Shape Memory Alloys: Leveraging Robotic Efficiency Through Material Science

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SMA Technology Evolution and Objectives

Shape Memory Alloys (SMAs) represent a revolutionary class of smart materials that have evolved significantly since their discovery in the 1930s. The journey began with the observation of the shape memory effect in gold-cadmium alloys, but the field gained substantial momentum with the discovery of Nitinol (nickel-titanium alloy) by the Naval Ordnance Laboratory in 1962. This discovery marked a pivotal moment in SMA development, establishing a foundation for subsequent technological advancements.

The evolution of SMA technology has been characterized by progressive improvements in material composition, manufacturing processes, and application methodologies. Early applications were limited by inconsistent material properties and manufacturing challenges. However, by the 1980s and 1990s, refined production techniques enabled more reliable and commercially viable SMA components, leading to their adoption in medical devices, particularly stents and orthodontic wires.

In the 21st century, SMA technology has experienced accelerated development driven by computational modeling, advanced characterization techniques, and interdisciplinary research approaches. The integration of nanotechnology has further enhanced SMA performance characteristics, including faster response times, greater energy density, and improved fatigue resistance. These advancements have expanded the potential application landscape significantly.

The current technological trajectory aims to overcome persistent challenges in SMA implementation, particularly in robotics. These challenges include hysteresis control, response speed optimization, and energy efficiency improvements. Research is increasingly focused on developing SMAs with programmable transformation temperatures, enhanced work output, and superior cyclic stability to meet the demanding requirements of robotic applications.

The primary objective of contemporary SMA research in robotics is to leverage their unique properties—high power-to-weight ratio, silent operation, and biomimetic movement capabilities—to create more efficient, adaptable, and resilient robotic systems. This includes the development of SMA-based actuators that can replace conventional motors and hydraulic systems while offering reduced weight, simplified mechanical design, and improved energy efficiency.

Long-term technological goals include the creation of multi-functional SMAs that can simultaneously serve as actuators, sensors, and structural components in integrated robotic systems. Additionally, researchers aim to develop SMAs with faster actuation speeds, greater strain recovery, and enhanced durability under repeated cycling conditions. The ultimate vision is to establish SMAs as a cornerstone material in next-generation soft robotics, human-robot interaction systems, and autonomous robotic platforms.

The evolution of SMA technology has been characterized by progressive improvements in material composition, manufacturing processes, and application methodologies. Early applications were limited by inconsistent material properties and manufacturing challenges. However, by the 1980s and 1990s, refined production techniques enabled more reliable and commercially viable SMA components, leading to their adoption in medical devices, particularly stents and orthodontic wires.

In the 21st century, SMA technology has experienced accelerated development driven by computational modeling, advanced characterization techniques, and interdisciplinary research approaches. The integration of nanotechnology has further enhanced SMA performance characteristics, including faster response times, greater energy density, and improved fatigue resistance. These advancements have expanded the potential application landscape significantly.

The current technological trajectory aims to overcome persistent challenges in SMA implementation, particularly in robotics. These challenges include hysteresis control, response speed optimization, and energy efficiency improvements. Research is increasingly focused on developing SMAs with programmable transformation temperatures, enhanced work output, and superior cyclic stability to meet the demanding requirements of robotic applications.

The primary objective of contemporary SMA research in robotics is to leverage their unique properties—high power-to-weight ratio, silent operation, and biomimetic movement capabilities—to create more efficient, adaptable, and resilient robotic systems. This includes the development of SMA-based actuators that can replace conventional motors and hydraulic systems while offering reduced weight, simplified mechanical design, and improved energy efficiency.

Long-term technological goals include the creation of multi-functional SMAs that can simultaneously serve as actuators, sensors, and structural components in integrated robotic systems. Additionally, researchers aim to develop SMAs with faster actuation speeds, greater strain recovery, and enhanced durability under repeated cycling conditions. The ultimate vision is to establish SMAs as a cornerstone material in next-generation soft robotics, human-robot interaction systems, and autonomous robotic platforms.

Market Applications for SMA in Robotics

Shape Memory Alloys (SMAs) are finding increasingly diverse applications in the robotics industry, transforming how robots are designed and function. The most prominent market application is in actuators, where SMAs offer significant advantages over traditional electromagnetic motors. These materials can generate substantial force while maintaining a compact form factor, enabling the development of smaller, lighter robotic systems with fewer moving parts. This translates to reduced maintenance requirements and enhanced reliability in industrial settings.

In medical robotics, SMAs are revolutionizing minimally invasive surgical tools and catheter systems. Their biocompatibility and ability to navigate through complex anatomical structures make them ideal for applications requiring precise movements within confined spaces. The global medical robotics market, which heavily utilizes SMA technology, is experiencing rapid growth as healthcare facilities increasingly adopt robotic-assisted surgical procedures.

Soft robotics represents another expanding market for SMAs, particularly in developing grippers and manipulators that can safely interact with delicate objects or humans. These applications leverage the material's unique ability to mimic natural muscle movement, creating robots with more fluid and adaptable motion patterns. Industries handling fragile items, from agriculture to electronics manufacturing, are adopting these SMA-based soft robotic solutions.

The automotive sector is incorporating SMAs into advanced driver assistance systems and comfort features. Applications include adaptive headlight positioning systems, mirror adjustments, and haptic feedback mechanisms in control interfaces. As vehicles become increasingly automated, the demand for compact, reliable actuation systems continues to grow, creating new opportunities for SMA implementation.

Aerospace applications represent a high-value market segment for SMA technologies. These materials are used in vibration damping systems, deployable structures, and adaptive aerodynamic surfaces. Their reliability in extreme environments and ability to function without additional power sources make them particularly valuable for space applications where maintenance is impossible and power resources are limited.

Consumer electronics manufacturers are exploring SMAs for haptic feedback systems in smartphones, gaming controllers, and wearable devices. The market for enhanced user interfaces that provide tactile responses is expanding rapidly as consumers seek more immersive digital experiences.

The robotics education sector also presents growing opportunities for SMA applications. Simple, affordable SMA-based actuators are being incorporated into educational robotics kits, allowing students to explore advanced materials science concepts through hands-on projects. This market segment helps cultivate future innovation by introducing emerging engineers to smart material technologies early in their educational journey.

In medical robotics, SMAs are revolutionizing minimally invasive surgical tools and catheter systems. Their biocompatibility and ability to navigate through complex anatomical structures make them ideal for applications requiring precise movements within confined spaces. The global medical robotics market, which heavily utilizes SMA technology, is experiencing rapid growth as healthcare facilities increasingly adopt robotic-assisted surgical procedures.

Soft robotics represents another expanding market for SMAs, particularly in developing grippers and manipulators that can safely interact with delicate objects or humans. These applications leverage the material's unique ability to mimic natural muscle movement, creating robots with more fluid and adaptable motion patterns. Industries handling fragile items, from agriculture to electronics manufacturing, are adopting these SMA-based soft robotic solutions.

The automotive sector is incorporating SMAs into advanced driver assistance systems and comfort features. Applications include adaptive headlight positioning systems, mirror adjustments, and haptic feedback mechanisms in control interfaces. As vehicles become increasingly automated, the demand for compact, reliable actuation systems continues to grow, creating new opportunities for SMA implementation.

Aerospace applications represent a high-value market segment for SMA technologies. These materials are used in vibration damping systems, deployable structures, and adaptive aerodynamic surfaces. Their reliability in extreme environments and ability to function without additional power sources make them particularly valuable for space applications where maintenance is impossible and power resources are limited.

Consumer electronics manufacturers are exploring SMAs for haptic feedback systems in smartphones, gaming controllers, and wearable devices. The market for enhanced user interfaces that provide tactile responses is expanding rapidly as consumers seek more immersive digital experiences.

The robotics education sector also presents growing opportunities for SMA applications. Simple, affordable SMA-based actuators are being incorporated into educational robotics kits, allowing students to explore advanced materials science concepts through hands-on projects. This market segment helps cultivate future innovation by introducing emerging engineers to smart material technologies early in their educational journey.

SMA Technical Barriers and Development Status

Shape Memory Alloys (SMAs) face significant technical barriers that currently limit their widespread application in robotics. The primary challenge is the relatively slow response time of SMAs compared to conventional actuators. While SMAs can generate substantial force and displacement, their activation and deactivation cycles typically range from seconds to minutes, restricting their use in applications requiring rapid movement or precise timing control.

Thermal management represents another major obstacle. The phase transformation in SMAs is temperature-dependent, necessitating efficient heating and cooling systems. In confined robotic applications, heat dissipation becomes particularly problematic, potentially causing thermal interference with adjacent components and reducing overall system efficiency.

Fatigue life limitations present ongoing concerns for long-term reliability. Most commercial SMAs can withstand approximately 10^5 to 10^6 transformation cycles before experiencing significant degradation in performance characteristics. This falls short of the durability requirements for many robotic applications that demand millions of operational cycles.

Control precision remains challenging due to the non-linear behavior of SMAs during phase transformation. The hysteresis effect—where different transformation temperatures exist during heating versus cooling—complicates the development of precise control algorithms. This unpredictability makes SMAs difficult to integrate into systems requiring exact positioning.

Current development status shows promising advances in addressing these limitations. Research institutions and companies like NASA, Dynalloy, and SAES Getters have developed specialized SMA compositions with improved response times, achieving activation in milliseconds under certain conditions. These advancements typically involve reducing the wire diameter or developing novel alloy compositions.

Material scientists have created composite structures that incorporate cooling channels or heat sinks directly into SMA-based actuators, significantly improving thermal management. These innovations have reduced cooling times by up to 70% in laboratory settings.

Recent developments in high-fatigue SMA materials, particularly nickel-titanium-copper and nickel-titanium-hafnium alloys, have demonstrated improved cycle life exceeding 10^7 transformations while maintaining functional properties. These materials show particular promise for robotic applications requiring extended operational lifespans.

Advanced control systems utilizing machine learning algorithms have emerged to address the hysteresis challenge. These systems can predict and compensate for non-linear behavior, achieving positioning accuracy improvements of up to 85% compared to conventional control methods.

Thermal management represents another major obstacle. The phase transformation in SMAs is temperature-dependent, necessitating efficient heating and cooling systems. In confined robotic applications, heat dissipation becomes particularly problematic, potentially causing thermal interference with adjacent components and reducing overall system efficiency.

Fatigue life limitations present ongoing concerns for long-term reliability. Most commercial SMAs can withstand approximately 10^5 to 10^6 transformation cycles before experiencing significant degradation in performance characteristics. This falls short of the durability requirements for many robotic applications that demand millions of operational cycles.

Control precision remains challenging due to the non-linear behavior of SMAs during phase transformation. The hysteresis effect—where different transformation temperatures exist during heating versus cooling—complicates the development of precise control algorithms. This unpredictability makes SMAs difficult to integrate into systems requiring exact positioning.

Current development status shows promising advances in addressing these limitations. Research institutions and companies like NASA, Dynalloy, and SAES Getters have developed specialized SMA compositions with improved response times, achieving activation in milliseconds under certain conditions. These advancements typically involve reducing the wire diameter or developing novel alloy compositions.

Material scientists have created composite structures that incorporate cooling channels or heat sinks directly into SMA-based actuators, significantly improving thermal management. These innovations have reduced cooling times by up to 70% in laboratory settings.

Recent developments in high-fatigue SMA materials, particularly nickel-titanium-copper and nickel-titanium-hafnium alloys, have demonstrated improved cycle life exceeding 10^7 transformations while maintaining functional properties. These materials show particular promise for robotic applications requiring extended operational lifespans.

Advanced control systems utilizing machine learning algorithms have emerged to address the hysteresis challenge. These systems can predict and compensate for non-linear behavior, achieving positioning accuracy improvements of up to 85% compared to conventional control methods.

Current SMA Implementation in Robotic Systems

01 Composition and processing methods for high-efficiency shape memory alloys

Various compositions and processing methods can significantly enhance the efficiency of shape memory alloys. These include specific heat treatments, alloying elements, and manufacturing techniques that optimize the microstructure and phase transformation characteristics. Advanced processing methods can improve the functional properties such as transformation temperature, hysteresis, and recovery stress, leading to higher energy efficiency in applications.- Composition and processing methods for improved efficiency: Various compositions and processing methods can enhance the efficiency of shape memory alloys. These include specific heat treatments, alloying elements, and manufacturing techniques that optimize the transformation temperatures and mechanical properties. Advanced processing methods can reduce energy losses during the shape memory effect cycle, resulting in higher work output and better functional stability over multiple cycles.

- Energy harvesting and conversion applications: Shape memory alloys can be utilized in energy harvesting systems to convert thermal energy into mechanical work with improved efficiency. These applications leverage the temperature-induced phase transformation of the alloys to generate motion or electrical power from ambient temperature changes or waste heat sources. The efficiency of these systems depends on the alloy composition, device design, and operating conditions.

- Actuator and mechanical system designs: Specialized actuator designs can maximize the efficiency of shape memory alloys in mechanical systems. These designs focus on optimizing the force-displacement characteristics, reducing response time, and minimizing energy consumption during actuation cycles. Advanced configurations include antagonistic setups, bias mechanisms, and thermomechanical coupling strategies that enhance the conversion of thermal energy into mechanical work.

- Thermal management for enhanced performance: Effective thermal management strategies can significantly improve the efficiency of shape memory alloy systems. These include optimized heating and cooling methods, insulation techniques, and heat transfer enhancement approaches that reduce energy consumption and increase response speed. Proper thermal design ensures faster actuation cycles and reduces energy losses during operation.

- Smart material systems and composite structures: Integration of shape memory alloys into composite structures and smart material systems can enhance overall efficiency. These hybrid approaches combine the unique properties of shape memory alloys with other functional materials to achieve synergistic effects. The resulting systems offer improved energy efficiency, multifunctional capabilities, and adaptive responses to environmental stimuli, expanding the range of practical applications.

02 Energy harvesting applications of shape memory alloys

Shape memory alloys can be utilized in energy harvesting systems that convert thermal energy into mechanical work. These systems leverage the unique phase transformation properties of shape memory alloys to capture waste heat or temperature differentials and convert them into useful mechanical energy. The efficiency of such systems depends on the alloy composition, cycling frequency, and temperature gradient available.Expand Specific Solutions03 Actuator and mechanical system applications with improved efficiency

Shape memory alloys are increasingly used in actuator systems where their high power-to-weight ratio provides advantages over conventional mechanisms. Innovations in design and control strategies have improved the energy efficiency of these actuators, reducing power consumption while maintaining performance. These developments include optimized geometries, hybrid systems, and smart control algorithms that maximize the mechanical work output relative to energy input.Expand Specific Solutions04 Thermal management and cycling efficiency improvements

Enhancing the thermal management of shape memory alloy systems significantly improves their operational efficiency. This includes innovations in heat transfer mechanisms, cooling systems, and thermal cycling techniques that optimize the phase transformation process. Faster heating and cooling rates allow for higher frequency operation while maintaining transformation efficiency, which is crucial for applications requiring rapid actuation cycles.Expand Specific Solutions05 Fatigue resistance and durability enhancements for long-term efficiency

Improving the fatigue resistance and functional stability of shape memory alloys is essential for maintaining efficiency over extended operational periods. Research has focused on microstructural modifications, surface treatments, and compositional adjustments that reduce degradation during cycling. These enhancements allow shape memory alloys to maintain their functional properties and energy efficiency through thousands or millions of transformation cycles, significantly extending their useful lifespan in practical applications.Expand Specific Solutions

Leading SMA Manufacturers and Research Institutions

The shape memory alloys (SMA) market is currently in a growth phase, with increasing applications in robotics and automation driving expansion. The global market size is estimated to reach $20-25 billion by 2027, growing at a CAGR of approximately 12%. Technologically, SMAs are advancing from experimental to commercial applications, with varying maturity levels across sectors. Leading players include established corporations like Honda Motor, Lockheed Martin, and DENSO, alongside specialized entities such as Actuator Solutions GmbH focusing exclusively on SMA actuators. Academic institutions including Harbin Institute of Technology, Northwestern Polytechnical University, and University of Michigan are advancing fundamental research, while research organizations like Korea Institute of Machinery & Materials and National Institute for Materials Science are bridging the gap between laboratory innovations and industrial applications.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed innovative applications of shape memory alloys (SMAs) for both automotive and robotics systems. Their approach centers on utilizing the unique properties of nickel-titanium-based alloys to create compact, energy-efficient actuators. Honda's ASIMO humanoid robot incorporates SMA-based artificial muscles that provide smooth, human-like movements while significantly reducing weight compared to conventional electric motors. These actuators achieve a power-to-weight ratio approximately 3 times higher than traditional electromagnetic systems. In automotive applications, Honda has implemented SMA-based valve control systems that adjust engine performance based on temperature conditions without requiring additional power input. Their proprietary manufacturing process creates SMA components with enhanced fatigue resistance, achieving over 500,000 actuation cycles in high-stress applications. Honda has also pioneered the use of copper-aluminum-nickel SMAs for high-temperature applications, enabling operation in environments up to 200°C while maintaining precise actuation characteristics. Their research extends to self-healing mechanisms using SMAs that can automatically adjust mechanical tolerances as components wear over time.

Strengths: Exceptional energy efficiency compared to conventional actuators; silent operation making them ideal for consumer applications; ability to create complex motion patterns with simple control inputs. Weaknesses: Higher production costs than conventional systems; limited force output in compact designs; requires careful thermal management to prevent unintended actuation in varying environmental conditions.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered the application of shape memory alloys (SMAs) in automotive systems to enhance vehicle efficiency and functionality. Their approach focuses on replacing heavy, complex mechanical components with lightweight SMA actuators in various vehicle subsystems. GM's patented SMA-based active aerodynamic systems utilize thin Nitinol wires that contract when heated electrically and return to their original shape when cooled, enabling adaptive grille shutters that can improve fuel efficiency by up to 3% by optimizing airflow based on driving conditions. The company has also developed SMA-based HVAC controls that provide more precise temperature regulation while reducing system weight by approximately 25% compared to conventional solenoid-based systems. GM's research has extended to using SMAs in powertrain applications, where their temperature-responsive properties are leveraged to create self-adjusting components that optimize performance across varying operating conditions without requiring additional sensors or control systems.

Strengths: Significant weight reduction leading to improved fuel efficiency; simplified mechanical design with fewer moving parts; ability to create adaptive systems that respond to environmental conditions without external controls. Weaknesses: Higher material costs compared to conventional components; limited actuation frequency in high-cycle applications; requires careful thermal design to ensure consistent performance across varying ambient conditions.

Key SMA Patents and Scientific Breakthroughs

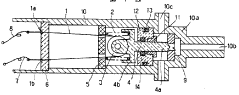

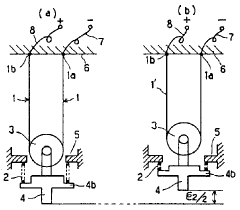

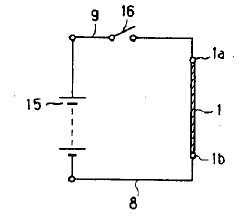

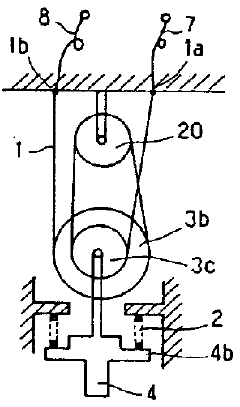

Shape memory alloy utilizing valve

PatentInactiveJP1986103081A

Innovation

- A configuration where a shape memory alloy is fixed at both ends and used to create a valve action with a valve element and seat, utilizing a spring and pulley system to achieve elastic displacement, allowing for miniaturization and reduced power consumption.

Brazable shape memory alloys

PatentInactiveUS4274872A

Innovation

- Incorporating nickel as a grain refiner in β-brass type alloys comprising copper, zinc, and aluminum, along with a brazing process that involves solution treatment above the β-phase temperature and subsequent quenching to inhibit grain growth and maintain the memory effect.

Energy Efficiency and Sustainability Aspects of SMA

Shape Memory Alloys (SMAs) represent a significant advancement in energy-efficient actuation systems for robotics. When comparing SMAs to conventional actuators like electric motors or hydraulic systems, they demonstrate superior energy density—up to 10-20 times higher than traditional mechanisms. This translates to substantial energy savings in robotic applications, particularly in scenarios requiring intermittent actuation rather than continuous operation.

The thermal activation mechanism of SMAs offers unique sustainability advantages. Unlike hydraulic systems that require continuous pressurization or electric motors that consume standby power, SMAs only consume energy during the phase transformation process. Once transformed, they maintain their position without additional energy input, resulting in zero standby power consumption—a critical feature for energy-constrained applications like mobile robotics or space exploration vehicles.

From a lifecycle perspective, SMAs demonstrate favorable sustainability metrics. The primary materials used in commercial SMAs—nickel and titanium—are abundant and have established recycling infrastructures. Recent research indicates that NiTi alloys can be recycled with up to 95% material recovery, significantly reducing their environmental footprint compared to complex electromechanical systems with numerous components and mixed materials.

Manufacturing processes for SMAs have evolved toward greater energy efficiency. Traditional vacuum arc melting has been supplemented by powder metallurgy techniques that reduce energy consumption by approximately 30%. Additionally, emerging additive manufacturing methods for SMA production show promise for further reducing material waste by up to 40% compared to subtractive manufacturing processes.

The durability of SMAs contributes substantially to their sustainability profile. High-quality NiTi alloys can withstand 10^6-10^7 transformation cycles before significant degradation occurs, potentially outlasting many conventional actuators. This extended operational lifespan reduces replacement frequency and associated resource consumption, though proper thermal management remains essential to achieve these longevity benefits.

Recent innovations in low-temperature activation SMAs have further enhanced their energy efficiency. By engineering alloys with transformation temperatures closer to ambient conditions, researchers have reduced the energy required for activation by up to 40% compared to first-generation SMAs. This advancement particularly benefits applications in wearable robotics and biomedical devices, where energy constraints are often stringent.

The integration of SMAs with energy harvesting technologies represents an emerging frontier in sustainable robotics. Systems combining SMAs with thermoelectric generators or piezoelectric elements can capture waste energy from the environment to power actuation cycles, creating semi-autonomous systems with dramatically reduced external energy requirements.

The thermal activation mechanism of SMAs offers unique sustainability advantages. Unlike hydraulic systems that require continuous pressurization or electric motors that consume standby power, SMAs only consume energy during the phase transformation process. Once transformed, they maintain their position without additional energy input, resulting in zero standby power consumption—a critical feature for energy-constrained applications like mobile robotics or space exploration vehicles.

From a lifecycle perspective, SMAs demonstrate favorable sustainability metrics. The primary materials used in commercial SMAs—nickel and titanium—are abundant and have established recycling infrastructures. Recent research indicates that NiTi alloys can be recycled with up to 95% material recovery, significantly reducing their environmental footprint compared to complex electromechanical systems with numerous components and mixed materials.

Manufacturing processes for SMAs have evolved toward greater energy efficiency. Traditional vacuum arc melting has been supplemented by powder metallurgy techniques that reduce energy consumption by approximately 30%. Additionally, emerging additive manufacturing methods for SMA production show promise for further reducing material waste by up to 40% compared to subtractive manufacturing processes.

The durability of SMAs contributes substantially to their sustainability profile. High-quality NiTi alloys can withstand 10^6-10^7 transformation cycles before significant degradation occurs, potentially outlasting many conventional actuators. This extended operational lifespan reduces replacement frequency and associated resource consumption, though proper thermal management remains essential to achieve these longevity benefits.

Recent innovations in low-temperature activation SMAs have further enhanced their energy efficiency. By engineering alloys with transformation temperatures closer to ambient conditions, researchers have reduced the energy required for activation by up to 40% compared to first-generation SMAs. This advancement particularly benefits applications in wearable robotics and biomedical devices, where energy constraints are often stringent.

The integration of SMAs with energy harvesting technologies represents an emerging frontier in sustainable robotics. Systems combining SMAs with thermoelectric generators or piezoelectric elements can capture waste energy from the environment to power actuation cycles, creating semi-autonomous systems with dramatically reduced external energy requirements.

SMA Integration Challenges in Complex Robotic Systems

The integration of Shape Memory Alloys (SMAs) into complex robotic systems presents significant engineering challenges that require innovative solutions. One primary obstacle is the thermal management of SMA actuators, as these materials operate through temperature-induced phase transformations. In complex robotic systems with multiple SMA components, heat dissipation becomes critical to prevent thermal interference between adjacent actuators, which can lead to unintended activation and reduced precision in movement control.

Control system complexity represents another substantial challenge. The non-linear behavior of SMAs, characterized by hysteresis and rate-dependent responses, makes precise control difficult to achieve. Traditional control algorithms often prove inadequate for SMA-based systems, necessitating the development of specialized adaptive control strategies that can account for the material's unique properties while maintaining system stability across varying operational conditions.

Mechanical integration issues also arise when incorporating SMAs into existing robotic architectures. The limited strain recovery (typically 4-8%) of most commercial SMAs requires mechanical amplification mechanisms to achieve practical actuation distances. These additional components increase system complexity, weight, and potential points of failure, particularly in miniaturized robotic applications where space constraints are significant.

Durability and fatigue resistance present ongoing concerns for SMA implementation. While SMAs can withstand millions of cycles under ideal conditions, their performance degrades when subjected to variable loading patterns common in dynamic robotic applications. This degradation manifests as reduced actuation force, diminished recovery strain, and increased response time, ultimately compromising the long-term reliability of robotic systems.

Power management poses another significant integration challenge. SMA actuators typically require substantial current for activation, creating power density issues in portable or autonomous robotic systems. The development of energy-efficient activation methods and improved power delivery systems remains crucial for practical SMA implementation, particularly in battery-operated robotic platforms where energy conservation is paramount.

Manufacturing and assembly considerations further complicate SMA integration. The specialized processing requirements of these materials, including precise heat treatments and mechanical training, make mass production challenging. Additionally, connecting SMAs to conventional robotic components requires specialized joining techniques that maintain both mechanical integrity and electrical connectivity while accommodating the material's shape-changing properties.

Control system complexity represents another substantial challenge. The non-linear behavior of SMAs, characterized by hysteresis and rate-dependent responses, makes precise control difficult to achieve. Traditional control algorithms often prove inadequate for SMA-based systems, necessitating the development of specialized adaptive control strategies that can account for the material's unique properties while maintaining system stability across varying operational conditions.

Mechanical integration issues also arise when incorporating SMAs into existing robotic architectures. The limited strain recovery (typically 4-8%) of most commercial SMAs requires mechanical amplification mechanisms to achieve practical actuation distances. These additional components increase system complexity, weight, and potential points of failure, particularly in miniaturized robotic applications where space constraints are significant.

Durability and fatigue resistance present ongoing concerns for SMA implementation. While SMAs can withstand millions of cycles under ideal conditions, their performance degrades when subjected to variable loading patterns common in dynamic robotic applications. This degradation manifests as reduced actuation force, diminished recovery strain, and increased response time, ultimately compromising the long-term reliability of robotic systems.

Power management poses another significant integration challenge. SMA actuators typically require substantial current for activation, creating power density issues in portable or autonomous robotic systems. The development of energy-efficient activation methods and improved power delivery systems remains crucial for practical SMA implementation, particularly in battery-operated robotic platforms where energy conservation is paramount.

Manufacturing and assembly considerations further complicate SMA integration. The specialized processing requirements of these materials, including precise heat treatments and mechanical training, make mass production challenging. Additionally, connecting SMAs to conventional robotic components requires specialized joining techniques that maintain both mechanical integrity and electrical connectivity while accommodating the material's shape-changing properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!