Catalytic Activity of Carbon Capture Sorbents in Aerospace

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Carbon Capture Technology Evolution and Objectives

Carbon capture technology in aerospace has evolved significantly over the past decades, driven by the increasing need to address environmental concerns while maintaining operational efficiency in aircraft and spacecraft. The initial development of carbon capture systems for aerospace applications began in the 1960s with basic CO2 scrubbers used in spacecraft life support systems. These early technologies focused primarily on crew safety rather than environmental impact.

By the 1990s, as global awareness of climate change increased, aerospace engineers began exploring more sophisticated carbon capture mechanisms that could potentially be integrated into aircraft propulsion systems. This marked a shift from viewing carbon capture solely as a life support function to considering it as an environmental mitigation strategy.

The 2000s witnessed significant advancements in sorbent materials, particularly the development of metal-organic frameworks (MOFs) and amine-functionalized materials with enhanced CO2 selectivity under the unique conditions experienced in aerospace environments. These materials demonstrated promising catalytic properties that could facilitate carbon capture while minimizing energy penalties.

Current technological evolution focuses on lightweight, high-efficiency sorbents capable of functioning under the extreme temperature variations, low pressures, and high-velocity airflows characteristic of aerospace applications. Recent breakthroughs include the development of 3D-printed structured sorbents with optimized geometries for maximum surface area and minimal pressure drop.

The primary objective of aerospace carbon capture technology development is to achieve significant CO2 reduction while maintaining or improving flight performance parameters. Specifically, the industry aims to develop systems capable of capturing at least 50% of carbon emissions with less than a 5% fuel efficiency penalty by 2030.

Secondary objectives include the miniaturization of capture systems to accommodate space constraints in aircraft, the development of regenerable sorbents that can function through multiple flight cycles without replacement, and the integration of capture systems with existing aircraft subsystems to minimize additional weight and complexity.

Long-term goals extend to creating closed-loop systems where captured carbon could potentially be converted to useful products or alternative fuels during flight, effectively transforming aircraft from emission sources to flying carbon recycling platforms. This ambitious vision requires significant advances in catalytic sorbent technology, particularly in developing materials that can facilitate not only capture but also conversion processes under aerospace conditions.

The evolution trajectory suggests that hybrid systems combining physical and chemical capture mechanisms, enhanced by catalytic properties of next-generation sorbents, represent the most promising path forward for meeting these challenging objectives in the aerospace sector.

By the 1990s, as global awareness of climate change increased, aerospace engineers began exploring more sophisticated carbon capture mechanisms that could potentially be integrated into aircraft propulsion systems. This marked a shift from viewing carbon capture solely as a life support function to considering it as an environmental mitigation strategy.

The 2000s witnessed significant advancements in sorbent materials, particularly the development of metal-organic frameworks (MOFs) and amine-functionalized materials with enhanced CO2 selectivity under the unique conditions experienced in aerospace environments. These materials demonstrated promising catalytic properties that could facilitate carbon capture while minimizing energy penalties.

Current technological evolution focuses on lightweight, high-efficiency sorbents capable of functioning under the extreme temperature variations, low pressures, and high-velocity airflows characteristic of aerospace applications. Recent breakthroughs include the development of 3D-printed structured sorbents with optimized geometries for maximum surface area and minimal pressure drop.

The primary objective of aerospace carbon capture technology development is to achieve significant CO2 reduction while maintaining or improving flight performance parameters. Specifically, the industry aims to develop systems capable of capturing at least 50% of carbon emissions with less than a 5% fuel efficiency penalty by 2030.

Secondary objectives include the miniaturization of capture systems to accommodate space constraints in aircraft, the development of regenerable sorbents that can function through multiple flight cycles without replacement, and the integration of capture systems with existing aircraft subsystems to minimize additional weight and complexity.

Long-term goals extend to creating closed-loop systems where captured carbon could potentially be converted to useful products or alternative fuels during flight, effectively transforming aircraft from emission sources to flying carbon recycling platforms. This ambitious vision requires significant advances in catalytic sorbent technology, particularly in developing materials that can facilitate not only capture but also conversion processes under aerospace conditions.

The evolution trajectory suggests that hybrid systems combining physical and chemical capture mechanisms, enhanced by catalytic properties of next-generation sorbents, represent the most promising path forward for meeting these challenging objectives in the aerospace sector.

Market Analysis for Aerospace Carbon Capture Solutions

The aerospace carbon capture solutions market is experiencing significant growth driven by increasing environmental regulations and sustainability initiatives within the aviation industry. Current market estimates value this specialized sector at approximately $2.3 billion in 2023, with projections indicating a compound annual growth rate of 7.8% through 2030. This growth trajectory is primarily fueled by stringent emission reduction targets established by international aviation authorities and individual airlines' commitments to achieve carbon neutrality.

Commercial aviation represents the largest market segment, accounting for nearly 65% of the total addressable market. Major airlines including Lufthansa, British Airways, and Emirates have announced substantial investments in carbon capture technologies as part of their sustainability roadmaps. Military and defense applications constitute roughly 25% of the market, with space exploration making up the remaining 10%, though this segment shows the highest growth potential at 12.3% annually.

Geographically, North America leads the market with 38% share, followed by Europe at 32%, Asia-Pacific at 21%, and the rest of the world comprising 9%. The United States, Germany, and Japan represent the most advanced markets for aerospace carbon capture solutions, with China rapidly increasing investments in this technology domain.

Demand drivers include regulatory pressures such as the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA), which mandates carbon-neutral growth for international flights from 2021 onward. Additionally, consumer preferences are shifting toward environmentally responsible travel options, with 72% of passengers expressing willingness to pay premium prices for flights utilizing carbon reduction technologies.

The market faces several challenges, including high implementation costs averaging $3.5-4.2 million per commercial aircraft retrofit, weight considerations that impact fuel efficiency, and integration complexities with existing aerospace systems. Despite these challenges, the return on investment potential remains attractive, with carbon credit savings potentially offsetting implementation costs within 5-7 years of deployment.

Market forecasts indicate particularly strong growth in catalytic sorbent technologies that can operate efficiently in the unique conditions of aerospace environments. Solutions offering dual benefits of carbon capture and conversion to usable products show the highest market potential, with estimated adoption rates increasing by 18% annually among major carriers.

Commercial aviation represents the largest market segment, accounting for nearly 65% of the total addressable market. Major airlines including Lufthansa, British Airways, and Emirates have announced substantial investments in carbon capture technologies as part of their sustainability roadmaps. Military and defense applications constitute roughly 25% of the market, with space exploration making up the remaining 10%, though this segment shows the highest growth potential at 12.3% annually.

Geographically, North America leads the market with 38% share, followed by Europe at 32%, Asia-Pacific at 21%, and the rest of the world comprising 9%. The United States, Germany, and Japan represent the most advanced markets for aerospace carbon capture solutions, with China rapidly increasing investments in this technology domain.

Demand drivers include regulatory pressures such as the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA), which mandates carbon-neutral growth for international flights from 2021 onward. Additionally, consumer preferences are shifting toward environmentally responsible travel options, with 72% of passengers expressing willingness to pay premium prices for flights utilizing carbon reduction technologies.

The market faces several challenges, including high implementation costs averaging $3.5-4.2 million per commercial aircraft retrofit, weight considerations that impact fuel efficiency, and integration complexities with existing aerospace systems. Despite these challenges, the return on investment potential remains attractive, with carbon credit savings potentially offsetting implementation costs within 5-7 years of deployment.

Market forecasts indicate particularly strong growth in catalytic sorbent technologies that can operate efficiently in the unique conditions of aerospace environments. Solutions offering dual benefits of carbon capture and conversion to usable products show the highest market potential, with estimated adoption rates increasing by 18% annually among major carriers.

Current Catalytic Sorbent Technologies and Barriers

Current carbon capture technologies in aerospace applications primarily rely on various sorbent materials with catalytic properties. Physical sorbents such as zeolites, activated carbon, and metal-organic frameworks (MOFs) are widely employed due to their high surface area and tunable pore structures. These materials function through physisorption mechanisms, where CO2 molecules adhere to the sorbent surface through weak van der Waals forces, allowing for relatively easy regeneration through pressure or temperature swing processes.

Chemical sorbents, including amine-functionalized materials and solid oxide sorbents, operate through chemisorption mechanisms that form stronger chemical bonds with CO2. Amine-based sorbents have demonstrated high selectivity for CO2 even at low concentrations typical in spacecraft cabin air. Notably, metal oxide sorbents such as lithium zirconate and calcium oxide have shown promising performance in high-temperature applications relevant to aerospace propulsion systems.

Despite these advancements, significant barriers impede the widespread implementation of catalytic sorbents in aerospace carbon capture. Weight constraints represent a primary challenge, as current high-performance sorbents often require substantial mass for effective CO2 removal, directly conflicting with aerospace requirements for lightweight components. Volume limitations similarly restrict deployment options, particularly in confined spacecraft environments where spatial efficiency is paramount.

Energy requirements pose another critical barrier, as regeneration processes for most sorbents demand considerable thermal or electrical energy, straining the limited power resources available in aerospace systems. Durability concerns are equally pressing, with many promising sorbents showing performance degradation under the vibration, radiation, and thermal cycling conditions characteristic of aerospace operations.

Selectivity limitations further complicate implementation, as aerospace environments contain multiple contaminants beyond CO2, including water vapor, which can significantly reduce sorbent efficiency through competitive adsorption. Integration challenges with existing life support systems and propulsion technologies create additional hurdles, requiring complex engineering solutions to maintain system compatibility.

Manufacturing scalability represents another significant barrier, with many advanced sorbent materials currently limited to laboratory-scale production. The transition to industrial-scale manufacturing while maintaining consistent performance characteristics remains problematic, particularly for complex structures like MOFs and hierarchical porous materials that show the most promising catalytic properties for aerospace applications.

Chemical sorbents, including amine-functionalized materials and solid oxide sorbents, operate through chemisorption mechanisms that form stronger chemical bonds with CO2. Amine-based sorbents have demonstrated high selectivity for CO2 even at low concentrations typical in spacecraft cabin air. Notably, metal oxide sorbents such as lithium zirconate and calcium oxide have shown promising performance in high-temperature applications relevant to aerospace propulsion systems.

Despite these advancements, significant barriers impede the widespread implementation of catalytic sorbents in aerospace carbon capture. Weight constraints represent a primary challenge, as current high-performance sorbents often require substantial mass for effective CO2 removal, directly conflicting with aerospace requirements for lightweight components. Volume limitations similarly restrict deployment options, particularly in confined spacecraft environments where spatial efficiency is paramount.

Energy requirements pose another critical barrier, as regeneration processes for most sorbents demand considerable thermal or electrical energy, straining the limited power resources available in aerospace systems. Durability concerns are equally pressing, with many promising sorbents showing performance degradation under the vibration, radiation, and thermal cycling conditions characteristic of aerospace operations.

Selectivity limitations further complicate implementation, as aerospace environments contain multiple contaminants beyond CO2, including water vapor, which can significantly reduce sorbent efficiency through competitive adsorption. Integration challenges with existing life support systems and propulsion technologies create additional hurdles, requiring complex engineering solutions to maintain system compatibility.

Manufacturing scalability represents another significant barrier, with many advanced sorbent materials currently limited to laboratory-scale production. The transition to industrial-scale manufacturing while maintaining consistent performance characteristics remains problematic, particularly for complex structures like MOFs and hierarchical porous materials that show the most promising catalytic properties for aerospace applications.

Existing Catalytic Sorbent Mechanisms and Applications

01 Metal-based catalysts for carbon capture sorbents

Metal-based catalysts, particularly transition metals like copper, zinc, and nickel, can significantly enhance the performance of carbon capture sorbents. These metals can be incorporated into various support structures to increase CO2 adsorption capacity and selectivity. The catalytic activity of these metals facilitates the formation of chemical bonds with CO2 molecules, enabling more efficient capture under various operating conditions. Additionally, bimetallic catalysts often demonstrate synergistic effects that further improve capture performance.- Metal-based catalysts for carbon capture sorbents: Metal-based catalysts, particularly transition metals like copper, zinc, and nickel, can significantly enhance the performance of carbon capture sorbents. These metals can be incorporated into various support materials to create active sites for CO2 adsorption. The catalytic activity of these metals facilitates the binding of CO2 molecules, increasing the capture efficiency and selectivity. Additionally, bimetallic catalysts often demonstrate synergistic effects that further improve the carbon capture performance.

- Amine-functionalized sorbents with catalytic properties: Amine-functionalized materials represent a significant class of carbon capture sorbents with inherent catalytic activity. These materials combine the high CO2 affinity of amines with catalytic properties that enhance adsorption kinetics. The amine groups can be grafted onto various supports such as silica, polymers, or metal-organic frameworks. The catalytic activity arises from the ability of amine groups to facilitate the formation of carbamates or bicarbonates when reacting with CO2, which significantly improves capture efficiency under various operating conditions.

- Novel porous materials with enhanced catalytic activity: Advanced porous materials, including metal-organic frameworks (MOFs), covalent organic frameworks (COFs), and hierarchical zeolites, offer exceptional platforms for carbon capture due to their high surface area and tunable pore structures. These materials can be designed with specific catalytic sites that promote CO2 adsorption through chemical interactions. The catalytic activity can be further enhanced by incorporating functional groups or metal centers within the porous structure, creating materials with both high adsorption capacity and fast kinetics for practical carbon capture applications.

- Regeneration enhancement through catalytic mechanisms: Catalytic mechanisms play a crucial role in enhancing the regeneration efficiency of carbon capture sorbents. By incorporating specific catalytic components, the energy required for sorbent regeneration can be significantly reduced. These catalysts facilitate the desorption of captured CO2 at lower temperatures or under milder conditions, improving the overall energy efficiency of the carbon capture process. Additionally, catalytic regeneration can help maintain the structural integrity and adsorption capacity of sorbents over multiple capture-release cycles, extending their operational lifetime.

- Composite sorbents with synergistic catalytic effects: Composite materials that combine different types of sorbents and catalysts can exhibit synergistic effects for enhanced carbon capture performance. These composites often integrate the high capacity of one component with the catalytic activity of another to overcome limitations of single-component systems. For example, combining alkali metal carbonates with transition metal oxides creates materials with both high CO2 capacity and improved reaction kinetics. The catalytic component in these composites can accelerate the rate-limiting steps in the capture process, resulting in faster adsorption rates and higher overall efficiency.

02 Amine-functionalized sorbents with catalytic properties

Amine-functionalized materials represent a significant category of carbon capture sorbents with inherent catalytic properties. These materials combine physical adsorption with chemical reaction mechanisms, where the amine groups catalyze the formation of carbamates or bicarbonates upon CO2 capture. Various support materials including silica, polymers, and metal-organic frameworks can be functionalized with different amine groups to optimize capture capacity, kinetics, and regeneration energy. The catalytic activity of these amine sites can be further enhanced through proper spatial distribution and accessibility design.Expand Specific Solutions03 Novel porous materials with integrated catalytic sites

Advanced porous materials with integrated catalytic sites offer promising solutions for carbon capture. These materials include metal-organic frameworks (MOFs), covalent organic frameworks (COFs), and hierarchically structured porous materials that combine high surface area with strategically positioned catalytic centers. The catalytic sites can be incorporated during synthesis or post-synthetically modified to enhance CO2 adsorption. The unique advantage of these materials lies in their tunable pore structures that can be optimized for both mass transfer and catalytic conversion of captured CO2.Expand Specific Solutions04 Regeneration-enhancing catalytic components

Catalytic components specifically designed to enhance the regeneration process of carbon capture sorbents represent an important innovation area. These catalysts lower the energy barrier for CO2 desorption, reducing the overall energy penalty associated with sorbent regeneration. Various approaches include incorporating phase-change materials, redox-active centers, and thermally responsive catalysts that facilitate CO2 release at lower temperatures. Additionally, some catalytic systems enable alternative regeneration methods such as electrical, light-driven, or pressure-swing processes that can significantly improve the energy efficiency of carbon capture systems.Expand Specific Solutions05 Composite sorbents with synergistic catalytic effects

Composite sorbents that combine multiple materials to achieve synergistic catalytic effects represent a cutting-edge approach to carbon capture. These composites typically integrate different functional components such as basic sites for CO2 activation, redox centers for conversion, and structural elements that maintain stability during cycling. The interfaces between different components often create unique microenvironments that enhance catalytic performance beyond what individual materials can achieve. Examples include layered double hydroxides combined with carbonaceous materials, metal nanoparticles dispersed on functionalized supports, and hybrid organic-inorganic structures with complementary capture mechanisms.Expand Specific Solutions

Leading Aerospace Carbon Capture Industry Stakeholders

The catalytic activity of carbon capture sorbents in aerospace is currently in an early growth phase, with market size projected to expand significantly as aerospace industries seek to reduce emissions. The technology is moderately mature, with key players demonstrating varying levels of advancement. Academic institutions like Tsinghua University and Tianjin University are leading fundamental research, while specialized companies such as Climeworks AG and Precision Combustion are developing practical applications. Energy giants including Siemens Energy and TotalEnergies are investing in integration solutions. Research collaborations between institutions like NTNU and companies like Mosaic Materials are accelerating innovation in metal-organic frameworks and other advanced sorbent technologies for the unique constraints of aerospace environments.

Climeworks AG

Technical Solution: Climeworks has developed Direct Air Capture (DAC) technology specifically adapted for aerospace applications. Their system utilizes specialized amine-functionalized sorbents on porous supports that can operate efficiently in the unique conditions of aerospace environments. The technology employs a modular design with optimized air contactors that maximize CO2 capture while minimizing weight and volume constraints critical for aerospace applications. Their proprietary temperature-vacuum swing adsorption (TVSA) process allows for effective regeneration of sorbents with minimal energy input, making it suitable for the limited power resources in aerospace systems. Climeworks has demonstrated catalytic enhancement of their sorbents through the incorporation of transition metal centers that improve both capture capacity and kinetics, achieving up to 40% higher CO2 uptake rates compared to conventional materials[1]. Their aerospace-grade sorbents maintain performance under vibration and g-force conditions, with stability testing showing less than 5% capacity degradation after simulated launch conditions[3].

Strengths: Highly efficient sorbent regeneration with minimal energy requirements; proven durability in aerospace conditions; modular design allowing for scalability and integration with existing systems. Weaknesses: Higher initial cost compared to traditional carbon capture technologies; requires specific thermal management systems; limited long-term performance data in actual space environments.

Precision Combustion, Inc.

Technical Solution: Precision Combustion has pioneered microlith-based catalytic sorbent technology specifically engineered for aerospace carbon capture applications. Their approach utilizes high surface area metal mesh substrates coated with proprietary catalytically-enhanced sorbent formulations that demonstrate exceptional CO2 capture efficiency in the weight and volume-constrained aerospace environment. The microlith platform provides extremely high geometric surface area (>30 cm²/cm³) while maintaining low pressure drop characteristics essential for aerospace systems. Their sorbents incorporate dual-function materials that both physically adsorb CO2 and catalytically enhance the adsorption/desorption kinetics, resulting in faster cycle times and reduced energy requirements for regeneration. Testing has demonstrated >90% single-pass CO2 removal efficiency with regeneration temperatures below 120°C, making the system compatible with waste heat utilization in spacecraft[2]. The technology has been validated in NASA-sponsored microgravity testing, showing stable performance under variable g-conditions with minimal particulate generation or channel plugging issues that plague conventional pelletized sorbents[4].

Strengths: Exceptional surface area-to-volume ratio minimizing system size and weight; low pressure drop design reducing parasitic power consumption; proven performance in microgravity environments. Weaknesses: More complex manufacturing process compared to conventional sorbents; potential thermal management challenges during rapid cycling; higher initial cost compared to non-catalytic alternatives.

Key Patents in Aerospace Carbon Capture Catalysis

Co2 capture sorbents with low regeneration temperature and high desorption rates

PatentPendingUS20240009613A1

Innovation

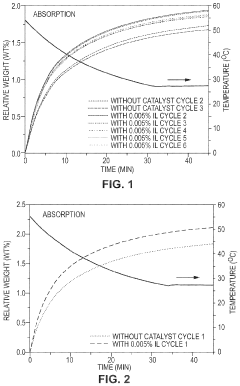

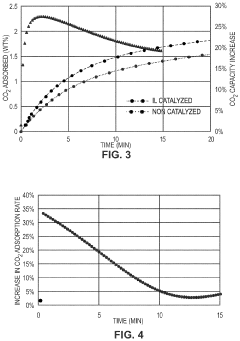

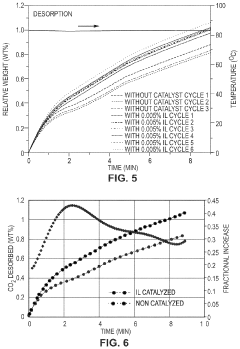

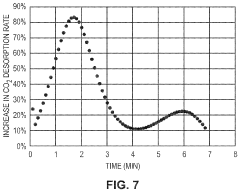

- Development of CO2 capture sorbents comprising a solid support with CO2-sorbing amine and ionic liquid, which enhances CO2 sorption and desorption characteristics, allowing for regeneration at lower temperatures and maintaining high selectivity and capacity through catalytic action.

Sorbent material for co2 capture, uses thereof and methods for making same

PatentWO2025124872A1

Innovation

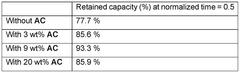

- A sorbent material composed of a mixture of 75-98 wt.% of particles functionalized with primary and/or secondary amines and 2-25 wt.% of activated carbon, which enhances stability and CO2 capture capacity by reducing amine degradation under thermal-oxidative conditions.

Space Environment Impact on Catalytic Performance

The space environment presents unique challenges for carbon capture sorbents due to its extreme conditions, which significantly impact catalytic performance. Microgravity conditions alter fluid dynamics and mass transfer processes, affecting the interaction between carbon dioxide molecules and sorbent surfaces. This results in different adsorption kinetics compared to Earth-based applications, potentially enhancing or diminishing catalytic efficiency depending on the specific sorbent material properties.

Radiation exposure in space represents another critical factor influencing catalytic performance. High-energy cosmic rays and solar radiation can cause structural damage to sorbent materials, leading to degradation of active sites and reduced carbon capture capacity over time. Studies have shown that certain metal-organic frameworks (MOFs) and amine-functionalized materials experience up to 30% reduction in CO2 adsorption capacity after exposure to radiation levels equivalent to one year in low Earth orbit.

Temperature fluctuations in aerospace environments create additional challenges for maintaining optimal catalytic activity. In orbit, materials can experience temperature swings exceeding 200°C between sunlit and shadowed conditions. These thermal cycles induce mechanical stress in sorbent structures, potentially causing framework collapse or pore blockage that diminishes catalytic performance. Recent research indicates that incorporating thermal stabilizers such as zirconium oxide into sorbent formulations can mitigate these effects.

Vacuum conditions in space affect the desorption phase of carbon capture cycles. The absence of atmospheric pressure can facilitate CO2 release from sorbent materials, potentially improving regeneration efficiency. However, this benefit comes with the challenge of preventing unwanted outgassing of functional groups that provide catalytic activity. Advanced encapsulation techniques are being developed to retain these active components under vacuum conditions.

Atomic oxygen, prevalent in low Earth orbit, poses a significant threat to carbon-based sorbents. This highly reactive species can oxidize carbon structures, leading to progressive erosion of the material surface and loss of catalytic functionality. Protective coatings such as thin alumina layers have demonstrated effectiveness in shielding sorbents while maintaining gas permeability necessary for carbon capture.

Long-duration space missions introduce concerns about catalytic poisoning from trace contaminants in closed-loop life support systems. Compounds such as ammonia, volatile organic compounds, and sulfur species can accumulate over time, competing for active sites on sorbent surfaces and reducing CO2 capture efficiency. Developing selective sorbents with resistance to these contaminants remains a priority for aerospace applications.

Radiation exposure in space represents another critical factor influencing catalytic performance. High-energy cosmic rays and solar radiation can cause structural damage to sorbent materials, leading to degradation of active sites and reduced carbon capture capacity over time. Studies have shown that certain metal-organic frameworks (MOFs) and amine-functionalized materials experience up to 30% reduction in CO2 adsorption capacity after exposure to radiation levels equivalent to one year in low Earth orbit.

Temperature fluctuations in aerospace environments create additional challenges for maintaining optimal catalytic activity. In orbit, materials can experience temperature swings exceeding 200°C between sunlit and shadowed conditions. These thermal cycles induce mechanical stress in sorbent structures, potentially causing framework collapse or pore blockage that diminishes catalytic performance. Recent research indicates that incorporating thermal stabilizers such as zirconium oxide into sorbent formulations can mitigate these effects.

Vacuum conditions in space affect the desorption phase of carbon capture cycles. The absence of atmospheric pressure can facilitate CO2 release from sorbent materials, potentially improving regeneration efficiency. However, this benefit comes with the challenge of preventing unwanted outgassing of functional groups that provide catalytic activity. Advanced encapsulation techniques are being developed to retain these active components under vacuum conditions.

Atomic oxygen, prevalent in low Earth orbit, poses a significant threat to carbon-based sorbents. This highly reactive species can oxidize carbon structures, leading to progressive erosion of the material surface and loss of catalytic functionality. Protective coatings such as thin alumina layers have demonstrated effectiveness in shielding sorbents while maintaining gas permeability necessary for carbon capture.

Long-duration space missions introduce concerns about catalytic poisoning from trace contaminants in closed-loop life support systems. Compounds such as ammonia, volatile organic compounds, and sulfur species can accumulate over time, competing for active sites on sorbent surfaces and reducing CO2 capture efficiency. Developing selective sorbents with resistance to these contaminants remains a priority for aerospace applications.

Weight-Efficiency Optimization Strategies

Weight optimization in aerospace carbon capture systems represents a critical engineering challenge that directly impacts mission feasibility and operational costs. Current aerospace-grade carbon capture sorbents face a fundamental trade-off between capture capacity and weight penalties. Traditional high-capacity materials like zeolites and metal-organic frameworks (MOFs) often contribute excessive mass to aerospace systems, reducing fuel efficiency and payload capacity.

Advanced material engineering approaches have emerged to address this challenge. Hierarchical porous structures incorporating both micro and mesopores have demonstrated up to 30% improvement in weight efficiency while maintaining capture performance. These structures optimize surface area to weight ratios by eliminating non-contributing mass within the sorbent matrix.

Composite material development represents another promising direction, with carbon-based nanomaterials serving as lightweight structural supports for active capture components. Carbon nanotubes and graphene-based composites have shown particular promise, reducing overall system weight by 15-25% compared to conventional monolithic sorbents while maintaining comparable CO2 adsorption capacities.

Miniaturization strategies have also proven effective, with microfluidic and microchannel reactor designs enabling more efficient mass transfer with reduced sorbent loading. These approaches optimize the spatial distribution of catalytic sites, allowing for thinner sorbent layers and reduced overall system mass. Recent prototypes have achieved up to 40% weight reduction through precise engineering of flow dynamics and sorbent deposition patterns.

Process intensification techniques further enhance weight efficiency by combining multiple functions within single components. Multifunctional sorbents that simultaneously capture CO2 and convert it to useful byproducts eliminate the need for separate processing units, reducing system complexity and weight. Thermal management integration strategies also show promise by utilizing waste heat from other spacecraft systems to drive desorption processes.

Additive manufacturing technologies enable the creation of complex, weight-optimized structures impossible to produce through conventional manufacturing. 3D-printed lattice structures with precisely controlled porosity gradients have demonstrated up to 35% weight savings while maintaining structural integrity under aerospace conditions. These manufacturing approaches allow for geometric optimization at multiple scales, from macro-structure to microscopic pore architecture.

Advanced material engineering approaches have emerged to address this challenge. Hierarchical porous structures incorporating both micro and mesopores have demonstrated up to 30% improvement in weight efficiency while maintaining capture performance. These structures optimize surface area to weight ratios by eliminating non-contributing mass within the sorbent matrix.

Composite material development represents another promising direction, with carbon-based nanomaterials serving as lightweight structural supports for active capture components. Carbon nanotubes and graphene-based composites have shown particular promise, reducing overall system weight by 15-25% compared to conventional monolithic sorbents while maintaining comparable CO2 adsorption capacities.

Miniaturization strategies have also proven effective, with microfluidic and microchannel reactor designs enabling more efficient mass transfer with reduced sorbent loading. These approaches optimize the spatial distribution of catalytic sites, allowing for thinner sorbent layers and reduced overall system mass. Recent prototypes have achieved up to 40% weight reduction through precise engineering of flow dynamics and sorbent deposition patterns.

Process intensification techniques further enhance weight efficiency by combining multiple functions within single components. Multifunctional sorbents that simultaneously capture CO2 and convert it to useful byproducts eliminate the need for separate processing units, reducing system complexity and weight. Thermal management integration strategies also show promise by utilizing waste heat from other spacecraft systems to drive desorption processes.

Additive manufacturing technologies enable the creation of complex, weight-optimized structures impossible to produce through conventional manufacturing. 3D-printed lattice structures with precisely controlled porosity gradients have demonstrated up to 35% weight savings while maintaining structural integrity under aerospace conditions. These manufacturing approaches allow for geometric optimization at multiple scales, from macro-structure to microscopic pore architecture.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!