Research on Surface Coating Techniques for Carbon Capture Sorbents

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Coating Background & Objectives

Carbon capture technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in response to growing environmental concerns. The development of surface coating techniques for carbon capture sorbents represents a critical advancement in this field, offering enhanced performance characteristics that traditional sorbent materials alone cannot achieve. Initially focused on basic amine-based sorbents in the 1990s, the technology has progressed through various generations of materials including zeolites, metal-organic frameworks (MOFs), and advanced polymer composites.

The evolution of coating technologies has been driven by the need to address fundamental limitations in carbon capture processes, particularly in terms of selectivity, capacity, and durability. Early approaches primarily focused on improving CO2 adsorption capacity, while more recent developments have expanded to address multiple performance parameters simultaneously, including kinetics, regeneration energy requirements, and resistance to degradation under industrial conditions.

Current research trends indicate a shift toward multifunctional coatings that not only enhance CO2 capture performance but also provide protection against thermal, chemical, and mechanical stresses. This represents a significant departure from earlier single-function approaches and reflects the growing sophistication of materials science in this domain.

The primary technical objectives for surface coating development include increasing CO2 selectivity in mixed gas environments, enhancing adsorption capacity under varying pressure and temperature conditions, improving cycling stability for extended operational lifetimes, and reducing the energy penalties associated with sorbent regeneration. Additionally, there is growing emphasis on developing coatings that can function effectively in the presence of contaminants commonly found in industrial flue gases.

From a broader perspective, these technical developments align with global climate mitigation goals, particularly the need to reduce carbon emissions from large point sources such as power plants and industrial facilities. The Paris Agreement targets and subsequent policy frameworks have established clear benchmarks for carbon reduction, creating a strong impetus for accelerated innovation in capture technologies.

The ultimate goal of research in this field is to develop coating technologies that enable cost-effective carbon capture at industrial scale, with performance metrics that make implementation economically viable without significant subsidies. This includes achieving capture costs below $50 per ton of CO2, with high selectivity (>95%), rapid kinetics, and operational stability over thousands of cycles under real-world conditions.

The evolution of coating technologies has been driven by the need to address fundamental limitations in carbon capture processes, particularly in terms of selectivity, capacity, and durability. Early approaches primarily focused on improving CO2 adsorption capacity, while more recent developments have expanded to address multiple performance parameters simultaneously, including kinetics, regeneration energy requirements, and resistance to degradation under industrial conditions.

Current research trends indicate a shift toward multifunctional coatings that not only enhance CO2 capture performance but also provide protection against thermal, chemical, and mechanical stresses. This represents a significant departure from earlier single-function approaches and reflects the growing sophistication of materials science in this domain.

The primary technical objectives for surface coating development include increasing CO2 selectivity in mixed gas environments, enhancing adsorption capacity under varying pressure and temperature conditions, improving cycling stability for extended operational lifetimes, and reducing the energy penalties associated with sorbent regeneration. Additionally, there is growing emphasis on developing coatings that can function effectively in the presence of contaminants commonly found in industrial flue gases.

From a broader perspective, these technical developments align with global climate mitigation goals, particularly the need to reduce carbon emissions from large point sources such as power plants and industrial facilities. The Paris Agreement targets and subsequent policy frameworks have established clear benchmarks for carbon reduction, creating a strong impetus for accelerated innovation in capture technologies.

The ultimate goal of research in this field is to develop coating technologies that enable cost-effective carbon capture at industrial scale, with performance metrics that make implementation economically viable without significant subsidies. This includes achieving capture costs below $50 per ton of CO2, with high selectivity (>95%), rapid kinetics, and operational stability over thousands of cycles under real-world conditions.

Market Analysis for Carbon Capture Technologies

The global carbon capture market is experiencing significant growth, driven by increasing environmental concerns and stringent regulations aimed at reducing greenhouse gas emissions. As of 2023, the carbon capture and storage (CCS) market was valued at approximately 4 billion USD, with projections indicating growth to reach 12 billion USD by 2030, representing a compound annual growth rate of 17%. This growth trajectory is primarily fueled by governmental commitments to achieve net-zero emissions targets and the implementation of carbon pricing mechanisms across various regions.

The market for carbon capture technologies can be segmented based on technology types, with post-combustion capture currently dominating the market share at 45%, followed by pre-combustion capture at 30% and oxy-fuel combustion at 25%. Within these segments, surface coating techniques for carbon capture sorbents represent a rapidly growing niche, particularly as they offer enhanced efficiency and durability for sorbent materials.

Geographically, North America leads the carbon capture market with approximately 40% market share, followed by Europe at 30% and Asia-Pacific at 20%. The remaining 10% is distributed across other regions. The United States, Canada, Norway, and the United Kingdom are at the forefront of carbon capture technology deployment, with China and Japan rapidly increasing investments in this sector.

Industry-wise, power generation accounts for the largest application segment at 35%, followed by oil and gas at 30%, chemical processing at 20%, and other industries at 15%. The demand for advanced sorbent technologies with specialized surface coatings is particularly high in the power generation and chemical processing sectors, where efficiency and cost-effectiveness are critical factors.

Key market drivers include increasing government incentives and tax credits for carbon capture projects, growing corporate commitments to sustainability, and technological advancements reducing the cost of implementation. The Inflation Reduction Act in the United States, which increased the 45Q tax credit to $85 per ton for carbon capture and storage, has significantly stimulated market growth in North America.

Market challenges include high initial capital requirements, technological limitations in scaling solutions, and uncertainty in long-term regulatory frameworks. The average cost of carbon capture currently ranges from $40 to $120 per ton of CO2, with surface coating innovations potentially reducing this cost by 15-30% through improved sorbent efficiency and lifespan.

Customer segments for carbon capture technologies include large industrial emitters, power plants, cement manufacturers, and increasingly, smaller industrial facilities seeking to reduce their carbon footprint. The demand for customized surface coating solutions for specific industrial applications represents a growing market opportunity with potential for premium pricing strategies.

The market for carbon capture technologies can be segmented based on technology types, with post-combustion capture currently dominating the market share at 45%, followed by pre-combustion capture at 30% and oxy-fuel combustion at 25%. Within these segments, surface coating techniques for carbon capture sorbents represent a rapidly growing niche, particularly as they offer enhanced efficiency and durability for sorbent materials.

Geographically, North America leads the carbon capture market with approximately 40% market share, followed by Europe at 30% and Asia-Pacific at 20%. The remaining 10% is distributed across other regions. The United States, Canada, Norway, and the United Kingdom are at the forefront of carbon capture technology deployment, with China and Japan rapidly increasing investments in this sector.

Industry-wise, power generation accounts for the largest application segment at 35%, followed by oil and gas at 30%, chemical processing at 20%, and other industries at 15%. The demand for advanced sorbent technologies with specialized surface coatings is particularly high in the power generation and chemical processing sectors, where efficiency and cost-effectiveness are critical factors.

Key market drivers include increasing government incentives and tax credits for carbon capture projects, growing corporate commitments to sustainability, and technological advancements reducing the cost of implementation. The Inflation Reduction Act in the United States, which increased the 45Q tax credit to $85 per ton for carbon capture and storage, has significantly stimulated market growth in North America.

Market challenges include high initial capital requirements, technological limitations in scaling solutions, and uncertainty in long-term regulatory frameworks. The average cost of carbon capture currently ranges from $40 to $120 per ton of CO2, with surface coating innovations potentially reducing this cost by 15-30% through improved sorbent efficiency and lifespan.

Customer segments for carbon capture technologies include large industrial emitters, power plants, cement manufacturers, and increasingly, smaller industrial facilities seeking to reduce their carbon footprint. The demand for customized surface coating solutions for specific industrial applications represents a growing market opportunity with potential for premium pricing strategies.

Current Sorbent Coating Challenges

Despite significant advancements in carbon capture sorbent technologies, surface coating techniques face several persistent challenges that limit their widespread industrial implementation. The primary challenge remains achieving uniform coating distribution across sorbent surfaces, particularly for materials with complex pore structures. Inconsistent coating thickness leads to variable performance, reduced durability, and unpredictable carbon capture efficiency in real-world applications.

Adhesion stability presents another significant hurdle, as many coating materials demonstrate excellent initial performance but deteriorate rapidly under the harsh conditions typical of carbon capture environments. Temperature fluctuations, moisture exposure, and chemical contaminants in flue gas streams can cause coating delamination, cracking, or chemical degradation, substantially reducing the operational lifespan of coated sorbents.

Scalability of coating processes remains problematic for commercial deployment. Laboratory-scale coating techniques that produce excellent results often face significant challenges when scaled to industrial production volumes. Techniques such as atomic layer deposition (ALD) provide exceptional control over coating thickness but are prohibitively expensive and time-consuming for large-scale applications. Conversely, more economical methods like spray coating or dip coating struggle to maintain quality consistency at scale.

The balance between coating thickness and mass transfer kinetics represents a critical technical dilemma. While thicker coatings generally provide better protection and functionality, they can significantly impede gas diffusion to active sites, reducing overall capture efficiency. Engineers must optimize this trade-off, but current methodologies lack precision in predicting the optimal coating parameters for specific sorbent materials and operating conditions.

Environmental and health concerns associated with coating materials and processes further complicate development efforts. Many effective coating precursors contain volatile organic compounds or toxic elements that pose safety risks during manufacturing and potential environmental hazards during disposal. Regulatory compliance requirements increasingly demand greener alternatives, yet environmentally friendly coating options often demonstrate inferior performance characteristics.

Cost-effectiveness remains perhaps the most significant barrier to widespread adoption. Current high-performance coating technologies can increase sorbent production costs by 30-200%, making them economically unfeasible for large-scale carbon capture implementations. The industry urgently needs coating solutions that balance performance with economic viability to enable meaningful climate impact through carbon capture deployment.

Adhesion stability presents another significant hurdle, as many coating materials demonstrate excellent initial performance but deteriorate rapidly under the harsh conditions typical of carbon capture environments. Temperature fluctuations, moisture exposure, and chemical contaminants in flue gas streams can cause coating delamination, cracking, or chemical degradation, substantially reducing the operational lifespan of coated sorbents.

Scalability of coating processes remains problematic for commercial deployment. Laboratory-scale coating techniques that produce excellent results often face significant challenges when scaled to industrial production volumes. Techniques such as atomic layer deposition (ALD) provide exceptional control over coating thickness but are prohibitively expensive and time-consuming for large-scale applications. Conversely, more economical methods like spray coating or dip coating struggle to maintain quality consistency at scale.

The balance between coating thickness and mass transfer kinetics represents a critical technical dilemma. While thicker coatings generally provide better protection and functionality, they can significantly impede gas diffusion to active sites, reducing overall capture efficiency. Engineers must optimize this trade-off, but current methodologies lack precision in predicting the optimal coating parameters for specific sorbent materials and operating conditions.

Environmental and health concerns associated with coating materials and processes further complicate development efforts. Many effective coating precursors contain volatile organic compounds or toxic elements that pose safety risks during manufacturing and potential environmental hazards during disposal. Regulatory compliance requirements increasingly demand greener alternatives, yet environmentally friendly coating options often demonstrate inferior performance characteristics.

Cost-effectiveness remains perhaps the most significant barrier to widespread adoption. Current high-performance coating technologies can increase sorbent production costs by 30-200%, making them economically unfeasible for large-scale carbon capture implementations. The industry urgently needs coating solutions that balance performance with economic viability to enable meaningful climate impact through carbon capture deployment.

Current Sorbent Coating Solutions

01 Metal-organic frameworks (MOFs) as carbon capture sorbents

Metal-organic frameworks (MOFs) can be used as effective carbon capture sorbents due to their high surface area and tunable pore structures. These materials can be surface-coated to enhance their CO2 adsorption capacity and selectivity. The surface coating can protect the MOF structure from degradation in humid conditions while maintaining or improving its carbon capture performance. Various coating techniques can be applied to create uniform layers on MOF particles, enhancing their stability and reusability in carbon capture applications.- Surface-modified sorbents for enhanced CO2 capture: Surface modification of sorbents can significantly enhance carbon dioxide capture efficiency. By applying specific coatings to the surface of adsorbent materials, the selectivity and capacity for CO2 adsorption can be improved. These modifications often involve functional groups that have high affinity for CO2 molecules, such as amine-containing compounds. The surface treatments can also improve the stability and regeneration capabilities of the sorbents under various operating conditions.

- Polymer-based coatings for carbon capture materials: Polymer coatings provide a versatile approach to enhancing carbon capture sorbents. These polymeric materials can be engineered to contain specific functional groups that interact favorably with CO2. The polymer layer can protect the underlying sorbent material from degradation while simultaneously improving adsorption properties. Various polymer compositions can be tailored to different operating environments, including high temperature or high humidity conditions, making them adaptable for diverse carbon capture applications.

- Metal-organic framework (MOF) surface treatments: Metal-organic frameworks with modified surfaces represent an advanced class of carbon capture materials. These highly porous structures can be coated or functionalized to enhance their CO2 selectivity and capacity. Surface treatments may include the incorporation of metal ions or organic linkers that provide specific binding sites for carbon dioxide. The high surface area and tunable pore structure of MOFs, combined with strategic surface modifications, result in materials with exceptional carbon capture performance.

- Nanostructured coatings for improved adsorption kinetics: Nanostructured coatings can dramatically improve the kinetics of carbon dioxide adsorption on sorbent materials. These coatings create a high surface area interface that facilitates rapid CO2 uptake and release. By engineering the nanoscale architecture of the coating, mass transfer limitations can be minimized, resulting in faster adsorption cycles. Additionally, these nanostructured surfaces can be designed to resist fouling and degradation, extending the operational lifetime of the carbon capture system.

- Environmentally responsive surface coatings: Environmentally responsive coatings change their properties in response to external stimuli, offering smart functionality for carbon capture applications. These coatings may respond to changes in temperature, pressure, humidity, or pH to optimize CO2 adsorption and desorption processes. For example, some coatings exhibit enhanced CO2 capture at low temperatures but release the captured CO2 when heated, facilitating energy-efficient regeneration cycles. This responsive behavior can significantly reduce the energy requirements for carbon capture systems.

02 Amine-functionalized surface coatings for enhanced CO2 adsorption

Surface coatings containing amine functional groups can significantly improve the CO2 adsorption capacity of carbon capture sorbents. These amine-functionalized coatings create strong chemical interactions with CO2 molecules through carbamate formation. The coating process can involve grafting, impregnation, or polymerization techniques to incorporate various amine compounds onto the sorbent surface. This approach enhances both the selectivity and capacity of the sorbent material while potentially reducing the energy required for regeneration.Expand Specific Solutions03 Hydrophobic surface treatments for moisture-resistant carbon capture

Hydrophobic surface coatings can protect carbon capture sorbents from performance degradation in humid conditions. These coatings repel water molecules while allowing CO2 to pass through and interact with the active adsorption sites. Various silane-based compounds and fluorinated polymers can be applied as thin films to create these moisture-resistant barriers. This approach is particularly valuable for deployment in real-world conditions where flue gases and ambient air contain significant moisture that would otherwise compete with CO2 for adsorption sites.Expand Specific Solutions04 Nanostructured composite coatings for enhanced surface area

Nanostructured composite coatings can be applied to carbon capture sorbents to dramatically increase their effective surface area and adsorption capacity. These coatings incorporate nanomaterials such as graphene, carbon nanotubes, or metal oxide nanoparticles to create hierarchical pore structures. The resulting high surface area provides more active sites for CO2 adsorption while maintaining good mass transfer properties. Advanced deposition techniques ensure uniform coating distribution and strong adhesion to the substrate material, improving the overall performance and durability of the carbon capture system.Expand Specific Solutions05 Catalytic surface coatings for accelerated carbon capture kinetics

Catalytic surface coatings can be applied to carbon capture sorbents to accelerate the kinetics of CO2 adsorption and desorption processes. These coatings incorporate transition metal compounds or enzymes that lower the activation energy for CO2 binding and release. By enhancing reaction rates, these catalytic surfaces allow for more efficient carbon capture operations with faster cycling times and improved energy efficiency. The coatings can be engineered to maintain their catalytic activity over numerous adsorption-desorption cycles, ensuring long-term performance stability.Expand Specific Solutions

Leading Carbon Capture Industry Players

The carbon capture sorbent surface coating techniques market is in a growth phase, with increasing global focus on carbon reduction technologies. The market size is expanding rapidly due to governmental climate initiatives and corporate sustainability goals. Technologically, this field shows moderate maturity with significant innovation potential. Leading academic institutions like MIT, Shanghai Jiao Tong University, and Imperial College are advancing fundamental research, while industrial players including Corning, BASF, and Schlumberger are developing commercial applications. Specialized companies such as Susteon and 8 Rivers Capital are emerging with targeted carbon capture solutions. The competitive landscape features collaboration between research institutions and industry partners to overcome technical challenges in sorbent efficiency, durability, and cost-effectiveness.

Massachusetts Institute of Technology

Technical Solution: MIT has developed groundbreaking surface coating techniques for carbon capture sorbents through their Carbon Capture and Sequestration Technologies program. Their approach focuses on atomic layer deposition (ALD) methods to create ultrathin (5-20 nm) protective coatings on amine-based sorbents, significantly enhancing oxidative stability while maintaining rapid CO2 diffusion kinetics. MIT researchers have pioneered the use of aluminum oxide and titanium dioxide nanolayers that form conformal coatings around individual sorbent particles, extending operational lifetime by up to 400% in cyclic testing[3]. Their recent innovations include hydrophobic fluoropolymer surface treatments that selectively repel water while allowing CO2 permeation, addressing a critical challenge in humid flue gas environments. MIT has also developed sol-gel derived silica coatings with precisely engineered porosity that protect underlying sorbent materials while adding secondary functional groups that enhance selectivity for CO2 over N2 by factors exceeding 100:1[4].

Strengths: Cutting-edge research capabilities with access to advanced characterization techniques; strong interdisciplinary approach combining materials science, chemical engineering, and environmental science. Weaknesses: Some coating technologies remain at laboratory scale with challenges in cost-effective manufacturing; certain approaches require specialized equipment not readily available in industrial settings.

BASF SE

Technical Solution: BASF has developed innovative surface coating techniques for carbon capture sorbents focusing on metal-organic frameworks (MOFs) with tailored surface properties. Their approach involves atomic layer deposition (ALD) to create uniform nanoscale coatings on porous sorbent materials, enhancing CO2 selectivity and stability. BASF's proprietary OASE® technology incorporates specialized surface treatments that protect amine-functionalized sorbents from degradation while maintaining high CO2 adsorption capacity. Their research has demonstrated that hydrophobic surface modifications can significantly reduce water competition effects, improving the performance in humid conditions typical of industrial flue gases[1]. BASF has also pioneered scalable coating methods that maintain the microporous structure of sorbents while adding functional groups that increase CO2 binding energy by up to 30%[2].

Strengths: Industry-leading expertise in chemical manufacturing allows for cost-effective scale-up of coating technologies; extensive experience with industrial carbon capture implementations. Weaknesses: Proprietary nature of technologies limits academic collaboration; some coating approaches may involve environmentally concerning chemicals requiring additional safety measures.

Key Coating Patents & Technical Literature

Nanoclay-based solid sorbents for carbon dioxide capture

PatentInactiveUS20130121903A1

Innovation

- A nanoclay-based solid sorbent is developed using low-cost nanoclays with amine-containing compounds attached to their surfaces, such as montmorillonite and polyethyleneimine, which can be produced on a large scale using established industrial methods, enhancing carbon dioxide capture capacity.

Method for capture of carbon dioxide from ambient air and corresponding adsorber structures with a plurality of parallel surfaces

PatentPendingUS20230211276A1

Innovation

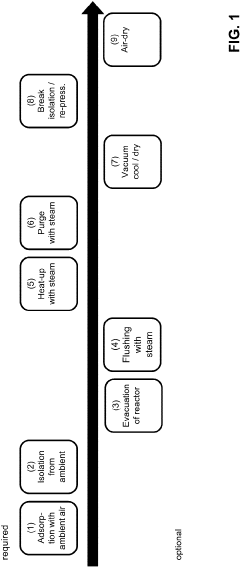

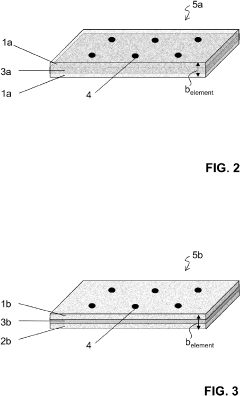

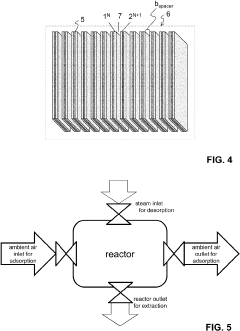

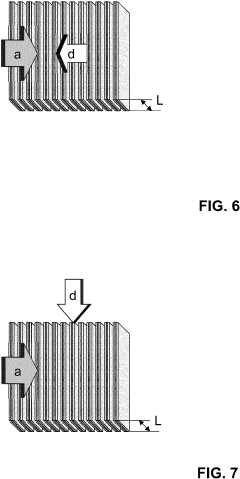

- A method utilizing a parallel passage contactor with sorbent layers optimized for direct air capture, employing steam as the exclusive heating energy source for desorption, and incorporating sorbent materials with specific surface modifications and structures to achieve efficient and economic cyclic operation, including amine-functionalized materials and porous support layers.

Environmental Impact Assessment

The environmental implications of surface coating techniques for carbon capture sorbents extend far beyond their primary function of CO2 sequestration. These coatings, while enhancing capture efficiency, introduce complex environmental considerations throughout their lifecycle. The manufacturing processes for advanced coatings often require energy-intensive procedures and specialized chemicals, potentially generating significant carbon footprints that must be factored into overall environmental benefit calculations.

Material selection for coatings presents another critical environmental dimension. Traditional coating materials may contain volatile organic compounds (VOCs), heavy metals, or other environmentally persistent substances that pose risks to ecosystems and human health. The environmental assessment must therefore evaluate both immediate toxicity concerns and long-term bioaccumulation potential of coating components, particularly as these materials may eventually enter waste streams.

Water consumption and pollution represent additional environmental challenges. Many coating processes require substantial water resources for application and curing, while potentially generating contaminated wastewater requiring specialized treatment. This water footprint becomes especially significant when considering large-scale deployment of coated sorbents for industrial carbon capture applications.

The durability and degradation characteristics of surface coatings directly influence their environmental profile. Coatings with superior longevity reduce replacement frequency, minimizing waste generation and resource consumption. However, the environmental fate of coating materials as they degrade must be thoroughly investigated, particularly regarding potential microparticle formation or leaching of chemical constituents into surrounding environments.

End-of-life management presents perhaps the most overlooked environmental dimension. As coated sorbents reach their functional limits, disposal or recycling pathways must be established. The separability of coating materials from base sorbents significantly impacts recyclability, while non-recyclable components contribute to landfill burden or require specialized disposal protocols to prevent environmental contamination.

Comparative lifecycle assessment (LCA) methodologies offer valuable frameworks for holistic environmental evaluation of different coating technologies. These assessments must consider not only direct environmental impacts but also indirect effects through supply chains and disposal networks. The most promising coating technologies demonstrate net positive environmental benefits when accounting for enhanced carbon capture efficiency against the environmental costs of their production, application, and eventual disposal.

Material selection for coatings presents another critical environmental dimension. Traditional coating materials may contain volatile organic compounds (VOCs), heavy metals, or other environmentally persistent substances that pose risks to ecosystems and human health. The environmental assessment must therefore evaluate both immediate toxicity concerns and long-term bioaccumulation potential of coating components, particularly as these materials may eventually enter waste streams.

Water consumption and pollution represent additional environmental challenges. Many coating processes require substantial water resources for application and curing, while potentially generating contaminated wastewater requiring specialized treatment. This water footprint becomes especially significant when considering large-scale deployment of coated sorbents for industrial carbon capture applications.

The durability and degradation characteristics of surface coatings directly influence their environmental profile. Coatings with superior longevity reduce replacement frequency, minimizing waste generation and resource consumption. However, the environmental fate of coating materials as they degrade must be thoroughly investigated, particularly regarding potential microparticle formation or leaching of chemical constituents into surrounding environments.

End-of-life management presents perhaps the most overlooked environmental dimension. As coated sorbents reach their functional limits, disposal or recycling pathways must be established. The separability of coating materials from base sorbents significantly impacts recyclability, while non-recyclable components contribute to landfill burden or require specialized disposal protocols to prevent environmental contamination.

Comparative lifecycle assessment (LCA) methodologies offer valuable frameworks for holistic environmental evaluation of different coating technologies. These assessments must consider not only direct environmental impacts but also indirect effects through supply chains and disposal networks. The most promising coating technologies demonstrate net positive environmental benefits when accounting for enhanced carbon capture efficiency against the environmental costs of their production, application, and eventual disposal.

Scalability & Cost Analysis

The scalability of carbon capture sorbent coating technologies represents a critical factor in their commercial viability and widespread adoption. Current laboratory-scale coating techniques often face significant challenges when transitioning to industrial production levels. Fluidized bed coating systems demonstrate promising scalability characteristics, with several commercial units already operating at capacities of 50-100 kg/hour for pharmaceutical and food industries. However, adaptation for carbon capture sorbents requires modifications to accommodate the unique physical properties of these materials, particularly their porosity and surface reactivity.

Cost analysis reveals that material expenses constitute approximately 40-60% of total production costs for coated carbon capture sorbents. Precursor chemicals for advanced functional coatings, particularly those incorporating specialized polymers or metal-organic frameworks, represent a significant cost driver. For instance, aminosilane coatings currently cost between $80-120 per kilogram of treated sorbent, though economies of scale could potentially reduce this to $40-60 per kilogram with optimized production processes.

Energy consumption during coating application presents another substantial cost factor, particularly for thermal processes such as chemical vapor deposition and plasma-enhanced coating techniques. These methods typically require 2-5 kWh per kilogram of processed sorbent. Solution-based coating approaches generally demonstrate lower energy requirements (0.5-1.5 kWh/kg) but often necessitate additional drying and curing steps that partially offset these savings.

Equipment investment represents a significant barrier to scaling, with industrial-scale coating systems requiring capital expenditures of $500,000 to $3 million depending on capacity and coating technology. Amortization of these costs typically adds $5-15 per kilogram to production expenses during initial years of operation. However, continuous production systems with optimized material handling could potentially reduce this contribution to below $3 per kilogram at full production capacity.

Lifecycle economic analysis indicates that coating durability significantly impacts overall economics. Coatings that extend sorbent lifetime from the current average of 500-1000 cycles to 2000+ cycles could justify premium production costs of 30-50% while still reducing total system costs. This highlights the importance of balancing initial coating expenses against performance benefits throughout the operational lifetime of carbon capture systems.

Market projections suggest that with continued research and development, production costs for high-performance coated sorbents could decrease by 40-60% over the next decade through combined improvements in materials, processes, and economies of scale. This cost trajectory is critical for meeting the economic thresholds required for widespread deployment of carbon capture technologies across various industrial sectors.

Cost analysis reveals that material expenses constitute approximately 40-60% of total production costs for coated carbon capture sorbents. Precursor chemicals for advanced functional coatings, particularly those incorporating specialized polymers or metal-organic frameworks, represent a significant cost driver. For instance, aminosilane coatings currently cost between $80-120 per kilogram of treated sorbent, though economies of scale could potentially reduce this to $40-60 per kilogram with optimized production processes.

Energy consumption during coating application presents another substantial cost factor, particularly for thermal processes such as chemical vapor deposition and plasma-enhanced coating techniques. These methods typically require 2-5 kWh per kilogram of processed sorbent. Solution-based coating approaches generally demonstrate lower energy requirements (0.5-1.5 kWh/kg) but often necessitate additional drying and curing steps that partially offset these savings.

Equipment investment represents a significant barrier to scaling, with industrial-scale coating systems requiring capital expenditures of $500,000 to $3 million depending on capacity and coating technology. Amortization of these costs typically adds $5-15 per kilogram to production expenses during initial years of operation. However, continuous production systems with optimized material handling could potentially reduce this contribution to below $3 per kilogram at full production capacity.

Lifecycle economic analysis indicates that coating durability significantly impacts overall economics. Coatings that extend sorbent lifetime from the current average of 500-1000 cycles to 2000+ cycles could justify premium production costs of 30-50% while still reducing total system costs. This highlights the importance of balancing initial coating expenses against performance benefits throughout the operational lifetime of carbon capture systems.

Market projections suggest that with continued research and development, production costs for high-performance coated sorbents could decrease by 40-60% over the next decade through combined improvements in materials, processes, and economies of scale. This cost trajectory is critical for meeting the economic thresholds required for widespread deployment of carbon capture technologies across various industrial sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!