Carbon Capture Efficiency: A Catalyst Approach

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Technology Background and Objectives

Carbon capture technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in response to growing environmental concerns. The journey began in the 1970s with early experiments in carbon dioxide separation, primarily focused on enhanced oil recovery applications rather than environmental mitigation. By the 1990s, as climate change awareness increased, carbon capture research expanded substantially, leading to the development of first-generation capture systems primarily implemented in power plants and industrial facilities.

The technological landscape has diversified into three primary approaches: post-combustion capture, which extracts CO2 from flue gases; pre-combustion capture, which processes fuel before combustion; and oxy-fuel combustion, which uses pure oxygen for combustion to produce concentrated CO2 streams. Each approach presents unique advantages and challenges, with catalyst-based solutions emerging as particularly promising across all three methodologies.

Current global carbon emissions exceed 35 billion tonnes annually, with industrial processes and power generation contributing approximately 65% of these emissions. Traditional carbon capture methods typically achieve 30-40% efficiency while consuming 25-40% of a power plant's energy output, creating significant economic barriers to widespread adoption. The catalyst approach aims to dramatically improve these metrics by reducing energy requirements while increasing capture rates.

The primary technical objectives for catalyst-based carbon capture include achieving capture efficiency exceeding 90% while reducing energy penalties below 15%, developing catalysts with operational lifespans of 5+ years under industrial conditions, and creating systems that can be retrofitted to existing infrastructure at reasonable cost. Additionally, research aims to develop catalysts that function effectively across varying CO2 concentrations, from dilute atmospheric levels (approximately 412 ppm) to concentrated industrial emissions (up to 15%).

Recent breakthroughs in nanomaterial science, particularly metal-organic frameworks (MOFs) and functionalized porous materials, have accelerated progress in this field. These advanced materials offer unprecedented surface areas and customizable chemical properties that can be optimized for CO2 selectivity and binding strength. The integration of computational modeling with experimental approaches has further accelerated catalyst development, allowing researchers to predict performance characteristics before physical synthesis.

Looking forward, the technology trajectory suggests potential for transformative advances through biomimetic catalysts inspired by natural carbon-fixing processes, hybrid systems combining multiple capture mechanisms, and direct air capture technologies that could eventually address historical carbon emissions rather than just current output streams.

The technological landscape has diversified into three primary approaches: post-combustion capture, which extracts CO2 from flue gases; pre-combustion capture, which processes fuel before combustion; and oxy-fuel combustion, which uses pure oxygen for combustion to produce concentrated CO2 streams. Each approach presents unique advantages and challenges, with catalyst-based solutions emerging as particularly promising across all three methodologies.

Current global carbon emissions exceed 35 billion tonnes annually, with industrial processes and power generation contributing approximately 65% of these emissions. Traditional carbon capture methods typically achieve 30-40% efficiency while consuming 25-40% of a power plant's energy output, creating significant economic barriers to widespread adoption. The catalyst approach aims to dramatically improve these metrics by reducing energy requirements while increasing capture rates.

The primary technical objectives for catalyst-based carbon capture include achieving capture efficiency exceeding 90% while reducing energy penalties below 15%, developing catalysts with operational lifespans of 5+ years under industrial conditions, and creating systems that can be retrofitted to existing infrastructure at reasonable cost. Additionally, research aims to develop catalysts that function effectively across varying CO2 concentrations, from dilute atmospheric levels (approximately 412 ppm) to concentrated industrial emissions (up to 15%).

Recent breakthroughs in nanomaterial science, particularly metal-organic frameworks (MOFs) and functionalized porous materials, have accelerated progress in this field. These advanced materials offer unprecedented surface areas and customizable chemical properties that can be optimized for CO2 selectivity and binding strength. The integration of computational modeling with experimental approaches has further accelerated catalyst development, allowing researchers to predict performance characteristics before physical synthesis.

Looking forward, the technology trajectory suggests potential for transformative advances through biomimetic catalysts inspired by natural carbon-fixing processes, hybrid systems combining multiple capture mechanisms, and direct air capture technologies that could eventually address historical carbon emissions rather than just current output streams.

Market Analysis for Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures to reduce greenhouse gas emissions. As of 2023, the market size for carbon capture technologies has reached approximately $7 billion, with projections indicating a compound annual growth rate of 19.2% through 2030, potentially reaching $35 billion by the end of the decade. This growth trajectory is supported by substantial government investments, with the United States allocating $12 billion for carbon capture development in recent infrastructure legislation and the European Union committing €10 billion through various climate initiatives.

The demand for catalyst-based carbon capture solutions is particularly strong in power generation, cement production, and heavy manufacturing sectors, which collectively account for over 60% of global carbon emissions. These industries face mounting pressure to decarbonize while maintaining operational efficiency, creating a prime market opportunity for advanced catalyst technologies that can improve carbon capture rates while reducing energy penalties.

Regional analysis reveals varying market dynamics, with North America currently leading in carbon capture implementation due to established regulatory frameworks and tax incentives such as the 45Q tax credit in the US, which offers up to $85 per metric ton for permanent carbon sequestration. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with projected growth rates exceeding 25% annually as these nations balance rapid industrialization with climate commitments.

Customer segmentation within the carbon capture market shows distinct needs across different sectors. Utility companies prioritize solutions that can be retrofitted to existing infrastructure with minimal operational disruption, while industrial manufacturers seek technologies compatible with high-temperature processes. The oil and gas sector, representing about 30% of current market demand, focuses on enhanced oil recovery applications alongside emissions reduction.

Pricing models for carbon capture solutions vary significantly based on technology maturity and implementation scale. Current cost benchmarks for catalyst-based systems range from $40-80 per ton of CO2 captured, with industry targets aiming to reduce this to below $30 per ton by 2030 to achieve widespread commercial viability. This price reduction is critical as carbon pricing mechanisms and emissions trading schemes continue to evolve globally.

Market barriers include high initial capital requirements, uncertain regulatory landscapes in emerging markets, and competition from alternative decarbonization strategies. However, the catalyst approach to carbon capture holds particular promise for overcoming the efficiency and cost barriers that have historically limited widespread adoption of carbon capture technologies.

The demand for catalyst-based carbon capture solutions is particularly strong in power generation, cement production, and heavy manufacturing sectors, which collectively account for over 60% of global carbon emissions. These industries face mounting pressure to decarbonize while maintaining operational efficiency, creating a prime market opportunity for advanced catalyst technologies that can improve carbon capture rates while reducing energy penalties.

Regional analysis reveals varying market dynamics, with North America currently leading in carbon capture implementation due to established regulatory frameworks and tax incentives such as the 45Q tax credit in the US, which offers up to $85 per metric ton for permanent carbon sequestration. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with projected growth rates exceeding 25% annually as these nations balance rapid industrialization with climate commitments.

Customer segmentation within the carbon capture market shows distinct needs across different sectors. Utility companies prioritize solutions that can be retrofitted to existing infrastructure with minimal operational disruption, while industrial manufacturers seek technologies compatible with high-temperature processes. The oil and gas sector, representing about 30% of current market demand, focuses on enhanced oil recovery applications alongside emissions reduction.

Pricing models for carbon capture solutions vary significantly based on technology maturity and implementation scale. Current cost benchmarks for catalyst-based systems range from $40-80 per ton of CO2 captured, with industry targets aiming to reduce this to below $30 per ton by 2030 to achieve widespread commercial viability. This price reduction is critical as carbon pricing mechanisms and emissions trading schemes continue to evolve globally.

Market barriers include high initial capital requirements, uncertain regulatory landscapes in emerging markets, and competition from alternative decarbonization strategies. However, the catalyst approach to carbon capture holds particular promise for overcoming the efficiency and cost barriers that have historically limited widespread adoption of carbon capture technologies.

Current Catalyst Technologies and Challenges

Carbon capture technologies currently employ a variety of catalysts to enhance CO2 absorption and conversion efficiency. Metal-organic frameworks (MOFs) represent one of the most promising catalyst categories, offering exceptional surface area and tunable pore structures. These characteristics enable MOFs to achieve CO2 capture capacities of up to 1.5 g CO2/g catalyst under optimal conditions. Notable examples include Mg-MOF-74 and HKUST-1, which demonstrate remarkable selectivity for CO2 over other atmospheric gases.

Zeolites constitute another significant catalyst class, valued for their thermal stability and regeneration capabilities. These aluminosilicate materials feature uniform microporous structures that can be tailored for specific CO2 capture applications. Commercial zeolites such as 13X and 5A are widely deployed in pressure swing adsorption systems, achieving capture efficiencies of 80-90% in controlled environments.

Amine-functionalized silica represents a hybrid approach combining the mechanical stability of inorganic supports with the chemical reactivity of amines. These materials operate through chemisorption mechanisms, forming carbamates with CO2 molecules. Current iterations demonstrate capture capacities of 2-3 mmol CO2/g under ambient conditions, with regeneration temperatures typically ranging from 100-120°C.

Despite these advances, significant challenges persist in catalyst-based carbon capture. Energy requirements for regeneration remain prohibitively high, with most systems requiring 2.5-4 GJ/ton CO2 captured. This energy penalty substantially impacts the economic viability of large-scale implementation. Additionally, catalyst degradation presents a critical obstacle, with performance decreases of 10-15% observed after just 100 cycles in many systems.

Water tolerance represents another major challenge, as moisture in flue gas streams can dramatically reduce catalyst performance through competitive adsorption or degradation mechanisms. Most current catalysts experience 30-50% capacity reduction in high-humidity environments, necessitating costly pre-treatment systems.

Scalability issues further complicate industrial adoption, as many high-performing laboratory catalysts face manufacturing barriers when produced at commercial scales. Production costs for advanced MOFs, for instance, can exceed $200/kg, compared to conventional adsorbents at $5-20/kg.

Selectivity limitations also persist, particularly in mixed-gas environments typical of industrial emissions. Current catalysts struggle to maintain performance in the presence of SOx, NOx, and other contaminants, with some experiencing irreversible poisoning after minimal exposure. Research efforts are increasingly focused on developing robust catalysts that maintain efficiency under realistic operating conditions while addressing these fundamental challenges.

Zeolites constitute another significant catalyst class, valued for their thermal stability and regeneration capabilities. These aluminosilicate materials feature uniform microporous structures that can be tailored for specific CO2 capture applications. Commercial zeolites such as 13X and 5A are widely deployed in pressure swing adsorption systems, achieving capture efficiencies of 80-90% in controlled environments.

Amine-functionalized silica represents a hybrid approach combining the mechanical stability of inorganic supports with the chemical reactivity of amines. These materials operate through chemisorption mechanisms, forming carbamates with CO2 molecules. Current iterations demonstrate capture capacities of 2-3 mmol CO2/g under ambient conditions, with regeneration temperatures typically ranging from 100-120°C.

Despite these advances, significant challenges persist in catalyst-based carbon capture. Energy requirements for regeneration remain prohibitively high, with most systems requiring 2.5-4 GJ/ton CO2 captured. This energy penalty substantially impacts the economic viability of large-scale implementation. Additionally, catalyst degradation presents a critical obstacle, with performance decreases of 10-15% observed after just 100 cycles in many systems.

Water tolerance represents another major challenge, as moisture in flue gas streams can dramatically reduce catalyst performance through competitive adsorption or degradation mechanisms. Most current catalysts experience 30-50% capacity reduction in high-humidity environments, necessitating costly pre-treatment systems.

Scalability issues further complicate industrial adoption, as many high-performing laboratory catalysts face manufacturing barriers when produced at commercial scales. Production costs for advanced MOFs, for instance, can exceed $200/kg, compared to conventional adsorbents at $5-20/kg.

Selectivity limitations also persist, particularly in mixed-gas environments typical of industrial emissions. Current catalysts struggle to maintain performance in the presence of SOx, NOx, and other contaminants, with some experiencing irreversible poisoning after minimal exposure. Research efforts are increasingly focused on developing robust catalysts that maintain efficiency under realistic operating conditions while addressing these fundamental challenges.

Current Catalyst-Based Carbon Capture Methods

01 Adsorption-based carbon capture technologies

Adsorption-based technologies utilize specialized materials to selectively capture CO2 from gas streams. These systems employ adsorbents such as activated carbon, zeolites, or metal-organic frameworks (MOFs) that can efficiently bind CO2 molecules to their surfaces. The efficiency of these technologies depends on the adsorbent properties, including selectivity, capacity, and regeneration energy requirements. Advanced adsorbent materials are being developed to improve capture rates while reducing the energy penalty associated with the regeneration process.- Amine-based carbon capture systems: Amine-based technologies represent a significant approach in carbon capture, utilizing various amine compounds to absorb CO2 from flue gases. These systems typically involve a solvent that selectively binds with carbon dioxide, allowing for its separation from other gases. The efficiency of these systems depends on factors such as amine concentration, temperature control, and regeneration processes. Recent innovations have focused on improving energy consumption during the regeneration phase and developing more stable amine formulations that resist degradation during repeated capture cycles.

- Membrane-based separation technologies: Membrane-based carbon capture technologies utilize selective permeable barriers to separate CO2 from gas mixtures. These systems offer advantages in terms of operational simplicity and potentially lower energy requirements compared to traditional absorption methods. The efficiency of membrane systems depends on factors such as membrane material composition, thickness, porosity, and operating conditions. Recent developments have focused on creating advanced membrane materials with higher CO2 selectivity and permeability, as well as designing multi-stage membrane systems to achieve higher capture rates while maintaining energy efficiency.

- Direct air capture (DAC) systems: Direct air capture technologies focus on extracting CO2 directly from ambient air rather than from concentrated point sources. These systems typically employ specialized sorbents or solutions that can effectively capture carbon dioxide despite its relatively low concentration in the atmosphere. The efficiency challenges for DAC include high energy requirements and the need for innovative designs to process large volumes of air. Recent advancements have focused on reducing energy consumption, developing more durable and selective capture materials, and integrating renewable energy sources to power the capture process.

- Efficiency monitoring and optimization systems: Advanced monitoring and optimization systems play a crucial role in maximizing carbon capture efficiency. These technologies incorporate sensors, data analytics, and control algorithms to continuously assess and adjust operational parameters. By monitoring factors such as gas flow rates, temperature profiles, pressure differentials, and capture medium performance, these systems can identify inefficiencies and implement real-time adjustments. Machine learning and artificial intelligence approaches are increasingly being applied to predict performance trends and recommend operational changes that maximize capture efficiency while minimizing energy consumption.

- Integrated carbon capture and utilization systems: Integrated systems that combine carbon capture with utilization pathways represent an approach to improving overall efficiency. These technologies capture CO2 and then convert it into valuable products such as construction materials, chemicals, or synthetic fuels. By creating economic value from captured carbon, these systems can offset some of the costs associated with the capture process. The efficiency of these integrated approaches depends on both the capture technology and the conversion processes. Recent innovations have focused on catalysts that can efficiently transform CO2 into target compounds and process designs that minimize energy losses between capture and utilization stages.

02 Membrane separation systems for CO2 capture

Membrane-based carbon capture technologies utilize selective permeable barriers that allow CO2 to pass through while blocking other gases. These systems offer advantages in terms of operational simplicity, compact design, and continuous operation capability. The efficiency of membrane separation depends on factors such as membrane permeability, selectivity, and stability under operating conditions. Recent innovations focus on developing composite membranes with enhanced CO2 separation performance and durability to improve overall capture efficiency while minimizing energy consumption.Expand Specific Solutions03 Chemical absorption processes for carbon capture

Chemical absorption technologies utilize liquid solvents, such as amines, to chemically bind with CO2 from flue gases. These processes typically involve absorption towers where the solvent contacts the gas stream, followed by a regeneration step where the CO2 is released and the solvent is recycled. The efficiency of these systems is determined by the solvent's absorption capacity, reaction kinetics, and regeneration energy requirements. Innovations in solvent formulations aim to reduce the energy penalty associated with regeneration while maintaining high capture rates.Expand Specific Solutions04 Efficiency monitoring and optimization systems

Advanced monitoring and control systems are essential for optimizing carbon capture efficiency. These technologies incorporate sensors, data analytics, and machine learning algorithms to continuously assess performance parameters and make real-time adjustments. By monitoring key variables such as temperature, pressure, flow rates, and capture rates, these systems can identify inefficiencies and implement corrective actions. Predictive modeling capabilities enable operators to anticipate performance issues and optimize operating conditions to maximize CO2 removal while minimizing energy consumption and operational costs.Expand Specific Solutions05 Biological and hybrid carbon capture approaches

Biological and hybrid carbon capture systems utilize microorganisms, algae, or enzymatic processes to remove CO2 from gas streams. These approaches can offer advantages in terms of energy efficiency and environmental compatibility. Microalgae-based systems, for example, can capture CO2 while producing valuable biomass that can be used for biofuels or other products. Hybrid systems combine biological processes with conventional capture technologies to enhance overall efficiency. Research in this area focuses on improving biological agent performance, system integration, and scaling up these technologies for industrial applications.Expand Specific Solutions

Leading Companies in Carbon Capture Catalyst Development

Carbon capture technology is currently in a growth phase, with the market expected to expand significantly due to increasing climate change concerns. The global carbon capture market size is projected to reach $7-10 billion by 2030, growing at a CAGR of approximately 15%. Technologically, catalyst-based approaches are advancing rapidly but remain in early commercial maturity. Leading players include established energy corporations like China Petroleum & Chemical Corp. (Sinopec) and Repsol SA, who are leveraging their industrial infrastructure, alongside specialized research institutions such as Huaneng Clean Energy Research Institute and Korea Institute of Energy Research. Academic institutions like Tsinghua University and University of Wyoming are driving fundamental catalyst innovations, while companies like Nisshinbo Holdings and Saipem SpA are developing commercial applications, creating a competitive landscape balanced between research excellence and industrial implementation.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative amine-based solvent system with proprietary catalysts that significantly enhances carbon capture efficiency. Their technology employs a dual-catalyst approach combining metal-organic frameworks (MOFs) and ionic liquids to reduce energy penalties during CO2 absorption. The system achieves up to 90% capture efficiency while reducing regeneration energy requirements by approximately 30% compared to conventional amine processes. Sinopec has implemented this technology in several pilot projects across their refineries, demonstrating scalability from 100,000 to 1 million tons of CO2 annually. Their catalyst formulation specifically addresses the degradation issues common in traditional amine systems, extending operational lifetime by 40-50% and maintaining performance under industrial flue gas conditions with various contaminants.

Strengths: Extensive industrial implementation experience; proprietary catalyst formulations with proven durability; integrated approach leveraging existing infrastructure. Weaknesses: Higher initial capital costs compared to conventional systems; technology optimization still required for non-hydrocarbon industrial applications; potential catalyst poisoning in certain industrial environments.

Saipem SpA

Technical Solution: Saipem has developed an advanced enzymatic catalyst system called "CO2 Solutions by Saipem" that mimics the carbonic anhydrase enzyme found in human respiration. This biocatalytic approach operates at near-ambient temperatures (40-70°C) and atmospheric pressure, significantly reducing energy requirements compared to conventional amine processes. The system utilizes a proprietary enzyme immobilization technique that extends catalyst lifetime to over 2,000 hours in industrial conditions. Their technology achieves capture rates exceeding 90% while consuming approximately 0.8 GJ/ton of CO2 captured, representing a 30-40% energy reduction compared to traditional methods. Saipem has successfully demonstrated this technology at commercial scale with their 30-ton per day demonstration plant in Saint-Félicien, Quebec, and has expanded implementation to various industrial sectors including cement, steel, and power generation facilities.

Strengths: Low energy consumption; operates at mild conditions reducing equipment costs; environmentally benign catalyst with no toxic emissions; flexible application across various industries. Weaknesses: Enzyme stability challenges in certain industrial environments; higher catalyst replacement costs compared to chemical alternatives; performance sensitivity to specific contaminants in flue gas streams.

Key Patents and Research in Catalyst Efficiency

High-efficiency catalyst for co2 capture for increasing co2 desorption efficiency in regeneration process and method thereof

PatentActiveKR1020220077984A

Innovation

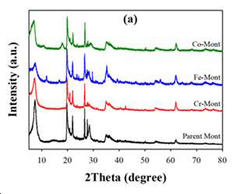

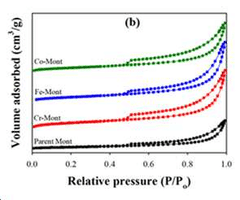

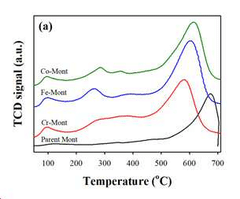

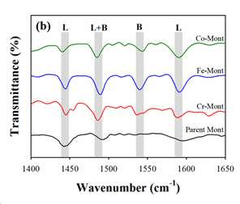

- Development of an ion-exchanged montmorillonite catalyst with transition metals like Cr, Fe, or Co to enhance desorption rates by optimizing BET surface area, surface acidity, and mesoporosity, allowing for efficient carbon dioxide capture at temperatures below 100°C.

Catalyst for capturing and converting carbon dioxide

PatentWO2023043005A1

Innovation

- A carbon dioxide capture and conversion catalyst is developed by pulverizing oxide and metal powders, preparing crystallized synthetic zeolite, and mixing them with alkaline solutions to create a stable catalyst that captures and converts CO2 into sodium carbonate or bicarbonate, reducing energy consumption and impurity interference.

Environmental Policy Impact on Carbon Capture Development

Environmental policies have emerged as critical drivers in the development and implementation of carbon capture technologies globally. The regulatory landscape has evolved significantly over the past decade, creating both incentives and compliance requirements that shape research priorities and commercial deployment of catalyst-based carbon capture solutions.

In the United States, the introduction of the 45Q tax credit has been transformative, offering up to $50 per metric ton of CO2 sequestered. This policy mechanism has accelerated investment in catalyst research, particularly for post-combustion capture applications where efficiency improvements directly translate to economic benefits. Similarly, the European Union's Emissions Trading System (ETS) has established a carbon pricing framework that makes catalyst-enhanced capture technologies increasingly competitive against conventional emission approaches.

Regulatory standards for emissions from power plants and industrial facilities have progressively tightened across developed economies. These standards have created a compliance-driven market for high-efficiency catalysts that can achieve the mandated reduction targets while minimizing energy penalties. Japan's environmental regulations, for instance, have specifically encouraged the development of zeolite-based catalysts optimized for the country's space-constrained industrial facilities.

Public funding mechanisms represent another significant policy lever affecting catalyst development. Government research grants in China have prioritized metal-organic framework catalysts, while Canada's Clean Growth Program has directed resources toward enzyme-mimicking catalysts suitable for oil sands operations. These targeted investments have accelerated innovation in specific catalyst categories aligned with national priorities.

International agreements, particularly the Paris Climate Accord, have established a global framework that signals long-term commitment to decarbonization. This policy stability has encouraged private sector investment in fundamental catalyst research with longer development horizons. The agreement's transparency mechanisms have also facilitated knowledge sharing across borders, enabling more rapid iteration of catalyst designs.

Regulatory approaches to carbon accounting and life cycle assessment have increasingly influenced catalyst development pathways. Policies requiring comprehensive emissions accounting have favored catalysts with lower embedded carbon footprints and reduced reliance on critical minerals. This has stimulated research into bio-derived catalysts and regeneration processes that extend catalyst lifespans.

Looking forward, emerging policy trends suggest increasing emphasis on circular economy principles that will likely shape the next generation of carbon capture catalysts. Regulations promoting materials recovery and waste minimization are driving interest in catalyst designs that facilitate easier metal reclamation and regeneration, creating additional economic incentives beyond the primary carbon capture function.

In the United States, the introduction of the 45Q tax credit has been transformative, offering up to $50 per metric ton of CO2 sequestered. This policy mechanism has accelerated investment in catalyst research, particularly for post-combustion capture applications where efficiency improvements directly translate to economic benefits. Similarly, the European Union's Emissions Trading System (ETS) has established a carbon pricing framework that makes catalyst-enhanced capture technologies increasingly competitive against conventional emission approaches.

Regulatory standards for emissions from power plants and industrial facilities have progressively tightened across developed economies. These standards have created a compliance-driven market for high-efficiency catalysts that can achieve the mandated reduction targets while minimizing energy penalties. Japan's environmental regulations, for instance, have specifically encouraged the development of zeolite-based catalysts optimized for the country's space-constrained industrial facilities.

Public funding mechanisms represent another significant policy lever affecting catalyst development. Government research grants in China have prioritized metal-organic framework catalysts, while Canada's Clean Growth Program has directed resources toward enzyme-mimicking catalysts suitable for oil sands operations. These targeted investments have accelerated innovation in specific catalyst categories aligned with national priorities.

International agreements, particularly the Paris Climate Accord, have established a global framework that signals long-term commitment to decarbonization. This policy stability has encouraged private sector investment in fundamental catalyst research with longer development horizons. The agreement's transparency mechanisms have also facilitated knowledge sharing across borders, enabling more rapid iteration of catalyst designs.

Regulatory approaches to carbon accounting and life cycle assessment have increasingly influenced catalyst development pathways. Policies requiring comprehensive emissions accounting have favored catalysts with lower embedded carbon footprints and reduced reliance on critical minerals. This has stimulated research into bio-derived catalysts and regeneration processes that extend catalyst lifespans.

Looking forward, emerging policy trends suggest increasing emphasis on circular economy principles that will likely shape the next generation of carbon capture catalysts. Regulations promoting materials recovery and waste minimization are driving interest in catalyst designs that facilitate easier metal reclamation and regeneration, creating additional economic incentives beyond the primary carbon capture function.

Economic Feasibility of Catalyst-Based Solutions

The economic viability of catalyst-based carbon capture solutions represents a critical factor in their potential widespread adoption. Current cost analyses indicate that traditional carbon capture methods range from $40-120 per ton of CO2 captured, creating significant economic barriers for implementation across industries. Catalyst-based approaches offer promising pathways to reduce these costs through improved efficiency and reduced energy requirements.

Metal-organic frameworks (MOFs) and zeolite-based catalysts demonstrate particularly favorable economic profiles, with recent advancements reducing operational costs by approximately 15-30% compared to conventional amine scrubbing technologies. The economic advantage stems primarily from lower regeneration energy requirements and extended operational lifespans of these materials.

Investment considerations must account for both capital expenditure (CAPEX) and operational expenditure (OPEX) factors. While catalyst-based systems often require higher initial investment—approximately 20-35% more than conventional systems—their reduced energy consumption typically results in OPEX savings of 25-40% over a standard 15-year operational period. This creates a compelling total cost of ownership (TCO) proposition for many industrial applications.

Scale remains a significant economic challenge. Laboratory-scale catalysts demonstrating high efficiency often face manufacturing constraints when scaled to industrial requirements. Production costs for advanced catalysts like porous coordination polymers currently range from $200-500 per kilogram, necessitating further manufacturing innovations to achieve economic viability at scale.

Government incentives significantly impact the economic equation. Carbon pricing mechanisms, tax credits for carbon capture (such as the 45Q tax credit in the United States offering $50-85 per ton of sequestered CO2), and regulatory frameworks increasingly favor investment in these technologies. Market analyses suggest that with carbon prices exceeding $60-70 per ton, catalyst-based capture systems become economically competitive across multiple industrial sectors.

Return on investment (ROI) calculations indicate that catalyst-based systems typically achieve breakeven points between 5-8 years in high-emission industries such as cement production and power generation. This timeframe aligns with typical industrial capital investment cycles, enhancing adoption potential. Sensitivity analyses demonstrate that catalyst performance degradation rates and energy costs represent the most significant variables affecting long-term economic viability.

Future economic prospects appear increasingly favorable as manufacturing techniques advance and regulatory pressures intensify. Industry projections suggest that by 2030, catalyst-based carbon capture costs could decrease to $25-40 per ton of CO2, positioning these technologies as economically viable solutions for meeting increasingly stringent emissions targets across global markets.

Metal-organic frameworks (MOFs) and zeolite-based catalysts demonstrate particularly favorable economic profiles, with recent advancements reducing operational costs by approximately 15-30% compared to conventional amine scrubbing technologies. The economic advantage stems primarily from lower regeneration energy requirements and extended operational lifespans of these materials.

Investment considerations must account for both capital expenditure (CAPEX) and operational expenditure (OPEX) factors. While catalyst-based systems often require higher initial investment—approximately 20-35% more than conventional systems—their reduced energy consumption typically results in OPEX savings of 25-40% over a standard 15-year operational period. This creates a compelling total cost of ownership (TCO) proposition for many industrial applications.

Scale remains a significant economic challenge. Laboratory-scale catalysts demonstrating high efficiency often face manufacturing constraints when scaled to industrial requirements. Production costs for advanced catalysts like porous coordination polymers currently range from $200-500 per kilogram, necessitating further manufacturing innovations to achieve economic viability at scale.

Government incentives significantly impact the economic equation. Carbon pricing mechanisms, tax credits for carbon capture (such as the 45Q tax credit in the United States offering $50-85 per ton of sequestered CO2), and regulatory frameworks increasingly favor investment in these technologies. Market analyses suggest that with carbon prices exceeding $60-70 per ton, catalyst-based capture systems become economically competitive across multiple industrial sectors.

Return on investment (ROI) calculations indicate that catalyst-based systems typically achieve breakeven points between 5-8 years in high-emission industries such as cement production and power generation. This timeframe aligns with typical industrial capital investment cycles, enhancing adoption potential. Sensitivity analyses demonstrate that catalyst performance degradation rates and energy costs represent the most significant variables affecting long-term economic viability.

Future economic prospects appear increasingly favorable as manufacturing techniques advance and regulatory pressures intensify. Industry projections suggest that by 2030, catalyst-based carbon capture costs could decrease to $25-40 per ton of CO2, positioning these technologies as economically viable solutions for meeting increasingly stringent emissions targets across global markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!