The Influence of ALD Coating on Surface Energy Modulation

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ALD Coating Technology Background and Objectives

Atomic Layer Deposition (ALD) technology has evolved significantly since its inception in the 1970s, transitioning from a niche research technique to a mainstream industrial process. The fundamental principle of ALD involves sequential, self-limiting surface reactions that enable precise control over film thickness at the atomic scale. This unique capability has positioned ALD as a critical technology in various high-tech industries, particularly in semiconductor manufacturing, where nanometer-scale precision is essential.

The evolution of ALD technology has been marked by several key milestones. Initially developed for electroluminescent display production, ALD found broader applications in the 1990s with the miniaturization of semiconductor devices. The early 2000s witnessed significant advancements in precursor chemistry and reactor designs, expanding ALD's material repertoire beyond simple oxides to include metals, nitrides, and complex compounds.

Surface energy modulation through ALD coatings represents a particularly promising frontier in this field. By precisely controlling the chemical composition and thickness of deposited films, ALD enables unprecedented manipulation of surface properties, including wettability, adhesion, and biocompatibility. This capability has opened new avenues for applications in areas ranging from microfluidics to biomedical implants.

The primary technical objective in ALD coating for surface energy modulation is to achieve precise, stable, and uniform control over surface properties across complex geometries and diverse substrate materials. This includes developing processes that can selectively modify surface energy characteristics while maintaining compatibility with existing manufacturing workflows and environmental standards.

Current research trends indicate growing interest in multi-component ALD films that can provide multifunctional surface properties. Additionally, there is increasing focus on low-temperature ALD processes to enable coating of temperature-sensitive substrates, such as polymers and biological materials, which would significantly expand the application scope of surface energy modulation.

The global research landscape shows accelerating innovation in ALD technology, with significant contributions from research institutions in North America, Europe, and East Asia. Industry adoption is following closely, with major investments in ALD equipment and process development across semiconductor, display, energy storage, and medical device sectors.

The ultimate goal of this technological trajectory is to establish ALD coating as a versatile, scalable platform for precise surface engineering, enabling next-generation devices and materials with tailored interfacial properties that can address emerging challenges in energy efficiency, healthcare, and advanced manufacturing.

The evolution of ALD technology has been marked by several key milestones. Initially developed for electroluminescent display production, ALD found broader applications in the 1990s with the miniaturization of semiconductor devices. The early 2000s witnessed significant advancements in precursor chemistry and reactor designs, expanding ALD's material repertoire beyond simple oxides to include metals, nitrides, and complex compounds.

Surface energy modulation through ALD coatings represents a particularly promising frontier in this field. By precisely controlling the chemical composition and thickness of deposited films, ALD enables unprecedented manipulation of surface properties, including wettability, adhesion, and biocompatibility. This capability has opened new avenues for applications in areas ranging from microfluidics to biomedical implants.

The primary technical objective in ALD coating for surface energy modulation is to achieve precise, stable, and uniform control over surface properties across complex geometries and diverse substrate materials. This includes developing processes that can selectively modify surface energy characteristics while maintaining compatibility with existing manufacturing workflows and environmental standards.

Current research trends indicate growing interest in multi-component ALD films that can provide multifunctional surface properties. Additionally, there is increasing focus on low-temperature ALD processes to enable coating of temperature-sensitive substrates, such as polymers and biological materials, which would significantly expand the application scope of surface energy modulation.

The global research landscape shows accelerating innovation in ALD technology, with significant contributions from research institutions in North America, Europe, and East Asia. Industry adoption is following closely, with major investments in ALD equipment and process development across semiconductor, display, energy storage, and medical device sectors.

The ultimate goal of this technological trajectory is to establish ALD coating as a versatile, scalable platform for precise surface engineering, enabling next-generation devices and materials with tailored interfacial properties that can address emerging challenges in energy efficiency, healthcare, and advanced manufacturing.

Market Applications for Surface Energy Modulation

Surface energy modulation through ALD coating technology has found significant applications across multiple industries, transforming product performance and enabling new functionalities. In the semiconductor industry, precise control of surface energy has become critical for advanced node manufacturing, where ALD coatings enable selective deposition processes and improved pattern definition. Market analysis indicates that semiconductor applications alone represent approximately 35% of the current ALD coating market for surface energy applications.

The medical device sector has embraced ALD-enabled surface energy modulation for creating biocompatible interfaces, controlling protein adsorption, and developing antimicrobial surfaces. This market segment has shown consistent growth as healthcare providers seek solutions that reduce infection risks and improve implant integration. The ability to precisely tune hydrophobicity or hydrophilicity at the nanoscale has proven particularly valuable for cardiovascular and orthopedic implants.

Consumer electronics manufacturers have implemented ALD coatings to modulate surface energy for water-repellent and fingerprint-resistant displays. This application has expanded rapidly with the proliferation of touch-enabled devices, creating demand for coatings that maintain optical clarity while reducing maintenance requirements. The automotive industry has similarly adopted these technologies for developing self-cleaning surfaces and anti-fogging capabilities in sensors and displays critical for advanced driver assistance systems.

In renewable energy applications, ALD-modified surface energy characteristics have improved the efficiency and durability of solar panels by creating anti-soiling surfaces that maintain optimal light transmission. The textile industry has incorporated ALD coatings to develop advanced fabrics with controlled wettability, creating opportunities in high-performance sportswear and protective clothing markets.

The packaging industry represents an emerging application area, where ALD coatings can modulate surface energy to create barriers with specific permeability characteristics. This enables improved shelf life for sensitive products while potentially reducing the environmental impact of packaging materials. Market forecasts suggest this segment could experience the fastest growth over the next five years.

Industrial equipment manufacturers have adopted ALD surface energy modulation to address friction and wear challenges in precision components, extending operational lifetimes and reducing maintenance requirements. The aerospace sector has similarly implemented these technologies to develop ice-phobic surfaces and control fluid dynamics across aircraft surfaces.

The medical device sector has embraced ALD-enabled surface energy modulation for creating biocompatible interfaces, controlling protein adsorption, and developing antimicrobial surfaces. This market segment has shown consistent growth as healthcare providers seek solutions that reduce infection risks and improve implant integration. The ability to precisely tune hydrophobicity or hydrophilicity at the nanoscale has proven particularly valuable for cardiovascular and orthopedic implants.

Consumer electronics manufacturers have implemented ALD coatings to modulate surface energy for water-repellent and fingerprint-resistant displays. This application has expanded rapidly with the proliferation of touch-enabled devices, creating demand for coatings that maintain optical clarity while reducing maintenance requirements. The automotive industry has similarly adopted these technologies for developing self-cleaning surfaces and anti-fogging capabilities in sensors and displays critical for advanced driver assistance systems.

In renewable energy applications, ALD-modified surface energy characteristics have improved the efficiency and durability of solar panels by creating anti-soiling surfaces that maintain optimal light transmission. The textile industry has incorporated ALD coatings to develop advanced fabrics with controlled wettability, creating opportunities in high-performance sportswear and protective clothing markets.

The packaging industry represents an emerging application area, where ALD coatings can modulate surface energy to create barriers with specific permeability characteristics. This enables improved shelf life for sensitive products while potentially reducing the environmental impact of packaging materials. Market forecasts suggest this segment could experience the fastest growth over the next five years.

Industrial equipment manufacturers have adopted ALD surface energy modulation to address friction and wear challenges in precision components, extending operational lifetimes and reducing maintenance requirements. The aerospace sector has similarly implemented these technologies to develop ice-phobic surfaces and control fluid dynamics across aircraft surfaces.

Current State and Challenges in ALD Coating Technology

Atomic Layer Deposition (ALD) coating technology has evolved significantly over the past two decades, transitioning from a niche laboratory technique to a mainstream industrial process. Currently, ALD stands as one of the most precise thin film deposition methods available, capable of producing conformal coatings with atomic-level thickness control. The global market for ALD equipment reached approximately $1.8 billion in 2022, with projections suggesting growth to $3.6 billion by 2027, indicating robust industry adoption.

Despite its remarkable progress, ALD coating technology faces several critical challenges that limit its broader application in surface energy modulation. The foremost challenge remains the relatively slow deposition rates, typically 0.1-0.3 nm per cycle, which translates to extended processing times for thicker films. This limitation particularly affects high-volume manufacturing environments where throughput is paramount.

Another significant challenge involves precursor chemistry limitations. Many ALD processes rely on specific precursor combinations that may introduce unwanted impurities or fail to achieve desired surface energy characteristics. The development of novel precursors that can effectively modulate surface energy while maintaining compatibility with ALD processes represents an ongoing research focus.

Temperature constraints present additional hurdles. Traditional ALD processes often require elevated temperatures (150-350°C), which restricts applications involving temperature-sensitive substrates. While low-temperature ALD variants exist, they frequently compromise film quality or deposition rate, creating a difficult trade-off when precise surface energy modulation is required.

Scalability challenges persist in transitioning from laboratory demonstrations to industrial implementation. Large-area uniformity becomes increasingly difficult to maintain as substrate dimensions increase, particularly for applications requiring precise surface energy gradients or patterns across substantial areas.

From a geographical perspective, ALD technology development shows distinct regional characteristics. North America and Europe lead in fundamental research and equipment development, while East Asia dominates in high-volume manufacturing implementation. This distribution creates knowledge transfer challenges that can impede technological advancement.

Cost considerations remain a significant barrier to widespread adoption. The high capital expenditure for ALD equipment, coupled with operational expenses related to precursor materials and maintenance, limits implementation in cost-sensitive applications. This economic factor particularly affects surface energy modulation applications in emerging markets like flexible electronics and biomedical devices.

Recent advancements in plasma-enhanced ALD and spatial ALD offer promising pathways to overcome some of these challenges, but significant research gaps remain in optimizing these approaches specifically for surface energy modulation applications.

Despite its remarkable progress, ALD coating technology faces several critical challenges that limit its broader application in surface energy modulation. The foremost challenge remains the relatively slow deposition rates, typically 0.1-0.3 nm per cycle, which translates to extended processing times for thicker films. This limitation particularly affects high-volume manufacturing environments where throughput is paramount.

Another significant challenge involves precursor chemistry limitations. Many ALD processes rely on specific precursor combinations that may introduce unwanted impurities or fail to achieve desired surface energy characteristics. The development of novel precursors that can effectively modulate surface energy while maintaining compatibility with ALD processes represents an ongoing research focus.

Temperature constraints present additional hurdles. Traditional ALD processes often require elevated temperatures (150-350°C), which restricts applications involving temperature-sensitive substrates. While low-temperature ALD variants exist, they frequently compromise film quality or deposition rate, creating a difficult trade-off when precise surface energy modulation is required.

Scalability challenges persist in transitioning from laboratory demonstrations to industrial implementation. Large-area uniformity becomes increasingly difficult to maintain as substrate dimensions increase, particularly for applications requiring precise surface energy gradients or patterns across substantial areas.

From a geographical perspective, ALD technology development shows distinct regional characteristics. North America and Europe lead in fundamental research and equipment development, while East Asia dominates in high-volume manufacturing implementation. This distribution creates knowledge transfer challenges that can impede technological advancement.

Cost considerations remain a significant barrier to widespread adoption. The high capital expenditure for ALD equipment, coupled with operational expenses related to precursor materials and maintenance, limits implementation in cost-sensitive applications. This economic factor particularly affects surface energy modulation applications in emerging markets like flexible electronics and biomedical devices.

Recent advancements in plasma-enhanced ALD and spatial ALD offer promising pathways to overcome some of these challenges, but significant research gaps remain in optimizing these approaches specifically for surface energy modulation applications.

Existing ALD Coating Solutions for Surface Energy Control

01 Surface energy modification through ALD coatings

Atomic Layer Deposition (ALD) can be used to modify the surface energy of various substrates by depositing thin films with specific properties. By controlling the composition and thickness of the ALD coating, the surface energy can be tailored to be either hydrophilic or hydrophobic. This modification affects properties such as wettability, adhesion, and friction, which are crucial for various applications including electronics, optics, and biomedical devices.- Surface energy modification through ALD coatings: Atomic Layer Deposition (ALD) can be used to modify the surface energy of various substrates by depositing thin films with specific properties. The process allows precise control over the hydrophobicity or hydrophilicity of surfaces by selecting appropriate coating materials and process parameters. These modifications can enhance wettability characteristics for specific applications while maintaining the underlying substrate properties.

- ALD coating materials for controlling surface energy: Different materials deposited via ALD can yield varying surface energy properties. Metal oxides like aluminum oxide, titanium oxide, and zirconium oxide typically produce hydrophilic surfaces, while organic or fluorinated coatings create hydrophobic surfaces. The selection of precursors and reaction conditions during the ALD process significantly influences the resulting surface energy characteristics, enabling customization for specific applications.

- Multi-layer ALD coatings for enhanced surface properties: Multi-layer ALD coatings can be engineered to achieve specific surface energy profiles by combining different materials in nanolaminates or gradient structures. This approach allows for the creation of surfaces with unique properties that cannot be achieved with single-material coatings. The thickness and composition of each layer can be precisely controlled to optimize surface energy for applications ranging from microelectronics to biomedical devices.

- ALD process parameters affecting surface energy: Process parameters in ALD, such as temperature, pressure, pulse and purge times, and substrate preparation, significantly impact the resulting surface energy of coatings. Optimizing these parameters allows for fine-tuning of surface properties without changing the coating material. Post-deposition treatments like annealing or plasma exposure can further modify surface energy characteristics to meet specific requirements.

- Applications of ALD coatings with controlled surface energy: ALD coatings with tailored surface energy properties find applications across various industries. In electronics, they improve adhesion between layers and provide moisture barriers. In optical applications, they reduce reflection and enhance light transmission. For medical devices, they can improve biocompatibility or create antimicrobial surfaces. Industrial applications include corrosion protection and friction reduction in mechanical components.

02 ALD coating materials for controlling surface energy

Different materials deposited via ALD can significantly influence the resulting surface energy. Metal oxides like aluminum oxide, titanium dioxide, and zirconium oxide typically produce hydrophilic surfaces with high surface energy, while organic or fluorinated coatings create hydrophobic surfaces with low surface energy. The selection of precursors and process parameters during ALD allows precise control over the chemical composition of the coating and consequently the surface energy properties.Expand Specific Solutions03 ALD process parameters affecting surface energy

The surface energy of ALD coatings can be controlled by adjusting various process parameters. Temperature, pressure, pulse and purge times, and substrate preparation all influence the growth mechanism and resulting film properties. Lower deposition temperatures often lead to incomplete reactions and incorporation of impurities, which can alter surface energy. Post-deposition treatments such as annealing or plasma exposure can further modify the surface energy characteristics of the coating.Expand Specific Solutions04 Multilayer and nanocomposite ALD coatings for surface energy control

Advanced ALD techniques involve depositing multilayer structures or nanocomposite coatings to achieve specific surface energy profiles. By alternating layers of different materials or creating mixed-phase nanocomposites, it's possible to develop surfaces with gradient or patterned surface energy. These sophisticated coating architectures enable the creation of surfaces with region-specific wettability, which is valuable for applications such as microfluidics, selective deposition, and anti-fouling surfaces.Expand Specific Solutions05 Applications of ALD coatings with controlled surface energy

ALD coatings with tailored surface energy find applications across numerous industries. In electronics, they improve the performance of semiconductor devices and protect sensitive components from environmental factors. In optical applications, they reduce reflection and enhance light transmission. For biomedical devices, they control protein adsorption and cell adhesion. Industrial applications include corrosion protection, friction reduction, and catalysis enhancement, where the precise control of surface energy plays a crucial role in functionality.Expand Specific Solutions

Leading Companies and Research Institutions in ALD Field

The Atomic Layer Deposition (ALD) coating market for surface energy modulation is currently in a growth phase, with increasing applications across semiconductor, energy storage, and optical industries. The global market is expanding rapidly, estimated at several billion dollars with projected double-digit annual growth. Technologically, companies demonstrate varying maturity levels: established players like Applied Materials, Beneq, and Micron Technology offer commercial solutions, while research-focused entities such as Forge Nano and Nanexa are advancing specialized applications. Academic institutions (North Carolina State University, KU Leuven) and research organizations (Imec, CEA) are driving fundamental innovations. The competitive landscape features both large corporations integrating ALD into broader product portfolios and specialized firms developing proprietary techniques for precise surface energy control across industrial, medical, and electronic applications.

Beneq Group Oy

Technical Solution: Beneq has pioneered ALD (Atomic Layer Deposition) technology for surface energy modulation through their proprietary TFS (Thin Film Solutions) platform. Their approach enables precise control of surface properties by depositing conformal nanoscale coatings that can transform hydrophilic surfaces to hydrophobic (or vice versa) with exceptional uniformity. The company's technology allows for tailoring surface energy characteristics through selection of specific precursor chemistries and process parameters, achieving contact angle modifications from below 10° to above 110°. Beneq's industrial-scale ALD systems can process complex 3D geometries while maintaining atomic-level precision, which is particularly valuable for applications requiring controlled wettability, adhesion properties, and surface reactivity. Their recent innovations include low-temperature ALD processes that enable coating of temperature-sensitive substrates while still achieving the desired surface energy modifications.

Strengths: Industry-leading expertise in ALD equipment manufacturing with exceptional coating uniformity and conformality on complex geometries. Weaknesses: Their systems typically require significant capital investment and specialized expertise to operate effectively, potentially limiting accessibility for smaller organizations.

Forge Nano, Inc.

Technical Solution: Forge Nano has developed a proprietary Atomic Armor™ technology platform that utilizes advanced ALD processes specifically optimized for surface energy modulation at commercial scale. Their innovation centers on high-throughput ALD systems capable of processing tons of material daily while maintaining precise atomic-level control. The company's approach involves tailoring the chemical composition and thickness of nanoscale coatings (typically 1-100nm) to precisely engineer surface energy characteristics for various applications. Their technology enables the creation of surfaces with controlled hydrophobicity/hydrophilicity, improved chemical resistance, and enhanced tribological properties. Forge Nano's systems can apply uniform ALD coatings to particles, powders, and complex geometries with exceptional conformality, allowing for surface energy modification of high-surface-area materials that traditional coating methods cannot effectively treat. Their recent advancements include specialized precursor chemistries designed specifically for energy storage applications where surface energy plays a critical role in performance.

Strengths: Unparalleled expertise in high-volume ALD processing with specialized focus on particle coating and energy storage applications. Weaknesses: Their technology may be less cost-effective for applications requiring only small production volumes or highly specialized surface modifications beyond their core focus areas.

Key Innovations in ALD-Based Surface Modification

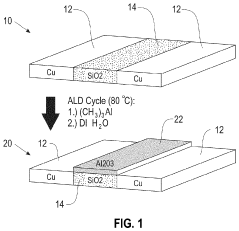

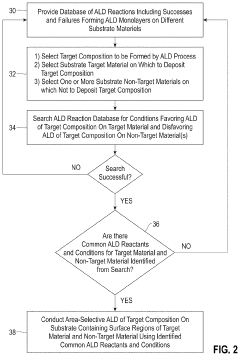

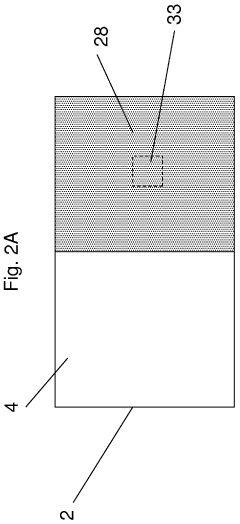

Methods of area-selective atomic layer deposition

PatentInactiveUS20200354834A1

Innovation

- The method involves contacting a substrate with a silicon dioxide surface and a zero-valent metal-containing surface with an organoaluminum compound at low temperatures, followed by exposure to water, to selectively form alumina on silicon dioxide surfaces without depositing on copper surfaces, using a database of ALD reactions to determine optimal conditions for selective deposition.

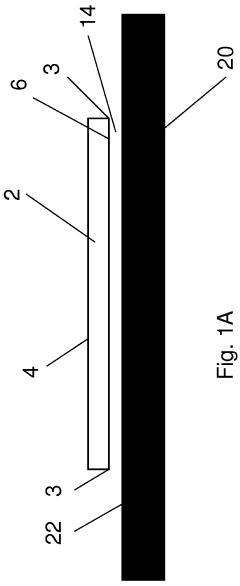

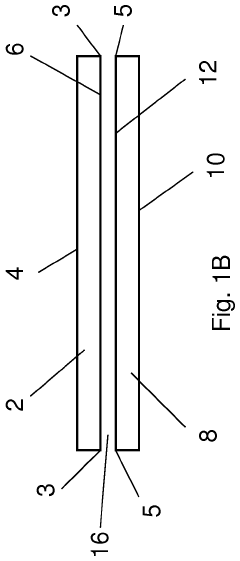

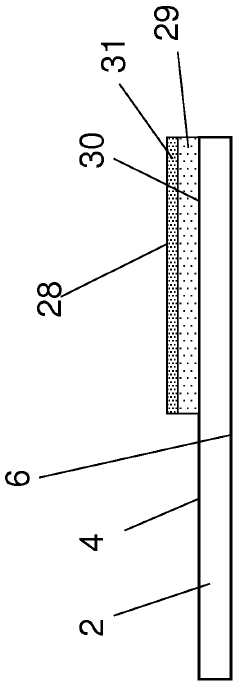

Barrier, carrier arrangement and method for preventing material growth

PatentWO2014191622A1

Innovation

- A barrier comprising a base-element and an absorption element with a higher specific surface area than the substrate, placed against the substrate to absorb precursor molecules and prevent material growth on specific areas, utilizing porous or fibrous materials to increase the surface area for diffusion and reaction within the absorption element.

Environmental Impact and Sustainability of ALD Processes

Atomic Layer Deposition (ALD) processes, while offering precise control over surface energy modulation, present significant environmental considerations that must be addressed for sustainable implementation. The environmental footprint of ALD primarily stems from precursor chemicals, energy consumption, and waste generation. Many traditional ALD precursors contain hazardous elements such as heavy metals or reactive compounds that pose environmental risks if improperly managed.

Energy consumption represents another critical environmental factor in ALD processes. The technique typically requires vacuum conditions and elevated temperatures, resulting in substantial energy demands. Recent studies indicate that a standard industrial ALD reactor can consume between 10-50 kWh per processing cycle, depending on substrate size and coating specifications. This energy intensity contributes significantly to the carbon footprint of ALD-based manufacturing.

Water usage in ALD processes, particularly for cooling systems and precursor preparation, presents additional sustainability challenges. Some facilities report using up to 1,000 liters of ultra-pure water per day for ALD operations, highlighting the resource-intensive nature of these processes. The purification of this water itself requires energy and chemical inputs, compounding the environmental impact.

Waste management represents a crucial aspect of ALD sustainability. Unreacted precursors, byproducts, and spent materials must be properly treated to prevent environmental contamination. Advanced abatement systems can capture and neutralize up to 99% of harmful emissions, though implementation rates vary significantly across different regions and manufacturing sectors.

Recent innovations have focused on developing "green ALD" approaches that address these environmental concerns. Water-based precursors, room-temperature processes, and energy recovery systems have demonstrated potential to reduce environmental impact by 30-60% compared to conventional methods. Additionally, closed-loop precursor delivery systems can minimize waste generation and reduce raw material consumption by up to 40%.

Life cycle assessment (LCA) studies comparing ALD to alternative coating technologies suggest that despite higher initial environmental impacts, the extended lifetime and enhanced performance of ALD-coated products may offer net environmental benefits in certain applications. For example, ALD-coated solar panels demonstrate 15-25% longer operational lifespans, potentially offsetting the environmental costs of the coating process through improved energy generation efficiency.

Industry-academic partnerships have emerged to establish sustainability standards specifically for ALD processes, with initiatives focusing on precursor selection criteria, energy efficiency benchmarks, and waste reduction protocols. These collaborative efforts aim to create a framework for environmentally responsible implementation of surface energy modulation technologies across various industrial sectors.

Energy consumption represents another critical environmental factor in ALD processes. The technique typically requires vacuum conditions and elevated temperatures, resulting in substantial energy demands. Recent studies indicate that a standard industrial ALD reactor can consume between 10-50 kWh per processing cycle, depending on substrate size and coating specifications. This energy intensity contributes significantly to the carbon footprint of ALD-based manufacturing.

Water usage in ALD processes, particularly for cooling systems and precursor preparation, presents additional sustainability challenges. Some facilities report using up to 1,000 liters of ultra-pure water per day for ALD operations, highlighting the resource-intensive nature of these processes. The purification of this water itself requires energy and chemical inputs, compounding the environmental impact.

Waste management represents a crucial aspect of ALD sustainability. Unreacted precursors, byproducts, and spent materials must be properly treated to prevent environmental contamination. Advanced abatement systems can capture and neutralize up to 99% of harmful emissions, though implementation rates vary significantly across different regions and manufacturing sectors.

Recent innovations have focused on developing "green ALD" approaches that address these environmental concerns. Water-based precursors, room-temperature processes, and energy recovery systems have demonstrated potential to reduce environmental impact by 30-60% compared to conventional methods. Additionally, closed-loop precursor delivery systems can minimize waste generation and reduce raw material consumption by up to 40%.

Life cycle assessment (LCA) studies comparing ALD to alternative coating technologies suggest that despite higher initial environmental impacts, the extended lifetime and enhanced performance of ALD-coated products may offer net environmental benefits in certain applications. For example, ALD-coated solar panels demonstrate 15-25% longer operational lifespans, potentially offsetting the environmental costs of the coating process through improved energy generation efficiency.

Industry-academic partnerships have emerged to establish sustainability standards specifically for ALD processes, with initiatives focusing on precursor selection criteria, energy efficiency benchmarks, and waste reduction protocols. These collaborative efforts aim to create a framework for environmentally responsible implementation of surface energy modulation technologies across various industrial sectors.

Scalability and Industrial Implementation Considerations

The scalability of Atomic Layer Deposition (ALD) coating technology for surface energy modulation represents a critical consideration for industrial adoption. Current ALD equipment can process substrates ranging from small laboratory samples to 300mm semiconductor wafers, with some specialized systems capable of handling even larger areas. However, transitioning from laboratory-scale demonstrations to high-volume manufacturing presents significant challenges. The inherently sequential nature of ALD processes, requiring alternating precursor exposures with purge steps, traditionally limits throughput compared to other deposition techniques.

Recent advancements in spatial ALD and roll-to-roll processing have substantially improved throughput capabilities. Spatial ALD separates precursor zones physically rather than temporally, allowing continuous substrate movement through different chemical environments. This approach has demonstrated deposition rates up to 100 times faster than conventional ALD while maintaining excellent film quality and conformality. Such innovations are particularly promising for industries requiring large-area surface energy modification, such as textiles, packaging, and architectural materials.

Cost considerations remain paramount for industrial implementation. While ALD offers precise control over surface properties, the capital expenditure for industrial-scale equipment ranges from $500,000 to several million dollars. Operating costs include precursor chemicals, carrier gases, maintenance, and energy consumption. Economic viability depends heavily on the value added by surface energy modulation in specific applications. High-value products in medical devices, precision optics, and advanced electronics can more readily justify the investment compared to commodity materials.

Process integration presents another significant challenge. Incorporating ALD coating steps into existing manufacturing lines requires careful consideration of compatibility with upstream and downstream processes. Factors such as thermal budget constraints, handling protocols, and quality control measures must be addressed. Additionally, the environmental impact of ALD processes, including precursor utilization efficiency and waste management, requires optimization for sustainable industrial implementation.

Standardization efforts are emerging to facilitate broader industrial adoption. Organizations such as SEMI and ASTM International are developing specifications for ALD processes, materials, and equipment. These standards will enable more consistent results across different manufacturing facilities and equipment platforms, accelerating technology transfer from research to production environments. Furthermore, they will provide frameworks for quality assurance and process validation essential for regulated industries.

Recent advancements in spatial ALD and roll-to-roll processing have substantially improved throughput capabilities. Spatial ALD separates precursor zones physically rather than temporally, allowing continuous substrate movement through different chemical environments. This approach has demonstrated deposition rates up to 100 times faster than conventional ALD while maintaining excellent film quality and conformality. Such innovations are particularly promising for industries requiring large-area surface energy modification, such as textiles, packaging, and architectural materials.

Cost considerations remain paramount for industrial implementation. While ALD offers precise control over surface properties, the capital expenditure for industrial-scale equipment ranges from $500,000 to several million dollars. Operating costs include precursor chemicals, carrier gases, maintenance, and energy consumption. Economic viability depends heavily on the value added by surface energy modulation in specific applications. High-value products in medical devices, precision optics, and advanced electronics can more readily justify the investment compared to commodity materials.

Process integration presents another significant challenge. Incorporating ALD coating steps into existing manufacturing lines requires careful consideration of compatibility with upstream and downstream processes. Factors such as thermal budget constraints, handling protocols, and quality control measures must be addressed. Additionally, the environmental impact of ALD processes, including precursor utilization efficiency and waste management, requires optimization for sustainable industrial implementation.

Standardization efforts are emerging to facilitate broader industrial adoption. Organizations such as SEMI and ASTM International are developing specifications for ALD processes, materials, and equipment. These standards will enable more consistent results across different manufacturing facilities and equipment platforms, accelerating technology transfer from research to production environments. Furthermore, they will provide frameworks for quality assurance and process validation essential for regulated industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!