Analysis of Carbon Capture Sorbents against Environmental Standards

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Technology Background and Objectives

Carbon capture technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in response to growing environmental concerns. The fundamental principle involves capturing carbon dioxide (CO2) emissions from industrial processes and power generation before they enter the atmosphere, thereby mitigating their contribution to global warming and climate change. Initially developed in the 1970s for enhanced oil recovery, carbon capture technologies have since expanded in scope and sophistication.

The evolution of carbon capture sorbents represents a critical advancement in this field. Early technologies primarily utilized liquid solvents such as monoethanolamine (MEA), which while effective, presented challenges including high energy requirements for regeneration and corrosion issues. Recent developments have focused on solid sorbents, including metal-organic frameworks (MOFs), zeolites, and amine-functionalized materials, which offer improved efficiency and reduced environmental impact.

Current environmental standards worldwide are becoming increasingly stringent, with many nations implementing carbon pricing mechanisms and emissions reduction targets aligned with the Paris Agreement. These regulatory frameworks have accelerated research and development in carbon capture technologies, particularly in the area of sorbent materials that can meet or exceed these standards while remaining economically viable.

The primary technical objectives in carbon capture sorbent development include enhancing CO2 selectivity, increasing adsorption capacity, improving regeneration efficiency, and extending operational lifespan. Additionally, researchers aim to reduce the environmental footprint of the sorbents themselves, addressing concerns about potential toxicity, resource intensity in production, and end-of-life disposal considerations.

Recent technological breakthroughs have demonstrated promising advancements in bio-based sorbents derived from sustainable materials, as well as hybrid systems that combine multiple capture mechanisms. These innovations suggest potential pathways toward more environmentally compatible carbon capture solutions that align with circular economy principles.

The trajectory of carbon capture technology is increasingly focused on integration with broader carbon utilization and storage systems, creating comprehensive carbon management solutions. This holistic approach aims not only to capture emissions but to transform captured carbon into valuable products or ensure its permanent sequestration, thereby closing the carbon cycle and potentially creating economic incentives for widespread adoption.

As global decarbonization efforts intensify, carbon capture sorbent technology stands at a critical juncture, with research priorities shifting toward materials and processes that can simultaneously achieve technical performance targets while meeting increasingly demanding environmental standards across their entire lifecycle.

The evolution of carbon capture sorbents represents a critical advancement in this field. Early technologies primarily utilized liquid solvents such as monoethanolamine (MEA), which while effective, presented challenges including high energy requirements for regeneration and corrosion issues. Recent developments have focused on solid sorbents, including metal-organic frameworks (MOFs), zeolites, and amine-functionalized materials, which offer improved efficiency and reduced environmental impact.

Current environmental standards worldwide are becoming increasingly stringent, with many nations implementing carbon pricing mechanisms and emissions reduction targets aligned with the Paris Agreement. These regulatory frameworks have accelerated research and development in carbon capture technologies, particularly in the area of sorbent materials that can meet or exceed these standards while remaining economically viable.

The primary technical objectives in carbon capture sorbent development include enhancing CO2 selectivity, increasing adsorption capacity, improving regeneration efficiency, and extending operational lifespan. Additionally, researchers aim to reduce the environmental footprint of the sorbents themselves, addressing concerns about potential toxicity, resource intensity in production, and end-of-life disposal considerations.

Recent technological breakthroughs have demonstrated promising advancements in bio-based sorbents derived from sustainable materials, as well as hybrid systems that combine multiple capture mechanisms. These innovations suggest potential pathways toward more environmentally compatible carbon capture solutions that align with circular economy principles.

The trajectory of carbon capture technology is increasingly focused on integration with broader carbon utilization and storage systems, creating comprehensive carbon management solutions. This holistic approach aims not only to capture emissions but to transform captured carbon into valuable products or ensure its permanent sequestration, thereby closing the carbon cycle and potentially creating economic incentives for widespread adoption.

As global decarbonization efforts intensify, carbon capture sorbent technology stands at a critical juncture, with research priorities shifting toward materials and processes that can simultaneously achieve technical performance targets while meeting increasingly demanding environmental standards across their entire lifecycle.

Market Analysis for Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. As of 2023, the market was valued at approximately $7.5 billion, with projections indicating a compound annual growth rate of 19.2% through 2030, potentially reaching $35.9 billion by the end of the decade. This growth trajectory is supported by substantial government investments, with the United States allocating $12 billion for carbon capture development in recent infrastructure legislation and the European Union committing €10 billion through various climate innovation funds.

The demand for carbon capture solutions spans multiple industries, with power generation, cement production, and steel manufacturing representing the largest market segments. Power generation alone accounts for roughly 40% of the current carbon capture market, as utilities face mounting pressure to decarbonize their operations while maintaining reliable energy production. Industrial applications collectively represent another 45% of market demand, with the remaining 15% distributed across emerging applications including direct air capture technologies.

Regional analysis reveals varying market maturity and growth potential. North America currently leads with approximately 35% market share, bolstered by favorable tax incentives like the 45Q tax credit in the United States. Europe follows closely at 30%, driven by stringent emissions regulations and carbon pricing mechanisms. The Asia-Pacific region, while currently representing 25% of the market, is expected to demonstrate the fastest growth rate over the next decade as China and India implement more aggressive climate policies.

Customer segmentation within the carbon capture market reveals three primary buyer categories: large industrial emitters seeking compliance solutions, energy companies pursuing enhanced oil recovery applications, and forward-looking corporations investing in carbon removal to meet net-zero commitments. The first segment currently dominates purchasing decisions, representing approximately 65% of market activity.

Pricing structures for carbon capture solutions vary significantly based on technology maturity and application scale. Current cost ranges for industrial point-source capture typically fall between $50-100 per ton of CO₂ captured, while direct air capture technologies remain considerably higher at $250-600 per ton. Market forecasts suggest these costs will decline by 30-50% over the next decade as technologies mature and achieve economies of scale.

Competition in the carbon capture market features established industrial gas companies, specialized technology startups, and diversifying energy majors. Recent market consolidation has been evident, with several high-profile acquisitions as larger corporations seek to expand their decarbonization portfolios through strategic technology acquisitions.

The demand for carbon capture solutions spans multiple industries, with power generation, cement production, and steel manufacturing representing the largest market segments. Power generation alone accounts for roughly 40% of the current carbon capture market, as utilities face mounting pressure to decarbonize their operations while maintaining reliable energy production. Industrial applications collectively represent another 45% of market demand, with the remaining 15% distributed across emerging applications including direct air capture technologies.

Regional analysis reveals varying market maturity and growth potential. North America currently leads with approximately 35% market share, bolstered by favorable tax incentives like the 45Q tax credit in the United States. Europe follows closely at 30%, driven by stringent emissions regulations and carbon pricing mechanisms. The Asia-Pacific region, while currently representing 25% of the market, is expected to demonstrate the fastest growth rate over the next decade as China and India implement more aggressive climate policies.

Customer segmentation within the carbon capture market reveals three primary buyer categories: large industrial emitters seeking compliance solutions, energy companies pursuing enhanced oil recovery applications, and forward-looking corporations investing in carbon removal to meet net-zero commitments. The first segment currently dominates purchasing decisions, representing approximately 65% of market activity.

Pricing structures for carbon capture solutions vary significantly based on technology maturity and application scale. Current cost ranges for industrial point-source capture typically fall between $50-100 per ton of CO₂ captured, while direct air capture technologies remain considerably higher at $250-600 per ton. Market forecasts suggest these costs will decline by 30-50% over the next decade as technologies mature and achieve economies of scale.

Competition in the carbon capture market features established industrial gas companies, specialized technology startups, and diversifying energy majors. Recent market consolidation has been evident, with several high-profile acquisitions as larger corporations seek to expand their decarbonization portfolios through strategic technology acquisitions.

Current Sorbent Technologies and Challenges

Carbon capture technologies have evolved significantly over the past decades, with various sorbent materials being developed to address the growing concern of carbon emissions. Currently, the market is dominated by several key sorbent technologies, each with distinct advantages and limitations when evaluated against environmental standards.

Amine-based sorbents represent the most mature technology in the carbon capture landscape. These materials, including monoethanolamine (MEA), diethanolamine (DEA), and methyldiethanolamine (MDEA), offer high CO2 selectivity and relatively fast kinetics. However, they face significant challenges including high regeneration energy requirements (3-4 GJ/tonne CO2), susceptibility to degradation in the presence of oxygen and sulfur compounds, and potential for harmful emissions through amine leaching.

Solid adsorbents such as zeolites, metal-organic frameworks (MOFs), and activated carbons have emerged as promising alternatives. These materials offer lower regeneration energy penalties (1.5-2.5 GJ/tonne CO2) and greater stability. MOFs, in particular, demonstrate exceptional CO2 capacity and tunability but struggle with moisture sensitivity and production scalability, limiting their industrial deployment despite laboratory success.

Calcium looping technology, utilizing limestone as a CO2 sorbent, presents a cost-effective option for large-scale applications. While abundant and inexpensive, calcium-based sorbents suffer from rapid performance degradation over multiple capture-release cycles, requiring frequent replacement and generating substantial solid waste streams that pose disposal challenges.

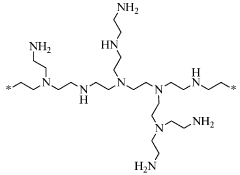

Novel hybrid materials combining the advantages of different sorbent types have recently gained attention. These include amine-functionalized silica and polymer-supported amine sorbents, which attempt to balance capture efficiency with environmental impact. However, these materials often involve complex synthesis procedures using potentially hazardous chemicals, raising concerns about their overall environmental footprint.

A critical challenge across all sorbent technologies remains the energy penalty associated with regeneration processes. This energy requirement significantly impacts the net carbon reduction benefit of capture systems, with current technologies requiring 15-30% of a power plant's energy output for operation. Additionally, water consumption during capture processes presents a growing concern, particularly in water-stressed regions.

Manufacturing scalability represents another substantial hurdle, as many promising laboratory-scale sorbents face significant barriers to industrial-scale production. The environmental impacts of sorbent production, including resource extraction, chemical synthesis, and waste generation, often remain inadequately assessed in technology evaluations.

Regulatory frameworks for evaluating sorbent environmental performance remain inconsistent globally, complicating technology comparison and selection. Current standards primarily focus on capture efficiency and direct emissions, with insufficient attention to lifecycle impacts, including raw material sourcing, manufacturing processes, and end-of-life management of spent sorbents.

Amine-based sorbents represent the most mature technology in the carbon capture landscape. These materials, including monoethanolamine (MEA), diethanolamine (DEA), and methyldiethanolamine (MDEA), offer high CO2 selectivity and relatively fast kinetics. However, they face significant challenges including high regeneration energy requirements (3-4 GJ/tonne CO2), susceptibility to degradation in the presence of oxygen and sulfur compounds, and potential for harmful emissions through amine leaching.

Solid adsorbents such as zeolites, metal-organic frameworks (MOFs), and activated carbons have emerged as promising alternatives. These materials offer lower regeneration energy penalties (1.5-2.5 GJ/tonne CO2) and greater stability. MOFs, in particular, demonstrate exceptional CO2 capacity and tunability but struggle with moisture sensitivity and production scalability, limiting their industrial deployment despite laboratory success.

Calcium looping technology, utilizing limestone as a CO2 sorbent, presents a cost-effective option for large-scale applications. While abundant and inexpensive, calcium-based sorbents suffer from rapid performance degradation over multiple capture-release cycles, requiring frequent replacement and generating substantial solid waste streams that pose disposal challenges.

Novel hybrid materials combining the advantages of different sorbent types have recently gained attention. These include amine-functionalized silica and polymer-supported amine sorbents, which attempt to balance capture efficiency with environmental impact. However, these materials often involve complex synthesis procedures using potentially hazardous chemicals, raising concerns about their overall environmental footprint.

A critical challenge across all sorbent technologies remains the energy penalty associated with regeneration processes. This energy requirement significantly impacts the net carbon reduction benefit of capture systems, with current technologies requiring 15-30% of a power plant's energy output for operation. Additionally, water consumption during capture processes presents a growing concern, particularly in water-stressed regions.

Manufacturing scalability represents another substantial hurdle, as many promising laboratory-scale sorbents face significant barriers to industrial-scale production. The environmental impacts of sorbent production, including resource extraction, chemical synthesis, and waste generation, often remain inadequately assessed in technology evaluations.

Regulatory frameworks for evaluating sorbent environmental performance remain inconsistent globally, complicating technology comparison and selection. Current standards primarily focus on capture efficiency and direct emissions, with insufficient attention to lifecycle impacts, including raw material sourcing, manufacturing processes, and end-of-life management of spent sorbents.

Current Sorbent Solutions Analysis

01 Amine-based carbon capture sorbents

Amine-based materials are widely used as sorbents for carbon capture due to their high CO2 selectivity and capacity. These sorbents typically consist of amine functional groups supported on porous materials such as silica or polymers. The environmental standards for these sorbents focus on their regeneration efficiency, stability over multiple cycles, and minimal amine leaching to prevent environmental contamination. Advanced formulations aim to reduce the energy requirements for regeneration while maintaining capture performance.- Amine-based sorbents for carbon capture: Amine-based materials are widely used as sorbents for carbon capture due to their high CO2 selectivity and capacity. These sorbents can be designed to meet environmental standards by optimizing their composition and structure to reduce energy requirements during regeneration and minimize harmful emissions. Advanced amine-based sorbents incorporate features that enhance stability, reduce degradation, and comply with environmental regulations regarding waste disposal and air quality.

- Metal-organic frameworks (MOFs) for sustainable carbon capture: Metal-organic frameworks represent an innovative class of carbon capture sorbents that can be tailored to meet stringent environmental standards. These highly porous materials offer exceptional surface area and tunable pore structures that enable efficient CO2 adsorption while minimizing environmental impact. MOFs can be designed with biodegradable components and synthesized using green chemistry principles to ensure compliance with sustainability requirements and reduce the environmental footprint of carbon capture operations.

- Regeneration processes meeting emissions standards: Carbon capture sorbent regeneration processes must comply with strict environmental standards regarding energy consumption and emissions. Advanced regeneration techniques utilize low-temperature desorption, vacuum swing processes, or novel heating methods to minimize energy requirements and reduce greenhouse gas emissions during the carbon capture cycle. These processes incorporate monitoring systems to ensure compliance with air quality regulations and prevent the release of harmful byproducts during sorbent regeneration.

- Environmentally friendly zeolite-based sorbents: Zeolite-based materials offer environmentally compatible solutions for carbon capture applications. These aluminosilicate materials can be synthesized from natural or waste materials, reducing their environmental impact while providing effective CO2 adsorption properties. Modified zeolites incorporate sustainable functional groups that enhance carbon capture performance while meeting environmental standards for material safety, disposal, and lifecycle assessment. Their thermal stability and resistance to degradation make them suitable for long-term carbon capture operations with minimal environmental consequences.

- Life cycle assessment and environmental impact monitoring: Carbon capture sorbent technologies must undergo comprehensive life cycle assessment to ensure compliance with environmental standards throughout their production, use, and disposal phases. Advanced monitoring systems track environmental impacts including water usage, energy consumption, and potential emissions of hazardous substances. These assessment frameworks incorporate sustainability metrics that evaluate the overall environmental footprint of sorbent materials, enabling the development of carbon capture solutions that minimize negative ecological impacts while maximizing CO2 removal efficiency.

02 Metal-organic frameworks for carbon capture

Metal-organic frameworks (MOFs) represent an innovative class of carbon capture sorbents with exceptionally high surface areas and tunable pore structures. Environmental standards for MOFs address their synthesis using green chemistry principles, stability in industrial conditions, and potential metal leaching concerns. These materials offer advantages in terms of selectivity and capacity but must meet durability requirements and demonstrate low environmental impact throughout their lifecycle to comply with increasingly stringent regulations.Expand Specific Solutions03 Regeneration processes and energy efficiency standards

The regeneration of carbon capture sorbents is a critical aspect governed by environmental standards that limit energy consumption and emissions. Technologies focus on reducing the temperature and energy required for sorbent regeneration while maintaining capture efficiency. Standards address the trade-off between capture capacity and regeneration energy, with requirements for minimal degradation products and emissions during the regeneration cycle. Advanced systems incorporate heat integration and recovery to improve overall process efficiency.Expand Specific Solutions04 Life cycle assessment and sustainability metrics

Environmental standards for carbon capture sorbents increasingly incorporate comprehensive life cycle assessment (LCA) methodologies to evaluate their overall environmental impact. These standards consider raw material sourcing, manufacturing processes, operational performance, and end-of-life disposal. Sustainability metrics include carbon footprint of sorbent production, water usage, toxicity profiles, and potential for recycling or safe disposal. Certification systems are being developed to validate sorbents that meet these holistic environmental criteria.Expand Specific Solutions05 Direct air capture sorbent standards

Direct air capture (DAC) technologies employ specialized sorbents designed to extract CO2 directly from ambient air, which requires meeting distinct environmental standards due to the low concentration of CO2. These standards address the high selectivity requirements, resistance to contaminants, and durability under atmospheric conditions. Environmental regulations for DAC sorbents focus on minimizing water consumption, preventing air pollution from sorbent degradation, and ensuring net carbon negativity across the entire capture process.Expand Specific Solutions

Key Industry Players in Carbon Capture

The carbon capture sorbent market is in a growth phase, with increasing global focus on decarbonization driving expansion. The market is projected to reach significant scale as environmental regulations tighten worldwide. Technologically, the field shows varying maturity levels across different approaches. Climeworks AG leads in direct air capture commercialization with operational plants in Iceland, while established industrial players like W.L. Gore, BASF, and Delta Electronics bring manufacturing expertise. Research institutions including Huaneng Clean Energy Research Institute, University of California, and Norwegian University of Science & Technology are advancing novel sorbent technologies. Chinese entities like Sinopec and Shandong De Shi are investing heavily in carbon capture integration with existing industrial infrastructure, positioning themselves for market leadership as the technology scales to meet global climate targets.

Climeworks AG

Technical Solution: Climeworks has developed a direct air capture (DAC) technology using solid sorbent filters that selectively capture CO2 from ambient air. Their modular collectors draw air through the filter using fans, where CO2 binds to the proprietary amine-based sorbent material. Once saturated, the collectors are heated to approximately 100°C, releasing concentrated CO2 that can be permanently sequestered underground or utilized in various applications. Climeworks' plants operate with renewable energy sources and have demonstrated the ability to remove thousands of tons of CO2 annually. Their Orca plant in Iceland, launched in 2021, represents the world's first commercial-scale DAC facility with 4,000 tons of CO2 removal capacity annually, where captured carbon is mineralized and stored underground through partnership with Carbfix technology, turning CO2 into stone within two years for permanent storage[1][2].

Strengths: Modular design allows for scalable deployment; integration with geothermal energy in Iceland provides renewable power source; permanent storage solution through mineralization; proven commercial implementation. Weaknesses: High energy requirements (1.5-2 MWh per ton of CO2); relatively high cost (currently $600-800 per ton of CO2 removed); limited capture capacity compared to global emissions; requires specific geological conditions for optimal storage.

Huaneng Clean Energy Research Institute

Technical Solution: Huaneng Clean Energy Research Institute has pioneered post-combustion carbon capture technology specifically designed for coal-fired power plants. Their approach utilizes advanced amine-based sorbents with proprietary additives that enhance CO2 absorption efficiency while reducing degradation and energy penalties. The institute has developed a two-stage absorption process that achieves capture rates exceeding 90% while reducing regeneration energy requirements by approximately 15% compared to conventional monoethanolamine (MEA) systems. Their technology has been successfully demonstrated at the Shidongkou Power Plant, capturing over 120,000 tons of CO2 annually with an energy consumption of 2.8-3.2 GJ/ton CO2. The institute has also developed specialized anti-corrosion materials and process optimization techniques that extend equipment lifespan and improve operational stability. Their latest generation sorbents demonstrate improved resistance to oxygen degradation and thermal stability, allowing for longer service life and reduced replacement costs[3][4].

Strengths: Specifically optimized for coal power plants which are prevalent in China; demonstrated at commercial scale; achieves high capture efficiency (>90%); reduced energy penalty compared to first-generation systems. Weaknesses: Still requires significant energy input for sorbent regeneration; primarily focused on point-source rather than direct air capture; potential environmental concerns with amine degradation products; technology primarily deployed within China with limited international implementation.

Critical Patents in Carbon Capture Sorbent Technology

sorbent

PatentPendingUS20250281904A1

Innovation

- Development of a solid sorbent comprising a silica support with covalently attached secondary amines confined inside its pores, optimized through controlled grafting and polymerization, achieving high amine density and stability.

Sorbents for carbon dioxide capture

PatentWO2024133317A1

Innovation

- A sorbent comprising polyalkyleneimine or alkoxylated polyalkyleneimine loaded onto an inorganic solid support with a water content greater than 2 wt%, allowing for aqueous solvent use and reducing the need for organic solvents, which enhances CO2 absorption rates and oxidative stability.

Environmental Compliance Framework

The Environmental Compliance Framework for carbon capture sorbents establishes a comprehensive structure for evaluating and ensuring adherence to environmental regulations and standards. This framework integrates multiple layers of compliance requirements, from international agreements to local regulations, creating a cohesive approach to environmental governance in carbon capture technologies.

At the international level, the framework incorporates key climate agreements such as the Paris Accord and UNFCCC protocols, which set broad targets for emissions reduction and environmental protection. These agreements establish the foundational principles that guide more specific regulatory mechanisms for carbon capture sorbents.

Regional regulatory bodies, including the European Union's Environmental Agency, the US Environmental Protection Agency, and similar organizations in Asia-Pacific regions, provide the next layer of compliance requirements. These entities establish specific standards for emissions, waste management, and environmental impact that directly affect the development and deployment of carbon capture technologies.

The framework also addresses industry-specific standards developed by organizations such as ISO, ASTM International, and the International Energy Agency. These standards provide technical specifications for sorbent performance, safety protocols, and environmental impact assessments that ensure consistency across the industry while promoting innovation within established environmental parameters.

Life cycle assessment (LCA) methodologies form a critical component of the compliance framework, enabling comprehensive evaluation of sorbents from production through disposal. These assessments consider energy consumption, resource utilization, emissions generation, and waste management across the entire sorbent lifecycle, providing a holistic view of environmental impact.

Certification and verification systems represent the operational aspect of the framework, establishing processes for third-party validation of compliance claims. These systems include laboratory testing protocols, field verification procedures, and documentation requirements that provide transparency and accountability in environmental performance reporting.

The framework incorporates adaptive mechanisms to accommodate evolving scientific understanding and technological capabilities. Regular review cycles, stakeholder consultation processes, and provisions for emerging technologies ensure that compliance requirements remain relevant and effective as carbon capture technologies advance and environmental priorities shift.

Implementation guidance completes the framework, offering practical tools for technology developers and operators to navigate compliance requirements efficiently. This includes decision support systems, compliance checklists, and best practice guidelines that translate regulatory requirements into actionable steps for industry participants.

At the international level, the framework incorporates key climate agreements such as the Paris Accord and UNFCCC protocols, which set broad targets for emissions reduction and environmental protection. These agreements establish the foundational principles that guide more specific regulatory mechanisms for carbon capture sorbents.

Regional regulatory bodies, including the European Union's Environmental Agency, the US Environmental Protection Agency, and similar organizations in Asia-Pacific regions, provide the next layer of compliance requirements. These entities establish specific standards for emissions, waste management, and environmental impact that directly affect the development and deployment of carbon capture technologies.

The framework also addresses industry-specific standards developed by organizations such as ISO, ASTM International, and the International Energy Agency. These standards provide technical specifications for sorbent performance, safety protocols, and environmental impact assessments that ensure consistency across the industry while promoting innovation within established environmental parameters.

Life cycle assessment (LCA) methodologies form a critical component of the compliance framework, enabling comprehensive evaluation of sorbents from production through disposal. These assessments consider energy consumption, resource utilization, emissions generation, and waste management across the entire sorbent lifecycle, providing a holistic view of environmental impact.

Certification and verification systems represent the operational aspect of the framework, establishing processes for third-party validation of compliance claims. These systems include laboratory testing protocols, field verification procedures, and documentation requirements that provide transparency and accountability in environmental performance reporting.

The framework incorporates adaptive mechanisms to accommodate evolving scientific understanding and technological capabilities. Regular review cycles, stakeholder consultation processes, and provisions for emerging technologies ensure that compliance requirements remain relevant and effective as carbon capture technologies advance and environmental priorities shift.

Implementation guidance completes the framework, offering practical tools for technology developers and operators to navigate compliance requirements efficiently. This includes decision support systems, compliance checklists, and best practice guidelines that translate regulatory requirements into actionable steps for industry participants.

Lifecycle Assessment of Sorbent Materials

The lifecycle assessment (LCA) of carbon capture sorbent materials provides critical insights into their overall environmental impact beyond just capture efficiency. This comprehensive evaluation examines environmental effects across the entire lifespan of sorbents, from raw material extraction to disposal or regeneration.

Primary analysis reveals that traditional amine-based sorbents, while effective for carbon capture, often present significant environmental challenges. Their production typically involves energy-intensive processes and petrochemical precursors, resulting in substantial carbon footprints before operational deployment. Studies indicate that manufacturing one ton of monoethanolamine (MEA) sorbent generates approximately 2-3 tons of CO2 equivalent emissions.

Water consumption represents another critical factor in sorbent lifecycle assessment. Zeolite-based materials require extensive washing during synthesis, consuming 80-120 liters of water per kilogram produced. In contrast, metal-organic frameworks (MOFs) demonstrate more favorable water usage profiles but often incorporate rare earth elements with problematic extraction impacts.

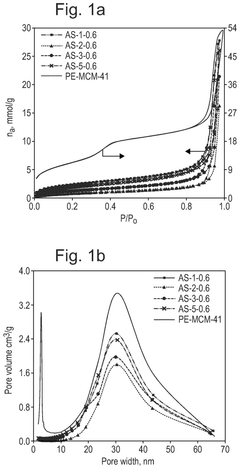

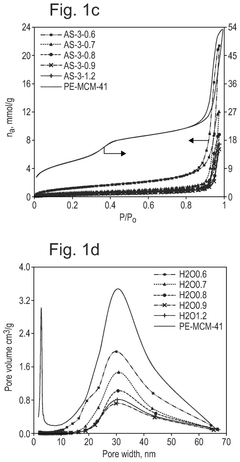

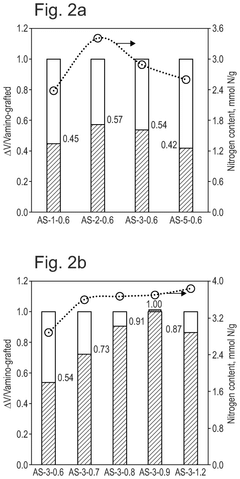

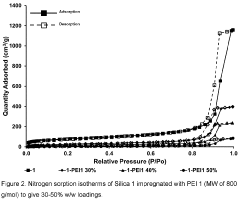

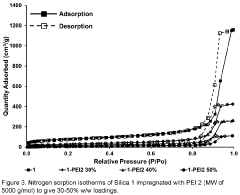

Durability and regeneration capacity significantly influence lifecycle performance. Advanced solid sorbents like polyethylenimine-modified silica demonstrate superior regeneration capabilities, maintaining 85-90% capacity after 100 cycles, compared to conventional materials that degrade to 60-70% efficiency after similar usage. This extended operational lifespan substantially reduces the environmental burden per ton of CO2 captured.

End-of-life considerations reveal further distinctions among sorbent classes. Biodegradable sorbents derived from chitosan and cellulose offer promising disposal pathways with minimal environmental persistence. Conversely, synthetic polymer-based materials present challenges regarding microplastic generation and extended decomposition timeframes.

Recent advancements in green chemistry approaches have yielded promising developments in environmentally conscious sorbent design. Bio-based precursors and ambient-temperature synthesis methods have reduced the embedded energy in next-generation materials by 40-60% compared to conventional alternatives. These improvements significantly enhance the net environmental benefit of carbon capture operations.

Standardized LCA methodologies specifically tailored for carbon capture materials remain underdeveloped, creating challenges for consistent cross-comparison. The International Organization for Standardization (ISO) has initiated development of specialized frameworks that incorporate carbon capture-specific metrics beyond traditional environmental indicators, expected for implementation within the next two years.

Primary analysis reveals that traditional amine-based sorbents, while effective for carbon capture, often present significant environmental challenges. Their production typically involves energy-intensive processes and petrochemical precursors, resulting in substantial carbon footprints before operational deployment. Studies indicate that manufacturing one ton of monoethanolamine (MEA) sorbent generates approximately 2-3 tons of CO2 equivalent emissions.

Water consumption represents another critical factor in sorbent lifecycle assessment. Zeolite-based materials require extensive washing during synthesis, consuming 80-120 liters of water per kilogram produced. In contrast, metal-organic frameworks (MOFs) demonstrate more favorable water usage profiles but often incorporate rare earth elements with problematic extraction impacts.

Durability and regeneration capacity significantly influence lifecycle performance. Advanced solid sorbents like polyethylenimine-modified silica demonstrate superior regeneration capabilities, maintaining 85-90% capacity after 100 cycles, compared to conventional materials that degrade to 60-70% efficiency after similar usage. This extended operational lifespan substantially reduces the environmental burden per ton of CO2 captured.

End-of-life considerations reveal further distinctions among sorbent classes. Biodegradable sorbents derived from chitosan and cellulose offer promising disposal pathways with minimal environmental persistence. Conversely, synthetic polymer-based materials present challenges regarding microplastic generation and extended decomposition timeframes.

Recent advancements in green chemistry approaches have yielded promising developments in environmentally conscious sorbent design. Bio-based precursors and ambient-temperature synthesis methods have reduced the embedded energy in next-generation materials by 40-60% compared to conventional alternatives. These improvements significantly enhance the net environmental benefit of carbon capture operations.

Standardized LCA methodologies specifically tailored for carbon capture materials remain underdeveloped, creating challenges for consistent cross-comparison. The International Organization for Standardization (ISO) has initiated development of specialized frameworks that incorporate carbon capture-specific metrics beyond traditional environmental indicators, expected for implementation within the next two years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!