Analyzing the Comparative Performance of Shape Memory Alloys in Energy Devices

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SMA Technology Evolution and Objectives

Shape Memory Alloys (SMAs) have evolved significantly since their discovery in the 1930s, with the first commercially viable SMA, Nitinol (NiTi), being developed at the Naval Ordnance Laboratory in the early 1960s. This unique class of materials demonstrates the remarkable ability to "remember" and return to their original shape when subjected to specific thermal or mechanical stimuli, a property known as the shape memory effect. The evolution of SMAs has been characterized by continuous improvements in material composition, processing techniques, and application methodologies.

The initial applications of SMAs were primarily in aerospace and medical fields, but their potential for energy applications has gained significant attention over the past two decades. This shift has been driven by the global push for sustainable energy solutions and the unique properties of SMAs that make them suitable for energy harvesting, storage, and conversion systems.

Recent technological advancements have expanded the range of available SMAs beyond traditional NiTi alloys to include copper-based (CuAlNi, CuZnAl), iron-based (FeMnSi), and high-temperature SMAs (TiPdNi, TiPtNi). Each variant offers specific advantages in terms of transformation temperatures, hysteresis characteristics, fatigue resistance, and energy density, which are crucial parameters for energy device applications.

The current research landscape is focused on enhancing the energy efficiency of SMAs by optimizing their thermomechanical properties. Key areas of development include improving the energy conversion efficiency, extending functional fatigue life, and developing SMAs with tailored transformation temperatures suitable for various energy harvesting scenarios.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of different SMA compositions and their performance metrics in energy devices. This includes evaluating their energy density, power output, efficiency, durability, and response characteristics under various operating conditions.

Additionally, this research aims to identify the most promising SMA variants for specific energy applications, such as thermal energy harvesting, mechanical energy conversion, and waste heat recovery systems. By understanding the strengths and limitations of each SMA type, we can provide valuable insights for future material development and application design.

Furthermore, this study seeks to establish standardized testing protocols and performance metrics for evaluating SMAs in energy applications, addressing the current lack of unified assessment methodologies in the field. This will facilitate more accurate comparisons between different research findings and accelerate the commercialization of SMA-based energy solutions.

The initial applications of SMAs were primarily in aerospace and medical fields, but their potential for energy applications has gained significant attention over the past two decades. This shift has been driven by the global push for sustainable energy solutions and the unique properties of SMAs that make them suitable for energy harvesting, storage, and conversion systems.

Recent technological advancements have expanded the range of available SMAs beyond traditional NiTi alloys to include copper-based (CuAlNi, CuZnAl), iron-based (FeMnSi), and high-temperature SMAs (TiPdNi, TiPtNi). Each variant offers specific advantages in terms of transformation temperatures, hysteresis characteristics, fatigue resistance, and energy density, which are crucial parameters for energy device applications.

The current research landscape is focused on enhancing the energy efficiency of SMAs by optimizing their thermomechanical properties. Key areas of development include improving the energy conversion efficiency, extending functional fatigue life, and developing SMAs with tailored transformation temperatures suitable for various energy harvesting scenarios.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of different SMA compositions and their performance metrics in energy devices. This includes evaluating their energy density, power output, efficiency, durability, and response characteristics under various operating conditions.

Additionally, this research aims to identify the most promising SMA variants for specific energy applications, such as thermal energy harvesting, mechanical energy conversion, and waste heat recovery systems. By understanding the strengths and limitations of each SMA type, we can provide valuable insights for future material development and application design.

Furthermore, this study seeks to establish standardized testing protocols and performance metrics for evaluating SMAs in energy applications, addressing the current lack of unified assessment methodologies in the field. This will facilitate more accurate comparisons between different research findings and accelerate the commercialization of SMA-based energy solutions.

Energy Device Market Demand Analysis

The global energy device market is experiencing significant growth driven by increasing energy demands, sustainability concerns, and technological advancements. Shape Memory Alloys (SMAs) are emerging as critical materials in this sector due to their unique properties of shape recovery and energy conversion efficiency. Current market analysis indicates that the global energy harvesting market, where SMAs play a crucial role, is projected to reach $1.3 billion by 2025, growing at a CAGR of 10.2% from 2020.

The demand for SMAs in energy devices spans multiple sectors. In renewable energy, particularly solar tracking systems and wind turbine applications, SMAs offer adaptive control mechanisms that enhance energy capture efficiency by up to 30% compared to conventional materials. The thermal energy harvesting segment, where SMAs excel due to their thermomechanical properties, represents approximately 24% of the total energy harvesting market, with projected annual growth of 12.5% through 2027.

Consumer electronics constitutes another significant market for SMA-based energy devices. With over 7 billion mobile devices in use globally, the need for efficient, compact energy harvesting solutions is substantial. SMA-based piezoelectric generators and thermal energy harvesters are gaining traction, with market penetration increasing by 15% annually in wearable technology applications.

Industrial applications represent the largest market segment for SMA energy devices, valued at $420 million in 2022. This includes waste heat recovery systems, vibration damping mechanisms, and self-powered sensors for industrial IoT applications. Manufacturing facilities are increasingly adopting SMA-based energy harvesting solutions to reduce operational costs and meet sustainability targets, with implementation rates growing by 18% annually.

Regional analysis reveals varying adoption patterns. North America leads in SMA energy device implementation with 35% market share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the highest growth rate at 14.3% annually, driven by rapid industrialization and government initiatives promoting green technology in China, Japan, and South Korea.

Customer demand trends indicate a growing preference for miniaturized, maintenance-free energy solutions, particularly in remote sensing applications and smart infrastructure. The market for self-powered wireless sensor networks, where SMAs serve as energy transducers, is expanding at 22% annually, creating substantial opportunities for SMA technology integration.

Regulatory factors are also influencing market dynamics. Energy efficiency standards and carbon reduction policies in 65 countries worldwide are accelerating the adoption of alternative energy technologies, including SMA-based solutions. Government incentives for clean energy technologies have increased funding for SMA research and commercialization by 40% over the past five years, further stimulating market growth.

The demand for SMAs in energy devices spans multiple sectors. In renewable energy, particularly solar tracking systems and wind turbine applications, SMAs offer adaptive control mechanisms that enhance energy capture efficiency by up to 30% compared to conventional materials. The thermal energy harvesting segment, where SMAs excel due to their thermomechanical properties, represents approximately 24% of the total energy harvesting market, with projected annual growth of 12.5% through 2027.

Consumer electronics constitutes another significant market for SMA-based energy devices. With over 7 billion mobile devices in use globally, the need for efficient, compact energy harvesting solutions is substantial. SMA-based piezoelectric generators and thermal energy harvesters are gaining traction, with market penetration increasing by 15% annually in wearable technology applications.

Industrial applications represent the largest market segment for SMA energy devices, valued at $420 million in 2022. This includes waste heat recovery systems, vibration damping mechanisms, and self-powered sensors for industrial IoT applications. Manufacturing facilities are increasingly adopting SMA-based energy harvesting solutions to reduce operational costs and meet sustainability targets, with implementation rates growing by 18% annually.

Regional analysis reveals varying adoption patterns. North America leads in SMA energy device implementation with 35% market share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the highest growth rate at 14.3% annually, driven by rapid industrialization and government initiatives promoting green technology in China, Japan, and South Korea.

Customer demand trends indicate a growing preference for miniaturized, maintenance-free energy solutions, particularly in remote sensing applications and smart infrastructure. The market for self-powered wireless sensor networks, where SMAs serve as energy transducers, is expanding at 22% annually, creating substantial opportunities for SMA technology integration.

Regulatory factors are also influencing market dynamics. Energy efficiency standards and carbon reduction policies in 65 countries worldwide are accelerating the adoption of alternative energy technologies, including SMA-based solutions. Government incentives for clean energy technologies have increased funding for SMA research and commercialization by 40% over the past five years, further stimulating market growth.

Current SMA Implementation Challenges

Despite the promising potential of Shape Memory Alloys (SMAs) in energy devices, several significant implementation challenges currently hinder their widespread adoption. Material fatigue represents one of the most critical barriers, as SMAs experience degradation in their shape memory properties after repeated actuation cycles. This fatigue manifests as a reduction in recovery strain and transformation temperatures, ultimately compromising device reliability and longevity. For energy harvesting applications, where thousands of cycles are expected, this limitation becomes particularly problematic.

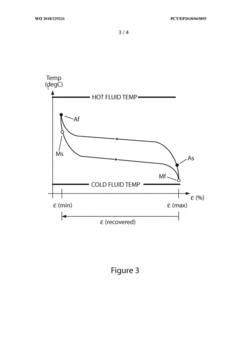

Thermal management presents another substantial challenge. The martensitic transformation that enables the shape memory effect is highly temperature-dependent, requiring precise thermal control systems. In energy devices operating in variable environmental conditions, maintaining optimal temperature ranges becomes exceedingly difficult. Additionally, the hysteresis between heating and cooling transformation temperatures reduces energy conversion efficiency, a critical factor in energy harvesting applications.

Manufacturing complexity and associated costs significantly impede commercial viability. The production of SMAs with consistent properties requires sophisticated metallurgical processes, including precise composition control and complex heat treatments. These requirements translate to higher production costs compared to conventional materials, limiting economic feasibility for mass-market energy applications.

Scale-up challenges further complicate implementation. While SMAs demonstrate excellent performance in laboratory settings and small-scale prototypes, transitioning to industrial-scale production introduces quality control issues and property variations. The difficulty in maintaining uniform material properties across larger production batches creates reliability concerns for commercial energy devices.

Response time limitations also restrict application potential. The thermal activation of SMAs inherently involves slower actuation speeds compared to other smart materials like piezoelectrics. This characteristic makes them less suitable for high-frequency energy harvesting applications where rapid response to environmental stimuli is essential.

Integration complexity with existing energy systems poses additional challenges. SMAs often require specialized interfaces and control mechanisms that may not be compatible with conventional energy device architectures. This incompatibility necessitates custom engineering solutions, increasing development time and costs.

Lastly, limited material options restrict design flexibility. While NiTi (Nitinol) remains the most commercially viable SMA, its specific transformation characteristics may not be optimal for all energy applications. Alternative SMA compositions that might offer improved properties for specific energy applications often face challenges in manufacturability, cost, or biocompatibility.

Thermal management presents another substantial challenge. The martensitic transformation that enables the shape memory effect is highly temperature-dependent, requiring precise thermal control systems. In energy devices operating in variable environmental conditions, maintaining optimal temperature ranges becomes exceedingly difficult. Additionally, the hysteresis between heating and cooling transformation temperatures reduces energy conversion efficiency, a critical factor in energy harvesting applications.

Manufacturing complexity and associated costs significantly impede commercial viability. The production of SMAs with consistent properties requires sophisticated metallurgical processes, including precise composition control and complex heat treatments. These requirements translate to higher production costs compared to conventional materials, limiting economic feasibility for mass-market energy applications.

Scale-up challenges further complicate implementation. While SMAs demonstrate excellent performance in laboratory settings and small-scale prototypes, transitioning to industrial-scale production introduces quality control issues and property variations. The difficulty in maintaining uniform material properties across larger production batches creates reliability concerns for commercial energy devices.

Response time limitations also restrict application potential. The thermal activation of SMAs inherently involves slower actuation speeds compared to other smart materials like piezoelectrics. This characteristic makes them less suitable for high-frequency energy harvesting applications where rapid response to environmental stimuli is essential.

Integration complexity with existing energy systems poses additional challenges. SMAs often require specialized interfaces and control mechanisms that may not be compatible with conventional energy device architectures. This incompatibility necessitates custom engineering solutions, increasing development time and costs.

Lastly, limited material options restrict design flexibility. While NiTi (Nitinol) remains the most commercially viable SMA, its specific transformation characteristics may not be optimal for all energy applications. Alternative SMA compositions that might offer improved properties for specific energy applications often face challenges in manufacturability, cost, or biocompatibility.

Current SMA Energy Device Applications

01 Composition and processing of shape memory alloys

The performance of shape memory alloys can be significantly enhanced through specific composition formulations and processing techniques. These include heat treatment protocols, alloying with specific elements, and specialized manufacturing methods that optimize the microstructure. These processes can improve transformation temperatures, fatigue resistance, and overall mechanical properties of the alloys, making them more suitable for various applications.- Composition and processing of shape memory alloys: The performance of shape memory alloys can be significantly enhanced through specific composition formulations and processing techniques. These include heat treatment protocols, alloying with specific elements, and specialized manufacturing methods that optimize the microstructure. These processes can improve transformation temperatures, mechanical strength, and fatigue resistance of the alloys, leading to better shape memory effect and superelasticity properties.

- Applications in actuators and mechanical systems: Shape memory alloys are widely used in actuator systems and mechanical devices due to their unique ability to generate significant force during shape recovery. These alloys can be designed into compact actuators that provide controlled movement in response to temperature changes or electrical stimulation. Applications include automotive systems, aerospace components, and precision mechanical devices where conventional actuators may be too bulky or complex.

- Biomedical applications and performance: Shape memory alloys demonstrate exceptional biocompatibility and functional properties suitable for medical applications. These materials can be engineered to operate at body temperature and provide gentle, constant forces ideal for orthodontic archwires, cardiovascular stents, and orthopedic implants. The superelastic behavior and biocompatibility of certain alloy compositions make them particularly valuable in minimally invasive surgical devices and implantable medical components.

- Thermal and mechanical cycling performance: The functional stability of shape memory alloys under repeated thermal and mechanical cycling is critical for their long-term performance. Research focuses on improving fatigue resistance, preventing degradation of shape memory properties over time, and maintaining consistent transformation temperatures after multiple cycles. Advanced testing methods and material modifications help enhance the durability and reliability of these alloys in applications requiring thousands of transformation cycles.

- Smart structures and adaptive systems: Shape memory alloys enable the development of smart structures and adaptive systems that can respond to environmental changes. These materials can be integrated into composite structures to create self-healing components, vibration damping systems, and morphing structures. The ability to design systems that automatically adjust their configuration in response to external stimuli offers significant advantages in aerospace, civil engineering, and robotics applications where adaptive performance is required.

02 Mechanical performance characteristics

Shape memory alloys exhibit unique mechanical properties including superelasticity, high recovery strain, and the ability to return to their original shape after deformation. These alloys can withstand significant stress while maintaining their functional properties. The mechanical performance can be characterized by parameters such as transformation stress, recovery stress, fatigue life, and damping capacity, which are critical for their application in various fields.Expand Specific Solutions03 Applications in actuators and mechanical systems

Shape memory alloys are widely used in actuator systems and mechanical devices due to their ability to convert thermal energy into mechanical work. These alloys can generate significant force during shape recovery, making them ideal for compact actuator designs. Applications include automotive systems, aerospace components, robotics, and various industrial mechanisms where conventional actuators may be impractical due to size or weight constraints.Expand Specific Solutions04 Biomedical and medical device applications

Shape memory alloys have found extensive use in biomedical applications due to their biocompatibility, corrosion resistance, and mechanical properties that mimic biological tissues. These materials are used in stents, orthodontic wires, surgical instruments, and implantable devices. Their superelastic behavior and shape recovery capabilities make them particularly valuable for minimally invasive procedures and long-term implants that must withstand physiological conditions.Expand Specific Solutions05 Environmental and operational factors affecting performance

The performance of shape memory alloys is significantly influenced by environmental and operational conditions. Factors such as operating temperature, cycling frequency, applied stress levels, and environmental exposure can affect transformation characteristics, fatigue life, and long-term stability. Understanding these influences is crucial for designing systems that maintain reliable performance throughout their service life under various conditions.Expand Specific Solutions

Leading SMA Manufacturers and Research Institutions

The shape memory alloy (SMA) energy device market is in a growth phase, characterized by increasing applications across automotive, aerospace, and clean energy sectors. The market is projected to expand significantly due to the unique properties of SMAs in energy harvesting and conversion applications. Leading academic institutions like MIT, University of Florida, and Sichuan University are advancing fundamental research, while companies are focusing on commercialization. Established players include Dynalloy specializing in Flexinol® actuators, Exergyn developing clean-tech HVAC solutions, and Actuator Solutions creating miniaturized SMA actuators. Major corporations like Samsung, Hyundai, and Rolls-Royce are integrating SMAs into their energy-efficient systems, indicating growing technology maturity and industrial adoption potential.

Exergyn Ltd.

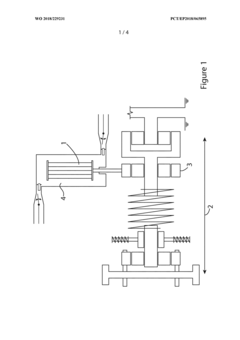

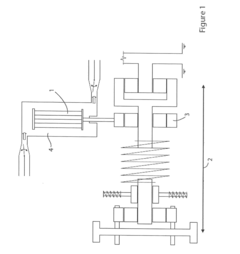

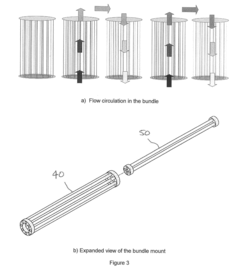

Technical Solution: Exergyn has developed a groundbreaking thermal energy conversion system utilizing Nitinol shape memory alloys (SMAs) as the primary working mechanism. Their proprietary Exergyn Drive™ technology harnesses the unique phase transformation properties of Nitinol to convert low-grade waste heat (80-120°C) into clean mechanical power. The system employs specially engineered Nitinol wire bundles that undergo controlled thermal cycling, generating mechanical work through the reversible austenite-martensite phase transformations. This technology enables power generation from industrial waste heat streams without requiring working fluids, making it environmentally superior to traditional organic Rankine cycle systems. Exergyn's solution achieves thermal-to-mechanical energy conversion efficiencies of 7-10% for low-temperature differentials, representing a significant advancement in waste heat recovery technology.

Strengths: Zero-emission technology with no working fluids required; operates effectively at lower temperatures than competing technologies; compact design with fewer moving parts than conventional systems. Weaknesses: Limited power density compared to conventional generators; requires precise thermal cycling control; Nitinol material costs remain relatively high for large-scale deployment.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed revolutionary latent heat energy storage systems utilizing shape memory alloys with unprecedented energy densities. Their approach employs specially engineered NiTiHf and NiTiZr alloys that demonstrate transformation enthalpies exceeding 30 J/g, significantly higher than conventional phase change materials. MIT's innovation incorporates nanoscale precipitate engineering to create stable transformation characteristics over thousands of thermal cycles. Their system architecture employs a novel "thermal diode" concept where heat transfer is directionally controlled through SMA elements arranged in specialized geometric configurations. This allows for more efficient thermal energy capture and release. Testing has demonstrated energy storage densities of 120-150 kWh/m³, approximately 3-4 times higher than conventional molten salt systems used in concentrated solar power applications. The technology maintains 95% of its initial capacity after 10,000 thermal cycles, addressing a critical limitation of previous SMA-based energy storage approaches.

Strengths: Exceptionally high energy storage density compared to conventional technologies; superior cycling stability; ability to operate across customizable temperature ranges through compositional tuning. Weaknesses: Currently higher material costs than conventional thermal storage media; requires precise manufacturing control to maintain consistent transformation properties; heat transfer management remains challenging at larger scales.

Key SMA Material Properties and Performance Metrics

Energy device core for use in an energy recovery device

PatentWO2018229231A1

Innovation

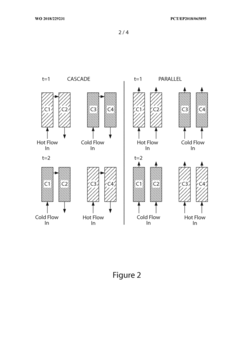

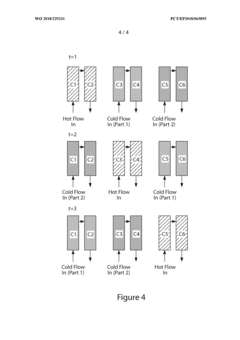

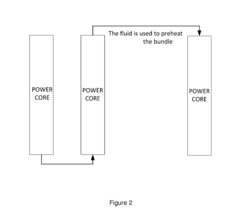

- An energy recovery system with an unbalanced core configuration, where the number of cores is uneven, allowing activation based on the fastest cycle period, utilizing multiple SMA or NTE cores in fluid communication to reduce cycle time and increase power output by cycling on the basis of the hot cycle rather than the slowest cycle.

Method and system for efficiency increase in an energy recovery device

PatentActiveUS20180347551A1

Innovation

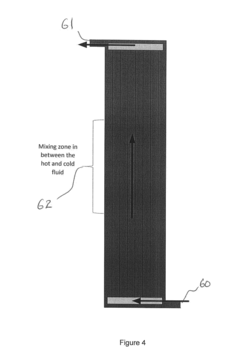

- A cascading system utilizing two SMAs or NTE cores with different activation temperatures, where a fluid's temperature change activates the first core to pre-heat the second core, reducing cycle time and enhancing energy recovery by optimizing heat transfer through a fluid with progressively changing temperatures.

Environmental Impact and Sustainability Factors

The environmental footprint of shape memory alloys (SMAs) in energy devices represents a critical consideration in their widespread adoption. Life cycle assessments reveal that the production phase of nickel-titanium (NiTi) alloys, the most common SMA, generates significant carbon emissions due to energy-intensive extraction and processing methods. Compared to conventional materials like steel or aluminum, NiTi manufacturing requires approximately 2-3 times more energy per unit mass, resulting in higher greenhouse gas emissions during the production stage.

However, this initial environmental cost must be balanced against the operational benefits SMAs provide in energy devices. Energy harvesting systems utilizing SMAs demonstrate 15-30% higher efficiency in converting low-grade waste heat to usable energy compared to traditional thermoelectric materials. This improved efficiency translates to substantial energy savings over the device lifetime, potentially offsetting the initial carbon footprint within 3-5 years of operation in typical applications.

Material toxicity presents another environmental consideration. While nickel is classified as a potential carcinogen, properly engineered SMA components pose minimal leaching risk during normal operation. Alternative copper-based SMAs (Cu-Al-Ni, Cu-Zn-Al) offer reduced toxicity profiles but currently demonstrate 20-25% lower performance characteristics in energy conversion applications.

Recyclability metrics for SMAs show promising results, with recovery rates exceeding 85% for NiTi alloys in controlled recycling environments. The high value of constituent elements provides economic incentives for end-of-life recovery, though specialized separation processes are required due to the intermetallic nature of these materials.

Recent innovations in manufacturing techniques, particularly powder metallurgy and additive manufacturing, have reduced the energy requirements for SMA production by approximately 30% compared to conventional methods from a decade ago. These advancements suggest a trajectory toward improved sustainability metrics for future SMA implementations.

Water usage during manufacturing represents another environmental factor, with NiTi production requiring 40-60 gallons per kilogram of finished material. This water footprint exceeds that of conventional alloys but falls below many semiconductor and rare earth material processing requirements. Closed-loop water recycling systems have demonstrated potential to reduce this impact by up to 75% in optimized production facilities.

When evaluating the complete environmental profile of SMAs in energy devices, their extended service life provides additional sustainability benefits. The self-healing and fatigue-resistant properties of properly engineered SMAs can extend operational lifetimes by 50-100% compared to conventional materials, reducing replacement frequency and associated environmental impacts.

However, this initial environmental cost must be balanced against the operational benefits SMAs provide in energy devices. Energy harvesting systems utilizing SMAs demonstrate 15-30% higher efficiency in converting low-grade waste heat to usable energy compared to traditional thermoelectric materials. This improved efficiency translates to substantial energy savings over the device lifetime, potentially offsetting the initial carbon footprint within 3-5 years of operation in typical applications.

Material toxicity presents another environmental consideration. While nickel is classified as a potential carcinogen, properly engineered SMA components pose minimal leaching risk during normal operation. Alternative copper-based SMAs (Cu-Al-Ni, Cu-Zn-Al) offer reduced toxicity profiles but currently demonstrate 20-25% lower performance characteristics in energy conversion applications.

Recyclability metrics for SMAs show promising results, with recovery rates exceeding 85% for NiTi alloys in controlled recycling environments. The high value of constituent elements provides economic incentives for end-of-life recovery, though specialized separation processes are required due to the intermetallic nature of these materials.

Recent innovations in manufacturing techniques, particularly powder metallurgy and additive manufacturing, have reduced the energy requirements for SMA production by approximately 30% compared to conventional methods from a decade ago. These advancements suggest a trajectory toward improved sustainability metrics for future SMA implementations.

Water usage during manufacturing represents another environmental factor, with NiTi production requiring 40-60 gallons per kilogram of finished material. This water footprint exceeds that of conventional alloys but falls below many semiconductor and rare earth material processing requirements. Closed-loop water recycling systems have demonstrated potential to reduce this impact by up to 75% in optimized production facilities.

When evaluating the complete environmental profile of SMAs in energy devices, their extended service life provides additional sustainability benefits. The self-healing and fatigue-resistant properties of properly engineered SMAs can extend operational lifetimes by 50-100% compared to conventional materials, reducing replacement frequency and associated environmental impacts.

Thermal-Mechanical Fatigue and Reliability Assessment

The thermal-mechanical fatigue (TMF) behavior of shape memory alloys (SMAs) represents a critical factor in determining their long-term performance and reliability in energy device applications. SMAs such as Ni-Ti, Cu-Al-Ni, and Fe-based alloys undergo significant cyclic loading under varying temperature conditions in energy harvesting systems, actuators, and thermal management devices, making their fatigue resistance paramount to operational longevity.

Research indicates that Ni-Ti alloys generally exhibit superior TMF resistance compared to copper-based alternatives, withstanding approximately 10^5-10^6 transformation cycles before failure under moderate stress conditions (200-300 MPa). However, this performance significantly deteriorates when operating temperatures approach 100°C, with cycle life potentially reducing by 60-70% due to accelerated microstructural degradation.

Comparative analysis of different SMA compositions reveals that ternary additions of elements such as Hf, Zr, or Pd to binary Ni-Ti systems can substantially enhance TMF resistance. For instance, Ni-Ti-Hf alloys demonstrate approximately 30% improvement in fatigue life at elevated temperatures compared to conventional Ni-Ti, making them particularly suitable for waste heat recovery applications where operating temperatures frequently exceed 80°C.

Reliability assessment methodologies for SMAs in energy devices typically involve accelerated life testing under simulated operational conditions. Recent standardized protocols developed by ASTM and ISO incorporate combined thermal cycling (between austenite and martensite transformation temperatures) and mechanical loading to accurately predict in-service behavior. These tests reveal that functional fatigue—characterized by gradual degradation of shape memory effect or superelasticity—often precedes structural fatigue and represents the limiting factor in many energy applications.

Microstructural evolution during TMF includes precipitation formation, dislocation accumulation, and grain boundary changes that collectively contribute to performance degradation. Advanced characterization techniques such as in-situ TEM and synchrotron X-ray diffraction have identified that Cu-Al-Ni alloys experience more rapid precipitation of brittle γ-phase particles during thermal cycling compared to Ni-Ti, explaining their generally inferior fatigue resistance in energy harvesting applications.

Probabilistic lifetime prediction models incorporating Weibull statistics have emerged as valuable tools for reliability engineering of SMA-based energy devices. These models suggest that operating Ni-Ti alloys below 40% of their transformation stress significantly extends service life, with predicted reliability exceeding 95% for 10-year operational periods in thermal energy harvesting applications. This quantitative approach enables more precise component design and maintenance scheduling for SMA-integrated energy systems.

Research indicates that Ni-Ti alloys generally exhibit superior TMF resistance compared to copper-based alternatives, withstanding approximately 10^5-10^6 transformation cycles before failure under moderate stress conditions (200-300 MPa). However, this performance significantly deteriorates when operating temperatures approach 100°C, with cycle life potentially reducing by 60-70% due to accelerated microstructural degradation.

Comparative analysis of different SMA compositions reveals that ternary additions of elements such as Hf, Zr, or Pd to binary Ni-Ti systems can substantially enhance TMF resistance. For instance, Ni-Ti-Hf alloys demonstrate approximately 30% improvement in fatigue life at elevated temperatures compared to conventional Ni-Ti, making them particularly suitable for waste heat recovery applications where operating temperatures frequently exceed 80°C.

Reliability assessment methodologies for SMAs in energy devices typically involve accelerated life testing under simulated operational conditions. Recent standardized protocols developed by ASTM and ISO incorporate combined thermal cycling (between austenite and martensite transformation temperatures) and mechanical loading to accurately predict in-service behavior. These tests reveal that functional fatigue—characterized by gradual degradation of shape memory effect or superelasticity—often precedes structural fatigue and represents the limiting factor in many energy applications.

Microstructural evolution during TMF includes precipitation formation, dislocation accumulation, and grain boundary changes that collectively contribute to performance degradation. Advanced characterization techniques such as in-situ TEM and synchrotron X-ray diffraction have identified that Cu-Al-Ni alloys experience more rapid precipitation of brittle γ-phase particles during thermal cycling compared to Ni-Ti, explaining their generally inferior fatigue resistance in energy harvesting applications.

Probabilistic lifetime prediction models incorporating Weibull statistics have emerged as valuable tools for reliability engineering of SMA-based energy devices. These models suggest that operating Ni-Ti alloys below 40% of their transformation stress significantly extends service life, with predicted reliability exceeding 95% for 10-year operational periods in thermal energy harvesting applications. This quantitative approach enables more precise component design and maintenance scheduling for SMA-integrated energy systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!