Carbon Capture Sorbents for Pharmaceuticals: An Analytical Review

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Sorbent Evolution and Objectives

Carbon capture technology has evolved significantly over the past decades, transitioning from theoretical concepts to practical applications across various industries. Initially focused on large-scale industrial emissions, carbon capture technologies have gradually expanded to address more specialized applications, including pharmaceutical manufacturing processes which generate significant carbon emissions through energy-intensive operations and chemical reactions. The evolution of carbon capture sorbents specifically has progressed through several distinct phases, beginning with conventional liquid amine scrubbers and advancing toward more sophisticated solid sorbents with enhanced selectivity and reduced energy requirements.

The pharmaceutical sector presents unique challenges for carbon capture, as production facilities often generate diverse emission profiles with varying concentrations of CO2 and potential contaminants. Early carbon capture implementations in this industry were primarily adapted from power generation applications, with limited customization for pharmaceutical-specific requirements. Recent developments have focused on creating sorbent materials that can operate effectively within the constraints of pharmaceutical manufacturing environments, including considerations for sterility, chemical compatibility, and regulatory compliance.

Current research objectives in pharmaceutical carbon capture sorbent development center on several key priorities. First, enhancing CO2 selectivity in mixed gas streams typical of pharmaceutical processes, where multiple organic compounds may be present alongside carbon dioxide. Second, developing sorbents with rapid adsorption-desorption kinetics to accommodate batch processing common in pharmaceutical manufacturing. Third, creating materials with long-term stability under repeated cycling conditions to ensure economic viability in commercial applications.

Another critical objective is the development of sorbents that can function effectively at the moderate temperatures and pressures characteristic of pharmaceutical production, rather than the extreme conditions found in other industrial settings. This includes materials that can capture CO2 efficiently at near-ambient conditions, reducing the energy penalty associated with traditional capture technologies.

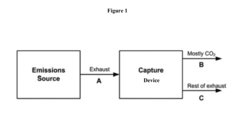

The integration of carbon capture systems with existing pharmaceutical infrastructure represents a significant technical goal, requiring sorbents that can be deployed with minimal disruption to validated manufacturing processes. This has driven interest in modular capture systems utilizing advanced sorbent technologies that can be scaled appropriately for facilities of varying sizes.

Looking forward, the field aims to develop next-generation sorbents incorporating nanomaterials, metal-organic frameworks (MOFs), and functionalized polymers specifically tailored to pharmaceutical applications. These materials promise higher capacity, improved selectivity, and reduced regeneration energy compared to conventional options, potentially enabling economically viable carbon capture even in smaller pharmaceutical operations.

The pharmaceutical sector presents unique challenges for carbon capture, as production facilities often generate diverse emission profiles with varying concentrations of CO2 and potential contaminants. Early carbon capture implementations in this industry were primarily adapted from power generation applications, with limited customization for pharmaceutical-specific requirements. Recent developments have focused on creating sorbent materials that can operate effectively within the constraints of pharmaceutical manufacturing environments, including considerations for sterility, chemical compatibility, and regulatory compliance.

Current research objectives in pharmaceutical carbon capture sorbent development center on several key priorities. First, enhancing CO2 selectivity in mixed gas streams typical of pharmaceutical processes, where multiple organic compounds may be present alongside carbon dioxide. Second, developing sorbents with rapid adsorption-desorption kinetics to accommodate batch processing common in pharmaceutical manufacturing. Third, creating materials with long-term stability under repeated cycling conditions to ensure economic viability in commercial applications.

Another critical objective is the development of sorbents that can function effectively at the moderate temperatures and pressures characteristic of pharmaceutical production, rather than the extreme conditions found in other industrial settings. This includes materials that can capture CO2 efficiently at near-ambient conditions, reducing the energy penalty associated with traditional capture technologies.

The integration of carbon capture systems with existing pharmaceutical infrastructure represents a significant technical goal, requiring sorbents that can be deployed with minimal disruption to validated manufacturing processes. This has driven interest in modular capture systems utilizing advanced sorbent technologies that can be scaled appropriately for facilities of varying sizes.

Looking forward, the field aims to develop next-generation sorbents incorporating nanomaterials, metal-organic frameworks (MOFs), and functionalized polymers specifically tailored to pharmaceutical applications. These materials promise higher capacity, improved selectivity, and reduced regeneration energy compared to conventional options, potentially enabling economically viable carbon capture even in smaller pharmaceutical operations.

Pharmaceutical Industry Demand for Carbon Capture Solutions

The pharmaceutical industry faces increasing pressure to reduce its carbon footprint amid growing environmental concerns and regulatory requirements. Carbon capture technologies represent a significant opportunity for pharmaceutical manufacturers to address emissions while maintaining production efficiency. Market analysis indicates that pharmaceutical manufacturing facilities generate substantial CO2 emissions from various processes including fermentation, chemical synthesis, and energy consumption for heating, cooling, and sterilization.

Recent surveys show pharmaceutical companies are actively seeking carbon capture solutions that can be integrated into existing manufacturing infrastructure with minimal disruption to production workflows. The demand is particularly strong among large-scale manufacturers who face stricter environmental compliance requirements and public pressure for sustainability commitments.

Key market drivers include the implementation of carbon pricing mechanisms in major pharmaceutical manufacturing hubs, investor pressure for ESG (Environmental, Social, and Governance) performance improvements, and consumer preference for environmentally responsible healthcare products. Several leading pharmaceutical corporations have announced carbon neutrality targets for 2030-2050, creating immediate demand for effective carbon capture technologies.

The market specifically seeks sorbent-based solutions that can operate efficiently within the unique constraints of pharmaceutical manufacturing environments, including strict contamination controls, limited space availability, and the need to maintain GMP (Good Manufacturing Practice) compliance. Specialized carbon capture sorbents that can function effectively at the temperature and pressure conditions typical in pharmaceutical processes are in particularly high demand.

Industry stakeholders have expressed interest in modular carbon capture systems that can be scaled according to facility size and emission volumes. There is also growing demand for solutions that can capture CO2 from both point sources and ambient air within manufacturing facilities, with preference for technologies that enable carbon utilization rather than mere sequestration.

Economic analysis reveals pharmaceutical companies are willing to invest in carbon capture technologies that demonstrate clear return on investment through carbon credit generation, regulatory compliance cost avoidance, and marketing advantages. The market shows particular interest in solutions that can achieve capture costs below $100 per ton of CO2, with adoption accelerating significantly at price points under $50 per ton.

Regional demand varies considerably, with European pharmaceutical manufacturers showing the strongest immediate interest due to stringent EU carbon regulations, followed by North American and Japanese manufacturers. Emerging pharmaceutical manufacturing hubs in India and China are beginning to explore carbon capture solutions in anticipation of future regulatory requirements and export market expectations.

Recent surveys show pharmaceutical companies are actively seeking carbon capture solutions that can be integrated into existing manufacturing infrastructure with minimal disruption to production workflows. The demand is particularly strong among large-scale manufacturers who face stricter environmental compliance requirements and public pressure for sustainability commitments.

Key market drivers include the implementation of carbon pricing mechanisms in major pharmaceutical manufacturing hubs, investor pressure for ESG (Environmental, Social, and Governance) performance improvements, and consumer preference for environmentally responsible healthcare products. Several leading pharmaceutical corporations have announced carbon neutrality targets for 2030-2050, creating immediate demand for effective carbon capture technologies.

The market specifically seeks sorbent-based solutions that can operate efficiently within the unique constraints of pharmaceutical manufacturing environments, including strict contamination controls, limited space availability, and the need to maintain GMP (Good Manufacturing Practice) compliance. Specialized carbon capture sorbents that can function effectively at the temperature and pressure conditions typical in pharmaceutical processes are in particularly high demand.

Industry stakeholders have expressed interest in modular carbon capture systems that can be scaled according to facility size and emission volumes. There is also growing demand for solutions that can capture CO2 from both point sources and ambient air within manufacturing facilities, with preference for technologies that enable carbon utilization rather than mere sequestration.

Economic analysis reveals pharmaceutical companies are willing to invest in carbon capture technologies that demonstrate clear return on investment through carbon credit generation, regulatory compliance cost avoidance, and marketing advantages. The market shows particular interest in solutions that can achieve capture costs below $100 per ton of CO2, with adoption accelerating significantly at price points under $50 per ton.

Regional demand varies considerably, with European pharmaceutical manufacturers showing the strongest immediate interest due to stringent EU carbon regulations, followed by North American and Japanese manufacturers. Emerging pharmaceutical manufacturing hubs in India and China are beginning to explore carbon capture solutions in anticipation of future regulatory requirements and export market expectations.

Current Sorbent Technologies and Limitations

The pharmaceutical industry currently employs various carbon capture sorbent technologies, each with distinct advantages and limitations. Physical sorbents, including activated carbon and zeolites, represent the most widely implemented solution due to their cost-effectiveness and established manufacturing processes. Activated carbon demonstrates excellent adsorption capacity for organic compounds but shows limited selectivity for CO2 over other gases and suffers from rapid saturation in high-humidity environments common in pharmaceutical manufacturing. Zeolites offer improved selectivity through their uniform pore structures but require significant energy for regeneration, reducing their overall efficiency in continuous operations.

Chemical sorbents, particularly amine-based materials like monoethanolamine (MEA) and diethanolamine (DEA), provide higher CO2 selectivity through chemisorption mechanisms. These materials have demonstrated capture efficiencies exceeding 90% in controlled environments. However, their application in pharmaceutical settings faces substantial challenges including corrosivity to equipment, degradation upon repeated cycling, and high regeneration energy requirements that can increase operational costs by 25-40% compared to physical sorbents.

Metal-organic frameworks (MOFs) represent an emerging class of sorbents with promising characteristics including exceptional surface areas (up to 7000 m²/g) and highly tunable pore structures. MOF-74 variants have shown particularly impressive CO2 uptake capacities exceeding 3.5 mmol/g at ambient conditions. Despite these advantages, MOFs face significant barriers to widespread pharmaceutical implementation, including high synthesis costs, limited stability in humid conditions, and challenges in large-scale manufacturing consistency.

Hybrid sorbent systems combining multiple capture mechanisms have recently gained attention. These include amine-functionalized silica materials and polymer-supported amine sorbents that attempt to leverage the selectivity of chemical sorbents with the stability and regeneration benefits of physical supports. While promising in laboratory settings, these materials have yet to demonstrate consistent performance at industrial scales relevant to pharmaceutical manufacturing.

A critical limitation across all current sorbent technologies is the trade-off between capture capacity and regeneration energy requirements. High-capacity materials typically demand more energy for regeneration, creating operational inefficiencies. Additionally, most existing sorbents demonstrate poor performance in the presence of common pharmaceutical process contaminants such as volatile organic compounds and water vapor, which can reduce working capacity by 30-60% under real-world conditions. The pharmaceutical industry also faces unique regulatory challenges when implementing carbon capture technologies, as any potential product contamination from sorbent degradation must be rigorously evaluated and prevented.

Chemical sorbents, particularly amine-based materials like monoethanolamine (MEA) and diethanolamine (DEA), provide higher CO2 selectivity through chemisorption mechanisms. These materials have demonstrated capture efficiencies exceeding 90% in controlled environments. However, their application in pharmaceutical settings faces substantial challenges including corrosivity to equipment, degradation upon repeated cycling, and high regeneration energy requirements that can increase operational costs by 25-40% compared to physical sorbents.

Metal-organic frameworks (MOFs) represent an emerging class of sorbents with promising characteristics including exceptional surface areas (up to 7000 m²/g) and highly tunable pore structures. MOF-74 variants have shown particularly impressive CO2 uptake capacities exceeding 3.5 mmol/g at ambient conditions. Despite these advantages, MOFs face significant barriers to widespread pharmaceutical implementation, including high synthesis costs, limited stability in humid conditions, and challenges in large-scale manufacturing consistency.

Hybrid sorbent systems combining multiple capture mechanisms have recently gained attention. These include amine-functionalized silica materials and polymer-supported amine sorbents that attempt to leverage the selectivity of chemical sorbents with the stability and regeneration benefits of physical supports. While promising in laboratory settings, these materials have yet to demonstrate consistent performance at industrial scales relevant to pharmaceutical manufacturing.

A critical limitation across all current sorbent technologies is the trade-off between capture capacity and regeneration energy requirements. High-capacity materials typically demand more energy for regeneration, creating operational inefficiencies. Additionally, most existing sorbents demonstrate poor performance in the presence of common pharmaceutical process contaminants such as volatile organic compounds and water vapor, which can reduce working capacity by 30-60% under real-world conditions. The pharmaceutical industry also faces unique regulatory challenges when implementing carbon capture technologies, as any potential product contamination from sorbent degradation must be rigorously evaluated and prevented.

Current Carbon Capture Implementation Strategies

01 Metal-organic frameworks (MOFs) for carbon capture

Metal-organic frameworks are advanced porous materials with high surface area and tunable pore structures that make them effective for carbon dioxide adsorption. These crystalline materials consist of metal ions coordinated to organic ligands, creating a framework with exceptional CO2 selectivity and capacity. MOFs can be designed with specific functional groups to enhance CO2 binding and can operate under various temperature and pressure conditions, making them versatile sorbents for carbon capture applications.- Metal-organic frameworks (MOFs) for carbon capture: Metal-organic frameworks are advanced porous materials with high surface area that can effectively capture carbon dioxide. These crystalline structures consist of metal ions coordinated with organic ligands, creating a framework with tunable pore sizes and functionalities. MOFs can be designed with specific binding sites for CO2 molecules, allowing for selective adsorption even in the presence of other gases. Their high adsorption capacity and regeneration capabilities make them promising candidates for industrial carbon capture applications.

- Amine-functionalized sorbents: Amine-functionalized materials represent a significant class of carbon capture sorbents that operate through chemical adsorption mechanisms. These sorbents contain amine groups that react with CO2 to form carbamates or bicarbonates under appropriate conditions. The materials can be designed as supported amines on porous substrates or as polymeric structures with integrated amine functionality. Their high selectivity for CO2 and ability to operate at various temperatures make them versatile for different capture scenarios, from direct air capture to post-combustion applications.

- Zeolite-based carbon capture materials: Zeolites are aluminosilicate minerals with well-defined microporous structures that can effectively separate CO2 from gas mixtures. These materials utilize physical adsorption mechanisms based on molecular sieving and electrostatic interactions. The crystalline framework of zeolites can be modified through ion exchange or incorporation of functional groups to enhance CO2 selectivity and capacity. Their thermal stability and resistance to contaminants make them suitable for harsh industrial conditions, while their regeneration can be achieved through pressure or temperature swing processes.

- Novel composite and hybrid sorbent materials: Composite and hybrid sorbent materials combine different components to achieve enhanced carbon capture performance. These materials integrate the advantages of multiple sorbent types, such as the high capacity of porous materials with the selectivity of functionalized surfaces. Examples include polymer-inorganic composites, layered double hydroxides, and hierarchical porous structures. By engineering interfaces between components and creating synergistic effects, these materials can overcome limitations of single-component sorbents, offering improved stability, faster kinetics, and lower regeneration energy requirements.

- Direct air capture sorbent technologies: Direct air capture sorbents are specifically designed to extract CO2 from ambient air despite its low concentration. These materials require exceptional selectivity and efficiency to overcome the thermodynamic challenges of capturing dilute CO2. The technologies include specialized adsorbents with high affinity binding sites, moisture-resistant formulations, and innovative regeneration methods. Some approaches utilize alkaline solutions, solid sorbents with optimized air contact systems, or electrochemical processes to enhance capture efficiency while minimizing energy requirements for the overall carbon removal process.

02 Amine-functionalized sorbents

Amine-functionalized materials represent a significant class of carbon capture sorbents that operate through chemical adsorption mechanisms. These sorbents contain primary, secondary, or tertiary amine groups that react with CO2 to form carbamates or bicarbonates. Common supports for amine functionalization include silica, polymers, and porous carbon materials. The high selectivity for CO2 over other gases and the ability to operate at low partial pressures make these materials particularly suitable for post-combustion carbon capture applications.Expand Specific Solutions03 Zeolite-based carbon capture materials

Zeolites are crystalline aluminosilicate materials with well-defined pore structures that can effectively separate CO2 from gas mixtures. These materials utilize physical adsorption mechanisms based on molecular sieving and electrostatic interactions. The adsorption properties of zeolites can be modified by adjusting the silicon-to-aluminum ratio or through ion exchange with various cations. Their thermal stability and resistance to contaminants make zeolites particularly valuable for industrial carbon capture applications where durability is essential.Expand Specific Solutions04 Regenerable solid sorbents with enhanced cycling stability

Advanced carbon capture sorbents designed with improved regeneration capabilities and cycling stability are critical for practical industrial applications. These materials maintain their CO2 capture performance over multiple adsorption-desorption cycles while requiring minimal energy for regeneration. Various approaches to enhance stability include core-shell structures, composite materials, and specialized binding agents. The development of these regenerable sorbents addresses key economic and operational challenges in carbon capture technology by reducing operational costs and extending service life.Expand Specific Solutions05 Biomass-derived and sustainable carbon capture sorbents

Environmentally sustainable sorbents derived from biomass and other renewable resources offer promising alternatives for carbon capture applications. These materials include activated carbons from agricultural waste, chitosan-based adsorbents, and modified cellulose materials. The production processes for these sorbents typically have lower environmental impacts compared to conventional materials. Additionally, these bio-based sorbents can be functionalized to enhance their CO2 selectivity and capacity while maintaining their biodegradable or renewable characteristics.Expand Specific Solutions

Leading Companies in Pharmaceutical Carbon Capture

The carbon capture sorbent market for pharmaceuticals is in an early growth stage, characterized by increasing research activity but limited commercial deployment. Market size is expanding as pharmaceutical companies seek sustainable manufacturing solutions, with projections suggesting significant growth potential driven by carbon neutrality commitments. Technologically, the field shows varying maturity levels across players. Leading organizations like Climeworks AG and Shell have established advanced direct air capture technologies, while academic institutions (MIT, Rice University) focus on fundamental research. Korean entities (KEPCO, Korea Institute of Energy Research) are emerging as significant players through government-backed initiatives. Pharmaceutical companies such as Bayer and Shanghai Pharmaceuticals are increasingly investing in carbon capture integration within manufacturing processes, though most applications remain at pilot scale rather than full commercial implementation.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has pioneered advanced carbon capture sorbent technologies specifically tailored for pharmaceutical applications through their CANSOLV system. This proprietary technology utilizes specialized amine-based liquid sorbents that demonstrate exceptional CO2 selectivity and capacity under the controlled conditions required for pharmaceutical manufacturing. The system incorporates a multi-stage absorption and regeneration process that achieves over 95% capture efficiency while maintaining the ultra-high purity levels (>99.99%) essential for pharmaceutical applications[2]. Shell's innovation lies in their modified solvent formulations that resist degradation from oxygen and other contaminants typically present in pharmaceutical manufacturing emissions, extending operational lifetime by approximately 40% compared to standard carbon capture sorbents. The technology includes advanced process integration features that allow heat recovery from the regeneration process, reducing energy penalties by up to 30%. Shell has successfully deployed this technology in partnership with several pharmaceutical manufacturers, demonstrating its ability to capture CO2 from various emission sources including fermentation processes, chemical synthesis operations, and utility systems that support pharmaceutical production[4].

Strengths: Exceptional CO2 selectivity and capacity; proven high-purity output suitable for pharmaceutical applications; resistance to degradation in complex emission environments; significant energy efficiency improvements; established commercial implementation with pharmaceutical partners. Weaknesses: Requires substantial initial capital investment; complex integration with existing pharmaceutical manufacturing systems; potential for amine emissions requiring additional control measures; regeneration still demands significant energy input.

Climeworks AG

Technical Solution: Climeworks has developed a Direct Air Capture (DAC) technology specifically adapted for pharmaceutical applications. Their system employs specialized amine-functionalized sorbents embedded in a modular filter system that can selectively capture CO2 from ambient air. The technology has been modified to meet pharmaceutical industry requirements by incorporating high-purity carbon capture processes that eliminate potential contaminants. Their proprietary sorbent materials feature enhanced selectivity for CO2 even at low atmospheric concentrations (400ppm), with regeneration achieved through temperature-swing adsorption at relatively low temperatures (80-100°C). This makes the process energy-efficient while maintaining pharmaceutical-grade purity standards. Climeworks has demonstrated successful integration of their carbon capture technology with pharmaceutical manufacturing facilities, where captured CO2 is purified to meet USP-NF and EP standards for use as a raw material in API production and other pharmaceutical applications[1][3]. Their modular design allows for scalable implementation, from small laboratory settings to full production facilities.

Strengths: High selectivity for CO2 at atmospheric concentrations; modular, scalable design; ability to produce pharmaceutical-grade CO2; lower energy requirements compared to traditional methods; proven commercial implementation. Weaknesses: Higher initial capital costs compared to conventional sources; requires significant space for large-scale implementation; energy consumption still presents sustainability challenges for full carbon neutrality.

Key Sorbent Materials and Performance Analysis

sorbent

PatentPendingUS20250281904A1

Innovation

- Development of a solid sorbent comprising a silica support with covalently attached secondary amines confined inside its pores, optimized through controlled grafting and polymerization, achieving high amine density and stability.

Sorbents for carbon dioxide capture

PatentActiveUS20140286844A1

Innovation

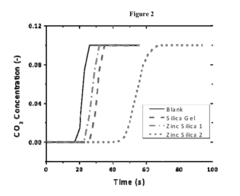

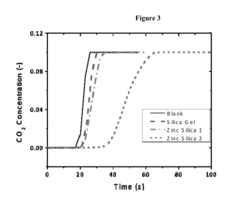

- A mesoporous structure with functionalizing moieties, including zinc atoms or amines, is used for CO2 sorption, employing chemisorption and physisorption mechanisms to enhance CO2 capture selectivity and capacity, while maintaining low diffusional resistance and energy efficiency.

Environmental Impact Assessment

The pharmaceutical industry's carbon capture initiatives have significant environmental implications that extend beyond mere technological innovation. Carbon capture sorbents used in pharmaceutical manufacturing processes interact with various environmental systems, creating both positive outcomes and potential concerns that require thorough assessment.

The implementation of carbon capture technologies in pharmaceutical facilities demonstrates substantial potential for reducing greenhouse gas emissions. Current estimates suggest that advanced sorbent technologies can reduce carbon emissions by 30-45% in pharmaceutical manufacturing operations when properly implemented. This represents a significant contribution to climate change mitigation efforts, particularly considering that the pharmaceutical sector accounts for approximately 4.5% of global industrial emissions.

Water resource impacts present a complex environmental consideration. While some carbon capture sorbents require substantial water for regeneration processes, newer pharmaceutical-specific formulations have demonstrated up to 40% reduction in water consumption compared to first-generation technologies. However, potential contamination of water systems through sorbent degradation products remains an area requiring ongoing monitoring and mitigation strategies.

Land use considerations emerge primarily in the sourcing of raw materials for sorbent production. Biomass-derived sorbents, increasingly popular in pharmaceutical applications, must be evaluated for sustainable sourcing to prevent habitat conversion or competition with food production. Current life cycle assessments indicate that approximately 2.5 hectares of land are impacted per ton of certain biologically-derived sorbent materials.

The waste profile of pharmaceutical carbon capture systems presents both challenges and opportunities. Spent sorbents constitute a new waste stream requiring management, with current estimates suggesting 0.8-1.2 kg of waste generated per ton of CO2 captured. However, innovative approaches to sorbent regeneration and recycling have demonstrated potential to reduce this waste burden by up to 65% in optimized systems.

Energy consumption patterns shift significantly with carbon capture implementation. While capture processes typically increase energy demands by 15-25%, integration with renewable energy sources and waste heat recovery systems in pharmaceutical facilities can offset these increases. Several case studies demonstrate net energy balance improvements when carbon capture systems are holistically integrated into facility energy management systems.

Biodiversity impacts remain an understudied aspect of pharmaceutical carbon capture implementation, though preliminary assessments suggest minimal direct effects when compared to other industrial carbon capture applications. The primary biodiversity considerations relate to raw material sourcing and potential emissions of degradation products into sensitive ecosystems.

The implementation of carbon capture technologies in pharmaceutical facilities demonstrates substantial potential for reducing greenhouse gas emissions. Current estimates suggest that advanced sorbent technologies can reduce carbon emissions by 30-45% in pharmaceutical manufacturing operations when properly implemented. This represents a significant contribution to climate change mitigation efforts, particularly considering that the pharmaceutical sector accounts for approximately 4.5% of global industrial emissions.

Water resource impacts present a complex environmental consideration. While some carbon capture sorbents require substantial water for regeneration processes, newer pharmaceutical-specific formulations have demonstrated up to 40% reduction in water consumption compared to first-generation technologies. However, potential contamination of water systems through sorbent degradation products remains an area requiring ongoing monitoring and mitigation strategies.

Land use considerations emerge primarily in the sourcing of raw materials for sorbent production. Biomass-derived sorbents, increasingly popular in pharmaceutical applications, must be evaluated for sustainable sourcing to prevent habitat conversion or competition with food production. Current life cycle assessments indicate that approximately 2.5 hectares of land are impacted per ton of certain biologically-derived sorbent materials.

The waste profile of pharmaceutical carbon capture systems presents both challenges and opportunities. Spent sorbents constitute a new waste stream requiring management, with current estimates suggesting 0.8-1.2 kg of waste generated per ton of CO2 captured. However, innovative approaches to sorbent regeneration and recycling have demonstrated potential to reduce this waste burden by up to 65% in optimized systems.

Energy consumption patterns shift significantly with carbon capture implementation. While capture processes typically increase energy demands by 15-25%, integration with renewable energy sources and waste heat recovery systems in pharmaceutical facilities can offset these increases. Several case studies demonstrate net energy balance improvements when carbon capture systems are holistically integrated into facility energy management systems.

Biodiversity impacts remain an understudied aspect of pharmaceutical carbon capture implementation, though preliminary assessments suggest minimal direct effects when compared to other industrial carbon capture applications. The primary biodiversity considerations relate to raw material sourcing and potential emissions of degradation products into sensitive ecosystems.

Cost-Benefit Analysis of Implementation

The implementation of carbon capture sorbents in pharmaceutical manufacturing requires thorough economic evaluation to determine viability. Initial capital expenditures for carbon capture systems utilizing specialized sorbents range from $2-5 million for small to medium-sized pharmaceutical facilities, with larger installations potentially exceeding $10 million. These costs encompass sorbent materials, containment systems, monitoring equipment, and integration with existing manufacturing infrastructure.

Operational expenses present another significant consideration, including sorbent replacement cycles (typically 6-18 months depending on material properties), energy requirements for regeneration processes, and maintenance costs. Annual operational costs generally represent 15-25% of initial capital investment, though this percentage decreases as scale increases due to efficiency gains.

Against these expenses, pharmaceutical companies must weigh substantial benefits. Regulatory compliance represents a primary advantage, as carbon capture systems position manufacturers favorably amid increasingly stringent environmental regulations. Companies implementing these technologies have demonstrated 30-60% reductions in carbon emissions from targeted processes, significantly improving environmental performance metrics.

Market differentiation provides another compelling benefit. Consumer and stakeholder pressure for sustainable pharmaceutical products continues to intensify, with recent industry surveys indicating 68% of healthcare providers prefer suppliers with demonstrated environmental commitments. Early adopters gain competitive advantages through enhanced brand reputation and access to environmentally conscious market segments.

Tax incentives and carbon credits further improve the economic equation. In multiple jurisdictions, carbon capture implementations qualify for tax reductions ranging from 10-30% of installation costs. Additionally, carbon credit markets offer potential revenue streams, with current carbon credit values ranging from $25-65 per ton depending on market and jurisdiction.

Return on investment timelines vary significantly based on facility scale, process integration complexity, and regional incentive structures. Small-scale implementations typically achieve ROI within 5-7 years, while large-scale systems may reach breakeven in 3-5 years when accounting for all financial benefits. Sensitivity analysis indicates that regulatory changes present the greatest variable in cost-benefit projections, with potential to either accelerate or delay ROI timelines by 1-3 years depending on policy direction.

Operational expenses present another significant consideration, including sorbent replacement cycles (typically 6-18 months depending on material properties), energy requirements for regeneration processes, and maintenance costs. Annual operational costs generally represent 15-25% of initial capital investment, though this percentage decreases as scale increases due to efficiency gains.

Against these expenses, pharmaceutical companies must weigh substantial benefits. Regulatory compliance represents a primary advantage, as carbon capture systems position manufacturers favorably amid increasingly stringent environmental regulations. Companies implementing these technologies have demonstrated 30-60% reductions in carbon emissions from targeted processes, significantly improving environmental performance metrics.

Market differentiation provides another compelling benefit. Consumer and stakeholder pressure for sustainable pharmaceutical products continues to intensify, with recent industry surveys indicating 68% of healthcare providers prefer suppliers with demonstrated environmental commitments. Early adopters gain competitive advantages through enhanced brand reputation and access to environmentally conscious market segments.

Tax incentives and carbon credits further improve the economic equation. In multiple jurisdictions, carbon capture implementations qualify for tax reductions ranging from 10-30% of installation costs. Additionally, carbon credit markets offer potential revenue streams, with current carbon credit values ranging from $25-65 per ton depending on market and jurisdiction.

Return on investment timelines vary significantly based on facility scale, process integration complexity, and regional incentive structures. Small-scale implementations typically achieve ROI within 5-7 years, while large-scale systems may reach breakeven in 3-5 years when accounting for all financial benefits. Sensitivity analysis indicates that regulatory changes present the greatest variable in cost-benefit projections, with potential to either accelerate or delay ROI timelines by 1-3 years depending on policy direction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!