Carbon Capture Sorbents and Aerospace Material Compliance

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Sorbent Technology Background and Objectives

Carbon capture technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in response to growing climate change concerns. The journey began in the 1970s with initial research into carbon dioxide separation methods, primarily focused on natural gas processing. By the 1990s, as global warming awareness increased, carbon capture research expanded to address emissions from power plants and industrial facilities, marking the beginning of modern carbon capture and storage (CCS) development.

The evolution of sorbent materials represents a critical advancement trajectory in this field. Early carbon capture systems relied predominantly on liquid amine solutions, which, while effective, presented significant energy penalties and corrosion challenges. The past two decades have witnessed remarkable progress in solid sorbent development, including metal-organic frameworks (MOFs), zeolites, activated carbons, and amine-functionalized materials, each offering unique advantages in selectivity, capacity, and regeneration efficiency.

Current technological trends indicate a shift toward materials that can operate under diverse conditions while maintaining performance integrity in aerospace and other demanding environments. This includes the development of composite sorbents that combine the advantages of multiple material classes and the engineering of sorbent structures at the nanoscale to optimize surface area and binding site accessibility.

The primary objective of carbon capture sorbent research is to develop materials that demonstrate high CO2 selectivity and capacity while requiring minimal energy for regeneration. These materials must maintain structural integrity and performance across repeated adsorption-desorption cycles under variable temperature and pressure conditions. For aerospace applications specifically, these sorbents must additionally comply with stringent weight, volume, and safety requirements unique to flight environments.

Secondary objectives include reducing the overall cost of carbon capture processes, minimizing the environmental footprint of sorbent production and deployment, and ensuring compatibility with existing infrastructure. The development of multifunctional sorbents capable of capturing CO2 while simultaneously addressing other environmental concerns represents an emerging goal in this field.

Looking forward, the integration of advanced manufacturing techniques, such as 3D printing and microfluidic fabrication, promises to revolutionize sorbent design and production. Computational modeling and machine learning approaches are increasingly employed to accelerate material discovery and optimization, potentially reducing development timelines from decades to years or even months. These technological trajectories collectively aim to establish carbon capture as an economically viable and technically feasible approach to mitigating climate change while meeting the specialized requirements of aerospace and other advanced applications.

The evolution of sorbent materials represents a critical advancement trajectory in this field. Early carbon capture systems relied predominantly on liquid amine solutions, which, while effective, presented significant energy penalties and corrosion challenges. The past two decades have witnessed remarkable progress in solid sorbent development, including metal-organic frameworks (MOFs), zeolites, activated carbons, and amine-functionalized materials, each offering unique advantages in selectivity, capacity, and regeneration efficiency.

Current technological trends indicate a shift toward materials that can operate under diverse conditions while maintaining performance integrity in aerospace and other demanding environments. This includes the development of composite sorbents that combine the advantages of multiple material classes and the engineering of sorbent structures at the nanoscale to optimize surface area and binding site accessibility.

The primary objective of carbon capture sorbent research is to develop materials that demonstrate high CO2 selectivity and capacity while requiring minimal energy for regeneration. These materials must maintain structural integrity and performance across repeated adsorption-desorption cycles under variable temperature and pressure conditions. For aerospace applications specifically, these sorbents must additionally comply with stringent weight, volume, and safety requirements unique to flight environments.

Secondary objectives include reducing the overall cost of carbon capture processes, minimizing the environmental footprint of sorbent production and deployment, and ensuring compatibility with existing infrastructure. The development of multifunctional sorbents capable of capturing CO2 while simultaneously addressing other environmental concerns represents an emerging goal in this field.

Looking forward, the integration of advanced manufacturing techniques, such as 3D printing and microfluidic fabrication, promises to revolutionize sorbent design and production. Computational modeling and machine learning approaches are increasingly employed to accelerate material discovery and optimization, potentially reducing development timelines from decades to years or even months. These technological trajectories collectively aim to establish carbon capture as an economically viable and technically feasible approach to mitigating climate change while meeting the specialized requirements of aerospace and other advanced applications.

Market Analysis for Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. Current market valuations place the carbon capture, utilization, and storage (CCUS) sector at approximately 2.5 billion USD in 2023, with projections indicating potential growth to reach 7-10 billion USD by 2030, representing a compound annual growth rate of 15-20%.

Key market segments within carbon capture solutions include post-combustion capture technologies, pre-combustion systems, and direct air capture (DAC) methods. Post-combustion technologies currently dominate with roughly 60% market share due to their retrofit compatibility with existing infrastructure. However, DAC solutions are experiencing the fastest growth rate at nearly 30% annually, albeit from a smaller base.

Regional analysis reveals North America leads the market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 20%. China's rapid industrialization coupled with ambitious carbon neutrality targets is expected to significantly alter this distribution by 2030, potentially capturing up to 25% of the global market.

Industry-specific demand shows power generation and industrial manufacturing (particularly cement, steel, and chemical production) as primary adopters of carbon capture technologies. These sectors collectively account for over 70% of current implementation. Emerging applications in hydrogen production facilities and waste-to-energy plants represent promising growth vectors.

The competitive landscape features both established energy corporations and specialized technology startups. Major energy companies have allocated substantial R&D budgets toward carbon capture, with investments exceeding 500 million USD annually. Meanwhile, venture capital funding for carbon capture startups has surged, with over 1.8 billion USD invested in 2022 alone.

Customer adoption barriers include high implementation costs, with current capture costs ranging from 40-120 USD per ton of CO2 depending on the technology and application. Government incentives, such as the 45Q tax credit in the United States offering up to 85 USD per ton for sequestered carbon, are proving critical for market acceleration.

Market forecasts suggest carbon capture sorbent materials will experience particularly strong demand growth, with advanced materials that offer improved capacity, selectivity, and regeneration properties commanding premium pricing. The intersection with aerospace material compliance requirements presents a specialized niche market with stringent performance specifications but potentially higher margins and technological spillover benefits.

Key market segments within carbon capture solutions include post-combustion capture technologies, pre-combustion systems, and direct air capture (DAC) methods. Post-combustion technologies currently dominate with roughly 60% market share due to their retrofit compatibility with existing infrastructure. However, DAC solutions are experiencing the fastest growth rate at nearly 30% annually, albeit from a smaller base.

Regional analysis reveals North America leads the market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 20%. China's rapid industrialization coupled with ambitious carbon neutrality targets is expected to significantly alter this distribution by 2030, potentially capturing up to 25% of the global market.

Industry-specific demand shows power generation and industrial manufacturing (particularly cement, steel, and chemical production) as primary adopters of carbon capture technologies. These sectors collectively account for over 70% of current implementation. Emerging applications in hydrogen production facilities and waste-to-energy plants represent promising growth vectors.

The competitive landscape features both established energy corporations and specialized technology startups. Major energy companies have allocated substantial R&D budgets toward carbon capture, with investments exceeding 500 million USD annually. Meanwhile, venture capital funding for carbon capture startups has surged, with over 1.8 billion USD invested in 2022 alone.

Customer adoption barriers include high implementation costs, with current capture costs ranging from 40-120 USD per ton of CO2 depending on the technology and application. Government incentives, such as the 45Q tax credit in the United States offering up to 85 USD per ton for sequestered carbon, are proving critical for market acceleration.

Market forecasts suggest carbon capture sorbent materials will experience particularly strong demand growth, with advanced materials that offer improved capacity, selectivity, and regeneration properties commanding premium pricing. The intersection with aerospace material compliance requirements presents a specialized niche market with stringent performance specifications but potentially higher margins and technological spillover benefits.

Current Challenges in Aerospace-Grade Carbon Capture

The aerospace industry faces significant challenges in integrating carbon capture technologies due to the stringent requirements for materials used in aircraft and spacecraft. Current carbon capture sorbents, while effective in stationary applications, encounter numerous obstacles when adapted for aerospace environments. These challenges stem from the extreme conditions experienced during flight, including rapid temperature fluctuations, high-altitude pressure differentials, and intense vibration loads.

Weight constraints represent perhaps the most critical limitation. Conventional carbon capture materials such as zeolites, metal-organic frameworks (MOFs), and amine-functionalized sorbents typically add substantial mass to systems. For aerospace applications, where every gram impacts fuel efficiency and operational costs, these materials must be significantly lightweighted without compromising capture efficiency—a balance that current technologies struggle to achieve.

Durability under aerospace conditions presents another major hurdle. Carbon capture sorbents must maintain structural integrity and performance despite exposure to thermal cycling between -60°C at high altitudes and potentially high temperatures during operation. Additionally, these materials must withstand mechanical stress from continuous vibration and potential shock events during takeoff, landing, and turbulence.

Compatibility with aerospace-grade materials introduces further complications. Many effective carbon capture sorbents contain compounds that can accelerate corrosion of aluminum alloys and composite materials commonly used in aircraft structures. The potential for outgassing toxic or corrosive compounds during operation raises serious safety concerns for crew and sensitive equipment.

Regeneration capabilities present unique challenges in aerospace contexts. While ground-based carbon capture systems can utilize energy-intensive processes for sorbent regeneration, aerospace applications require methods that function with limited energy resources and in confined spaces. Current regeneration approaches often demand heat, vacuum, or pressure swing conditions difficult to implement within aircraft systems.

Regulatory compliance adds another layer of complexity. Any materials incorporated into aerospace systems must meet rigorous certification standards from authorities like FAA, EASA, and military specifications. Current carbon capture materials lack the necessary qualification testing and certification history required for aerospace integration, creating a significant barrier to adoption.

The integration of carbon capture systems with existing aircraft environmental control systems (ECS) remains problematic. Current ECS designs lack the space, power, and thermal management capabilities to accommodate carbon capture components without substantial redesign, presenting both technical and economic obstacles to implementation.

Weight constraints represent perhaps the most critical limitation. Conventional carbon capture materials such as zeolites, metal-organic frameworks (MOFs), and amine-functionalized sorbents typically add substantial mass to systems. For aerospace applications, where every gram impacts fuel efficiency and operational costs, these materials must be significantly lightweighted without compromising capture efficiency—a balance that current technologies struggle to achieve.

Durability under aerospace conditions presents another major hurdle. Carbon capture sorbents must maintain structural integrity and performance despite exposure to thermal cycling between -60°C at high altitudes and potentially high temperatures during operation. Additionally, these materials must withstand mechanical stress from continuous vibration and potential shock events during takeoff, landing, and turbulence.

Compatibility with aerospace-grade materials introduces further complications. Many effective carbon capture sorbents contain compounds that can accelerate corrosion of aluminum alloys and composite materials commonly used in aircraft structures. The potential for outgassing toxic or corrosive compounds during operation raises serious safety concerns for crew and sensitive equipment.

Regeneration capabilities present unique challenges in aerospace contexts. While ground-based carbon capture systems can utilize energy-intensive processes for sorbent regeneration, aerospace applications require methods that function with limited energy resources and in confined spaces. Current regeneration approaches often demand heat, vacuum, or pressure swing conditions difficult to implement within aircraft systems.

Regulatory compliance adds another layer of complexity. Any materials incorporated into aerospace systems must meet rigorous certification standards from authorities like FAA, EASA, and military specifications. Current carbon capture materials lack the necessary qualification testing and certification history required for aerospace integration, creating a significant barrier to adoption.

The integration of carbon capture systems with existing aircraft environmental control systems (ECS) remains problematic. Current ECS designs lack the space, power, and thermal management capabilities to accommodate carbon capture components without substantial redesign, presenting both technical and economic obstacles to implementation.

Current Sorbent Solutions for Aerospace Applications

01 Metal-organic frameworks (MOFs) for carbon capture

Metal-organic frameworks are advanced porous materials with high surface area and tunable pore structures that make them effective for carbon dioxide adsorption. These crystalline materials consist of metal ions coordinated to organic ligands, creating a framework with exceptional CO2 selectivity and capacity. MOFs can be designed with specific functional groups to enhance their affinity for CO2, and their modular nature allows for customization based on specific capture conditions.- Metal-organic frameworks (MOFs) for carbon capture: Metal-organic frameworks are advanced porous materials with high surface area that can effectively capture carbon dioxide. These crystalline structures consist of metal ions coordinated with organic ligands, creating a framework with tunable pore sizes ideal for selective CO2 adsorption. MOFs can be designed with specific functional groups to enhance CO2 binding affinity and selectivity, making them promising candidates for industrial carbon capture applications.

- Amine-functionalized sorbents for CO2 capture: Amine-functionalized materials represent a significant class of carbon capture sorbents that utilize the chemical reaction between amines and CO2 to form carbamates. These sorbents can be created by incorporating amine groups onto various support materials such as silica, polymers, or porous carbon. The high selectivity for CO2 over other gases and strong binding capacity make these materials particularly effective for post-combustion carbon capture applications, even at low CO2 concentrations.

- Zeolite-based carbon capture materials: Zeolites are aluminosilicate minerals with well-defined microporous structures that can be utilized for carbon dioxide adsorption. Their crystalline framework contains regular channels and cavities that can selectively capture CO2 molecules through physical adsorption mechanisms. The adsorption properties of zeolites can be modified by adjusting the silicon-to-aluminum ratio or by incorporating various cations, allowing for customization based on specific carbon capture requirements.

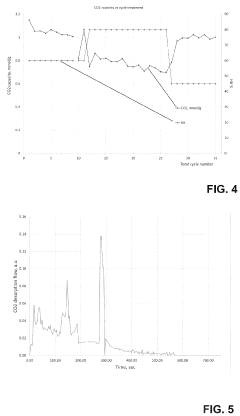

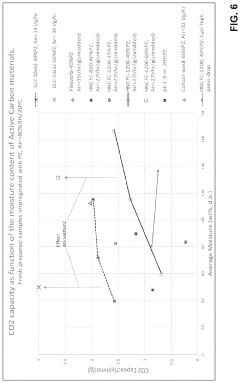

- Regenerable solid sorbents for cyclic carbon capture: Regenerable solid sorbents are designed for continuous carbon capture operations through repeated adsorption-desorption cycles. These materials can capture CO2 under specific conditions and then release it when conditions are changed, such as through temperature or pressure swing processes. Key considerations for these sorbents include working capacity, regeneration energy requirements, mechanical stability over multiple cycles, and resistance to contaminants in flue gas streams.

- Novel composite and hybrid carbon capture materials: Composite and hybrid materials combine different types of sorbents to leverage complementary properties and overcome limitations of single-component systems. These innovative materials may integrate organic and inorganic components, incorporate multiple functional groups, or feature hierarchical pore structures to enhance both CO2 selectivity and capacity. Advanced manufacturing techniques such as 3D printing, layer-by-layer assembly, and controlled polymerization are being employed to create these next-generation carbon capture materials with optimized performance characteristics.

02 Amine-functionalized sorbents

Amine-functionalized materials represent a significant class of carbon capture sorbents that operate through chemical adsorption mechanisms. These sorbents contain amine groups that react with CO2 to form carbamates or bicarbonates, enabling selective capture even at low CO2 concentrations. Common supports include silica, polymers, and porous carbons that are modified with various amine compounds. These materials offer advantages including high CO2 selectivity, good performance under humid conditions, and relatively low regeneration energy requirements.Expand Specific Solutions03 Zeolite-based carbon capture materials

Zeolites are crystalline aluminosilicate materials with well-defined microporous structures that make them effective for carbon dioxide adsorption. Their molecular sieving properties allow for selective capture of CO2 from gas mixtures. These materials can be modified through ion exchange, framework substitution, or surface functionalization to enhance their CO2 adsorption capacity and selectivity. Zeolites offer advantages including high thermal stability, resistance to harsh conditions, and relatively low production costs.Expand Specific Solutions04 Carbon-based sorbents for CO2 capture

Carbon-based materials, including activated carbons, carbon nanotubes, and graphene derivatives, serve as effective sorbents for carbon dioxide capture. These materials can be produced from various precursors including biomass, polymers, or fossil resources, and offer high surface areas and tunable pore structures. Their performance can be enhanced through chemical activation, heteroatom doping, or surface functionalization to increase CO2 binding affinity. Carbon-based sorbents are valued for their low cost, high stability, and potential for sustainable production from waste materials.Expand Specific Solutions05 Novel composite and hybrid sorbent materials

Composite and hybrid sorbent materials combine different components to achieve enhanced carbon capture performance beyond what individual materials can offer. These innovative materials integrate multiple functionalities, such as combining the high surface area of one component with the chemical selectivity of another. Examples include polymer-inorganic hybrids, mixed matrix materials, and layered composites. These materials are designed to overcome limitations of traditional sorbents by offering improved stability, selectivity, capacity, and regeneration properties for more efficient carbon dioxide capture processes.Expand Specific Solutions

Leading Organizations in Carbon Capture Materials

The carbon capture sorbent and aerospace material compliance market is currently in a growth phase, with increasing global focus on decarbonization driving innovation. The market size is expanding rapidly, projected to reach significant scale as carbon reduction commitments intensify worldwide. Technologically, the field shows varying maturity levels, with companies like Climeworks AG and DACMa GmbH leading commercial direct air capture deployment, while research institutions such as MIT, Rice University, and Tianjin University advance fundamental sorbent technologies. Industrial players including BASF, W.L. Gore, and Sinopec are leveraging their materials expertise to develop compliant aerospace-grade carbon capture solutions. The competitive landscape features a mix of specialized startups (Global Thermostat, Matrix Sensors), established chemical companies, and academic research centers collaborating to overcome cost and efficiency challenges.

Climeworks AG

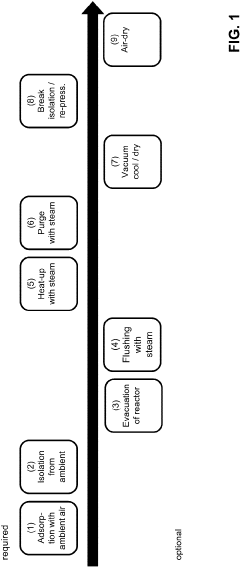

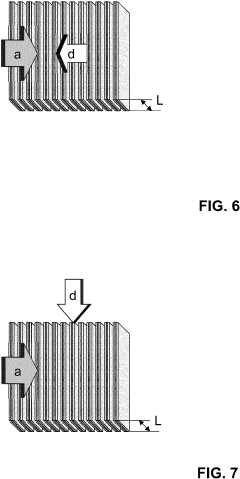

Technical Solution: Climeworks has developed a direct air capture (DAC) technology using solid sorbent filters that selectively capture CO2 from ambient air. Their modular collectors draw air through a filter where CO2 molecules chemically bind to the sorbent material. Once saturated, the filters are heated to approximately 100°C, releasing concentrated CO2 that can be permanently stored underground or utilized in various applications. Their latest technology iteration achieves capture costs around $600-800 per ton of CO2[1], with their Orca plant in Iceland demonstrating commercial-scale implementation where captured CO2 is mineralized and stored in basaltic rock formations. Climeworks' approach uses renewable geothermal energy to power the process, making it carbon-negative. Their technology has evolved through multiple generations, with each improving energy efficiency and sorbent durability[2].

Strengths: Modular design allows for scalable deployment; integration with geothermal energy sources creates carbon-negative system; proven commercial implementation with permanent storage solution. Weaknesses: Higher cost per ton of CO2 compared to point-source capture; energy requirements for sorbent regeneration remain significant; limited by geographical constraints for optimal renewable energy access.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has leveraged their expertise in advanced materials to develop specialized membrane-based carbon capture sorbents that meet aerospace material compliance standards. Their proprietary technology utilizes expanded polytetrafluoroethylene (ePTFE) membranes functionalized with selective CO2-philic compounds that enable efficient separation of carbon dioxide from gas mixtures. The membrane architecture features nanoporous structures with precisely controlled pore size distribution, creating high surface area interfaces that maximize CO2 capture while maintaining excellent gas permeability. Gore's sorbent technology demonstrates exceptional thermal stability (operating range -65°C to 260°C), chemical resistance, and mechanical durability - critical requirements for aerospace applications[9]. Their materials have been engineered to meet stringent FAA and NASA outgassing specifications, with total mass loss <1.0% and collected volatile condensable materials <0.1%. The company has integrated these sorbents into cabin air quality management systems for spacecraft and aircraft, where they simultaneously capture CO2 and volatile organic compounds while meeting flame retardancy requirements per FAR 25.853[10].

Strengths: Unparalleled materials expertise with established aerospace industry credentials; membrane-based approach offers lower pressure drop and energy requirements than packed bed systems; materials meet stringent aerospace compliance standards for outgassing, flame retardancy, and durability. Weaknesses: Higher manufacturing costs compared to conventional sorbents; technology optimized for controlled environments rather than industrial-scale carbon capture; requires specialized integration engineering for each application.

Key Innovations in Carbon Capture Materials

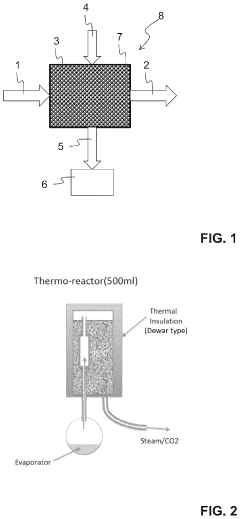

Method for capture of carbon dioxide from ambient air and corresponding adsorber structures with a plurality of parallel surfaces

PatentPendingUS20230211276A1

Innovation

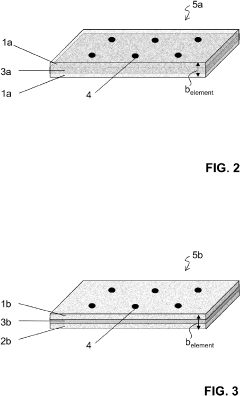

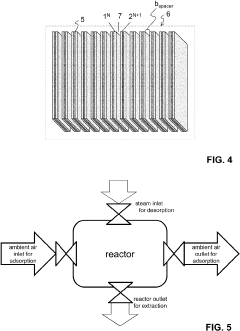

- A method utilizing a parallel passage contactor with sorbent layers optimized for direct air capture, employing steam as the exclusive heating energy source for desorption, and incorporating sorbent materials with specific surface modifications and structures to achieve efficient and economic cyclic operation, including amine-functionalized materials and porous support layers.

Improved materials for direct air capture and uses thereof

PatentPendingUS20240001281A1

Innovation

- The use of a high nitrogen-containing aromatic secondary amine, such as piperazine, combined with a water-retaining and porous support material, allows for efficient CO2 capture and desorption, even at high water vapor pressures, through cyclic adsorption/desorption processes using a sorbent material impregnated with a secondary cycloaliphatic or aromatic amine compound.

Regulatory Framework for Aerospace Materials

The aerospace industry operates under one of the most stringent regulatory frameworks globally, necessitating careful consideration when integrating carbon capture sorbents into aerospace materials. The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) establish comprehensive requirements for all materials used in aircraft construction, with particular emphasis on fire resistance, toxicity, and structural integrity under extreme conditions.

Materials incorporating carbon capture technologies must comply with FAA regulations 14 CFR Part 25 for transport category aircraft, which specifies flammability standards and smoke emission limitations. Similarly, EASA's CS-25 certification specifications mandate rigorous testing protocols for novel materials before airworthiness certification. These regulations create significant barriers to entry for innovative carbon capture sorbents in aerospace applications.

International standards organizations, including the International Organization for Standardization (ISO) and ASTM International, have developed specific testing methodologies for aerospace materials. Carbon capture sorbents must undergo qualification testing according to standards such as ASTM E84 for surface burning characteristics and ASTM E662 for smoke density. The ISO 9000 series provides quality management frameworks essential for consistent production of compliant materials.

Military specifications add another layer of complexity, with standards like MIL-STD-810 requiring materials to withstand environmental stresses including temperature extremes, humidity, and vibration. For carbon capture sorbents to achieve aerospace qualification, they must maintain functionality and structural integrity throughout these challenging conditions without performance degradation.

Environmental regulations increasingly influence aerospace material selection, with the International Civil Aviation Organization (ICAO) implementing the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA). This creates potential opportunities for carbon capture technologies while simultaneously imposing additional compliance requirements. The EU's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation further restricts certain chemical compounds that might be used in sorbent formulations.

Certification pathways for novel materials typically involve a multi-phase approach beginning with material characterization, followed by coupon-level testing, component testing, and finally full-scale demonstration. This process can span 5-7 years and cost millions of dollars, representing a significant investment for developers of carbon capture sorbent technologies targeting aerospace applications.

Recent regulatory developments show a trend toward performance-based rather than prescriptive requirements, potentially creating more flexibility for innovative materials. However, the aerospace industry's conservative approach to material qualification remains a substantial hurdle that carbon capture sorbent technologies must overcome to achieve widespread adoption in this sector.

Materials incorporating carbon capture technologies must comply with FAA regulations 14 CFR Part 25 for transport category aircraft, which specifies flammability standards and smoke emission limitations. Similarly, EASA's CS-25 certification specifications mandate rigorous testing protocols for novel materials before airworthiness certification. These regulations create significant barriers to entry for innovative carbon capture sorbents in aerospace applications.

International standards organizations, including the International Organization for Standardization (ISO) and ASTM International, have developed specific testing methodologies for aerospace materials. Carbon capture sorbents must undergo qualification testing according to standards such as ASTM E84 for surface burning characteristics and ASTM E662 for smoke density. The ISO 9000 series provides quality management frameworks essential for consistent production of compliant materials.

Military specifications add another layer of complexity, with standards like MIL-STD-810 requiring materials to withstand environmental stresses including temperature extremes, humidity, and vibration. For carbon capture sorbents to achieve aerospace qualification, they must maintain functionality and structural integrity throughout these challenging conditions without performance degradation.

Environmental regulations increasingly influence aerospace material selection, with the International Civil Aviation Organization (ICAO) implementing the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA). This creates potential opportunities for carbon capture technologies while simultaneously imposing additional compliance requirements. The EU's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation further restricts certain chemical compounds that might be used in sorbent formulations.

Certification pathways for novel materials typically involve a multi-phase approach beginning with material characterization, followed by coupon-level testing, component testing, and finally full-scale demonstration. This process can span 5-7 years and cost millions of dollars, representing a significant investment for developers of carbon capture sorbent technologies targeting aerospace applications.

Recent regulatory developments show a trend toward performance-based rather than prescriptive requirements, potentially creating more flexibility for innovative materials. However, the aerospace industry's conservative approach to material qualification remains a substantial hurdle that carbon capture sorbent technologies must overcome to achieve widespread adoption in this sector.

Environmental Impact Assessment

Carbon capture technologies, particularly sorbent-based systems, present significant environmental implications that must be thoroughly assessed. The lifecycle environmental impact of carbon capture sorbents begins with raw material extraction, where mining activities for zeolites, metal-organic frameworks (MOFs), and amine-based materials can lead to habitat disruption, water pollution, and energy consumption. Manufacturing processes for these sorbents typically require high temperatures and specialized chemical treatments, resulting in considerable energy expenditure and potential emissions if not powered by renewable sources.

During operational phases, carbon capture systems demonstrate positive environmental effects through greenhouse gas reduction, with modern sorbents capable of capturing 85-95% of CO2 from point sources. However, this environmental benefit must be weighed against the energy penalty—the additional 15-30% energy required to operate capture systems—which can offset some emission reductions unless powered by clean energy sources.

Water usage represents another critical environmental consideration, as certain sorbent regeneration processes consume 0.2-0.6 gallons of water per kilowatt-hour of electricity generated. This poses particular challenges in water-stressed regions where carbon capture implementation might compete with agricultural and municipal water needs.

The aerospace material compliance dimension introduces additional complexity, as materials used in carbon capture systems deployed in aerospace applications must meet stringent environmental regulations. These include restrictions on volatile organic compounds (VOCs), hazardous air pollutants, and ozone-depleting substances under frameworks such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and aerospace-specific environmental standards.

End-of-life management of spent sorbents presents both challenges and opportunities. While some materials contain potentially hazardous components requiring specialized disposal, others offer recycling potential. Research indicates that certain MOFs and activated carbons can be regenerated 5-10 times before significant performance degradation, reducing waste generation and resource consumption.

Long-term environmental monitoring of carbon capture implementations reveals secondary environmental effects, including potential ammonia emissions from amine-based sorbents and localized temperature changes near large-scale direct air capture installations. These effects, while generally minor compared to the climate benefits, require ongoing assessment and mitigation strategies to ensure comprehensive environmental protection.

During operational phases, carbon capture systems demonstrate positive environmental effects through greenhouse gas reduction, with modern sorbents capable of capturing 85-95% of CO2 from point sources. However, this environmental benefit must be weighed against the energy penalty—the additional 15-30% energy required to operate capture systems—which can offset some emission reductions unless powered by clean energy sources.

Water usage represents another critical environmental consideration, as certain sorbent regeneration processes consume 0.2-0.6 gallons of water per kilowatt-hour of electricity generated. This poses particular challenges in water-stressed regions where carbon capture implementation might compete with agricultural and municipal water needs.

The aerospace material compliance dimension introduces additional complexity, as materials used in carbon capture systems deployed in aerospace applications must meet stringent environmental regulations. These include restrictions on volatile organic compounds (VOCs), hazardous air pollutants, and ozone-depleting substances under frameworks such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and aerospace-specific environmental standards.

End-of-life management of spent sorbents presents both challenges and opportunities. While some materials contain potentially hazardous components requiring specialized disposal, others offer recycling potential. Research indicates that certain MOFs and activated carbons can be regenerated 5-10 times before significant performance degradation, reducing waste generation and resource consumption.

Long-term environmental monitoring of carbon capture implementations reveals secondary environmental effects, including potential ammonia emissions from amine-based sorbents and localized temperature changes near large-scale direct air capture installations. These effects, while generally minor compared to the climate benefits, require ongoing assessment and mitigation strategies to ensure comprehensive environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!