The Role of ALD Coating in Strengthening Aerospace Composites

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ALD Coating Evolution and Aerospace Applications

Atomic Layer Deposition (ALD) coating technology has undergone significant evolution since its inception in the 1970s. Initially developed for semiconductor applications, ALD has transformed into a versatile technique capable of depositing ultra-thin, conformal coatings on complex geometries with atomic-level precision. The evolution of ALD can be traced through several key developmental phases, each marked by technological breakthroughs that expanded its application scope.

In the early stages (1970s-1990s), ALD was primarily confined to research laboratories, with limited industrial applications. The technology was known as Atomic Layer Epitaxy (ALE) and focused on semiconductor thin films. The transition period (1990s-2000s) saw significant advancements in precursor chemistry and reactor designs, enabling more diverse material deposition capabilities and improved process control.

The modern era of ALD (2000s-present) has been characterized by the expansion into new application domains, including aerospace. This expansion was facilitated by the development of specialized precursors, enhanced reactor technologies, and improved understanding of surface chemistry mechanisms. The ability to deposit uniform coatings on high-aspect-ratio structures made ALD particularly valuable for aerospace applications.

In aerospace specifically, ALD coatings have evolved from experimental treatments to critical components in composite material protection systems. Early aerospace applications focused on thermal barrier coatings for engine components. As the technology matured, applications expanded to include environmental protection coatings for composite structures, which shield against moisture, UV radiation, and chemical exposure.

Recent developments have seen ALD emerge as a key technology for enhancing the mechanical properties of aerospace composites. By creating nanoscale reinforcement at fiber-matrix interfaces, ALD coatings can significantly improve interlaminar shear strength, fracture toughness, and fatigue resistance of composite materials. This capability addresses critical weaknesses in traditional aerospace composites without adding significant weight.

The latest frontier in aerospace ALD applications involves multifunctional coatings that simultaneously provide mechanical reinforcement, environmental protection, and additional functionalities such as electrical conductivity, EMI shielding, or self-sensing capabilities. These advanced coatings represent a paradigm shift from passive protection to active enhancement of composite performance.

Looking forward, the trajectory of ALD coating evolution in aerospace applications points toward increased integration with digital manufacturing technologies, development of self-healing coating systems, and expansion into new material combinations specifically designed for extreme aerospace environments.

In the early stages (1970s-1990s), ALD was primarily confined to research laboratories, with limited industrial applications. The technology was known as Atomic Layer Epitaxy (ALE) and focused on semiconductor thin films. The transition period (1990s-2000s) saw significant advancements in precursor chemistry and reactor designs, enabling more diverse material deposition capabilities and improved process control.

The modern era of ALD (2000s-present) has been characterized by the expansion into new application domains, including aerospace. This expansion was facilitated by the development of specialized precursors, enhanced reactor technologies, and improved understanding of surface chemistry mechanisms. The ability to deposit uniform coatings on high-aspect-ratio structures made ALD particularly valuable for aerospace applications.

In aerospace specifically, ALD coatings have evolved from experimental treatments to critical components in composite material protection systems. Early aerospace applications focused on thermal barrier coatings for engine components. As the technology matured, applications expanded to include environmental protection coatings for composite structures, which shield against moisture, UV radiation, and chemical exposure.

Recent developments have seen ALD emerge as a key technology for enhancing the mechanical properties of aerospace composites. By creating nanoscale reinforcement at fiber-matrix interfaces, ALD coatings can significantly improve interlaminar shear strength, fracture toughness, and fatigue resistance of composite materials. This capability addresses critical weaknesses in traditional aerospace composites without adding significant weight.

The latest frontier in aerospace ALD applications involves multifunctional coatings that simultaneously provide mechanical reinforcement, environmental protection, and additional functionalities such as electrical conductivity, EMI shielding, or self-sensing capabilities. These advanced coatings represent a paradigm shift from passive protection to active enhancement of composite performance.

Looking forward, the trajectory of ALD coating evolution in aerospace applications points toward increased integration with digital manufacturing technologies, development of self-healing coating systems, and expansion into new material combinations specifically designed for extreme aerospace environments.

Market Demand Analysis for Advanced Aerospace Composites

The aerospace composites market is experiencing robust growth, driven by increasing demand for lightweight, high-performance materials in aircraft and spacecraft manufacturing. Current market valuations place the global aerospace composites sector at approximately 32 billion USD in 2023, with projections indicating a compound annual growth rate of 9.3% through 2030. This growth trajectory is primarily fueled by the commercial aviation segment, which accounts for over 60% of the total market share.

The demand for advanced aerospace composites is particularly evident in next-generation aircraft programs, where manufacturers are seeking to reduce aircraft weight by 20-25% compared to previous generations. This weight reduction directly translates to fuel efficiency improvements of 15-20%, addressing both economic and environmental concerns in the aviation industry.

ALD (Atomic Layer Deposition) coated composites represent an emerging segment within this market, with specialized applications showing annual growth rates exceeding 12%. The superior performance characteristics of ALD-enhanced composites, including improved thermal stability, erosion resistance, and mechanical strength, position them as premium solutions for critical aerospace applications.

Regional analysis reveals that North America currently dominates the aerospace composites market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the fastest growth rate, driven by expanding aerospace manufacturing capabilities in China, Japan, and India.

Customer requirements are increasingly focused on multi-functional composites that offer not only structural integrity but also additional properties such as electromagnetic shielding, lightning strike protection, and self-sensing capabilities. ALD coating technology directly addresses these evolving needs by enabling the integration of multiple functionalities into composite structures without significant weight penalties.

Defense aerospace applications represent another significant market driver, with military aircraft and unmanned aerial vehicles requiring composites with enhanced durability and stealth characteristics. The defense sector's demand for ALD-coated composites is projected to grow at 11% annually through 2028, outpacing the overall market.

Supply chain considerations are becoming increasingly important, with aerospace manufacturers seeking materials and technologies that can be sourced reliably and sustainably. ALD coating processes, while currently specialized, are demonstrating potential for scaling to meet industrial production volumes, which will be critical for widespread market adoption.

The demand for advanced aerospace composites is particularly evident in next-generation aircraft programs, where manufacturers are seeking to reduce aircraft weight by 20-25% compared to previous generations. This weight reduction directly translates to fuel efficiency improvements of 15-20%, addressing both economic and environmental concerns in the aviation industry.

ALD (Atomic Layer Deposition) coated composites represent an emerging segment within this market, with specialized applications showing annual growth rates exceeding 12%. The superior performance characteristics of ALD-enhanced composites, including improved thermal stability, erosion resistance, and mechanical strength, position them as premium solutions for critical aerospace applications.

Regional analysis reveals that North America currently dominates the aerospace composites market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the fastest growth rate, driven by expanding aerospace manufacturing capabilities in China, Japan, and India.

Customer requirements are increasingly focused on multi-functional composites that offer not only structural integrity but also additional properties such as electromagnetic shielding, lightning strike protection, and self-sensing capabilities. ALD coating technology directly addresses these evolving needs by enabling the integration of multiple functionalities into composite structures without significant weight penalties.

Defense aerospace applications represent another significant market driver, with military aircraft and unmanned aerial vehicles requiring composites with enhanced durability and stealth characteristics. The defense sector's demand for ALD-coated composites is projected to grow at 11% annually through 2028, outpacing the overall market.

Supply chain considerations are becoming increasingly important, with aerospace manufacturers seeking materials and technologies that can be sourced reliably and sustainably. ALD coating processes, while currently specialized, are demonstrating potential for scaling to meet industrial production volumes, which will be critical for widespread market adoption.

Current ALD Technology Status and Implementation Challenges

Atomic Layer Deposition (ALD) technology has evolved significantly over the past two decades, transitioning from a niche laboratory technique to a commercially viable manufacturing process for aerospace composites. Currently, ALD coating systems operate with remarkable precision, capable of depositing uniform layers at the atomic scale (typically 0.1-3 Å per cycle) across complex geometries and high-aspect-ratio structures. This precision makes ALD particularly valuable for aerospace applications where component reliability is critical.

The global market for ALD equipment has reached approximately $1.8 billion as of 2023, with aerospace applications representing about 12% of this market. Major equipment manufacturers have developed specialized systems capable of handling larger components and higher throughput requirements, addressing previous limitations in scaling the technology for industrial aerospace production.

Despite these advancements, significant implementation challenges persist. The deposition rate remains relatively slow compared to alternative coating methods, with typical growth rates of 0.05-0.1 μm/hour. This creates a throughput bottleneck for large aerospace components, where coating times can extend to several days, impacting production schedules and increasing manufacturing costs.

Temperature sensitivity presents another critical challenge. While low-temperature ALD processes (80-150°C) have been developed, many high-performance coatings still require temperatures exceeding 250°C, which can compromise the structural integrity of certain polymer-based composites used in aerospace applications. This temperature constraint limits the application scope for heat-sensitive composite materials.

Precursor chemistry optimization remains an ongoing challenge. The ideal precursors must exhibit high volatility, thermal stability, and reactivity while being non-toxic and cost-effective. Currently, many high-performance ALD coatings rely on expensive or hazardous precursors, creating barriers to widespread industrial adoption in aerospace manufacturing environments.

Scalability issues continue to impact implementation. While ALD can theoretically coat components of any size, practical limitations in chamber design and gas flow dynamics create uniformity challenges for large aerospace structures. Current industrial ALD systems struggle to maintain coating uniformity across components exceeding 2 meters in any dimension.

Quality control and in-situ monitoring capabilities remain underdeveloped compared to other coating technologies. Real-time thickness monitoring and composition analysis during the ALD process are technically challenging, necessitating post-deposition characterization that extends production cycles and increases costs.

Cost considerations represent perhaps the most significant barrier to widespread adoption. The total cost of ownership for ALD systems, including equipment acquisition, maintenance, precursor materials, and operational expenses, remains substantially higher than conventional coating technologies, with estimates suggesting a 30-50% premium for ALD-coated aerospace components.

The global market for ALD equipment has reached approximately $1.8 billion as of 2023, with aerospace applications representing about 12% of this market. Major equipment manufacturers have developed specialized systems capable of handling larger components and higher throughput requirements, addressing previous limitations in scaling the technology for industrial aerospace production.

Despite these advancements, significant implementation challenges persist. The deposition rate remains relatively slow compared to alternative coating methods, with typical growth rates of 0.05-0.1 μm/hour. This creates a throughput bottleneck for large aerospace components, where coating times can extend to several days, impacting production schedules and increasing manufacturing costs.

Temperature sensitivity presents another critical challenge. While low-temperature ALD processes (80-150°C) have been developed, many high-performance coatings still require temperatures exceeding 250°C, which can compromise the structural integrity of certain polymer-based composites used in aerospace applications. This temperature constraint limits the application scope for heat-sensitive composite materials.

Precursor chemistry optimization remains an ongoing challenge. The ideal precursors must exhibit high volatility, thermal stability, and reactivity while being non-toxic and cost-effective. Currently, many high-performance ALD coatings rely on expensive or hazardous precursors, creating barriers to widespread industrial adoption in aerospace manufacturing environments.

Scalability issues continue to impact implementation. While ALD can theoretically coat components of any size, practical limitations in chamber design and gas flow dynamics create uniformity challenges for large aerospace structures. Current industrial ALD systems struggle to maintain coating uniformity across components exceeding 2 meters in any dimension.

Quality control and in-situ monitoring capabilities remain underdeveloped compared to other coating technologies. Real-time thickness monitoring and composition analysis during the ALD process are technically challenging, necessitating post-deposition characterization that extends production cycles and increases costs.

Cost considerations represent perhaps the most significant barrier to widespread adoption. The total cost of ownership for ALD systems, including equipment acquisition, maintenance, precursor materials, and operational expenses, remains substantially higher than conventional coating technologies, with estimates suggesting a 30-50% premium for ALD-coated aerospace components.

Existing ALD Solutions for Composite Reinforcement

01 ALD coating for mechanical strength enhancement

Atomic Layer Deposition (ALD) can be used to create thin, conformal coatings that significantly enhance the mechanical strength of various substrates. The precise control of film thickness at the atomic level allows for the creation of strong protective layers that can improve hardness, wear resistance, and overall durability of components. These coatings can be applied to various materials including metals, ceramics, and polymers to enhance their mechanical properties while maintaining dimensional accuracy.- ALD coating for mechanical strength enhancement: Atomic Layer Deposition (ALD) can be used to create conformal coatings that significantly enhance the mechanical strength of various substrates. The process allows for precise control of coating thickness at the atomic level, resulting in uniform layers that improve hardness, wear resistance, and overall durability of the base material. These strengthened materials show improved performance under mechanical stress and extended service life in demanding applications.

- ALD coatings for electronic and semiconductor applications: ALD technology provides superior strengthening coatings for electronic components and semiconductor devices. The nanoscale precision of ALD enables the creation of ultra-thin, defect-free protective layers that enhance the durability and reliability of electronic components while maintaining their electrical properties. These coatings protect against environmental factors, prevent oxidation, and improve the overall performance and longevity of semiconductor devices.

- Barrier and protective ALD coatings: ALD coatings serve as effective barriers against environmental factors such as moisture, oxygen, and corrosive substances. These protective layers significantly enhance the durability and longevity of various materials and components. The atomic-level precision of ALD allows for the creation of pinhole-free barriers that provide superior protection compared to conventional coating methods, making them ideal for applications requiring high reliability and extended service life.

- ALD coating process optimization for strength enhancement: Optimizing ALD coating processes is crucial for achieving maximum strength enhancement. Parameters such as temperature, precursor selection, pulse and purge times, and cycle counts significantly impact the quality and performance of the resulting coating. Advanced process control techniques enable the creation of tailored coatings with specific mechanical properties, including enhanced hardness, adhesion, and stress resistance, leading to superior strengthening effects for various substrate materials.

- Multi-layer and composite ALD coatings for enhanced strength: Multi-layer and composite ALD coatings offer superior strengthening properties compared to single-layer applications. By alternating different materials in nanolaminates or creating gradient compositions, these advanced coating structures can provide customized mechanical properties such as improved hardness, flexibility, and crack resistance. The ability to precisely control the composition and thickness of each layer allows for the development of coatings with optimized performance characteristics for specific applications and operating conditions.

02 Barrier properties of ALD coatings

ALD coatings provide excellent barrier properties against corrosion, oxidation, and environmental degradation. The layer-by-layer deposition process creates dense, pinhole-free films that effectively protect underlying materials from chemical attack and moisture penetration. These barrier coatings can significantly extend the service life of components in harsh environments while maintaining their structural integrity and performance characteristics.Expand Specific Solutions03 ALD coating for electronic and semiconductor applications

In electronic and semiconductor applications, ALD coatings provide crucial strengthening and protection for sensitive components. These coatings can enhance the performance and reliability of electronic devices by providing uniform, conformal layers that protect against electrical breakdown, improve thermal management, and enhance device longevity. The atomic-level precision of ALD allows for the creation of ultra-thin dielectric layers and protective barriers that are essential for advanced microelectronic devices.Expand Specific Solutions04 Multi-layer and composite ALD coatings

Multi-layer and composite ALD coatings combine different materials in alternating layers to achieve enhanced mechanical properties beyond what single-material coatings can provide. By engineering these nanolaminates with precisely controlled thickness and composition, significant improvements in hardness, toughness, and wear resistance can be achieved. These composite structures can be tailored to specific applications by selecting appropriate material combinations and layer architectures to optimize strength enhancement.Expand Specific Solutions05 Temperature and process optimization for ALD strengthening

The strengthening effect of ALD coatings can be optimized through careful control of deposition parameters such as temperature, precursor chemistry, and cycle timing. Process optimization is critical for achieving the desired mechanical properties while ensuring good adhesion to the substrate. Advanced ALD techniques, including plasma-enhanced ALD and spatial ALD, can further enhance coating performance by allowing for lower deposition temperatures or higher throughput while maintaining excellent film quality and strengthening characteristics.Expand Specific Solutions

Key Industry Players in ALD Coating and Aerospace Composites

The ALD coating market for aerospace composites is in a growth phase, characterized by increasing adoption of this advanced technology to enhance composite material performance. The market is expanding due to rising demand for lightweight, durable materials in aerospace applications, with projections indicating significant growth potential. Technologically, ALD coating has reached moderate maturity, with established players like Applied Materials, Beneq Group, and Picosun leading innovation in equipment manufacturing. DuPont and Honeywell are advancing material science applications, while research institutions like North Carolina State University and UChicago Argonne contribute to fundamental advancements. Companies like Forge Nano are commercializing specialized aerospace applications, bridging the gap between laboratory research and industrial implementation.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed an integrated ALD coating solution for aerospace composites that builds upon their extensive experience with high-performance materials. Their approach combines their Kevlar® and Nomex® advanced fiber technologies with nanoscale ALD protective coatings to create multi-functional composite systems. DuPont's proprietary process applies ultra-thin (5-20nm) aluminum oxide and titanium dioxide layers that significantly enhance UV resistance, flame retardancy, and chemical stability of aerospace composites. Their technology has demonstrated particular effectiveness in protecting composites from galvanic corrosion when in contact with metal components, a common issue in aerospace applications. DuPont has also pioneered hybrid organic-inorganic ALD coatings that provide both barrier properties and impact resistance, addressing multiple degradation mechanisms simultaneously. Testing has shown these coatings can extend the service life of aerospace composites by 30-50% under extreme environmental conditions.

Strengths: Comprehensive materials science expertise; integration with existing high-performance fibers; ability to address multiple degradation mechanisms; established presence in aerospace supply chains. Weaknesses: More complex processing requirements; higher cost compared to conventional protective measures; requires specialized equipment for optimal application.

Beneq Group Oy

Technical Solution: Beneq has pioneered specialized ALD equipment and processes specifically optimized for aerospace composite applications. Their TFS 200 and P800 systems are designed for industrial-scale coating of aerospace components with precise control over film thickness and composition. Beneq's technology focuses on applying conformal Al2O3, TiO2, and SiO2 nanolaminates that enhance the environmental durability of carbon and glass fiber composites. Their proprietary Atmospheric Pressure ALD (AP-ALD) process allows for continuous roll-to-roll coating of composite fabrics before resin infusion, enabling protection at the fiber level. This approach has demonstrated up to 85% improvement in moisture resistance and 70% reduction in oxygen permeability for treated composites. Beneq has also developed specialized high-temperature ALD processes that can deposit protective coatings capable of withstanding temperatures up to 600°C, making them suitable for engine nacelles and other high-heat aerospace applications.

Strengths: Specialized equipment designed specifically for aerospace applications; ability to coat fibers before composite formation; excellent conformality and uniformity; industrial-scale production capability. Weaknesses: Higher initial capital investment; requires integration into existing manufacturing workflows; limited to certain types of precursor chemicals.

Critical Patents and Research in ALD Coating Technology

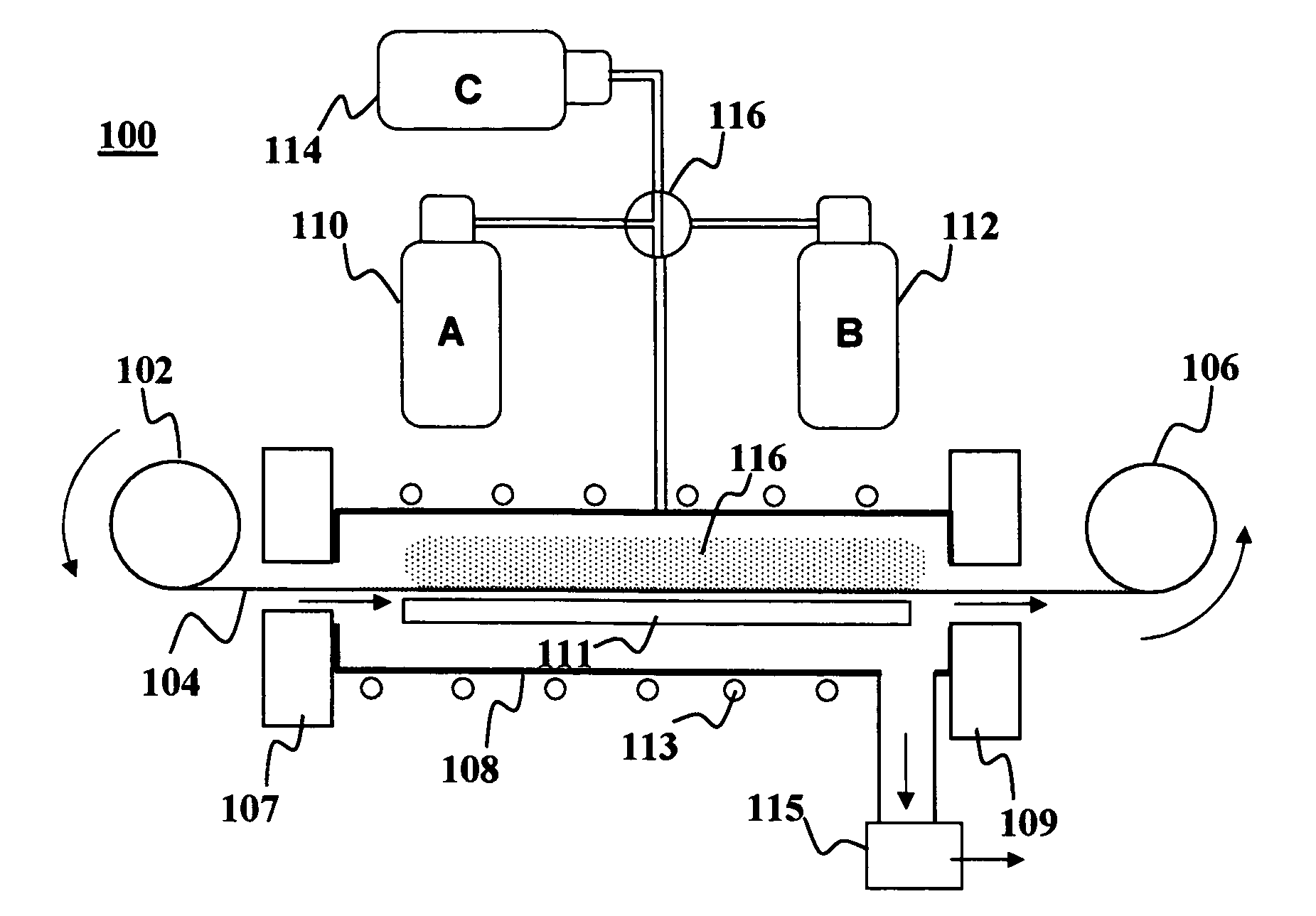

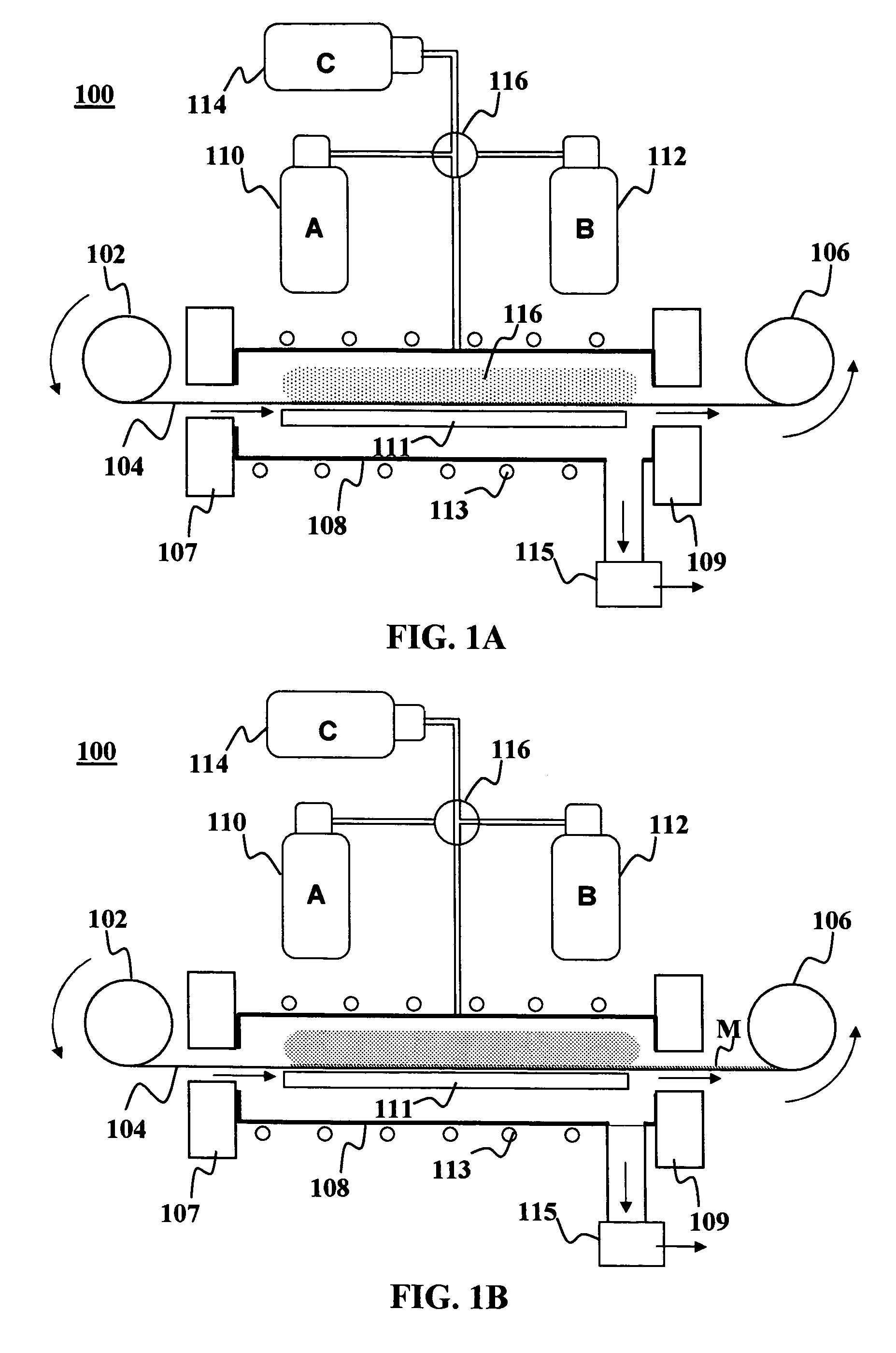

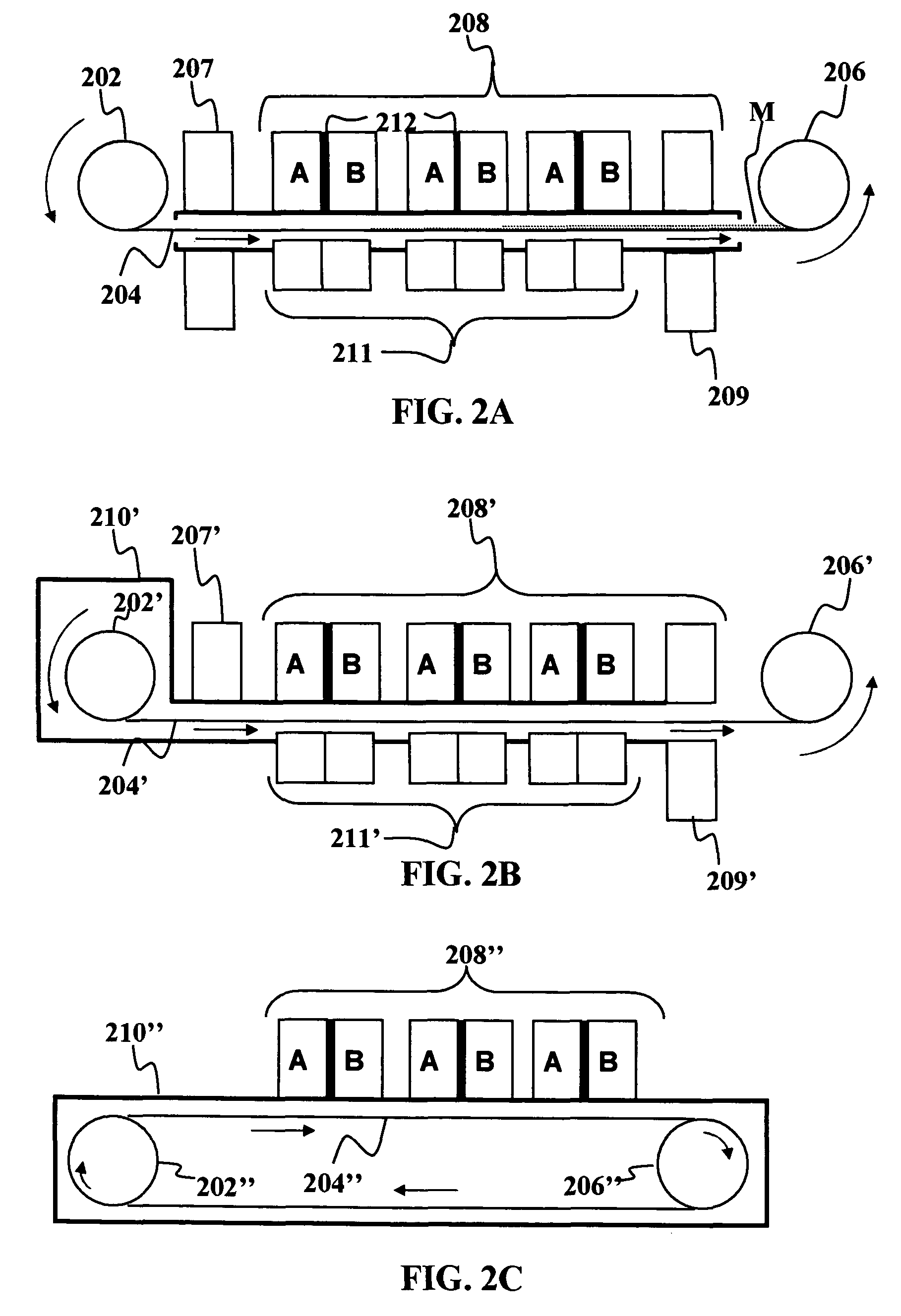

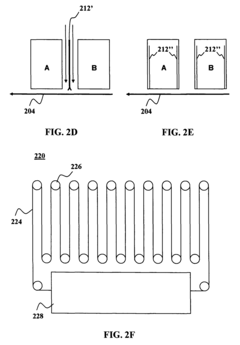

Roll-to-roll atomic layer deposition method and system

PatentInactiveUS8304019B1

Innovation

- A roll-to-roll production system for ALD that uses a continuous substrate flow through a chamber with multiple ALD sections, allowing for sequential exposure to reactant gases and temperature control, enabling high-throughput deposition of thin films on large area substrates.

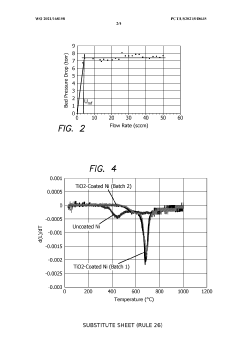

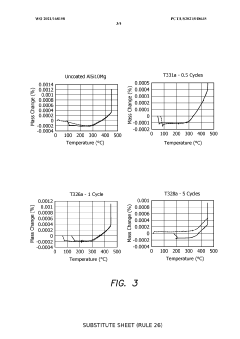

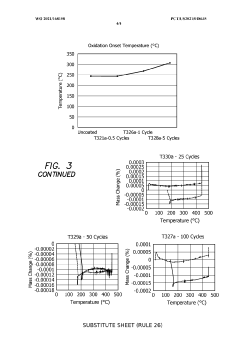

ATOMIC LAYER DEPOSITION (ALD) FOR MULTI-LAYER CERAMIC CAPACITORS (MLCCs)

PatentWO2021168158A2

Innovation

- The application of Atomic Layer Deposition (ALD) techniques to coat metal and ceramic powders with ultra-thin, uniform layers, enabling smaller particle sizes, improved sintering control, and the elimination of sintering retardants, resulting in enhanced capacitance and heat management.

Environmental Impact and Sustainability Considerations

The environmental impact of Atomic Layer Deposition (ALD) coating processes in aerospace composite manufacturing requires careful consideration as the industry moves toward more sustainable practices. Traditional composite manufacturing and coating processes often involve hazardous chemicals and significant energy consumption. ALD technology offers several environmental advantages, including precise material deposition that minimizes waste and reduces the need for excess chemicals typically associated with conventional coating methods.

ALD processes operate at relatively low temperatures compared to other coating technologies, resulting in lower energy consumption during application. This energy efficiency translates to reduced carbon emissions throughout the manufacturing lifecycle. Additionally, the thin-film nature of ALD coatings means less raw material is required to achieve the desired protective properties, further reducing resource consumption and environmental footprint.

The durability enhancement provided by ALD coatings contributes significantly to sustainability by extending the service life of aerospace components. Longer-lasting components reduce the frequency of replacements, thereby decreasing the overall material consumption and waste generation across the aerospace industry. This lifecycle extension represents a key sustainability benefit that should be quantified in environmental impact assessments.

However, certain ALD precursors may contain rare earth elements or toxic compounds that present environmental challenges. The industry is actively researching greener precursor alternatives that maintain coating performance while reducing environmental hazards. Water-based precursors and bio-inspired compounds are emerging as promising candidates for next-generation environmentally friendly ALD processes.

End-of-life considerations for ALD-coated composites present both challenges and opportunities. The nanoscale integration of coating materials with composite substrates can complicate recycling processes. Research into specialized recycling technologies capable of separating and recovering these materials is ongoing, with promising developments in selective chemical dissolution and advanced mechanical separation techniques.

Regulatory frameworks worldwide are increasingly emphasizing lifecycle assessment for aerospace materials. Manufacturers implementing ALD coating technologies must document comprehensive environmental impact data, from raw material extraction through manufacturing, use phase, and eventual disposal. This holistic approach enables meaningful comparisons between different coating technologies and drives continuous improvement in environmental performance.

The aerospace industry's push toward carbon neutrality creates additional incentives for optimizing ALD processes. Integration with renewable energy sources for powering ALD equipment and development of closed-loop precursor recovery systems represent frontier areas for enhancing the sustainability profile of this technology while maintaining its performance benefits for aerospace composites.

ALD processes operate at relatively low temperatures compared to other coating technologies, resulting in lower energy consumption during application. This energy efficiency translates to reduced carbon emissions throughout the manufacturing lifecycle. Additionally, the thin-film nature of ALD coatings means less raw material is required to achieve the desired protective properties, further reducing resource consumption and environmental footprint.

The durability enhancement provided by ALD coatings contributes significantly to sustainability by extending the service life of aerospace components. Longer-lasting components reduce the frequency of replacements, thereby decreasing the overall material consumption and waste generation across the aerospace industry. This lifecycle extension represents a key sustainability benefit that should be quantified in environmental impact assessments.

However, certain ALD precursors may contain rare earth elements or toxic compounds that present environmental challenges. The industry is actively researching greener precursor alternatives that maintain coating performance while reducing environmental hazards. Water-based precursors and bio-inspired compounds are emerging as promising candidates for next-generation environmentally friendly ALD processes.

End-of-life considerations for ALD-coated composites present both challenges and opportunities. The nanoscale integration of coating materials with composite substrates can complicate recycling processes. Research into specialized recycling technologies capable of separating and recovering these materials is ongoing, with promising developments in selective chemical dissolution and advanced mechanical separation techniques.

Regulatory frameworks worldwide are increasingly emphasizing lifecycle assessment for aerospace materials. Manufacturers implementing ALD coating technologies must document comprehensive environmental impact data, from raw material extraction through manufacturing, use phase, and eventual disposal. This holistic approach enables meaningful comparisons between different coating technologies and drives continuous improvement in environmental performance.

The aerospace industry's push toward carbon neutrality creates additional incentives for optimizing ALD processes. Integration with renewable energy sources for powering ALD equipment and development of closed-loop precursor recovery systems represent frontier areas for enhancing the sustainability profile of this technology while maintaining its performance benefits for aerospace composites.

Certification and Quality Assurance Standards

The implementation of ALD coating technologies in aerospace composites necessitates adherence to rigorous certification and quality assurance standards. The aerospace industry operates under stringent regulatory frameworks established by organizations such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Organization for Standardization (ISO). These bodies have developed comprehensive standards specifically addressing composite materials and surface treatments, including ALD coatings.

AS9100 certification represents the aerospace industry's gold standard for quality management systems, incorporating ISO 9001 requirements with additional aerospace-specific criteria. For ALD coating processes, this certification demands meticulous documentation of process parameters, equipment calibration records, and material traceability. Manufacturers must demonstrate consistent coating thickness, uniformity, and adhesion strength across production batches.

NADCAP (National Aerospace and Defense Contractors Accreditation Program) accreditation is particularly relevant for special processes like ALD coating. This industry-managed approach establishes technical requirements for coating processes and conducts rigorous audits to ensure compliance. Companies applying ALD technology to aerospace composites must satisfy NADCAP's Chemical Processing (CP) and Coatings (CT) task group requirements.

Material qualification standards such as ASTM D3359 for adhesion testing and ASTM B117 for salt spray resistance are essential for validating ALD coating performance. These standards provide standardized methodologies for evaluating coating durability under various environmental conditions. Additionally, MIL-STD-810 environmental testing protocols assess how ALD-coated composites withstand temperature extremes, humidity, and vibration stresses encountered during aerospace operations.

Non-destructive testing (NDT) techniques play a crucial role in quality assurance for ALD-coated composites. Standards like ASTM E2580 guide the application of ultrasonic inspection methods to detect coating delamination or substrate defects without compromising structural integrity. Advanced techniques including thermography and acoustic emission testing are increasingly incorporated into inspection protocols for these sophisticated materials.

Environmental compliance standards are equally important, with regulations like REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe and EPA guidelines in the United States governing the chemical precursors used in ALD processes. Manufacturers must document compliance with these regulations, particularly regarding the handling and disposal of potentially hazardous materials.

As ALD coating technology evolves, certification bodies are developing more specific standards addressing atomic-level deposition processes. These emerging standards focus on process validation methodologies, in-situ monitoring techniques, and accelerated aging protocols to predict long-term performance of ALD-coated aerospace composites under operational conditions.

AS9100 certification represents the aerospace industry's gold standard for quality management systems, incorporating ISO 9001 requirements with additional aerospace-specific criteria. For ALD coating processes, this certification demands meticulous documentation of process parameters, equipment calibration records, and material traceability. Manufacturers must demonstrate consistent coating thickness, uniformity, and adhesion strength across production batches.

NADCAP (National Aerospace and Defense Contractors Accreditation Program) accreditation is particularly relevant for special processes like ALD coating. This industry-managed approach establishes technical requirements for coating processes and conducts rigorous audits to ensure compliance. Companies applying ALD technology to aerospace composites must satisfy NADCAP's Chemical Processing (CP) and Coatings (CT) task group requirements.

Material qualification standards such as ASTM D3359 for adhesion testing and ASTM B117 for salt spray resistance are essential for validating ALD coating performance. These standards provide standardized methodologies for evaluating coating durability under various environmental conditions. Additionally, MIL-STD-810 environmental testing protocols assess how ALD-coated composites withstand temperature extremes, humidity, and vibration stresses encountered during aerospace operations.

Non-destructive testing (NDT) techniques play a crucial role in quality assurance for ALD-coated composites. Standards like ASTM E2580 guide the application of ultrasonic inspection methods to detect coating delamination or substrate defects without compromising structural integrity. Advanced techniques including thermography and acoustic emission testing are increasingly incorporated into inspection protocols for these sophisticated materials.

Environmental compliance standards are equally important, with regulations like REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe and EPA guidelines in the United States governing the chemical precursors used in ALD processes. Manufacturers must document compliance with these regulations, particularly regarding the handling and disposal of potentially hazardous materials.

As ALD coating technology evolves, certification bodies are developing more specific standards addressing atomic-level deposition processes. These emerging standards focus on process validation methodologies, in-situ monitoring techniques, and accelerated aging protocols to predict long-term performance of ALD-coated aerospace composites under operational conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!