Carbon Capture Sorbent Optimization for Renewable Energy

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Technology Evolution and Objectives

Carbon capture technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in response to growing environmental concerns. The initial development phase in the 1970s focused primarily on basic absorption processes using liquid amines, with limited efficiency and high energy penalties. By the 1990s, research expanded to include membrane separation and cryogenic techniques, broadening the technological landscape but still facing significant cost barriers.

The early 2000s marked a pivotal shift with increased attention to solid sorbents, including activated carbons, zeolites, and metal-organic frameworks (MOFs), which offered improved capacity and selectivity compared to traditional methods. This period also saw the emergence of the first large-scale demonstration projects, primarily in the power generation sector, establishing proof-of-concept for industrial implementation.

The past decade has witnessed accelerated innovation in sorbent materials, with particular emphasis on nanoporous structures and chemically modified surfaces that can selectively capture CO2 while minimizing energy requirements for regeneration. Concurrently, integration strategies with renewable energy systems have gained prominence, recognizing the potential synergies between intermittent renewable power and carbon capture processes.

Current technological objectives center on developing sorbent materials that combine high CO2 selectivity, rapid adsorption kinetics, and low regeneration energy requirements. Specifically, researchers aim to achieve capture costs below $50 per ton of CO2 by 2030, compared to current costs of $80-120 per ton, while maintaining capture efficiencies above 90%.

Another critical objective involves enhancing sorbent durability under real-world conditions, including resistance to contaminants and stability through multiple adsorption-desorption cycles. The target is to develop materials capable of maintaining performance through at least 10,000 cycles without significant degradation.

Integration with renewable energy systems represents a particularly promising direction, with objectives focused on developing sorbents optimized for operation with variable energy inputs. This includes materials with tunable adsorption properties that can capitalize on excess renewable energy during peak production periods and minimize energy consumption during shortfalls.

The ultimate goal extends beyond mere carbon neutrality to carbon negativity, with sorbent technologies designed to enable direct air capture at economically viable scales, potentially removing historical carbon emissions while supporting the transition to renewable energy systems.

The early 2000s marked a pivotal shift with increased attention to solid sorbents, including activated carbons, zeolites, and metal-organic frameworks (MOFs), which offered improved capacity and selectivity compared to traditional methods. This period also saw the emergence of the first large-scale demonstration projects, primarily in the power generation sector, establishing proof-of-concept for industrial implementation.

The past decade has witnessed accelerated innovation in sorbent materials, with particular emphasis on nanoporous structures and chemically modified surfaces that can selectively capture CO2 while minimizing energy requirements for regeneration. Concurrently, integration strategies with renewable energy systems have gained prominence, recognizing the potential synergies between intermittent renewable power and carbon capture processes.

Current technological objectives center on developing sorbent materials that combine high CO2 selectivity, rapid adsorption kinetics, and low regeneration energy requirements. Specifically, researchers aim to achieve capture costs below $50 per ton of CO2 by 2030, compared to current costs of $80-120 per ton, while maintaining capture efficiencies above 90%.

Another critical objective involves enhancing sorbent durability under real-world conditions, including resistance to contaminants and stability through multiple adsorption-desorption cycles. The target is to develop materials capable of maintaining performance through at least 10,000 cycles without significant degradation.

Integration with renewable energy systems represents a particularly promising direction, with objectives focused on developing sorbents optimized for operation with variable energy inputs. This includes materials with tunable adsorption properties that can capitalize on excess renewable energy during peak production periods and minimize energy consumption during shortfalls.

The ultimate goal extends beyond mere carbon neutrality to carbon negativity, with sorbent technologies designed to enable direct air capture at economically viable scales, potentially removing historical carbon emissions while supporting the transition to renewable energy systems.

Market Analysis for Carbon Capture in Renewable Energy

The global carbon capture market is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. Current market valuations place the carbon capture sector at approximately $2 billion in 2023, with projections indicating expansion to reach $7 billion by 2030, representing a compound annual growth rate of 19.6%. This growth trajectory is particularly pronounced in regions with stringent carbon pricing mechanisms, such as the European Union, Canada, and increasingly, parts of the United States and Asia.

Within the renewable energy sector, carbon capture technologies are gaining traction as complementary solutions that enhance the overall carbon neutrality profile of energy systems. The integration of carbon capture with biomass energy (BECCS) represents a particularly promising market segment, offering the potential for negative emissions while generating renewable power. This segment is expected to grow at 25% annually through 2028, outpacing the broader carbon capture market.

Demand drivers for carbon capture sorbents in renewable energy applications include the need for higher efficiency in carbon removal processes, reduced energy penalties, and lower operational costs. Industrial stakeholders are increasingly seeking sorbents that can operate effectively under the variable conditions typical of renewable energy generation, including fluctuating temperatures and gas compositions.

Market segmentation reveals distinct preferences across different renewable energy subsectors. Biomass energy facilities prioritize sorbents with high tolerance to impurities, while hydrogen production via renewable pathways demands sorbents with rapid adsorption-desorption cycles. Solar thermal power generation facilities are exploring integration with carbon capture systems that can utilize excess heat, creating a specialized market for thermally-responsive sorbents.

Geographically, North America currently leads the market for carbon capture in renewable energy applications, accounting for 38% of global deployments. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate at 27% annually through 2030, driven by China's aggressive decarbonization targets and significant investments in both renewable energy and carbon capture technologies.

Customer willingness to pay for advanced carbon capture sorbents varies significantly by application and region. Utility-scale renewable energy providers typically demonstrate price sensitivity, with cost considerations often outweighing performance advantages unless regulatory incentives are present. Conversely, premium segments such as green hydrogen production and corporate carbon removal initiatives show greater willingness to invest in higher-performance sorbent technologies, with price premiums of up to 40% for solutions that deliver verified improvements in capture efficiency or reduced regeneration energy requirements.

Within the renewable energy sector, carbon capture technologies are gaining traction as complementary solutions that enhance the overall carbon neutrality profile of energy systems. The integration of carbon capture with biomass energy (BECCS) represents a particularly promising market segment, offering the potential for negative emissions while generating renewable power. This segment is expected to grow at 25% annually through 2028, outpacing the broader carbon capture market.

Demand drivers for carbon capture sorbents in renewable energy applications include the need for higher efficiency in carbon removal processes, reduced energy penalties, and lower operational costs. Industrial stakeholders are increasingly seeking sorbents that can operate effectively under the variable conditions typical of renewable energy generation, including fluctuating temperatures and gas compositions.

Market segmentation reveals distinct preferences across different renewable energy subsectors. Biomass energy facilities prioritize sorbents with high tolerance to impurities, while hydrogen production via renewable pathways demands sorbents with rapid adsorption-desorption cycles. Solar thermal power generation facilities are exploring integration with carbon capture systems that can utilize excess heat, creating a specialized market for thermally-responsive sorbents.

Geographically, North America currently leads the market for carbon capture in renewable energy applications, accounting for 38% of global deployments. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate at 27% annually through 2030, driven by China's aggressive decarbonization targets and significant investments in both renewable energy and carbon capture technologies.

Customer willingness to pay for advanced carbon capture sorbents varies significantly by application and region. Utility-scale renewable energy providers typically demonstrate price sensitivity, with cost considerations often outweighing performance advantages unless regulatory incentives are present. Conversely, premium segments such as green hydrogen production and corporate carbon removal initiatives show greater willingness to invest in higher-performance sorbent technologies, with price premiums of up to 40% for solutions that deliver verified improvements in capture efficiency or reduced regeneration energy requirements.

Current Sorbent Technologies and Limitations

Carbon capture sorbent technologies have evolved significantly over the past decades, with several distinct categories currently dominating the market. Physical sorbents, including activated carbon, zeolites, and metal-organic frameworks (MOFs), operate primarily through physical adsorption mechanisms. These materials offer advantages in regeneration energy requirements but often suffer from limited selectivity and capacity under practical operating conditions.

Chemical sorbents, particularly amine-based materials such as monoethanolamine (MEA) and diethanolamine (DEA), represent the most commercially mature technology. These sorbents form chemical bonds with CO2, enabling high selectivity and capacity at low partial pressures. However, they face significant challenges including high regeneration energy penalties (3-4 GJ/ton CO2), corrosion issues, and degradation over multiple cycles.

Solid amine sorbents, which combine the benefits of physical supports with chemical functionality, have emerged as promising alternatives. These materials, including amine-functionalized silica and polymeric resins, offer improved stability and reduced regeneration energy requirements compared to liquid amines, but currently demonstrate lower overall capacity and higher production costs.

Novel materials such as ionic liquids and metal-organic frameworks represent cutting-edge developments with exceptional theoretical performance. MOFs in particular have demonstrated record-breaking CO2 uptake capacities exceeding 300 mg/g under laboratory conditions. However, these advanced materials face significant barriers to commercial implementation, including complex synthesis procedures, high material costs, and insufficient stability under industrial conditions.

A critical limitation across all current sorbent technologies is the performance degradation in the presence of contaminants commonly found in renewable energy applications. Water vapor, SOx, NOx, and particulate matter significantly reduce working capacity and accelerate degradation of most sorbent materials. This is particularly problematic for direct air capture applications and integration with biomass energy systems.

Scalability presents another major challenge, with most advanced sorbents currently limited to laboratory or small pilot scale production. The complex synthesis procedures and expensive precursors for high-performance materials like functionalized MOFs create economic barriers to widespread deployment. Current cost estimates for novel sorbent materials range from $50-200/kg, significantly higher than the $2-5/kg target needed for economic viability in renewable energy applications.

Regeneration efficiency remains a fundamental limitation, with even advanced solid sorbents requiring 2-3 GJ/ton CO2 for thermal regeneration. This energy penalty significantly impacts the overall efficiency of carbon capture systems integrated with renewable energy generation, creating a critical need for materials that can be regenerated using low-grade heat or alternative mechanisms.

Chemical sorbents, particularly amine-based materials such as monoethanolamine (MEA) and diethanolamine (DEA), represent the most commercially mature technology. These sorbents form chemical bonds with CO2, enabling high selectivity and capacity at low partial pressures. However, they face significant challenges including high regeneration energy penalties (3-4 GJ/ton CO2), corrosion issues, and degradation over multiple cycles.

Solid amine sorbents, which combine the benefits of physical supports with chemical functionality, have emerged as promising alternatives. These materials, including amine-functionalized silica and polymeric resins, offer improved stability and reduced regeneration energy requirements compared to liquid amines, but currently demonstrate lower overall capacity and higher production costs.

Novel materials such as ionic liquids and metal-organic frameworks represent cutting-edge developments with exceptional theoretical performance. MOFs in particular have demonstrated record-breaking CO2 uptake capacities exceeding 300 mg/g under laboratory conditions. However, these advanced materials face significant barriers to commercial implementation, including complex synthesis procedures, high material costs, and insufficient stability under industrial conditions.

A critical limitation across all current sorbent technologies is the performance degradation in the presence of contaminants commonly found in renewable energy applications. Water vapor, SOx, NOx, and particulate matter significantly reduce working capacity and accelerate degradation of most sorbent materials. This is particularly problematic for direct air capture applications and integration with biomass energy systems.

Scalability presents another major challenge, with most advanced sorbents currently limited to laboratory or small pilot scale production. The complex synthesis procedures and expensive precursors for high-performance materials like functionalized MOFs create economic barriers to widespread deployment. Current cost estimates for novel sorbent materials range from $50-200/kg, significantly higher than the $2-5/kg target needed for economic viability in renewable energy applications.

Regeneration efficiency remains a fundamental limitation, with even advanced solid sorbents requiring 2-3 GJ/ton CO2 for thermal regeneration. This energy penalty significantly impacts the overall efficiency of carbon capture systems integrated with renewable energy generation, creating a critical need for materials that can be regenerated using low-grade heat or alternative mechanisms.

State-of-the-Art Sorbent Optimization Approaches

01 Metal-organic frameworks (MOFs) for carbon capture

Metal-organic frameworks represent a promising class of sorbents for carbon capture due to their high surface area, tunable pore size, and customizable chemistry. These crystalline materials consist of metal ions coordinated to organic ligands, creating porous structures that can selectively adsorb CO2. Optimization strategies include incorporating open metal sites, functionalizing organic linkers, and developing hierarchical pore structures to enhance CO2 adsorption capacity and selectivity while maintaining stability under various operating conditions.- Metal-organic frameworks (MOFs) for carbon capture: Metal-organic frameworks are advanced porous materials that can be optimized for carbon capture applications. These materials offer high surface area and tunable pore structures that can be engineered to selectively adsorb CO2. By modifying the metal centers and organic linkers, researchers can enhance the CO2 adsorption capacity, selectivity, and regeneration efficiency of MOFs. These materials show promise for post-combustion carbon capture due to their customizable chemistry and structural properties.

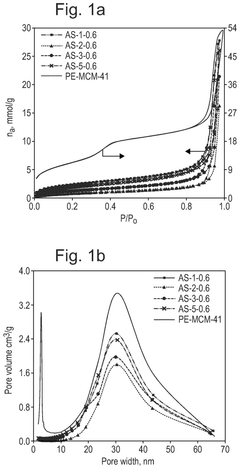

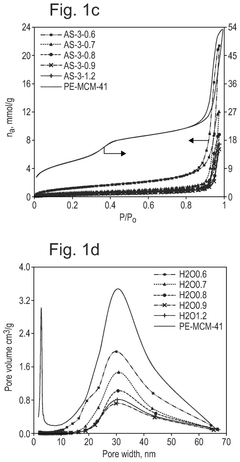

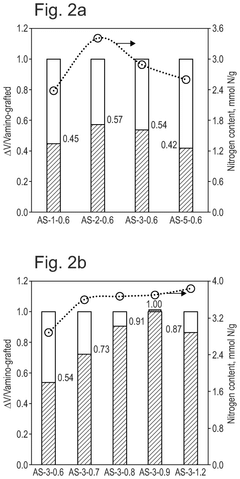

- Amine-functionalized sorbents: Amine-functionalized materials represent a significant class of carbon capture sorbents. These materials incorporate various amine groups onto support structures like silica, polymers, or porous carbons to enhance CO2 adsorption through chemical bonding. The optimization focuses on increasing amine loading, improving stability during multiple adsorption-desorption cycles, and reducing energy requirements for regeneration. Different types of amines (primary, secondary, tertiary) can be selected based on specific capture conditions and performance requirements.

- Novel composite and hybrid sorbent materials: Composite and hybrid materials combine different components to create sorbents with enhanced properties for carbon capture. These materials often integrate the benefits of multiple sorbent types, such as combining physical and chemical adsorption mechanisms. Examples include polymer-inorganic composites, layered double hydroxides, and hybrid membranes. The optimization of these materials focuses on improving the synergistic effects between components, enhancing mechanical stability, and maintaining performance under real-world conditions.

- Process optimization for sorbent regeneration: Optimizing the regeneration process is crucial for practical carbon capture applications. This involves developing methods to reduce the energy required to release captured CO2 from sorbents and preparing them for reuse. Techniques include temperature swing adsorption, pressure swing adsorption, vacuum swing adsorption, and combinations thereof. Advanced regeneration approaches may incorporate microwave heating, electrical swing adsorption, or steam stripping to improve energy efficiency and sorbent longevity across multiple capture cycles.

- Sorbent structural and morphological optimization: The physical structure and morphology of carbon capture sorbents significantly impact their performance. Optimization in this area focuses on controlling particle size, pore structure, surface area, and material density to enhance mass transfer, reduce pressure drop, and improve overall capture efficiency. Advanced manufacturing techniques like 3D printing, spray drying, and template-assisted synthesis are employed to create sorbents with optimized structures. These structural modifications can improve CO2 diffusion pathways, increase accessible adsorption sites, and enhance mechanical durability.

02 Amine-functionalized sorbents for enhanced CO2 capture

Amine-functionalized materials have shown exceptional performance in carbon capture applications due to their strong chemical affinity for CO2. These sorbents can be optimized by controlling the type, density, and distribution of amine groups on various support materials such as silica, polymers, or porous carbons. Optimization approaches include grafting different amine compounds, developing polyamine impregnation methods, and creating hybrid materials that combine physical and chemical adsorption mechanisms to maximize CO2 uptake while minimizing regeneration energy requirements.Expand Specific Solutions03 Zeolite and molecular sieve optimization for carbon capture

Zeolites and molecular sieves offer selective carbon capture capabilities through their well-defined pore structures and tunable chemical properties. Optimization techniques include ion exchange to modify framework cations, controlling the silicon-to-aluminum ratio, and developing composite structures with enhanced stability. These crystalline aluminosilicate materials can be tailored to achieve optimal CO2 adsorption kinetics, capacity, and selectivity over other gases, particularly in post-combustion capture applications where water vapor and other contaminants are present.Expand Specific Solutions04 Carbon-based sorbents with enhanced surface properties

Carbon-based materials including activated carbons, carbon nanotubes, and graphene derivatives can be optimized for CO2 capture through various surface modification techniques. These optimization approaches include chemical activation to increase porosity, nitrogen doping to create basic adsorption sites, and incorporation of metal nanoparticles to enhance CO2 binding. The advantages of carbon-based sorbents include high thermal stability, low cost, and excellent regenerability, making them particularly suitable for pressure swing adsorption systems and temperature swing adsorption processes.Expand Specific Solutions05 Process optimization and sorbent regeneration techniques

Beyond material design, process optimization plays a crucial role in carbon capture sorbent performance. This includes developing efficient regeneration methods such as temperature swing, pressure swing, and vacuum swing adsorption processes. Optimization strategies focus on minimizing energy requirements, reducing sorbent degradation during cycling, and enhancing overall system efficiency. Advanced approaches include hybrid processes combining multiple regeneration techniques, structured sorbent configurations to improve heat and mass transfer, and integration with existing industrial processes to utilize waste heat for sorbent regeneration.Expand Specific Solutions

Leading Organizations in Carbon Capture Sorbent Research

Carbon capture sorbent optimization for renewable energy is currently in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global carbon capture market is projected to reach $7-10 billion by 2030, driven by climate policies and net-zero commitments. Technologically, the field remains in development with varying maturity levels across different approaches. Leading players include established energy companies like ExxonMobil Technology & Engineering and Schlumberger, research institutions such as Korea Institute of Energy Research and Huaneng Clean Energy Research Institute, and specialized firms like Aker Carbon Capture and Susteon. Chinese institutions (China Petroleum & Chemical Corp., Zhejiang University) are increasingly active, while newer entrants like 280 Earth and TUM Carbon Removal Initiative are bringing innovative approaches to sorbent development for enhanced carbon capture efficiency.

Sintef TTO AS

Technical Solution: Sintef has pioneered advanced solid sorbent technologies specifically designed for carbon capture in renewable energy applications. Their approach centers on novel metal-organic frameworks (MOFs) and functionalized porous materials that demonstrate exceptional CO2 selectivity even in the presence of water vapor—a critical advantage for integration with biomass and other renewable energy systems. Sintef's proprietary sorbent formulations feature tailored pore structures and surface chemistry that enable rapid CO2 adsorption kinetics while maintaining stability through thousands of adsorption-desorption cycles. Their technology incorporates a temperature-swing adsorption process optimized for low-grade heat utilization, allowing efficient integration with waste heat streams from renewable energy facilities. Sintef has developed a modular system architecture that can be scaled from small distributed renewable installations to utility-scale operations, with demonstrated capture efficiencies exceeding 85% in field trials. Their latest generation sorbents show a remarkable 30% reduction in regeneration energy requirements compared to conventional amine-based systems, significantly improving the overall energy balance of the carbon capture process.

Strengths: Exceptional sorbent stability and performance in variable conditions typical of renewable energy systems; lower energy penalty for regeneration improves overall system efficiency; modular design enables flexible deployment across different scales. Weaknesses: Production of advanced sorbent materials at commercial scale remains challenging; higher initial material costs compared to conventional sorbents; requires precise process control to maintain optimal performance.

Susteon, Inc.

Technical Solution: Susteon has developed a revolutionary carbon capture platform specifically optimized for integration with renewable energy systems. Their technology employs structured sorbents with hierarchical pore architectures that maximize CO2 diffusion rates while minimizing pressure drop—critical factors for efficient operation with variable renewable energy sources. Susteon's proprietary sorbent formulations incorporate novel amine-functionalized silica materials that demonstrate exceptional CO2 selectivity even at the low concentrations found in many renewable energy applications. Their system features an innovative rapid-cycle temperature swing adsorption process that reduces regeneration energy requirements by up to 35% compared to conventional approaches. Susteon has pioneered a modular, containerized design that enables rapid deployment and scalability, making their technology particularly suitable for distributed renewable energy installations. Their latest generation system incorporates advanced process control algorithms that dynamically adjust operating parameters based on renewable energy availability, optimizing carbon capture performance during fluctuating conditions. Field demonstrations have shown sustained capture efficiencies above 90% while maintaining sorbent performance over thousands of cycles.

Strengths: Highly efficient sorbent materials specifically designed for renewable energy integration; modular design enables rapid deployment and scalability; advanced process control optimizes performance with variable renewable energy sources. Weaknesses: Limited large-scale commercial deployment history compared to established players; higher initial capital costs; requires specialized technical expertise for optimal operation and maintenance.

Key Patents and Breakthroughs in Sorbent Materials

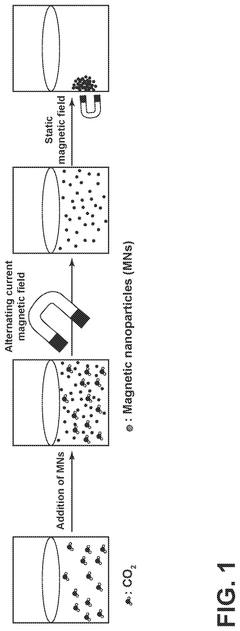

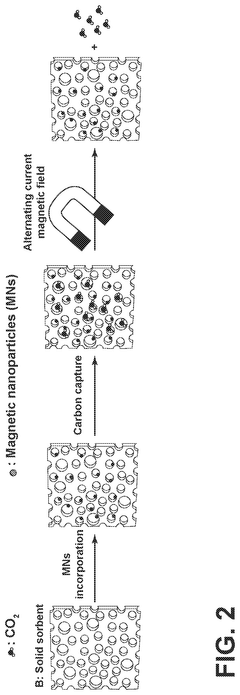

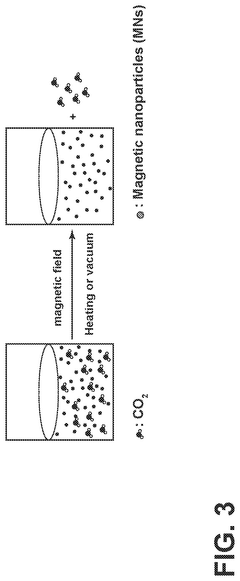

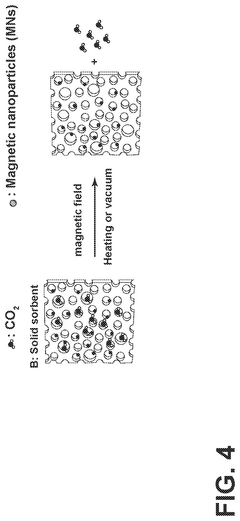

Carbon-capture sorbent regeneration by magnetic heating of nanoparticles

PatentPendingUS20250099901A1

Innovation

- The method employs magnetic nanoparticles to generate heat through a magnetic field, allowing for efficient regeneration of carbon-capture sorbents by releasing adsorbed carbon dioxide, thereby reducing energy costs and improving heat transfer efficiency.

sorbent

PatentPendingUS20250281904A1

Innovation

- Development of a solid sorbent comprising a silica support with covalently attached secondary amines confined inside its pores, optimized through controlled grafting and polymerization, achieving high amine density and stability.

Regulatory Framework for Carbon Capture Technologies

The regulatory landscape for carbon capture technologies is evolving rapidly as governments worldwide recognize the critical role these technologies play in meeting climate goals. The Paris Agreement has been instrumental in driving national policies that support carbon capture deployment, with many signatories incorporating carbon capture targets into their Nationally Determined Contributions (NDCs). These regulatory frameworks vary significantly across regions, creating a complex environment for technology developers and implementers.

In the United States, the 45Q tax credit provides substantial financial incentives for carbon capture projects, offering up to $50 per metric ton of CO2 permanently sequestered. Recent amendments through the Inflation Reduction Act have enhanced these incentives, lowering capture thresholds and increasing credit values. The EPA's Clean Air Act also regulates CO2 injection through the Underground Injection Control Program, establishing technical requirements for safe geological storage.

The European Union has established the EU Emissions Trading System (EU ETS) as its primary regulatory mechanism, creating a market-based approach to carbon pricing. The Innovation Fund specifically supports carbon capture projects, while the CCS Directive provides a legal framework for CO2 storage. Additionally, the European Green Deal and the Fit for 55 package have strengthened regulatory support for carbon capture technologies as essential components of the EU's decarbonization strategy.

In Asia, regulatory approaches vary widely. China has included carbon capture in its national climate strategy and is developing provincial carbon trading systems. Japan has implemented the Carbon Recycling Roadmap, providing regulatory guidance and financial support for carbon capture technologies. Meanwhile, Australia has established the Emissions Reduction Fund and developed specific regulations for offshore CO2 storage through the Offshore Petroleum and Greenhouse Gas Storage Act.

International standards for carbon capture technologies are emerging through organizations like ISO and the Global CCS Institute, addressing measurement, reporting, and verification protocols. These standards are crucial for ensuring consistency in carbon accounting and facilitating cross-border carbon capture projects and carbon credit trading.

For sorbent optimization specifically, regulations increasingly focus on environmental impact assessments, requiring developers to demonstrate minimal ecological footprints from sorbent production, use, and disposal. Chemical safety regulations like REACH in Europe and TSCA in the US impose additional requirements on novel sorbent materials, necessitating thorough toxicity testing and safety documentation before commercial deployment.

In the United States, the 45Q tax credit provides substantial financial incentives for carbon capture projects, offering up to $50 per metric ton of CO2 permanently sequestered. Recent amendments through the Inflation Reduction Act have enhanced these incentives, lowering capture thresholds and increasing credit values. The EPA's Clean Air Act also regulates CO2 injection through the Underground Injection Control Program, establishing technical requirements for safe geological storage.

The European Union has established the EU Emissions Trading System (EU ETS) as its primary regulatory mechanism, creating a market-based approach to carbon pricing. The Innovation Fund specifically supports carbon capture projects, while the CCS Directive provides a legal framework for CO2 storage. Additionally, the European Green Deal and the Fit for 55 package have strengthened regulatory support for carbon capture technologies as essential components of the EU's decarbonization strategy.

In Asia, regulatory approaches vary widely. China has included carbon capture in its national climate strategy and is developing provincial carbon trading systems. Japan has implemented the Carbon Recycling Roadmap, providing regulatory guidance and financial support for carbon capture technologies. Meanwhile, Australia has established the Emissions Reduction Fund and developed specific regulations for offshore CO2 storage through the Offshore Petroleum and Greenhouse Gas Storage Act.

International standards for carbon capture technologies are emerging through organizations like ISO and the Global CCS Institute, addressing measurement, reporting, and verification protocols. These standards are crucial for ensuring consistency in carbon accounting and facilitating cross-border carbon capture projects and carbon credit trading.

For sorbent optimization specifically, regulations increasingly focus on environmental impact assessments, requiring developers to demonstrate minimal ecological footprints from sorbent production, use, and disposal. Chemical safety regulations like REACH in Europe and TSCA in the US impose additional requirements on novel sorbent materials, necessitating thorough toxicity testing and safety documentation before commercial deployment.

Economic Viability and Scalability Assessment

The economic viability of carbon capture sorbent technologies for renewable energy applications hinges on several critical factors. Current cost analyses indicate that first-generation carbon capture technologies add approximately $50-90 per ton of CO2 captured, significantly impacting the levelized cost of energy production. For renewable energy integration, these costs must decrease to below $30 per ton to achieve commercial viability without substantial subsidies or carbon pricing mechanisms.

Material costs represent 40-60% of total sorbent expenses, with manufacturing processes accounting for the remainder. Novel sorbents such as metal-organic frameworks (MOFs) and amine-functionalized materials show promising capture efficiency but face economic barriers due to expensive precursors and complex synthesis requirements. Recent advancements in green synthesis methods have reduced production costs by 15-25%, though further optimization remains necessary.

Scalability presents another significant challenge. Laboratory-scale sorbents often demonstrate excellent performance characteristics that deteriorate when manufactured at industrial scales. The production capacity gap between current capabilities (hundreds of kilograms annually) and commercial requirements (thousands of tons) necessitates substantial process engineering innovations. Continuous flow manufacturing techniques have shown promise, increasing production volumes by factors of 10-50 while maintaining quality parameters.

Energy penalties associated with sorbent regeneration directly impact economic feasibility. Traditional temperature swing adsorption methods consume 2.5-3.5 GJ per ton of CO2 captured, whereas newer pressure-modulated approaches reduce this to 1.8-2.2 GJ per ton. This energy requirement must be further reduced to below 1.5 GJ per ton to achieve positive energy returns when integrated with renewable systems.

Infrastructure requirements for large-scale deployment present additional economic considerations. Capital expenditures for sorbent containment systems, regeneration equipment, and CO2 processing facilities range from $500-1,200 per kW of generation capacity. Modular designs have demonstrated potential cost reductions of 30-40% through standardization and economies of scale, particularly for distributed renewable energy applications.

Lifecycle economic assessment reveals that sorbent durability significantly impacts long-term viability. Current materials maintain optimal performance for 500-1,000 cycles before requiring replacement, whereas commercial viability demands 3,000-5,000 cycles. Recent innovations in sorbent stabilization have extended operational lifetimes by 40-60%, though further improvements remain essential for achieving positive return on investment within typical renewable energy project timeframes of 20-25 years.

Material costs represent 40-60% of total sorbent expenses, with manufacturing processes accounting for the remainder. Novel sorbents such as metal-organic frameworks (MOFs) and amine-functionalized materials show promising capture efficiency but face economic barriers due to expensive precursors and complex synthesis requirements. Recent advancements in green synthesis methods have reduced production costs by 15-25%, though further optimization remains necessary.

Scalability presents another significant challenge. Laboratory-scale sorbents often demonstrate excellent performance characteristics that deteriorate when manufactured at industrial scales. The production capacity gap between current capabilities (hundreds of kilograms annually) and commercial requirements (thousands of tons) necessitates substantial process engineering innovations. Continuous flow manufacturing techniques have shown promise, increasing production volumes by factors of 10-50 while maintaining quality parameters.

Energy penalties associated with sorbent regeneration directly impact economic feasibility. Traditional temperature swing adsorption methods consume 2.5-3.5 GJ per ton of CO2 captured, whereas newer pressure-modulated approaches reduce this to 1.8-2.2 GJ per ton. This energy requirement must be further reduced to below 1.5 GJ per ton to achieve positive energy returns when integrated with renewable systems.

Infrastructure requirements for large-scale deployment present additional economic considerations. Capital expenditures for sorbent containment systems, regeneration equipment, and CO2 processing facilities range from $500-1,200 per kW of generation capacity. Modular designs have demonstrated potential cost reductions of 30-40% through standardization and economies of scale, particularly for distributed renewable energy applications.

Lifecycle economic assessment reveals that sorbent durability significantly impacts long-term viability. Current materials maintain optimal performance for 500-1,000 cycles before requiring replacement, whereas commercial viability demands 3,000-5,000 cycles. Recent innovations in sorbent stabilization have extended operational lifetimes by 40-60%, though further improvements remain essential for achieving positive return on investment within typical renewable energy project timeframes of 20-25 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!