Sorbent-Coating Interactions in Carbon Capture Systems

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Sorbent Technology Background and Objectives

Carbon capture technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in response to growing climate change concerns. The interaction between sorbents and their coatings represents a critical frontier in carbon capture systems, with historical developments dating back to the 1930s when the first amine-based absorption processes were implemented industrially. Since then, the field has witnessed exponential growth, particularly after the 1990s when climate change mitigation became a global priority.

The evolution of sorbent technologies has progressed through distinct phases: from conventional liquid amine scrubbing to solid sorbents, and now toward advanced hybrid materials with specialized coatings that enhance capture efficiency and selectivity. These coating-sorbent interactions have become increasingly sophisticated, incorporating nanomaterials, polymeric membranes, and functionalized surfaces designed to optimize CO₂ adsorption while minimizing energy requirements for regeneration.

Current technological objectives in this field focus on addressing several key challenges. Primary among these is developing sorbent-coating systems that maintain high CO₂ selectivity while demonstrating resistance to degradation under industrial conditions. Researchers aim to achieve capture efficiencies exceeding 90% while reducing the energy penalty below 1.5 GJ/ton CO₂ captured—a significant improvement over current systems requiring 2.5-3.5 GJ/ton.

Another critical objective involves enhancing the mechanical and chemical stability of coated sorbents during multiple adsorption-desorption cycles. Current technologies typically demonstrate performance degradation after 1,000-2,000 cycles, whereas commercial viability requires stability beyond 10,000 cycles. This necessitates fundamental research into the molecular interactions at the sorbent-coating interface and how these evolve under repeated thermal and chemical stresses.

The field is also moving toward multifunctional coating designs that not only facilitate CO₂ capture but simultaneously address challenges like water tolerance, contaminant resistance, and heat management. These "smart coatings" represent a paradigm shift from passive to active materials that can adapt to changing operational conditions.

Looking forward, the technology roadmap emphasizes development of bio-inspired sorbent-coating systems that mimic natural carbon fixation processes, as well as integration with renewable energy sources to power the capture process. The ultimate goal remains developing economically viable carbon capture solutions that can be deployed at scale across various industries, particularly in hard-to-abate sectors like cement production, steel manufacturing, and power generation.

The evolution of sorbent technologies has progressed through distinct phases: from conventional liquid amine scrubbing to solid sorbents, and now toward advanced hybrid materials with specialized coatings that enhance capture efficiency and selectivity. These coating-sorbent interactions have become increasingly sophisticated, incorporating nanomaterials, polymeric membranes, and functionalized surfaces designed to optimize CO₂ adsorption while minimizing energy requirements for regeneration.

Current technological objectives in this field focus on addressing several key challenges. Primary among these is developing sorbent-coating systems that maintain high CO₂ selectivity while demonstrating resistance to degradation under industrial conditions. Researchers aim to achieve capture efficiencies exceeding 90% while reducing the energy penalty below 1.5 GJ/ton CO₂ captured—a significant improvement over current systems requiring 2.5-3.5 GJ/ton.

Another critical objective involves enhancing the mechanical and chemical stability of coated sorbents during multiple adsorption-desorption cycles. Current technologies typically demonstrate performance degradation after 1,000-2,000 cycles, whereas commercial viability requires stability beyond 10,000 cycles. This necessitates fundamental research into the molecular interactions at the sorbent-coating interface and how these evolve under repeated thermal and chemical stresses.

The field is also moving toward multifunctional coating designs that not only facilitate CO₂ capture but simultaneously address challenges like water tolerance, contaminant resistance, and heat management. These "smart coatings" represent a paradigm shift from passive to active materials that can adapt to changing operational conditions.

Looking forward, the technology roadmap emphasizes development of bio-inspired sorbent-coating systems that mimic natural carbon fixation processes, as well as integration with renewable energy sources to power the capture process. The ultimate goal remains developing economically viable carbon capture solutions that can be deployed at scale across various industries, particularly in hard-to-abate sectors like cement production, steel manufacturing, and power generation.

Market Analysis for Carbon Capture Sorbent Technologies

The global carbon capture market is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. As of 2023, the carbon capture and storage (CCS) market is valued at approximately $7.5 billion, with projections indicating growth to reach $15.3 billion by 2030, representing a compound annual growth rate of 10.7%. This growth trajectory is particularly relevant for sorbent technologies, which constitute about 35% of the total carbon capture technology market.

Sorbent-based carbon capture technologies are gaining traction due to their potential cost advantages over traditional amine-based liquid absorption systems. The market for specialized carbon capture sorbents is currently estimated at $2.6 billion, with solid sorbents showing the fastest growth segment at 12.3% annually. This acceleration is attributed to their lower energy requirements for regeneration and reduced environmental impacts compared to liquid systems.

Industrial sectors represent the primary demand drivers, with power generation, cement production, and steel manufacturing collectively accounting for 68% of the current market. Geographically, North America leads with 38% market share, followed by Europe (29%) and Asia-Pacific (24%), with the latter showing the highest growth rate due to rapid industrialization coupled with strengthening environmental policies in China and India.

The competitive landscape features both established chemical companies and specialized startups. Major chemical corporations like BASF, Honeywell UOP, and Mitsubishi Heavy Industries control approximately 45% of the sorbent market, leveraging their extensive distribution networks and R&D capabilities. Meanwhile, venture-backed startups focused exclusively on novel sorbent technologies have secured over $850 million in funding since 2020, indicating strong investor confidence in this sector.

Customer adoption patterns reveal a preference shift toward sorbent technologies that demonstrate durability under real-world conditions. End-users are increasingly prioritizing total cost of ownership over initial capital expenditure, with particular emphasis on sorbent-coating interaction stability that affects operational lifespan. Market surveys indicate that customers are willing to pay a 15-20% premium for sorbents that can maintain performance for over 1,000 cycles without significant degradation.

Regulatory frameworks are creating market pull factors across different regions. The European Union's carbon pricing mechanism, currently valuing carbon at €80-90 per tonne, has established a clear economic incentive for carbon capture implementation. Similarly, the United States' 45Q tax credit, offering up to $85 per tonne for captured and sequestered carbon, has stimulated market growth in North America.

Sorbent-based carbon capture technologies are gaining traction due to their potential cost advantages over traditional amine-based liquid absorption systems. The market for specialized carbon capture sorbents is currently estimated at $2.6 billion, with solid sorbents showing the fastest growth segment at 12.3% annually. This acceleration is attributed to their lower energy requirements for regeneration and reduced environmental impacts compared to liquid systems.

Industrial sectors represent the primary demand drivers, with power generation, cement production, and steel manufacturing collectively accounting for 68% of the current market. Geographically, North America leads with 38% market share, followed by Europe (29%) and Asia-Pacific (24%), with the latter showing the highest growth rate due to rapid industrialization coupled with strengthening environmental policies in China and India.

The competitive landscape features both established chemical companies and specialized startups. Major chemical corporations like BASF, Honeywell UOP, and Mitsubishi Heavy Industries control approximately 45% of the sorbent market, leveraging their extensive distribution networks and R&D capabilities. Meanwhile, venture-backed startups focused exclusively on novel sorbent technologies have secured over $850 million in funding since 2020, indicating strong investor confidence in this sector.

Customer adoption patterns reveal a preference shift toward sorbent technologies that demonstrate durability under real-world conditions. End-users are increasingly prioritizing total cost of ownership over initial capital expenditure, with particular emphasis on sorbent-coating interaction stability that affects operational lifespan. Market surveys indicate that customers are willing to pay a 15-20% premium for sorbents that can maintain performance for over 1,000 cycles without significant degradation.

Regulatory frameworks are creating market pull factors across different regions. The European Union's carbon pricing mechanism, currently valuing carbon at €80-90 per tonne, has established a clear economic incentive for carbon capture implementation. Similarly, the United States' 45Q tax credit, offering up to $85 per tonne for captured and sequestered carbon, has stimulated market growth in North America.

Current Challenges in Sorbent-Coating Interactions

Despite significant advancements in carbon capture technologies, sorbent-coating interactions present persistent challenges that impede optimal system performance. The interface between sorbents and their protective or functional coatings represents a critical zone where chemical and physical phenomena can significantly impact capture efficiency, selectivity, and durability.

A primary challenge lies in the chemical compatibility between sorbents and coating materials. Many high-performance sorbents exhibit chemical reactivity that can degrade coating integrity over time, particularly under the harsh conditions typical of industrial carbon capture operations. This degradation manifests as coating delamination, cracking, or chemical transformation, ultimately compromising the protective function intended by the coating application.

Thermal expansion mismatch between sorbent substrates and coating materials presents another significant hurdle. During temperature cycling—common in pressure/temperature swing adsorption processes—differential expansion rates create mechanical stresses at the interface. These stresses can lead to coating failure through mechanisms such as spallation, microcracking, and adhesion loss, reducing the operational lifespan of capture systems.

Diffusion limitations represent a fundamental challenge in coated sorbent systems. While coatings may enhance certain properties, they inevitably introduce mass transfer resistance that can slow CO₂ diffusion to active sorption sites. This kinetic limitation reduces the effective capture rate and capacity utilization, particularly in rapid-cycle operations where equilibrium conditions cannot be achieved.

Moisture sensitivity at the sorbent-coating interface poses additional complications. Water molecules can penetrate interface regions, catalyzing undesired reactions, promoting coating hydrolysis, or facilitating ion migration that accelerates degradation. This is especially problematic in flue gas applications where moisture content is variable and often high.

Manufacturing consistency presents a practical challenge in producing coated sorbents at industrial scale. Achieving uniform coating thickness, complete coverage, and consistent interfacial properties across large production volumes remains difficult. Variations in these parameters lead to unpredictable performance and accelerated failure in specific regions of capture systems.

Long-term stability under realistic operating conditions represents perhaps the most significant challenge. The combined effects of thermal cycling, chemical exposure, mechanical stress, and moisture create a complex degradation environment that is difficult to predict through accelerated testing. Many coating systems that perform well in laboratory settings fail prematurely when subjected to the multifaceted stresses of industrial carbon capture operations.

A primary challenge lies in the chemical compatibility between sorbents and coating materials. Many high-performance sorbents exhibit chemical reactivity that can degrade coating integrity over time, particularly under the harsh conditions typical of industrial carbon capture operations. This degradation manifests as coating delamination, cracking, or chemical transformation, ultimately compromising the protective function intended by the coating application.

Thermal expansion mismatch between sorbent substrates and coating materials presents another significant hurdle. During temperature cycling—common in pressure/temperature swing adsorption processes—differential expansion rates create mechanical stresses at the interface. These stresses can lead to coating failure through mechanisms such as spallation, microcracking, and adhesion loss, reducing the operational lifespan of capture systems.

Diffusion limitations represent a fundamental challenge in coated sorbent systems. While coatings may enhance certain properties, they inevitably introduce mass transfer resistance that can slow CO₂ diffusion to active sorption sites. This kinetic limitation reduces the effective capture rate and capacity utilization, particularly in rapid-cycle operations where equilibrium conditions cannot be achieved.

Moisture sensitivity at the sorbent-coating interface poses additional complications. Water molecules can penetrate interface regions, catalyzing undesired reactions, promoting coating hydrolysis, or facilitating ion migration that accelerates degradation. This is especially problematic in flue gas applications where moisture content is variable and often high.

Manufacturing consistency presents a practical challenge in producing coated sorbents at industrial scale. Achieving uniform coating thickness, complete coverage, and consistent interfacial properties across large production volumes remains difficult. Variations in these parameters lead to unpredictable performance and accelerated failure in specific regions of capture systems.

Long-term stability under realistic operating conditions represents perhaps the most significant challenge. The combined effects of thermal cycling, chemical exposure, mechanical stress, and moisture create a complex degradation environment that is difficult to predict through accelerated testing. Many coating systems that perform well in laboratory settings fail prematurely when subjected to the multifaceted stresses of industrial carbon capture operations.

Current Sorbent-Coating Interface Solutions

01 Surface modification techniques for enhanced sorbent-coating interactions

Various surface modification techniques can be employed to enhance the interaction between sorbents and coatings. These techniques involve altering the surface properties of the sorbent material to increase its affinity for specific coating compounds. By optimizing the surface chemistry, the interaction efficiency can be significantly improved, leading to better adhesion and performance. Methods include chemical functionalization, plasma treatment, and grafting of specific functional groups that can form strong bonds with coating materials.- Surface modification techniques for enhanced sorbent-coating interactions: Various surface modification techniques can be employed to enhance the interaction between sorbents and coatings. These techniques involve altering the surface properties of the sorbent material to increase its affinity for specific coating components. By optimizing the surface chemistry, the interaction efficiency between the sorbent and coating can be significantly improved, leading to better performance in applications such as separation processes, filtration systems, and environmental remediation.

- Polymer-based coatings for improved sorbent functionality: Polymer-based coatings can be applied to sorbent materials to enhance their interaction efficiency with target substances. These coatings can be designed with specific functional groups that increase selectivity and binding capacity. The polymer composition can be tailored to optimize properties such as hydrophilicity/hydrophobicity, charge distribution, and molecular recognition capabilities, resulting in improved sorption performance and extended service life of the sorbent materials.

- Computational modeling of sorbent-coating interaction dynamics: Advanced computational modeling techniques are being used to predict and optimize sorbent-coating interactions at the molecular level. These models simulate the physical and chemical processes occurring at the interface between sorbents and coatings, allowing researchers to understand interaction mechanisms and efficiency factors. By applying machine learning algorithms and molecular dynamics simulations, the design of sorbent-coating systems can be refined to achieve maximum interaction efficiency without extensive experimental testing.

- Nanomaterial-enhanced sorbent coatings for increased surface area: Incorporating nanomaterials into sorbent coatings significantly increases the available surface area for interactions. Nanomaterials such as carbon nanotubes, graphene, metal-organic frameworks, and nanoparticles can be integrated into coating formulations to create highly porous structures with enhanced sorption capacity. The increased surface area leads to more efficient interactions between the sorbent coating and target molecules, improving overall performance in applications ranging from gas separation to water purification.

- Real-time monitoring systems for sorbent-coating interaction efficiency: Advanced monitoring systems have been developed to evaluate sorbent-coating interaction efficiency in real-time. These systems utilize sensors and analytical techniques to measure parameters such as binding kinetics, saturation levels, and breakthrough curves during operation. By continuously monitoring the interaction efficiency, process parameters can be adjusted dynamically to maintain optimal performance. This approach enables adaptive control of sorbent-coating systems and facilitates predictive maintenance based on actual interaction efficiency metrics.

02 Nanomaterial-based sorbent coatings for improved efficiency

Nanomaterials offer unique properties that can significantly enhance sorbent-coating interaction efficiency. Their high surface area-to-volume ratio provides more active sites for interactions, while their tunable surface chemistry allows for optimized binding with specific target molecules. Nanomaterial-based sorbent coatings can be engineered to achieve selective adsorption, improved stability, and enhanced interaction kinetics. These materials can be incorporated into various matrices to create composite coatings with superior performance characteristics.Expand Specific Solutions03 Computational modeling of sorbent-coating interactions

Computational modeling approaches can be used to predict and optimize sorbent-coating interactions at the molecular level. These models simulate the physical and chemical interactions between sorbent surfaces and coating materials, allowing researchers to understand binding mechanisms and identify factors affecting interaction efficiency. By employing molecular dynamics simulations, quantum mechanical calculations, and machine learning algorithms, the design of sorbent-coating systems can be optimized before experimental validation, saving time and resources in development processes.Expand Specific Solutions04 Interface engineering for optimized sorbent-coating performance

Interface engineering focuses on controlling the boundary region between sorbent materials and coatings to maximize interaction efficiency. This approach involves designing specific interfacial structures that promote strong adhesion and effective mass transfer across the interface. Techniques include creating gradient interfaces, incorporating binding agents, and developing hierarchical structures that enhance the contact area between sorbent and coating. By carefully engineering the interface, issues such as delamination and reduced interaction efficiency can be mitigated.Expand Specific Solutions05 Dynamic response systems for adaptive sorbent-coating interactions

Dynamic response systems incorporate smart materials that can adapt their sorbent-coating interactions based on environmental conditions or external stimuli. These systems can modify their interaction efficiency in real-time, responding to changes in temperature, pH, pressure, or the presence of specific molecules. By incorporating stimuli-responsive polymers, shape-memory materials, or self-healing components, these adaptive sorbent-coating systems can maintain optimal interaction efficiency across varying operational conditions, extending their functional lifespan and performance range.Expand Specific Solutions

Leading Organizations in Carbon Capture Technology

The carbon capture technology landscape is evolving rapidly, with the market currently in a growth phase as global decarbonization efforts intensify. The sorbent-coating interactions field represents a critical technical challenge within carbon capture systems, attracting diverse players across research institutions, energy companies, and technology developers. Key players include established energy corporations like Huaneng Clean Energy Research Institute and Schlumberger alongside specialized carbon capture innovators such as Global Thermostat and Climeworks AG. Academic institutions including MIT, Shanghai Jiao Tong University, and Norwegian University of Science & Technology contribute significant research advancements. The technology remains in mid-maturity, with companies like Precision Combustion and Susteon developing novel sorbent materials while energy giants like GE and Equinor focus on large-scale implementation, creating a competitive ecosystem balancing innovation with commercial deployment capabilities.

Huaneng Clean Energy Research Institute

Technical Solution: Huaneng Clean Energy Research Institute has developed advanced amine-based sorbent coating technologies specifically optimized for post-combustion carbon capture in coal-fired power plants. Their approach focuses on polyethylenimine (PEI) and modified silica-based composite sorbents with enhanced stability and CO2 adsorption capacity. The institute has pioneered techniques to control coating morphology and thickness on structured supports, addressing common challenges like uneven distribution and poor adhesion. Their technology includes specialized surface treatment methods that improve the sorbent-substrate interface stability during thermal cycling. Notably, Huaneng has implemented this technology at commercial scale in their Shidongkou power plant, demonstrating the viability of their sorbent-coating system under real-world conditions. Their research has also focused on mitigating the effects of SOx and NOx contaminants on sorbent degradation through protective additives and regeneration protocols.

Strengths: Demonstrated commercial-scale implementation in actual power plant environments; specialized formulations to handle contaminants in coal flue gas; integration expertise with existing power generation infrastructure. Weaknesses: Technology primarily optimized for point-source capture rather than direct air capture; potential for higher regeneration energy requirements compared to some newer sorbent technologies; coating durability challenges in high-humidity environments.

Precision Combustion, Inc.

Technical Solution: Precision Combustion has developed advanced structured sorbent technologies for carbon capture focusing on metal-organic framework (MOF) coatings on microchannel substrates. Their approach utilizes precision coating techniques that create uniform, thin-film sorbent layers with optimized pore structures for enhanced CO2 selectivity and capacity. The company's microchannel architecture provides exceptional heat and mass transfer characteristics, addressing the thermal management challenges inherent in temperature-swing adsorption systems. Their technology incorporates specialized binding agents that maintain strong adhesion between the MOF sorbents and metallic substrates despite thermal cycling stresses. Precision Combustion has also developed methods to mitigate common degradation mechanisms at the sorbent-coating interface, including moisture sensitivity and oxidative degradation, through protective overcoatings and stabilizing additives.

Strengths: Microchannel design enables rapid thermal cycling and reduced energy consumption; structured sorbents minimize pressure drop compared to packed beds; excellent heat transfer properties improve regeneration efficiency. Weaknesses: Complex manufacturing processes increase capital costs; specialized MOF materials may have higher production costs than conventional sorbents; technology is at earlier commercial development stage compared to some competitors.

Key Patents in Sorbent-Coating Technology

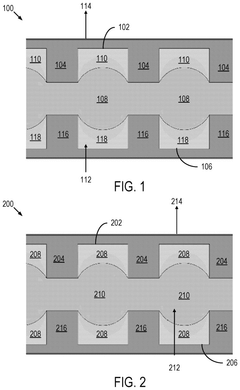

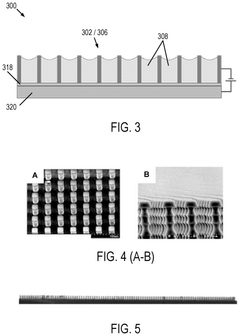

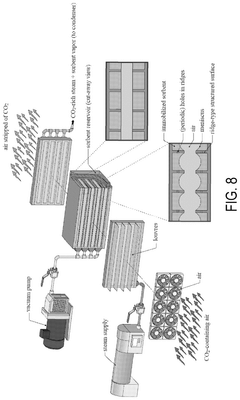

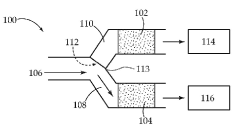

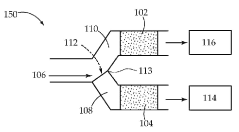

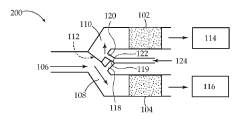

Carbon capture systems and methods

PatentPendingUS20240408847A1

Innovation

- The use of omniphobic and omniphilic surfaces with textured substrates and liquid sorbents in a Cassie-Baxter or Wenzel state to create microchannels for enhanced CO2 capture, reducing CAPEX and energy requirements, and enabling sorbent regeneration for purification.

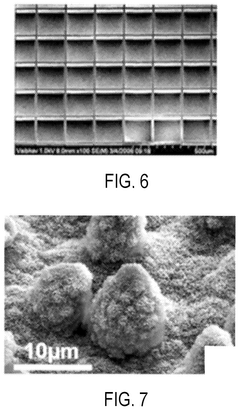

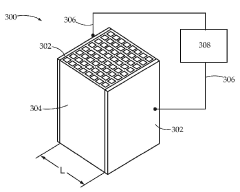

Sorbent structure applicable for carbon dioxide capture

PatentInactiveJP2015128771A

Innovation

- A novel sorbent structure comprising a continuous activated carbon body with additives like transition metal oxides and organic amines, designed for high surface area and low pressure drop, facilitating efficient CO2 capture and desorption through methods like temperature swing adsorption (TSA) and electrical swing adsorption (ESA).

Environmental Impact Assessment

The environmental implications of sorbent-coating interactions in carbon capture systems extend far beyond their technical performance metrics. These systems, while designed to mitigate climate change by reducing atmospheric CO2, may themselves create significant environmental footprints that warrant careful assessment.

The production of specialized sorbents and their coatings often involves energy-intensive manufacturing processes and potentially hazardous chemicals. For instance, the synthesis of amine-functionalized sorbents typically requires organic solvents and reactive chemicals that can generate substantial waste streams. Life cycle assessments indicate that the environmental burden of manufacturing these materials can partially offset their carbon reduction benefits, particularly when production scales increase to meet global deployment needs.

Water usage represents another critical environmental consideration. Many sorbent systems require significant water for regeneration cycles or cooling processes. In water-stressed regions, this demand could exacerbate existing resource competition. Additionally, the potential for water contamination exists if degraded sorbent materials or coating compounds leach into local water systems during operation or disposal phases.

The durability and degradation patterns of coated sorbents also present environmental concerns. As these materials degrade over multiple capture-regeneration cycles, they may release particulate matter or chemical compounds into air or water streams. The environmental fate of these degradation products remains inadequately characterized in many cases, particularly for newer, proprietary coating formulations.

Waste management challenges emerge at the end of sorbent life cycles. The composite nature of coated sorbents often complicates recycling efforts, potentially leading to increased landfill disposal. Some advanced sorbent materials contain rare earth elements or specialized compounds that represent both resource depletion concerns and potential environmental hazards if improperly managed.

Energy requirements for sorbent regeneration constitute perhaps the most significant environmental impact factor. The thermal energy needed to release captured CO2 from sorbents can substantially reduce the net carbon benefit of the entire system. While coating innovations aim to reduce these energy penalties, comprehensive environmental assessments must account for the full energy lifecycle, including sources used for regeneration processes.

Land use impacts also warrant consideration, particularly for large-scale direct air capture implementations utilizing coated sorbents. Such facilities require substantial physical footprints that could compete with other land uses or potentially disrupt local ecosystems depending on siting decisions and facility design.

The production of specialized sorbents and their coatings often involves energy-intensive manufacturing processes and potentially hazardous chemicals. For instance, the synthesis of amine-functionalized sorbents typically requires organic solvents and reactive chemicals that can generate substantial waste streams. Life cycle assessments indicate that the environmental burden of manufacturing these materials can partially offset their carbon reduction benefits, particularly when production scales increase to meet global deployment needs.

Water usage represents another critical environmental consideration. Many sorbent systems require significant water for regeneration cycles or cooling processes. In water-stressed regions, this demand could exacerbate existing resource competition. Additionally, the potential for water contamination exists if degraded sorbent materials or coating compounds leach into local water systems during operation or disposal phases.

The durability and degradation patterns of coated sorbents also present environmental concerns. As these materials degrade over multiple capture-regeneration cycles, they may release particulate matter or chemical compounds into air or water streams. The environmental fate of these degradation products remains inadequately characterized in many cases, particularly for newer, proprietary coating formulations.

Waste management challenges emerge at the end of sorbent life cycles. The composite nature of coated sorbents often complicates recycling efforts, potentially leading to increased landfill disposal. Some advanced sorbent materials contain rare earth elements or specialized compounds that represent both resource depletion concerns and potential environmental hazards if improperly managed.

Energy requirements for sorbent regeneration constitute perhaps the most significant environmental impact factor. The thermal energy needed to release captured CO2 from sorbents can substantially reduce the net carbon benefit of the entire system. While coating innovations aim to reduce these energy penalties, comprehensive environmental assessments must account for the full energy lifecycle, including sources used for regeneration processes.

Land use impacts also warrant consideration, particularly for large-scale direct air capture implementations utilizing coated sorbents. Such facilities require substantial physical footprints that could compete with other land uses or potentially disrupt local ecosystems depending on siting decisions and facility design.

Scalability and Cost Analysis

The scalability and cost considerations of sorbent-coating interactions represent critical factors in determining the commercial viability of carbon capture systems. Current industrial-scale implementation faces significant challenges related to the economic production of coated sorbents with consistent quality and performance characteristics. Manufacturing processes must transition from laboratory-scale production to industrial volumes while maintaining the integrity of sorbent-coating interactions that drive capture efficiency.

Production scaling presents several technical hurdles, including maintaining uniform coating thickness, ensuring consistent porosity, and preserving the chemical functionality of both the sorbent and coating materials. Batch-to-batch variations become increasingly problematic at larger scales, potentially compromising the reliability of carbon capture performance across industrial installations. Advanced manufacturing techniques such as fluidized bed coating and spray drying show promise for large-scale production but require substantial capital investment.

Economic analysis reveals that coating materials often constitute 30-45% of total sorbent production costs, with specialized high-performance coatings commanding premium prices. This cost structure creates a challenging optimization problem where performance benefits must justify increased production expenses. Recent market assessments indicate that economies of scale could potentially reduce coating application costs by 15-25% when production volumes exceed 1,000 tons annually, though this depends heavily on coating type and application method.

Lifecycle cost analysis demonstrates that while coated sorbents typically have higher initial costs compared to uncoated alternatives, their enhanced durability and regeneration characteristics often result in lower total cost of ownership over operational lifetimes of 3-5 years. The economic equation becomes particularly favorable when considering reduced energy penalties during regeneration cycles, which can represent 50-70% of operational expenses in carbon capture systems.

Infrastructure requirements for large-scale implementation present additional cost considerations. Retrofitting existing facilities to accommodate coated sorbent technologies may require significant capital expenditure, particularly for handling systems designed to minimize mechanical stress that could compromise coating integrity. New construction projects offer more flexibility but still face engineering challenges in designing systems that maximize the performance benefits of coated sorbents.

Market adoption will likely follow a staged approach, with initial implementation in high-value applications where performance benefits clearly outweigh cost premiums. As production volumes increase and manufacturing processes mature, broader market penetration becomes economically viable. Strategic partnerships between coating technology developers and established sorbent manufacturers represent a promising pathway to accelerate scale-up while distributing development costs and technical risks.

Production scaling presents several technical hurdles, including maintaining uniform coating thickness, ensuring consistent porosity, and preserving the chemical functionality of both the sorbent and coating materials. Batch-to-batch variations become increasingly problematic at larger scales, potentially compromising the reliability of carbon capture performance across industrial installations. Advanced manufacturing techniques such as fluidized bed coating and spray drying show promise for large-scale production but require substantial capital investment.

Economic analysis reveals that coating materials often constitute 30-45% of total sorbent production costs, with specialized high-performance coatings commanding premium prices. This cost structure creates a challenging optimization problem where performance benefits must justify increased production expenses. Recent market assessments indicate that economies of scale could potentially reduce coating application costs by 15-25% when production volumes exceed 1,000 tons annually, though this depends heavily on coating type and application method.

Lifecycle cost analysis demonstrates that while coated sorbents typically have higher initial costs compared to uncoated alternatives, their enhanced durability and regeneration characteristics often result in lower total cost of ownership over operational lifetimes of 3-5 years. The economic equation becomes particularly favorable when considering reduced energy penalties during regeneration cycles, which can represent 50-70% of operational expenses in carbon capture systems.

Infrastructure requirements for large-scale implementation present additional cost considerations. Retrofitting existing facilities to accommodate coated sorbent technologies may require significant capital expenditure, particularly for handling systems designed to minimize mechanical stress that could compromise coating integrity. New construction projects offer more flexibility but still face engineering challenges in designing systems that maximize the performance benefits of coated sorbents.

Market adoption will likely follow a staged approach, with initial implementation in high-value applications where performance benefits clearly outweigh cost premiums. As production volumes increase and manufacturing processes mature, broader market penetration becomes economically viable. Strategic partnerships between coating technology developers and established sorbent manufacturers represent a promising pathway to accelerate scale-up while distributing development costs and technical risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!