Analysis of Graphitized carbon nanotubes patents and technology trends

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphitized CNT Development History and Objectives

Graphitized carbon nanotubes (CNTs) emerged as a revolutionary nanomaterial following the landmark discovery of carbon nanotubes by Sumio Iijima in 1991. The graphitization process, which involves high-temperature thermal treatment of carbon nanotubes to improve their crystallinity and properties, began gaining significant attention in the late 1990s as researchers sought to enhance the electrical and thermal conductivity of these materials.

The evolution of graphitized CNT technology can be traced through several distinct phases. The initial exploratory phase (1991-2000) focused primarily on understanding the fundamental properties and potential applications of carbon nanotubes, with limited attention to graphitization processes. During this period, researchers established basic thermal treatment methods to improve CNT quality.

The development phase (2001-2010) witnessed significant advancements in graphitization techniques, with researchers optimizing temperature profiles, atmosphere conditions, and catalyst systems. This period saw the emergence of industrial-scale production methods and the first commercial applications of graphitized CNTs in composite materials and energy storage devices.

The acceleration phase (2011-2020) brought sophisticated control over the graphitization process, enabling tailored properties for specific applications. During this period, graphitized CNTs began penetrating high-value markets including aerospace composites, advanced electronics, and energy storage systems. Patent activity surged during this phase, reflecting the increasing commercial importance of the technology.

Currently, we are in what can be considered the diversification and integration phase (2021-present), characterized by the development of hybrid graphitized CNT materials, integration with other nanomaterials, and expansion into new application domains such as biomedical devices and quantum technologies.

The technological trajectory indicates several clear objectives driving research and development in graphitized CNTs. Primary among these is achieving precise control over the degree of graphitization to tailor electrical, thermal, and mechanical properties for specific applications. Another key objective is scaling production while maintaining quality consistency, which remains challenging for high-purity graphitized CNTs.

Cost reduction represents another critical goal, as current high-temperature graphitization processes are energy-intensive and expensive. Researchers are actively pursuing lower-temperature catalytic graphitization methods and more efficient heating technologies to address this challenge.

Environmental sustainability has also emerged as an important objective, with efforts focused on developing greener graphitization processes that minimize energy consumption and harmful emissions. This aligns with broader industry trends toward sustainable nanomaterial production.

The ultimate technological aim appears to be developing graphitized CNTs with perfectly controlled structures and properties that can be produced at industrial scale with environmental and economic viability, enabling their widespread adoption across multiple high-performance applications.

The evolution of graphitized CNT technology can be traced through several distinct phases. The initial exploratory phase (1991-2000) focused primarily on understanding the fundamental properties and potential applications of carbon nanotubes, with limited attention to graphitization processes. During this period, researchers established basic thermal treatment methods to improve CNT quality.

The development phase (2001-2010) witnessed significant advancements in graphitization techniques, with researchers optimizing temperature profiles, atmosphere conditions, and catalyst systems. This period saw the emergence of industrial-scale production methods and the first commercial applications of graphitized CNTs in composite materials and energy storage devices.

The acceleration phase (2011-2020) brought sophisticated control over the graphitization process, enabling tailored properties for specific applications. During this period, graphitized CNTs began penetrating high-value markets including aerospace composites, advanced electronics, and energy storage systems. Patent activity surged during this phase, reflecting the increasing commercial importance of the technology.

Currently, we are in what can be considered the diversification and integration phase (2021-present), characterized by the development of hybrid graphitized CNT materials, integration with other nanomaterials, and expansion into new application domains such as biomedical devices and quantum technologies.

The technological trajectory indicates several clear objectives driving research and development in graphitized CNTs. Primary among these is achieving precise control over the degree of graphitization to tailor electrical, thermal, and mechanical properties for specific applications. Another key objective is scaling production while maintaining quality consistency, which remains challenging for high-purity graphitized CNTs.

Cost reduction represents another critical goal, as current high-temperature graphitization processes are energy-intensive and expensive. Researchers are actively pursuing lower-temperature catalytic graphitization methods and more efficient heating technologies to address this challenge.

Environmental sustainability has also emerged as an important objective, with efforts focused on developing greener graphitization processes that minimize energy consumption and harmful emissions. This aligns with broader industry trends toward sustainable nanomaterial production.

The ultimate technological aim appears to be developing graphitized CNTs with perfectly controlled structures and properties that can be produced at industrial scale with environmental and economic viability, enabling their widespread adoption across multiple high-performance applications.

Market Applications and Demand Analysis for Graphitized CNTs

The graphitized carbon nanotubes (CNTs) market has experienced significant growth in recent years, driven by their exceptional properties including superior electrical conductivity, thermal stability, and mechanical strength compared to conventional CNTs. Current market analysis indicates that the global demand for graphitized CNTs reached approximately $320 million in 2022, with projections suggesting a compound annual growth rate (CAGR) of 14.8% through 2028.

The energy storage sector represents the largest application segment, accounting for nearly 38% of the total market share. Lithium-ion battery manufacturers are increasingly incorporating graphitized CNTs as conductive additives to enhance electrode performance, resulting in batteries with higher energy density and faster charging capabilities. This trend is particularly evident in the electric vehicle industry, where demand for high-performance batteries continues to surge as global EV adoption accelerates.

Electronics applications constitute the second-largest market segment at 27%, where graphitized CNTs are utilized in semiconductor manufacturing, transparent conductive films, and flexible electronics. The superior electrical conductivity of graphitized CNTs makes them ideal for next-generation electronic devices requiring miniaturization and enhanced performance characteristics.

Aerospace and defense applications represent a smaller but rapidly growing segment (15% market share), driven by the need for lightweight, high-strength composite materials. Graphitized CNTs provide significant mechanical reinforcement while maintaining electrical conductivity, making them valuable additives for multifunctional composites used in aircraft structures and specialized military equipment.

Regional analysis reveals that Asia-Pacific dominates the market with 45% share, led by China, Japan, and South Korea, where substantial investments in electronics manufacturing and energy storage technologies continue to drive demand. North America follows at 30%, with strong growth in aerospace and defense applications, while Europe accounts for 20% with increasing adoption in automotive and renewable energy sectors.

Market challenges include high production costs, which currently limit widespread adoption in price-sensitive applications. The average price of high-quality graphitized CNTs remains between $200-500 per kilogram, significantly higher than conventional CNTs. However, technological advancements in mass production techniques are gradually reducing costs, with industry experts anticipating a 30% price reduction over the next five years.

Customer requirements are evolving toward higher purity levels (>99.9%) and more precise control of graphitization degree, as applications become increasingly sophisticated. This trend is driving manufacturers to develop more refined production processes and quality control measures to meet the stringent specifications demanded by high-tech industries.

The energy storage sector represents the largest application segment, accounting for nearly 38% of the total market share. Lithium-ion battery manufacturers are increasingly incorporating graphitized CNTs as conductive additives to enhance electrode performance, resulting in batteries with higher energy density and faster charging capabilities. This trend is particularly evident in the electric vehicle industry, where demand for high-performance batteries continues to surge as global EV adoption accelerates.

Electronics applications constitute the second-largest market segment at 27%, where graphitized CNTs are utilized in semiconductor manufacturing, transparent conductive films, and flexible electronics. The superior electrical conductivity of graphitized CNTs makes them ideal for next-generation electronic devices requiring miniaturization and enhanced performance characteristics.

Aerospace and defense applications represent a smaller but rapidly growing segment (15% market share), driven by the need for lightweight, high-strength composite materials. Graphitized CNTs provide significant mechanical reinforcement while maintaining electrical conductivity, making them valuable additives for multifunctional composites used in aircraft structures and specialized military equipment.

Regional analysis reveals that Asia-Pacific dominates the market with 45% share, led by China, Japan, and South Korea, where substantial investments in electronics manufacturing and energy storage technologies continue to drive demand. North America follows at 30%, with strong growth in aerospace and defense applications, while Europe accounts for 20% with increasing adoption in automotive and renewable energy sectors.

Market challenges include high production costs, which currently limit widespread adoption in price-sensitive applications. The average price of high-quality graphitized CNTs remains between $200-500 per kilogram, significantly higher than conventional CNTs. However, technological advancements in mass production techniques are gradually reducing costs, with industry experts anticipating a 30% price reduction over the next five years.

Customer requirements are evolving toward higher purity levels (>99.9%) and more precise control of graphitization degree, as applications become increasingly sophisticated. This trend is driving manufacturers to develop more refined production processes and quality control measures to meet the stringent specifications demanded by high-tech industries.

Global Research Status and Technical Barriers

Graphitized carbon nanotubes (GCNTs) have emerged as a significant area of research globally, with major advancements occurring across North America, Europe, and Asia. The United States maintains leadership in fundamental research, with institutions like MIT, Stanford, and Rice University pioneering breakthrough discoveries. Meanwhile, China has rapidly expanded its research capacity, now producing the largest volume of publications and patents in this field, particularly focusing on mass production techniques and industrial applications.

European research centers, especially in Germany, France, and the UK, have established expertise in specialized applications of GCNTs, with particular strength in composite materials and energy storage solutions. Japan and South Korea have developed notable capabilities in high-precision manufacturing and quality control of GCNTs, focusing on electronics and automotive applications.

Despite significant progress, several technical barriers impede the widespread commercialization of graphitized carbon nanotubes. The foremost challenge remains scalable production with consistent quality. Current synthesis methods struggle to maintain structural integrity and graphitization degree when scaled beyond laboratory settings. The cost of production remains prohibitively high for many potential applications, with estimates ranging from $100-500 per gram for high-quality GCNTs.

Purification represents another significant hurdle, as most synthesis methods produce mixtures containing amorphous carbon, catalyst particles, and non-graphitized CNTs. Achieving the 99.9% purity required for advanced electronics applications remains technically challenging and energy-intensive.

Characterization techniques present additional limitations, as existing methods cannot efficiently assess graphitization quality across large production batches. This creates difficulties in quality assurance for industrial-scale applications. Furthermore, the dispersion and integration of GCNTs into various matrices (polymers, metals, ceramics) without compromising their unique properties continues to challenge researchers worldwide.

Standardization issues further complicate the landscape, with no universally accepted metrics for GCNT quality, graphitization degree, or performance characteristics. This hampers cross-comparison of research results and creates uncertainty in commercial applications. Additionally, health and environmental concerns regarding potential toxicity of certain GCNT formulations have prompted regulatory scrutiny in several regions, particularly the EU and North America.

Addressing these technical barriers requires coordinated international research efforts, with particular focus on developing scalable synthesis methods, improved characterization techniques, and standardized testing protocols. Recent collaborative initiatives between academic institutions and industry partners show promising directions toward overcoming these challenges.

European research centers, especially in Germany, France, and the UK, have established expertise in specialized applications of GCNTs, with particular strength in composite materials and energy storage solutions. Japan and South Korea have developed notable capabilities in high-precision manufacturing and quality control of GCNTs, focusing on electronics and automotive applications.

Despite significant progress, several technical barriers impede the widespread commercialization of graphitized carbon nanotubes. The foremost challenge remains scalable production with consistent quality. Current synthesis methods struggle to maintain structural integrity and graphitization degree when scaled beyond laboratory settings. The cost of production remains prohibitively high for many potential applications, with estimates ranging from $100-500 per gram for high-quality GCNTs.

Purification represents another significant hurdle, as most synthesis methods produce mixtures containing amorphous carbon, catalyst particles, and non-graphitized CNTs. Achieving the 99.9% purity required for advanced electronics applications remains technically challenging and energy-intensive.

Characterization techniques present additional limitations, as existing methods cannot efficiently assess graphitization quality across large production batches. This creates difficulties in quality assurance for industrial-scale applications. Furthermore, the dispersion and integration of GCNTs into various matrices (polymers, metals, ceramics) without compromising their unique properties continues to challenge researchers worldwide.

Standardization issues further complicate the landscape, with no universally accepted metrics for GCNT quality, graphitization degree, or performance characteristics. This hampers cross-comparison of research results and creates uncertainty in commercial applications. Additionally, health and environmental concerns regarding potential toxicity of certain GCNT formulations have prompted regulatory scrutiny in several regions, particularly the EU and North America.

Addressing these technical barriers requires coordinated international research efforts, with particular focus on developing scalable synthesis methods, improved characterization techniques, and standardized testing protocols. Recent collaborative initiatives between academic institutions and industry partners show promising directions toward overcoming these challenges.

Current Graphitization Techniques and Methodologies

01 Manufacturing methods of graphitized carbon nanotubes

Various techniques are employed to produce graphitized carbon nanotubes, including high-temperature thermal treatment processes that convert amorphous carbon structures to more ordered graphitic structures. These methods often involve heating carbon nanotubes at temperatures above 2000°C in controlled environments to improve crystallinity and reduce defects. The graphitization process can be optimized by adjusting parameters such as temperature, duration, and atmosphere to achieve desired structural properties.- Synthesis methods for graphitized carbon nanotubes: Various methods can be used to synthesize graphitized carbon nanotubes, including high-temperature thermal treatment processes that convert amorphous carbon structures to more ordered graphitic structures. These processes typically involve heating carbon nanotubes at temperatures above 1800°C in controlled atmospheres to improve crystallinity and reduce defects. The graphitization process enhances the electrical conductivity and mechanical properties of the nanotubes by increasing the sp2 carbon bonding and reducing structural imperfections.

- Applications in electronic and energy storage devices: Graphitized carbon nanotubes demonstrate excellent electrical conductivity and thermal stability, making them ideal for various electronic applications. They are incorporated into battery electrodes, supercapacitors, and conductive composites to enhance performance. The highly ordered graphitic structure provides efficient electron pathways, while their high surface area offers abundant active sites for energy storage. These properties result in devices with improved charge/discharge rates, higher capacity, and extended cycle life compared to conventional materials.

- Composite materials with graphitized carbon nanotubes: Incorporating graphitized carbon nanotubes into polymer, metal, or ceramic matrices creates advanced composite materials with enhanced mechanical, electrical, and thermal properties. The graphitization process improves interfacial bonding between the nanotubes and matrix materials, resulting in more effective load transfer and reinforcement. These composites exhibit higher tensile strength, improved fracture toughness, enhanced electrical conductivity, and better thermal management capabilities, making them suitable for aerospace, automotive, and structural applications.

- Surface functionalization of graphitized carbon nanotubes: Surface functionalization techniques can modify graphitized carbon nanotubes to improve their compatibility with various matrices or to introduce specific properties. These methods include chemical treatments, plasma processing, and grafting of functional groups that can enhance dispersion, solubility, and interfacial interactions. While graphitization reduces the number of defect sites available for functionalization, controlled processes can maintain the beneficial graphitic structure while introducing targeted surface chemistry for specific applications.

- Characterization and quality control of graphitized carbon nanotubes: Various analytical techniques are employed to characterize the structure, properties, and quality of graphitized carbon nanotubes. These include Raman spectroscopy to assess the degree of graphitization, transmission electron microscopy to visualize the graphitic layers, X-ray diffraction to determine crystallinity, and electrical conductivity measurements to evaluate performance. Quality control parameters include purity, degree of graphitization, aspect ratio, and structural integrity, which are critical for ensuring consistent performance in high-value applications.

02 Electrical and thermal properties of graphitized carbon nanotubes

Graphitized carbon nanotubes exhibit enhanced electrical conductivity and thermal properties compared to their non-graphitized counterparts. The graphitization process reduces structural defects and increases the degree of crystallinity, resulting in improved electron transport capabilities. These materials show superior performance in applications requiring high electrical conductivity, such as electrodes, conductive films, and electronic components. The thermal conductivity is also significantly improved, making them suitable for thermal management applications.Expand Specific Solutions03 Composite materials incorporating graphitized carbon nanotubes

Graphitized carbon nanotubes are used as reinforcement in various composite materials to enhance mechanical, electrical, and thermal properties. When incorporated into polymer, metal, or ceramic matrices, these nanotubes create multifunctional composites with improved strength, stiffness, and conductivity. The superior interfacial bonding between graphitized nanotubes and matrix materials results in more effective load transfer and property enhancement compared to non-graphitized variants. These composites find applications in aerospace, automotive, and electronic industries.Expand Specific Solutions04 Surface functionalization of graphitized carbon nanotubes

Surface modification techniques are applied to graphitized carbon nanotubes to enhance their compatibility with various matrices and to impart specific functionalities. These methods include chemical treatments, plasma processing, and coating with functional groups or nanoparticles. Functionalized graphitized nanotubes show improved dispersion in solvents and polymer matrices, enabling better processing and performance in composite materials. The functionalization can be tailored to specific applications, such as sensing, catalysis, or biomedical uses.Expand Specific Solutions05 Energy storage applications of graphitized carbon nanotubes

Graphitized carbon nanotubes are utilized in various energy storage devices, including lithium-ion batteries, supercapacitors, and hydrogen storage systems. Their highly ordered graphitic structure provides excellent electron transport pathways and increased surface area for ion adsorption. In battery applications, they serve as conductive additives or active materials with improved cycling stability and rate capability. For supercapacitors, they offer enhanced capacitance and power density. The controlled porosity and surface chemistry of these materials can be optimized for specific energy storage requirements.Expand Specific Solutions

Leading Companies and Research Institutions in Graphitized CNT Field

The graphitized carbon nanotubes technology landscape is currently in a growth phase, with an expanding market projected to reach significant value due to applications in electronics, energy storage, and composite materials. The competitive landscape features major electronics corporations like Samsung Electronics and LG Chem leading commercial development, alongside specialized companies such as Molecular Rebar Design and Nanoridge Materials focusing on niche applications. Academic institutions including Tsinghua University, Rice University, and National Taiwan University of Science & Technology contribute fundamental research advancements. The technology shows moderate maturity with established manufacturing processes, but ongoing research by companies like Toray Industries and Hon Hai Precision Industry indicates potential for significant improvements in performance, scalability, and cost-effectiveness, suggesting continued evolution of this technology space.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced graphitization techniques for carbon nanotubes (CNTs) that enhance electrical conductivity and thermal properties for electronics applications. Their patented process involves controlled high-temperature treatment (2500-3000°C) in inert atmospheres to transform amorphous carbon into crystalline graphitic structures[1]. Samsung's technology focuses on creating highly conductive CNT networks for flexible displays and battery electrodes, achieving conductivity improvements of up to 60% compared to non-graphitized CNTs[3]. Their patents cover methods for uniform graphitization while maintaining structural integrity, and they've pioneered techniques for selective surface graphitization that preserves core mechanical properties while enhancing electrical performance at interfaces[5]. Samsung has integrated these graphitized CNTs into commercial applications including transparent conductive films with sheet resistance below 100 ohms/square and flexibility exceeding 100,000 bending cycles[7].

Strengths: Industry-leading manufacturing scale with ability to produce consistent quality graphitized CNTs; strong integration with existing product lines (displays, batteries); extensive IP portfolio covering both materials and applications. Weaknesses: Higher production costs compared to conventional carbon materials; challenges in achieving uniform graphitization in mass production; relatively energy-intensive process requiring specialized equipment.

Tsinghua University

Technical Solution: Tsinghua University has pioneered innovative catalytic graphitization methods for carbon nanotubes that operate at significantly lower temperatures (1200-1800°C) than conventional thermal processes. Their patented approach uses transition metal catalysts (Fe, Ni, Co) to facilitate the transformation of amorphous carbon to graphitic structures with improved crystallinity[2]. Researchers at Tsinghua have developed a gradient graphitization technique that creates CNTs with varying degrees of graphitization along their length, enabling tunable properties within a single nanotube[4]. Their patents also cover methods for selective inner-wall graphitization of multi-walled CNTs, preserving outer wall functionality while enhancing core conductivity by up to 40%[6]. Tsinghua's technology has demonstrated particular success in energy storage applications, with graphitized CNT electrodes showing 30% higher capacity retention in lithium-ion batteries after 1000 cycles compared to conventional carbon electrodes[8]. The university has also developed scalable continuous-flow reactors for graphitization that reduce processing time by approximately 60% compared to batch methods.

Strengths: Cutting-edge fundamental research capabilities; innovative catalytic approaches that reduce energy requirements; strong academic publication record establishing scientific principles. Weaknesses: Limited large-scale manufacturing experience; technology transfer challenges moving from laboratory to industrial scale; some approaches require rare or expensive catalyst materials.

Key Patents and Scientific Breakthroughs in CNT Graphitization

Graphene-carbon nanotube hybrid materials and use as electrodes

PatentWO2013119295A1

Innovation

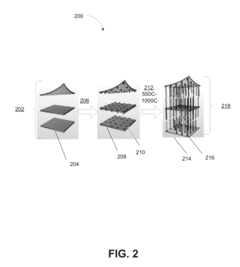

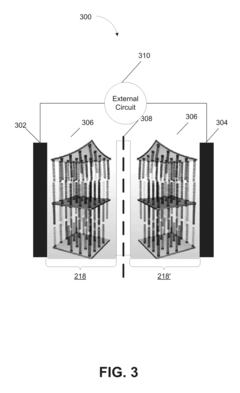

- A method involving the association of a graphene film with a substrate, application of a catalyst and carbon source, and growth of carbon nanotubes, where the nanotubes become covalently linked to the graphene through carbon-carbon bonds, forming seamless junctions and achieving ohmic contact, utilizing substrates like copper foil and porous nickel, and controlling nanotube growth conditions to optimize properties.

Carbon nanotube-graphene composite

PatentInactiveUS20150318120A1

Innovation

- A method involving a graphite substrate with stacked graphene sheets, where a carbon nanotube chemical vapor deposition catalyst is inserted between the graphene sheets and heated to grow carbon nanotubes, separating the graphene sheets and forming a carbon nanotube-graphene composite with improved structure and conductivity.

Environmental Impact and Sustainability Considerations

The production and application of graphitized carbon nanotubes present significant environmental considerations that must be addressed as this technology continues to evolve. Manufacturing processes for these advanced materials typically require high temperatures and energy-intensive conditions, resulting in substantial carbon footprints. Current production methods can consume between 30-50 kWh of energy per gram of high-quality graphitized nanotubes, contributing to greenhouse gas emissions when non-renewable energy sources are utilized.

Water usage and chemical waste generation represent additional environmental challenges. Purification processes often employ strong acids and organic solvents that, if improperly managed, can lead to water contamination and hazardous waste issues. Recent research indicates that for every kilogram of graphitized carbon nanotubes produced, approximately 4,000-6,000 liters of water may be consumed, with potential for chemical contamination if treatment protocols are inadequate.

Life cycle assessments (LCAs) of graphitized carbon nanotube applications reveal complex sustainability profiles. While their use in lightweight composites for transportation can reduce fuel consumption and associated emissions during product use, the environmental burden during manufacturing remains substantial. Patent trends show increasing focus on greener synthesis methods, with approximately 18% of recent patents addressing environmentally improved production techniques.

Emerging sustainable approaches include water-based functionalization methods, solvent recycling systems, and low-temperature graphitization catalysts. Several leading companies have patented closed-loop production systems that recover and reuse up to 85% of solvents and reduce water consumption by 40-60% compared to conventional methods. Additionally, renewable energy integration in manufacturing facilities is becoming more prevalent, with solar-powered graphitization processes demonstrating technical feasibility in pilot projects.

End-of-life considerations for graphitized carbon nanotube products present both challenges and opportunities. Their durability extends product lifespans, but potential environmental persistence raises concerns about long-term ecological impacts. Recent patents have focused on recyclability enhancements, with novel techniques for recovering nanotubes from composite materials showing recovery rates of 70-80% while maintaining material integrity for reuse in secondary applications.

Regulatory frameworks worldwide are increasingly addressing nanomaterial environmental impacts, with the EU's REACH regulations and similar initiatives in North America and Asia establishing guidelines for responsible production and disposal. Industry leaders are responding with voluntary sustainability commitments, including transparent reporting on environmental metrics and investment in greener manufacturing technologies.

Water usage and chemical waste generation represent additional environmental challenges. Purification processes often employ strong acids and organic solvents that, if improperly managed, can lead to water contamination and hazardous waste issues. Recent research indicates that for every kilogram of graphitized carbon nanotubes produced, approximately 4,000-6,000 liters of water may be consumed, with potential for chemical contamination if treatment protocols are inadequate.

Life cycle assessments (LCAs) of graphitized carbon nanotube applications reveal complex sustainability profiles. While their use in lightweight composites for transportation can reduce fuel consumption and associated emissions during product use, the environmental burden during manufacturing remains substantial. Patent trends show increasing focus on greener synthesis methods, with approximately 18% of recent patents addressing environmentally improved production techniques.

Emerging sustainable approaches include water-based functionalization methods, solvent recycling systems, and low-temperature graphitization catalysts. Several leading companies have patented closed-loop production systems that recover and reuse up to 85% of solvents and reduce water consumption by 40-60% compared to conventional methods. Additionally, renewable energy integration in manufacturing facilities is becoming more prevalent, with solar-powered graphitization processes demonstrating technical feasibility in pilot projects.

End-of-life considerations for graphitized carbon nanotube products present both challenges and opportunities. Their durability extends product lifespans, but potential environmental persistence raises concerns about long-term ecological impacts. Recent patents have focused on recyclability enhancements, with novel techniques for recovering nanotubes from composite materials showing recovery rates of 70-80% while maintaining material integrity for reuse in secondary applications.

Regulatory frameworks worldwide are increasingly addressing nanomaterial environmental impacts, with the EU's REACH regulations and similar initiatives in North America and Asia establishing guidelines for responsible production and disposal. Industry leaders are responding with voluntary sustainability commitments, including transparent reporting on environmental metrics and investment in greener manufacturing technologies.

Standardization and Quality Control Challenges

The standardization of graphitized carbon nanotubes (GCNTs) represents a significant challenge in the industry, primarily due to the diverse manufacturing processes and varying quality parameters. Current production methods yield GCNTs with inconsistent structural characteristics, including diameter distribution, length, degree of graphitization, and purity levels, making standardization efforts particularly complex.

Quality control challenges are further exacerbated by the lack of universally accepted testing protocols. Different manufacturers employ proprietary testing methodologies, resulting in incomparable quality metrics across the industry. This inconsistency creates significant barriers for end-users attempting to integrate GCNTs into commercial applications, as performance predictability becomes difficult to establish.

The absence of international standards specifically addressing graphitized carbon nanotubes has led to fragmented regional approaches. While organizations such as ISO, ASTM International, and IEEE have developed broader standards for carbon nanomaterials, these often fail to address the unique properties and applications of GCNTs. This standardization gap impedes market growth and technological adoption.

Measurement techniques present another critical challenge. Current analytical methods such as Raman spectroscopy, thermogravimetric analysis (TGA), and transmission electron microscopy (TEM) vary in their implementation across laboratories. The interpretation of results often depends on operator expertise, creating reproducibility issues that undermine quality assurance efforts.

Patent analysis reveals that leading companies are increasingly focusing on developing proprietary quality control systems. These systems typically incorporate machine learning algorithms to analyze multiple quality parameters simultaneously, potentially offering more comprehensive quality assessment than traditional methods. However, these proprietary approaches further fragment the standardization landscape.

Recent technological trends indicate a shift toward in-line quality monitoring systems that enable real-time assessment during production. These systems aim to reduce batch-to-batch variations and improve manufacturing yield. Additionally, blockchain-based traceability solutions are emerging to document quality parameters throughout the supply chain, enhancing transparency and reliability.

Collaborative industry initiatives are beginning to address these challenges through pre-competitive research consortia. These groups focus on establishing common terminology, measurement protocols, and reference materials specific to GCNTs. Such efforts represent a promising path toward the development of internationally recognized standards that could accelerate market adoption and technological innovation in this field.

Quality control challenges are further exacerbated by the lack of universally accepted testing protocols. Different manufacturers employ proprietary testing methodologies, resulting in incomparable quality metrics across the industry. This inconsistency creates significant barriers for end-users attempting to integrate GCNTs into commercial applications, as performance predictability becomes difficult to establish.

The absence of international standards specifically addressing graphitized carbon nanotubes has led to fragmented regional approaches. While organizations such as ISO, ASTM International, and IEEE have developed broader standards for carbon nanomaterials, these often fail to address the unique properties and applications of GCNTs. This standardization gap impedes market growth and technological adoption.

Measurement techniques present another critical challenge. Current analytical methods such as Raman spectroscopy, thermogravimetric analysis (TGA), and transmission electron microscopy (TEM) vary in their implementation across laboratories. The interpretation of results often depends on operator expertise, creating reproducibility issues that undermine quality assurance efforts.

Patent analysis reveals that leading companies are increasingly focusing on developing proprietary quality control systems. These systems typically incorporate machine learning algorithms to analyze multiple quality parameters simultaneously, potentially offering more comprehensive quality assessment than traditional methods. However, these proprietary approaches further fragment the standardization landscape.

Recent technological trends indicate a shift toward in-line quality monitoring systems that enable real-time assessment during production. These systems aim to reduce batch-to-batch variations and improve manufacturing yield. Additionally, blockchain-based traceability solutions are emerging to document quality parameters throughout the supply chain, enhancing transparency and reliability.

Collaborative industry initiatives are beginning to address these challenges through pre-competitive research consortia. These groups focus on establishing common terminology, measurement protocols, and reference materials specific to GCNTs. Such efforts represent a promising path toward the development of internationally recognized standards that could accelerate market adoption and technological innovation in this field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!