Analysis of Solvent Systems in Electrospinning for Polymer Synthesis

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Solvent Evolution and Objectives

Electrospinning technology has evolved significantly since its inception in the early 20th century, with the first patent filed by Formhals in 1934. The technique has progressed from a laboratory curiosity to an industrially viable process for producing nanofibers with diverse applications. The evolution of solvent systems has been particularly crucial in this development, as they directly influence fiber morphology, mechanical properties, and production efficiency.

Initially, electrospinning relied primarily on single-solvent systems using common organic solvents like chloroform, dimethylformamide (DMF), and tetrahydrofuran (THF). These early approaches faced challenges related to solvent volatility, polymer solubility, and environmental concerns. The 1990s marked a significant turning point with the introduction of mixed-solvent systems, which allowed for better control over fiber diameter and morphology.

Recent advancements have focused on green chemistry principles, with increasing emphasis on environmentally friendly solvent systems. Water-based electrospinning has gained prominence, particularly for biomedical applications where residual toxic solvents pose serious concerns. Additionally, ionic liquids and deep eutectic solvents have emerged as promising alternatives due to their negligible vapor pressure and tunable properties.

The technological trajectory indicates a shift toward solvent systems that enable precise control over nanofiber architecture while minimizing environmental impact. This includes the development of coaxial electrospinning techniques that utilize different solvent systems in core and shell solutions, allowing for the creation of complex fiber structures with enhanced functionality.

The primary objectives of current research in electrospinning solvent systems include: optimizing solvent compositions for specific polymer types; developing universal solvent systems applicable across multiple polymer families; reducing the environmental footprint through green solvent alternatives; enhancing process stability and reproducibility; and enabling the incorporation of bioactive compounds without compromising their efficacy.

Future goals involve the creation of predictive models for solvent-polymer interactions, which would streamline the development process for new electrospun materials. Additionally, there is significant interest in solvent recovery systems that would make the electrospinning process more economically viable at industrial scales, addressing both environmental and cost concerns simultaneously.

The convergence of computational modeling with experimental approaches is expected to accelerate innovation in this field, potentially leading to solvent systems that can be precisely tailored for specific applications ranging from tissue engineering scaffolds to energy storage devices and environmental remediation materials.

Initially, electrospinning relied primarily on single-solvent systems using common organic solvents like chloroform, dimethylformamide (DMF), and tetrahydrofuran (THF). These early approaches faced challenges related to solvent volatility, polymer solubility, and environmental concerns. The 1990s marked a significant turning point with the introduction of mixed-solvent systems, which allowed for better control over fiber diameter and morphology.

Recent advancements have focused on green chemistry principles, with increasing emphasis on environmentally friendly solvent systems. Water-based electrospinning has gained prominence, particularly for biomedical applications where residual toxic solvents pose serious concerns. Additionally, ionic liquids and deep eutectic solvents have emerged as promising alternatives due to their negligible vapor pressure and tunable properties.

The technological trajectory indicates a shift toward solvent systems that enable precise control over nanofiber architecture while minimizing environmental impact. This includes the development of coaxial electrospinning techniques that utilize different solvent systems in core and shell solutions, allowing for the creation of complex fiber structures with enhanced functionality.

The primary objectives of current research in electrospinning solvent systems include: optimizing solvent compositions for specific polymer types; developing universal solvent systems applicable across multiple polymer families; reducing the environmental footprint through green solvent alternatives; enhancing process stability and reproducibility; and enabling the incorporation of bioactive compounds without compromising their efficacy.

Future goals involve the creation of predictive models for solvent-polymer interactions, which would streamline the development process for new electrospun materials. Additionally, there is significant interest in solvent recovery systems that would make the electrospinning process more economically viable at industrial scales, addressing both environmental and cost concerns simultaneously.

The convergence of computational modeling with experimental approaches is expected to accelerate innovation in this field, potentially leading to solvent systems that can be precisely tailored for specific applications ranging from tissue engineering scaffolds to energy storage devices and environmental remediation materials.

Market Analysis for Electrospun Polymer Applications

The electrospun polymer market has experienced significant growth in recent years, driven by expanding applications across multiple industries. The global electrospun nanofiber market was valued at approximately 1.8 billion USD in 2022 and is projected to reach 3.6 billion USD by 2028, representing a compound annual growth rate of 12.3%. This growth trajectory is supported by increasing demand in healthcare, filtration, energy storage, and protective clothing sectors.

Healthcare applications currently dominate the market landscape, accounting for roughly 35% of the total market share. The exceptional properties of electrospun polymers, including high surface-to-volume ratio, controlled porosity, and biocompatibility, make them ideal for tissue engineering scaffolds, drug delivery systems, and wound dressings. The wound care segment alone is expected to grow at 14% annually through 2027, driven by aging populations and rising chronic disease prevalence.

Filtration represents the second-largest application segment, comprising approximately 28% of the market. The superior filtration efficiency of electrospun membranes, particularly for submicron particles and in air and water purification systems, has led to increased adoption in industrial and consumer applications. This segment is projected to expand rapidly as environmental regulations become more stringent globally and air quality concerns intensify in urban areas.

Energy storage applications, particularly in battery separators and components for fuel cells, constitute a fast-growing segment with 18% market share. The ability to create highly porous, electrically insulating membranes with excellent mechanical properties has positioned electrospun polymers as critical materials in next-generation energy storage solutions.

Regionally, North America and Europe currently lead the market with combined market share of 58%, primarily due to advanced healthcare infrastructure and strong research capabilities. However, Asia-Pacific represents the fastest-growing region with 16% annual growth rate, driven by expanding manufacturing capabilities in China, South Korea, and India, coupled with increasing healthcare expenditure and industrial development.

Key customer segments include medical device manufacturers, filtration system producers, battery manufacturers, and protective equipment suppliers. Customer requirements increasingly focus on consistency in fiber diameter, mechanical strength, biodegradability options, and scalable production capabilities. Price sensitivity varies significantly by application, with healthcare applications generally commanding premium pricing while industrial applications remain more cost-conscious.

Market barriers include high production costs, scalability challenges, and regulatory hurdles, particularly for medical applications. The complex relationship between solvent systems and resulting polymer properties represents both a technical challenge and market opportunity, as manufacturers who can optimize these parameters gain significant competitive advantage.

Healthcare applications currently dominate the market landscape, accounting for roughly 35% of the total market share. The exceptional properties of electrospun polymers, including high surface-to-volume ratio, controlled porosity, and biocompatibility, make them ideal for tissue engineering scaffolds, drug delivery systems, and wound dressings. The wound care segment alone is expected to grow at 14% annually through 2027, driven by aging populations and rising chronic disease prevalence.

Filtration represents the second-largest application segment, comprising approximately 28% of the market. The superior filtration efficiency of electrospun membranes, particularly for submicron particles and in air and water purification systems, has led to increased adoption in industrial and consumer applications. This segment is projected to expand rapidly as environmental regulations become more stringent globally and air quality concerns intensify in urban areas.

Energy storage applications, particularly in battery separators and components for fuel cells, constitute a fast-growing segment with 18% market share. The ability to create highly porous, electrically insulating membranes with excellent mechanical properties has positioned electrospun polymers as critical materials in next-generation energy storage solutions.

Regionally, North America and Europe currently lead the market with combined market share of 58%, primarily due to advanced healthcare infrastructure and strong research capabilities. However, Asia-Pacific represents the fastest-growing region with 16% annual growth rate, driven by expanding manufacturing capabilities in China, South Korea, and India, coupled with increasing healthcare expenditure and industrial development.

Key customer segments include medical device manufacturers, filtration system producers, battery manufacturers, and protective equipment suppliers. Customer requirements increasingly focus on consistency in fiber diameter, mechanical strength, biodegradability options, and scalable production capabilities. Price sensitivity varies significantly by application, with healthcare applications generally commanding premium pricing while industrial applications remain more cost-conscious.

Market barriers include high production costs, scalability challenges, and regulatory hurdles, particularly for medical applications. The complex relationship between solvent systems and resulting polymer properties represents both a technical challenge and market opportunity, as manufacturers who can optimize these parameters gain significant competitive advantage.

Current Solvent Systems and Technical Barriers

Electrospinning technology relies heavily on solvent systems to dissolve polymers and facilitate fiber formation. Currently, the most widely used solvents include dimethylformamide (DMF), tetrahydrofuran (THF), chloroform, acetone, and various alcohol-based solutions. These solvents are selected based on their ability to dissolve specific polymers, their volatility characteristics, and their impact on solution conductivity and viscosity.

Single-solvent systems, while straightforward to implement, often present limitations in polymer dissolution efficiency and fiber morphology control. Consequently, binary and ternary solvent systems have gained prominence in recent research. These multi-solvent approaches allow for fine-tuning of solution properties by combining solvents with complementary characteristics. For instance, DMF/THF combinations are frequently employed for polystyrene electrospinning, while water/ethanol mixtures serve well for water-soluble polymers like polyvinyl alcohol.

Despite advances in solvent system development, significant technical barriers persist. Solvent toxicity remains a primary concern, particularly with chlorinated solvents and DMF, which pose environmental and health risks. This has driven research toward greener alternatives, though these often demonstrate reduced efficiency in polymer dissolution or fiber formation processes.

Volatility control presents another substantial challenge. Highly volatile solvents evaporate too quickly, causing needle clogging and process interruption, while low-volatility solvents may result in wet fiber deposition and morphological defects. Achieving the optimal evaporation rate requires precise environmental control and often complex solvent mixtures.

Solution conductivity management represents a third major barrier. Insufficient conductivity leads to unstable jet formation and bead defects, while excessive conductivity can cause multiple jet splitting and reduced fiber diameter control. Researchers typically address this through conductive additives or solvent selection, but standardized approaches remain elusive.

Scale-up challenges further complicate industrial implementation. Laboratory-optimized solvent systems often perform differently at production scale due to variations in environmental conditions and equipment specifications. Additionally, solvent recovery systems necessary for industrial applications add complexity and cost to the manufacturing process.

Polymer-solvent compatibility issues constitute another significant barrier. Many advanced polymers with desirable properties exhibit limited solubility in conventional solvents, necessitating aggressive solvent conditions that may degrade polymer molecular weight or introduce unwanted chemical modifications.

Recent research has focused on developing specialized solvent systems for specific polymer classes, including biodegradable polymers, conductive polymers, and high-performance engineering polymers. However, a universal approach to solvent system design remains elusive, with most solutions being polymer-specific and requiring extensive empirical optimization.

Single-solvent systems, while straightforward to implement, often present limitations in polymer dissolution efficiency and fiber morphology control. Consequently, binary and ternary solvent systems have gained prominence in recent research. These multi-solvent approaches allow for fine-tuning of solution properties by combining solvents with complementary characteristics. For instance, DMF/THF combinations are frequently employed for polystyrene electrospinning, while water/ethanol mixtures serve well for water-soluble polymers like polyvinyl alcohol.

Despite advances in solvent system development, significant technical barriers persist. Solvent toxicity remains a primary concern, particularly with chlorinated solvents and DMF, which pose environmental and health risks. This has driven research toward greener alternatives, though these often demonstrate reduced efficiency in polymer dissolution or fiber formation processes.

Volatility control presents another substantial challenge. Highly volatile solvents evaporate too quickly, causing needle clogging and process interruption, while low-volatility solvents may result in wet fiber deposition and morphological defects. Achieving the optimal evaporation rate requires precise environmental control and often complex solvent mixtures.

Solution conductivity management represents a third major barrier. Insufficient conductivity leads to unstable jet formation and bead defects, while excessive conductivity can cause multiple jet splitting and reduced fiber diameter control. Researchers typically address this through conductive additives or solvent selection, but standardized approaches remain elusive.

Scale-up challenges further complicate industrial implementation. Laboratory-optimized solvent systems often perform differently at production scale due to variations in environmental conditions and equipment specifications. Additionally, solvent recovery systems necessary for industrial applications add complexity and cost to the manufacturing process.

Polymer-solvent compatibility issues constitute another significant barrier. Many advanced polymers with desirable properties exhibit limited solubility in conventional solvents, necessitating aggressive solvent conditions that may degrade polymer molecular weight or introduce unwanted chemical modifications.

Recent research has focused on developing specialized solvent systems for specific polymer classes, including biodegradable polymers, conductive polymers, and high-performance engineering polymers. However, a universal approach to solvent system design remains elusive, with most solutions being polymer-specific and requiring extensive empirical optimization.

Established Solvent Formulations and Parameters

01 Solvent selection criteria for electrospinning polymers

The selection of appropriate solvents is critical in electrospinning polymer synthesis. Ideal solvents should have suitable volatility, conductivity, and surface tension to facilitate fiber formation. The solvent must completely dissolve the polymer while maintaining appropriate viscosity for stable jet formation. Factors such as dielectric constant and boiling point significantly impact fiber morphology and diameter. Proper solvent selection enables control over the electrospinning process and resultant fiber properties.- Solvent selection criteria for electrospinning: The choice of solvent system is critical in electrospinning polymer synthesis as it affects fiber morphology and process efficiency. Ideal solvents should have appropriate volatility, conductivity, and surface tension to facilitate stable jet formation. Solvent properties directly influence polymer chain entanglement and solution viscosity, which determine fiber diameter and uniformity. Selection criteria include solubility parameters matching the polymer, evaporation rate suitable for the spinning distance, and compatibility with the desired application of the final nanofibers.

- Binary and multi-component solvent systems: Using mixtures of solvents can overcome limitations of single-solvent systems in electrospinning. Binary and multi-component solvent systems allow for fine-tuning of solution properties such as conductivity, viscosity, and evaporation rate. These mixed systems can improve spinnability of difficult polymers by balancing solubility and volatility parameters. For example, combining a good solvent with a poor solvent can create controlled polymer precipitation during jet elongation, resulting in unique fiber morphologies. Multi-component systems also enable processing of polymer blends with different solubility characteristics.

- Green and sustainable solvent alternatives: Environmental concerns have driven research toward green solvent systems for electrospinning. Sustainable alternatives to toxic organic solvents include bio-based solvents, ionic liquids, and water-based systems. These environmentally friendly options reduce hazardous waste and emissions while maintaining fiber quality. Water-based electrospinning systems are particularly advantageous for biomedical applications, eliminating concerns about residual toxic solvents. Recent innovations include using deep eutectic solvents and supercritical CO2 as green processing media for polymer electrospinning.

- Solvent effects on fiber morphology and properties: The solvent system significantly influences the final morphology and properties of electrospun fibers. Solvent volatility affects the solidification rate during jet travel, determining whether fibers or beads form. High boiling point solvents typically yield thicker fibers due to slower evaporation, while highly volatile solvents may cause premature solidification. Solvent-polymer interactions control chain conformation in solution, affecting crystallinity and mechanical properties of the resulting fibers. Strategic solvent selection can produce specialized structures like hollow fibers, porous surfaces, or core-shell architectures.

- Solvent systems for specialized polymer compositions: Different polymer classes require tailored solvent systems for successful electrospinning. Hydrophilic polymers often use water, alcohols, or their mixtures, while hydrophobic polymers typically require non-polar organic solvents. For high-performance polymers with rigid backbones, specialized solvent systems incorporating strong hydrogen bond acceptors or ionic compounds may be necessary to achieve sufficient dissolution. Biopolymers and biodegradable polymers benefit from benign solvent systems that preserve their bioactivity and degradation properties. Conductive polymers require solvent systems that maintain electronic properties while enabling fiber formation.

02 Binary and multi-component solvent systems

Binary and multi-component solvent systems offer enhanced control over electrospinning parameters compared to single solvents. These systems combine solvents with complementary properties to optimize polymer dissolution, solution conductivity, and evaporation rate. For example, mixing a highly volatile solvent with a less volatile one can prevent premature solidification while maintaining proper fiber formation. These solvent mixtures can also improve polymer chain entanglement and reduce surface tension, resulting in more uniform fibers with controlled porosity and surface characteristics.Expand Specific Solutions03 Green and environmentally friendly solvent systems

Environmentally friendly solvent systems are increasingly important in electrospinning polymer synthesis. These systems replace toxic organic solvents with more sustainable alternatives such as water, ionic liquids, or bio-based solvents. Green solvents reduce environmental impact and health hazards while maintaining electrospinning efficiency. Recent developments include using supercritical CO2, deep eutectic solvents, and recyclable solvent systems. These approaches align with sustainable chemistry principles and can produce biocompatible fibers suitable for medical applications.Expand Specific Solutions04 Solvent effects on fiber morphology and properties

The choice of solvent system significantly influences the final morphology and properties of electrospun fibers. Solvent properties such as evaporation rate, conductivity, and viscosity directly affect fiber diameter, porosity, crystallinity, and mechanical strength. Fast-evaporating solvents typically produce fibers with smaller diameters, while solvents with high dielectric constants enhance jet elongation through increased charge density. Controlled phase separation during solvent evaporation can create porous structures, and solvent-polymer interactions affect the molecular orientation within fibers, impacting their mechanical and thermal properties.Expand Specific Solutions05 Specialized solvent systems for functional polymers

Specialized solvent systems are developed for electrospinning functional polymers with specific applications. These include solvent combinations optimized for conductive polymers, biodegradable polymers, high-performance engineering polymers, and stimuli-responsive materials. For instance, fluorinated solvents may be used for processing fluoropolymers, while buffered aqueous systems are employed for sensitive biopolymers. These tailored solvent systems preserve the functional properties of the polymers during processing and can incorporate additives to enhance specific characteristics in the resulting fibers, such as electrical conductivity, drug release capabilities, or sensing properties.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The electrospinning solvent systems market is in a growth phase, characterized by increasing research activities and industrial applications. The market size is expanding due to rising demand in biomedical, filtration, and energy storage applications, with an estimated annual growth rate of 10-15%. Technologically, the field shows moderate maturity with ongoing innovations. Academic institutions like Donghua University, University of Delaware, and Virginia Commonwealth University lead fundamental research, while companies including BASF, LG Chem, and Medprin Regenerative Medical Technologies are commercializing applications. Industry-academia collaborations are prominent, with research institutions providing innovation pipelines for commercial players. Regional competition exists between North American, European, and Asian entities, with Asian players increasingly gaining market share through cost-effective manufacturing capabilities.

Donghua University

Technical Solution: Donghua University has pioneered advanced solvent system research for electrospinning, developing multi-component solvent systems that optimize polymer chain entanglement and viscoelastic properties. Their approach focuses on creating precise solvent mixtures that balance volatility, dielectric properties, and surface tension to enhance fiber formation. They've established systematic methodologies for solvent selection based on Hansen solubility parameters and polymer-solvent interactions[1]. Their research includes green solvent alternatives, replacing toxic solvents with environmentally friendly options while maintaining electrospinnability. Donghua's work has demonstrated that controlled solvent evaporation rates significantly impact fiber morphology, with their dual-solvent systems allowing fine-tuning of nanofiber diameter and porosity through differential evaporation kinetics[3].

Strengths: Exceptional expertise in multi-component solvent systems optimization; strong focus on green chemistry applications; comprehensive understanding of solvent-polymer interactions. Weaknesses: Some solutions may require complex solvent mixtures that are challenging to implement in industrial settings; potential scalability issues with precisely controlled evaporation environments.

BASF Corp.

Technical Solution: BASF has developed proprietary solvent system technologies for electrospinning that focus on industrial scalability and sustainability. Their approach integrates solvent recovery systems with electrospinning processes, significantly reducing environmental impact and operational costs. BASF's solvent formulations are designed to work with their extensive polymer portfolio, creating optimized combinations for specific applications[2]. Their technology includes specialized solvent blends that enhance polymer dissolution while maintaining appropriate conductivity and surface tension for stable jet formation. BASF has pioneered temperature-responsive solvent systems that allow for controlled viscosity adjustment during the electrospinning process, enabling production of fibers with tailored mechanical properties[4]. Their research also extends to solvent systems compatible with reactive electrospinning, where in-situ polymerization occurs during fiber formation.

Strengths: Extensive industrial scale implementation expertise; integrated approach connecting polymer synthesis with solvent system design; strong focus on sustainable and recoverable solvent systems. Weaknesses: Proprietary nature of solutions may limit academic collaboration; primarily focused on solutions for their own polymer portfolio rather than universal applications.

Critical Patents in Electrospinning Solvent Technology

Keratoprosthesis and uses thereof

PatentActiveUS20200253718A1

Innovation

- A keratoprosthesis assembly comprising a central optical core made from clear polymers and a peripheral skirt with a porous biocompatible layer, designed for improved optical quality, biointegration, and resistance to trauma, featuring a flexible or rigid core with a silicone hydrogel external layer and an electrospun nanofiber skirt for enhanced compatibility and stability.

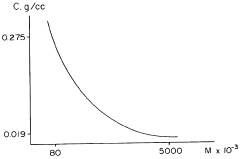

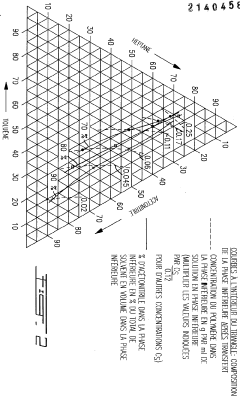

Process for obtaining an electrolyte solution for a solid polymer accumulator by transferring the polymer synthesis solvant

PatentInactiveCA2140458C

Innovation

- A direct transfer process is developed where the polymer is moved from its synthesis solvent to the solvent of the polymer-salt complex by adding the solvent of the complex and a non-solvent to the synthesis solution, separating into phases where the polymer predominantly resides in the solvent-rich phase, allowing for the addition of salt and subsequent separation.

Environmental Impact and Sustainability Assessment

The environmental impact of solvent systems in electrospinning processes represents a critical consideration for sustainable polymer synthesis. Traditional electrospinning operations predominantly utilize volatile organic compounds (VOCs) such as dimethylformamide (DMF), tetrahydrofuran (THF), and chloroform, which pose significant environmental and health hazards. These solvents contribute to air pollution through VOC emissions, potentially causing respiratory issues and environmental contamination when improperly handled or disposed of.

Recent sustainability assessments have quantified the environmental footprint of electrospinning operations, revealing that solvent selection accounts for approximately 65-80% of the total environmental impact in polymer nanofiber production. This impact manifests through multiple environmental indicators including global warming potential, ozone depletion, and ecotoxicity. For instance, the production of 1kg of polymer nanofibers using conventional DMF-based systems can generate up to 25kg CO2 equivalent emissions, primarily attributed to solvent manufacturing and disposal.

The water footprint of solvent-intensive electrospinning processes presents another sustainability concern. Conventional solvent systems require substantial water volumes for production and purification, with estimates suggesting 80-120 liters of water consumption per kilogram of processed polymer. Additionally, improper disposal of spent solvents can lead to groundwater contamination, affecting aquatic ecosystems and potentially entering the human water supply.

Industry and academic institutions have responded to these challenges by developing greener alternatives. Bio-based solvents derived from renewable resources, such as ethyl lactate and limonene, demonstrate promising performance while reducing environmental impact by 40-60% compared to petroleum-based counterparts. Water-based electrospinning systems represent another sustainable approach, though they currently face limitations in polymer compatibility and process efficiency.

Life cycle assessment (LCA) methodologies have been increasingly applied to electrospinning processes, enabling comprehensive evaluation of environmental impacts from raw material extraction through disposal. Recent LCA studies indicate that implementing solvent recovery systems can reduce the environmental footprint by 30-50%, offering both ecological and economic benefits through reduced waste management costs and regulatory compliance advantages.

Regulatory frameworks worldwide are evolving to address solvent-related environmental concerns. The European Union's REACH regulations, the United States EPA's Clean Air Act, and similar legislation in Asian manufacturing hubs increasingly restrict hazardous solvent usage, driving innovation toward greener alternatives. These regulatory pressures, combined with growing consumer demand for sustainable products, are accelerating the transition toward environmentally responsible electrospinning methodologies.

Recent sustainability assessments have quantified the environmental footprint of electrospinning operations, revealing that solvent selection accounts for approximately 65-80% of the total environmental impact in polymer nanofiber production. This impact manifests through multiple environmental indicators including global warming potential, ozone depletion, and ecotoxicity. For instance, the production of 1kg of polymer nanofibers using conventional DMF-based systems can generate up to 25kg CO2 equivalent emissions, primarily attributed to solvent manufacturing and disposal.

The water footprint of solvent-intensive electrospinning processes presents another sustainability concern. Conventional solvent systems require substantial water volumes for production and purification, with estimates suggesting 80-120 liters of water consumption per kilogram of processed polymer. Additionally, improper disposal of spent solvents can lead to groundwater contamination, affecting aquatic ecosystems and potentially entering the human water supply.

Industry and academic institutions have responded to these challenges by developing greener alternatives. Bio-based solvents derived from renewable resources, such as ethyl lactate and limonene, demonstrate promising performance while reducing environmental impact by 40-60% compared to petroleum-based counterparts. Water-based electrospinning systems represent another sustainable approach, though they currently face limitations in polymer compatibility and process efficiency.

Life cycle assessment (LCA) methodologies have been increasingly applied to electrospinning processes, enabling comprehensive evaluation of environmental impacts from raw material extraction through disposal. Recent LCA studies indicate that implementing solvent recovery systems can reduce the environmental footprint by 30-50%, offering both ecological and economic benefits through reduced waste management costs and regulatory compliance advantages.

Regulatory frameworks worldwide are evolving to address solvent-related environmental concerns. The European Union's REACH regulations, the United States EPA's Clean Air Act, and similar legislation in Asian manufacturing hubs increasingly restrict hazardous solvent usage, driving innovation toward greener alternatives. These regulatory pressures, combined with growing consumer demand for sustainable products, are accelerating the transition toward environmentally responsible electrospinning methodologies.

Scale-up Challenges and Industrial Implementation

The transition from laboratory-scale electrospinning to industrial production presents significant challenges that must be addressed for commercial viability. Current laboratory setups typically produce only small quantities of nanofibers, often less than a gram per hour, which is insufficient for industrial applications. Scaling up requires not only larger equipment but also fundamental redesigns of the electrospinning process to maintain fiber quality while increasing throughput.

One of the primary challenges in scale-up is maintaining consistent solvent evaporation rates across larger production volumes. As production scales increase, the dynamics of solvent evaporation change dramatically, potentially leading to inconsistent fiber morphology and properties. Industrial implementations must carefully control environmental parameters such as temperature, humidity, and air flow across much larger production spaces, requiring sophisticated environmental control systems.

Solvent recovery systems become economically and environmentally critical at industrial scales. The significant increase in solvent usage necessitates efficient recovery and recycling processes to reduce costs and minimize environmental impact. This is particularly important when working with toxic or expensive solvents commonly used in electrospinning polymer solutions.

Multi-needle or needleless electrospinning technologies have emerged as promising approaches for industrial scale-up. These systems can increase production rates by orders of magnitude compared to single-needle setups. However, they introduce new challenges in maintaining uniform electric fields and consistent fiber formation across multiple spinning sites. Solvent selection becomes even more critical in these systems, as solution properties must remain stable across larger volumes and longer production runs.

Regulatory compliance presents another significant hurdle for industrial implementation. Many solvents used in laboratory research face restrictions in industrial settings due to environmental, health, and safety regulations. Companies must often reformulate their solvent systems to use more environmentally friendly alternatives while maintaining the desired fiber characteristics, which requires extensive research and development efforts.

Quality control systems must be adapted for continuous production environments. Real-time monitoring of solvent evaporation rates, fiber diameter, and morphology becomes essential for maintaining product consistency. Advanced sensing technologies and automated process control systems are necessary investments for successful industrial implementation.

Economic considerations ultimately determine the feasibility of scale-up efforts. The capital investment required for industrial electrospinning equipment, solvent handling systems, and environmental controls must be balanced against projected product value. Optimizing solvent systems can significantly impact operational costs through reduced solvent consumption, improved production rates, and enhanced product quality.

One of the primary challenges in scale-up is maintaining consistent solvent evaporation rates across larger production volumes. As production scales increase, the dynamics of solvent evaporation change dramatically, potentially leading to inconsistent fiber morphology and properties. Industrial implementations must carefully control environmental parameters such as temperature, humidity, and air flow across much larger production spaces, requiring sophisticated environmental control systems.

Solvent recovery systems become economically and environmentally critical at industrial scales. The significant increase in solvent usage necessitates efficient recovery and recycling processes to reduce costs and minimize environmental impact. This is particularly important when working with toxic or expensive solvents commonly used in electrospinning polymer solutions.

Multi-needle or needleless electrospinning technologies have emerged as promising approaches for industrial scale-up. These systems can increase production rates by orders of magnitude compared to single-needle setups. However, they introduce new challenges in maintaining uniform electric fields and consistent fiber formation across multiple spinning sites. Solvent selection becomes even more critical in these systems, as solution properties must remain stable across larger volumes and longer production runs.

Regulatory compliance presents another significant hurdle for industrial implementation. Many solvents used in laboratory research face restrictions in industrial settings due to environmental, health, and safety regulations. Companies must often reformulate their solvent systems to use more environmentally friendly alternatives while maintaining the desired fiber characteristics, which requires extensive research and development efforts.

Quality control systems must be adapted for continuous production environments. Real-time monitoring of solvent evaporation rates, fiber diameter, and morphology becomes essential for maintaining product consistency. Advanced sensing technologies and automated process control systems are necessary investments for successful industrial implementation.

Economic considerations ultimately determine the feasibility of scale-up efforts. The capital investment required for industrial electrospinning equipment, solvent handling systems, and environmental controls must be balanced against projected product value. Optimizing solvent systems can significantly impact operational costs through reduced solvent consumption, improved production rates, and enhanced product quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!