where battery production is expanding rapidly.

From a circular economy perspective, ALD-coated battery components often demonstrate enhanced durability and longer functional lifespans, potentially extending overall battery life by 15-20%. This longevity reduces replacement frequency and associated environmental impacts from manufacturing new batteries.

However, implementation barriers exist for widespread ALD adoption, including higher initial capital investments and slower throughput rates for large-scale production. These factors must be balanced against the long-term environmental benefits when making sustainability-focused technology decisions for EV battery manufacturing.

ALD demonstrates superior material efficiency with precise atomic-level deposition that minimizes waste generation. The process typically achieves 90-95% material utilization rates compared to PVD's 30-60%, resulting in substantially reduced raw material consumption and associated extraction impacts. This efficiency translates to lower environmental footprints in upstream supply chains, particularly important for rare or precious metals often used in battery coatings.

Energy consumption patterns differ significantly between these technologies. PVD processes generally require higher vacuum levels and operating temperatures, consuming approximately 15-25 kWh per coating cycle. In contrast, ALD operates at lower temperatures and can achieve comparable coating quality while consuming only 8-12 kWh per cycle. This 40-50% energy reduction directly correlates to lower greenhouse gas emissions when considering grid-dependent manufacturing facilities.

Waste stream analysis reveals ALD produces minimal hazardous byproducts due to its precise chemical reactions. PVD generates more particulate matter and spent target materials requiring specialized disposal protocols. Life cycle assessments indicate ALD coating processes produce approximately 30% less CO2-equivalent emissions per functional unit of coated battery material compared to conventional PVD methods.

Water resource impacts also favor ALD technology, which typically requires 40-60% less process water than comparable PVD systems. This reduction becomes particularly relevant in water-stressed manufacturing regions where battery production is expanding rapidly.

From a circular economy perspective, ALD-coated battery components often demonstrate enhanced durability and longer functional lifespans, potentially extending overall battery life by 15-20%. This longevity reduces replacement frequency and associated environmental impacts from manufacturing new batteries.

However, implementation barriers exist for widespread ALD adoption, including higher initial capital investments and slower throughput rates for large-scale production. These factors must be balanced against the long-term environmental benefits when making sustainability-focused technology decisions for EV battery manufacturing.

Cost-Benefit Analysis and Manufacturing Scalability

When evaluating ALD (Atomic Layer Deposition) versus PVD (Physical Vapor Deposition) coating technologies for EV batteries, cost-benefit analysis reveals significant economic considerations that impact manufacturing decisions. ALD processes typically require higher initial capital investment for equipment, with systems costing 30-50% more than comparable PVD setups. This substantial upfront cost difference presents a significant barrier to entry, particularly for smaller manufacturers or startups entering the EV battery market.

Operational costs also differ markedly between these technologies. ALD demonstrates superior material efficiency with utilization rates of 80-95% compared to PVD's typical 40-60% efficiency. This translates to reduced precursor waste and lower material costs over time. However, ALD cycle times are considerably longer, with typical deposition rates of 0.1-0.2 nm per cycle compared to PVD's ability to deposit several nanometers per minute, potentially increasing production time and associated labor costs.

Energy consumption metrics favor ALD in many applications, with studies indicating 15-25% lower energy requirements per coated unit compared to PVD processes. This energy efficiency becomes increasingly significant when scaling to mass production volumes typical in the EV battery industry, where even marginal efficiency improvements translate to substantial cost savings and reduced carbon footprint.

From a manufacturing scalability perspective, PVD currently holds advantages in throughput capacity. Established PVD systems can process larger batch sizes and operate at higher speeds, making them more readily adaptable to existing high-volume manufacturing lines. Industry data suggests PVD systems can achieve throughput rates 3-4 times higher than comparable ALD systems in certain applications, though this gap is narrowing with technological advancements.

ALD's precision offers compelling long-term economic benefits through enhanced product performance and longevity. Batteries with ALD coatings have demonstrated 20-30% longer cycle life in laboratory testing, potentially reducing warranty claims and replacement costs. This performance advantage must be weighed against the higher per-unit production costs, which currently average 15-25% more than PVD-coated equivalents.

Recent innovations in spatial ALD and roll-to-roll processing are addressing scalability limitations, with next-generation systems demonstrating throughput improvements of 5-10x compared to traditional ALD. These developments suggest that the economic equation is shifting, with industry analysts projecting cost parity between optimized ALD and PVD processes for certain battery applications within 3-5 years, particularly as economies of scale improve and equipment costs decrease through wider adoption.

Operational costs also differ markedly between these technologies. ALD demonstrates superior material efficiency with utilization rates of 80-95% compared to PVD's typical 40-60% efficiency. This translates to reduced precursor waste and lower material costs over time. However, ALD cycle times are considerably longer, with typical deposition rates of 0.1-0.2 nm per cycle compared to PVD's ability to deposit several nanometers per minute, potentially increasing production time and associated labor costs.

Energy consumption metrics favor ALD in many applications, with studies indicating 15-25% lower energy requirements per coated unit compared to PVD processes. This energy efficiency becomes increasingly significant when scaling to mass production volumes typical in the EV battery industry, where even marginal efficiency improvements translate to substantial cost savings and reduced carbon footprint.

From a manufacturing scalability perspective, PVD currently holds advantages in throughput capacity. Established PVD systems can process larger batch sizes and operate at higher speeds, making them more readily adaptable to existing high-volume manufacturing lines. Industry data suggests PVD systems can achieve throughput rates 3-4 times higher than comparable ALD systems in certain applications, though this gap is narrowing with technological advancements.

ALD's precision offers compelling long-term economic benefits through enhanced product performance and longevity. Batteries with ALD coatings have demonstrated 20-30% longer cycle life in laboratory testing, potentially reducing warranty claims and replacement costs. This performance advantage must be weighed against the higher per-unit production costs, which currently average 15-25% more than PVD-coated equivalents.

Recent innovations in spatial ALD and roll-to-roll processing are addressing scalability limitations, with next-generation systems demonstrating throughput improvements of 5-10x compared to traditional ALD. These developments suggest that the economic equation is shifting, with industry analysts projecting cost parity between optimized ALD and PVD processes for certain battery applications within 3-5 years, particularly as economies of scale improve and equipment costs decrease through wider adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!