Shape Memory Alloys: Insights into Enhanced Cycle Life and Sustainability

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SMA Technology Evolution and Objectives

Shape Memory Alloys (SMAs) represent a class of smart materials that possess the remarkable ability to recover their original shape after deformation when subjected to specific stimuli, typically temperature changes or mechanical stress. The evolution of SMA technology traces back to the 1930s when the first observations of shape memory effect were documented in gold-cadmium alloys. However, the field gained significant momentum in the early 1960s with the discovery of Nitinol (Nickel-Titanium) by William J. Buehler at the Naval Ordnance Laboratory, marking a pivotal milestone in SMA development.

The technological trajectory of SMAs has been characterized by progressive improvements in material composition, processing techniques, and application methodologies. Initially, research focused primarily on understanding the fundamental mechanisms underlying the shape memory effect and superelasticity. This phase established the martensitic transformation as the key phenomenon responsible for these unique properties, laying the theoretical foundation for subsequent advancements.

By the 1980s and 1990s, research emphasis shifted toward enhancing functional properties and developing commercial applications. This period witnessed the emergence of various SMA systems beyond Nitinol, including copper-based alloys (Cu-Zn-Al, Cu-Al-Ni) and iron-based alloys, each offering distinct advantages for specific applications. Concurrently, processing technologies evolved to address challenges related to material fatigue, transformation temperature control, and manufacturing scalability.

The current technological landscape of SMAs is characterized by a dual focus on performance optimization and sustainability considerations. Recent research trends indicate growing interest in improving cycle life—the number of transformation cycles an SMA can undergo before significant degradation occurs—which represents a critical factor limiting widespread industrial adoption. Simultaneously, environmental concerns have prompted investigations into more sustainable SMA compositions and processing methods that reduce reliance on rare or toxic elements.

The primary objectives of contemporary SMA research and development center around several key areas. First, extending the functional fatigue life of SMAs to enable their application in high-cycle scenarios such as vibration damping and energy harvesting. Second, developing cost-effective manufacturing processes that maintain precise control over transformation temperatures and mechanical properties. Third, exploring novel SMA compositions with enhanced sustainability profiles, including reduced energy requirements for production and improved recyclability.

Looking forward, the technological roadmap for SMAs aims to address existing limitations while expanding application possibilities. This includes the development of high-temperature SMAs capable of operating in extreme environments, multi-functional SMAs that combine shape memory with additional properties such as electrical conductivity or magnetic responsiveness, and hybrid systems that integrate SMAs with other smart materials to create advanced adaptive structures.

The technological trajectory of SMAs has been characterized by progressive improvements in material composition, processing techniques, and application methodologies. Initially, research focused primarily on understanding the fundamental mechanisms underlying the shape memory effect and superelasticity. This phase established the martensitic transformation as the key phenomenon responsible for these unique properties, laying the theoretical foundation for subsequent advancements.

By the 1980s and 1990s, research emphasis shifted toward enhancing functional properties and developing commercial applications. This period witnessed the emergence of various SMA systems beyond Nitinol, including copper-based alloys (Cu-Zn-Al, Cu-Al-Ni) and iron-based alloys, each offering distinct advantages for specific applications. Concurrently, processing technologies evolved to address challenges related to material fatigue, transformation temperature control, and manufacturing scalability.

The current technological landscape of SMAs is characterized by a dual focus on performance optimization and sustainability considerations. Recent research trends indicate growing interest in improving cycle life—the number of transformation cycles an SMA can undergo before significant degradation occurs—which represents a critical factor limiting widespread industrial adoption. Simultaneously, environmental concerns have prompted investigations into more sustainable SMA compositions and processing methods that reduce reliance on rare or toxic elements.

The primary objectives of contemporary SMA research and development center around several key areas. First, extending the functional fatigue life of SMAs to enable their application in high-cycle scenarios such as vibration damping and energy harvesting. Second, developing cost-effective manufacturing processes that maintain precise control over transformation temperatures and mechanical properties. Third, exploring novel SMA compositions with enhanced sustainability profiles, including reduced energy requirements for production and improved recyclability.

Looking forward, the technological roadmap for SMAs aims to address existing limitations while expanding application possibilities. This includes the development of high-temperature SMAs capable of operating in extreme environments, multi-functional SMAs that combine shape memory with additional properties such as electrical conductivity or magnetic responsiveness, and hybrid systems that integrate SMAs with other smart materials to create advanced adaptive structures.

Market Applications and Demand Analysis

The global market for Shape Memory Alloys (SMAs) has been experiencing robust growth, driven by their unique properties of shape recovery and superelasticity. The market was valued at approximately $10.6 billion in 2020 and is projected to reach $19.5 billion by 2027, growing at a CAGR of 9.2% during the forecast period. This growth trajectory underscores the increasing adoption of SMAs across various industries and applications.

The medical sector represents the largest market segment for SMAs, accounting for over 40% of the total market share. Within healthcare, SMAs are extensively used in orthopedic implants, stents, surgical instruments, and dental applications. The demand is particularly strong for Nitinol-based devices due to their biocompatibility and mechanical properties that closely mimic human tissues. The aging global population and increasing prevalence of cardiovascular diseases are further amplifying this demand.

Aerospace and automotive industries collectively constitute approximately 30% of the SMA market. In aerospace, these materials are utilized in actuators, vibration dampers, and adaptive structures, offering significant weight reduction compared to conventional mechanical systems. The automotive sector employs SMAs in various applications including valves, sensors, and actuators, with a growing interest in their potential for improving fuel efficiency and reducing emissions.

Consumer electronics and robotics represent emerging application areas with substantial growth potential. The miniaturization trend in electronics has created opportunities for SMAs in micro-actuators, switches, and connectors. Similarly, the expanding robotics industry is exploring SMAs for artificial muscles and adaptive gripping mechanisms, leveraging their high power-to-weight ratio and silent operation.

Regional analysis reveals that North America and Europe currently dominate the SMA market, collectively accounting for approximately 60% of global consumption. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization, increasing healthcare expenditure, and expanding manufacturing capabilities in countries like China, Japan, and South Korea.

A significant market trend is the growing demand for SMAs with enhanced cycle life and sustainability characteristics. End-users across industries are increasingly prioritizing materials that can withstand thousands of transformation cycles without degradation, thereby reducing replacement frequency and associated costs. Additionally, there is mounting pressure for more environmentally sustainable production methods and recyclable SMA formulations, particularly in regions with stringent environmental regulations.

The medical sector represents the largest market segment for SMAs, accounting for over 40% of the total market share. Within healthcare, SMAs are extensively used in orthopedic implants, stents, surgical instruments, and dental applications. The demand is particularly strong for Nitinol-based devices due to their biocompatibility and mechanical properties that closely mimic human tissues. The aging global population and increasing prevalence of cardiovascular diseases are further amplifying this demand.

Aerospace and automotive industries collectively constitute approximately 30% of the SMA market. In aerospace, these materials are utilized in actuators, vibration dampers, and adaptive structures, offering significant weight reduction compared to conventional mechanical systems. The automotive sector employs SMAs in various applications including valves, sensors, and actuators, with a growing interest in their potential for improving fuel efficiency and reducing emissions.

Consumer electronics and robotics represent emerging application areas with substantial growth potential. The miniaturization trend in electronics has created opportunities for SMAs in micro-actuators, switches, and connectors. Similarly, the expanding robotics industry is exploring SMAs for artificial muscles and adaptive gripping mechanisms, leveraging their high power-to-weight ratio and silent operation.

Regional analysis reveals that North America and Europe currently dominate the SMA market, collectively accounting for approximately 60% of global consumption. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization, increasing healthcare expenditure, and expanding manufacturing capabilities in countries like China, Japan, and South Korea.

A significant market trend is the growing demand for SMAs with enhanced cycle life and sustainability characteristics. End-users across industries are increasingly prioritizing materials that can withstand thousands of transformation cycles without degradation, thereby reducing replacement frequency and associated costs. Additionally, there is mounting pressure for more environmentally sustainable production methods and recyclable SMA formulations, particularly in regions with stringent environmental regulations.

Current Challenges in SMA Cycle Life

Shape Memory Alloys (SMAs) face significant challenges in achieving extended cycle life, which remains a critical barrier to their widespread industrial adoption. The primary limitation is functional fatigue, characterized by the degradation of shape memory and superelastic properties over repeated transformation cycles. This degradation manifests as a reduction in transformation strain, shifts in transformation temperatures, and accumulation of irrecoverable strain, ultimately leading to mechanical failure.

Microstructural evolution during cycling presents a fundamental challenge. The repeated phase transformations between austenite and martensite induce dislocation formation, slip deformation, and precipitation of secondary phases. These microstructural changes progressively impair the material's ability to fully recover its original shape, particularly under high stress conditions or elevated temperatures.

Thermomechanical processing techniques currently employed to enhance cycle life often involve complex procedures that are difficult to standardize across different alloy compositions. The trade-off between improving fatigue resistance and maintaining other desirable properties, such as transformation temperatures and recovery stress, creates significant engineering dilemmas that have not been fully resolved.

Environmental factors further complicate SMA durability. Corrosion susceptibility, particularly in NiTi-based alloys in biological environments or industrial settings with aggressive media, accelerates degradation and reduces functional lifespan. The synergistic effects of corrosion and mechanical cycling can dramatically shorten service life in practical applications.

Energy dissipation during transformation cycles generates internal heating that can alter transformation behavior and accelerate fatigue processes. This self-heating effect becomes particularly problematic in high-frequency applications or devices requiring rapid actuation cycles, where insufficient heat dissipation leads to thermal fatigue and premature failure.

Manufacturing inconsistencies introduce additional variability in cycle life performance. Inclusions, compositional heterogeneities, and surface defects from processing serve as stress concentration sites that initiate crack formation during cycling. Current production methods struggle to consistently eliminate these defects at commercially viable scales.

The lack of standardized testing protocols and predictive models for SMA fatigue behavior hinders accurate lifetime predictions. The complex interplay between stress, temperature, cycling frequency, and environmental conditions makes empirical testing time-consuming and expensive, while theoretical models often fail to capture the multiphysics nature of SMA degradation mechanisms.

Addressing these challenges requires interdisciplinary approaches combining materials science, mechanical engineering, and computational modeling to develop next-generation SMAs with substantially improved cycle life characteristics.

Microstructural evolution during cycling presents a fundamental challenge. The repeated phase transformations between austenite and martensite induce dislocation formation, slip deformation, and precipitation of secondary phases. These microstructural changes progressively impair the material's ability to fully recover its original shape, particularly under high stress conditions or elevated temperatures.

Thermomechanical processing techniques currently employed to enhance cycle life often involve complex procedures that are difficult to standardize across different alloy compositions. The trade-off between improving fatigue resistance and maintaining other desirable properties, such as transformation temperatures and recovery stress, creates significant engineering dilemmas that have not been fully resolved.

Environmental factors further complicate SMA durability. Corrosion susceptibility, particularly in NiTi-based alloys in biological environments or industrial settings with aggressive media, accelerates degradation and reduces functional lifespan. The synergistic effects of corrosion and mechanical cycling can dramatically shorten service life in practical applications.

Energy dissipation during transformation cycles generates internal heating that can alter transformation behavior and accelerate fatigue processes. This self-heating effect becomes particularly problematic in high-frequency applications or devices requiring rapid actuation cycles, where insufficient heat dissipation leads to thermal fatigue and premature failure.

Manufacturing inconsistencies introduce additional variability in cycle life performance. Inclusions, compositional heterogeneities, and surface defects from processing serve as stress concentration sites that initiate crack formation during cycling. Current production methods struggle to consistently eliminate these defects at commercially viable scales.

The lack of standardized testing protocols and predictive models for SMA fatigue behavior hinders accurate lifetime predictions. The complex interplay between stress, temperature, cycling frequency, and environmental conditions makes empirical testing time-consuming and expensive, while theoretical models often fail to capture the multiphysics nature of SMA degradation mechanisms.

Addressing these challenges requires interdisciplinary approaches combining materials science, mechanical engineering, and computational modeling to develop next-generation SMAs with substantially improved cycle life characteristics.

Current Methods for Enhancing SMA Durability

01 Composition optimization for improved cycle life

Specific alloy compositions can significantly enhance the fatigue resistance and cycle life of shape memory alloys. By carefully controlling the proportions of constituent elements and incorporating certain additives, the transformation stability and mechanical durability can be improved. These optimized compositions maintain their shape memory properties over extended cycling periods, making them suitable for applications requiring numerous actuation cycles.- Composition and processing techniques for improved cycle life: Various composition modifications and processing techniques can significantly enhance the cycle life of shape memory alloys. These include specific heat treatments, alloying with elements like copper or niobium, and specialized thermomechanical processing. These methods can reduce fatigue, improve transformation stability, and increase the number of transformation cycles the alloy can withstand before failure.

- Testing and characterization methods for cycle life assessment: Specialized testing methodologies have been developed to evaluate and predict the cycle life of shape memory alloys. These include accelerated fatigue testing, thermomechanical cycling under controlled conditions, and advanced characterization techniques to monitor microstructural changes during cycling. These methods help in understanding degradation mechanisms and optimizing alloy performance for specific applications.

- Applications requiring high cycle life performance: Shape memory alloys with enhanced cycle life are crucial for specific applications such as actuators, medical devices, aerospace components, and automotive systems. These applications often involve repeated transformation cycles under varying stress and temperature conditions, requiring alloys that can maintain their functional properties over thousands or millions of cycles without significant degradation.

- Microstructural factors affecting cycle life: The microstructure of shape memory alloys plays a critical role in determining their cycle life. Factors such as grain size, precipitate distribution, crystallographic orientation, and phase stability significantly influence fatigue resistance and functional stability during cycling. Controlling these microstructural features through appropriate processing can lead to substantial improvements in the operational lifespan of these materials.

- Novel shape memory alloy systems with enhanced cycle life: Research has led to the development of new shape memory alloy systems specifically designed for improved cycle life. These include high-temperature shape memory alloys, thin film materials, nanostructured alloys, and composite systems. These novel materials often exhibit superior resistance to functional fatigue and can maintain their shape memory properties over extended cycling compared to conventional alloys.

02 Thermomechanical processing techniques

Various thermomechanical processing methods can enhance the cycle life of shape memory alloys. These include specific heat treatment protocols, mechanical training procedures, and controlled deformation processes that stabilize the microstructure. Such processing techniques can reduce internal stresses, refine grain structure, and create favorable precipitate distributions, all contributing to improved functional stability during repeated transformation cycles.Expand Specific Solutions03 Surface treatments and protective coatings

Surface treatments and protective coatings can significantly extend the cycle life of shape memory alloys by preventing degradation mechanisms such as corrosion, oxidation, and surface-initiated fatigue. These treatments modify the surface properties without affecting the bulk shape memory behavior, creating a protective barrier that maintains the integrity of the alloy during repeated actuation cycles in challenging environments.Expand Specific Solutions04 Testing and prediction methods for cycle life

Advanced testing methodologies and predictive models have been developed to evaluate and forecast the cycle life of shape memory alloys. These approaches include accelerated fatigue testing, microstructural analysis techniques, and computational models that simulate transformation behavior over multiple cycles. Such methods enable more accurate prediction of long-term performance and help in designing shape memory alloy components with optimized cycle life for specific applications.Expand Specific Solutions05 Application-specific design considerations

Design strategies tailored to specific applications can maximize the cycle life of shape memory alloy components. These include stress distribution optimization, limiting transformation strain to safe levels, and incorporating features that accommodate dimensional changes during cycling. By understanding the unique requirements and constraints of different applications, engineers can design shape memory alloy systems that maintain reliable performance throughout their intended service life.Expand Specific Solutions

Leading SMA Manufacturers and Research Institutions

The Shape Memory Alloys (SMA) market is currently in a growth phase, with increasing applications across automotive, aerospace, medical, and energy sectors. Market size is projected to reach approximately $20 billion by 2027, growing at a CAGR of 12%. Technologically, the field shows varying maturity levels, with companies like Exergyn, SAES Getters, and Actuator Solutions GmbH leading commercial applications, while research institutions such as MIT, University of Florida, and Harbin Institute of Technology drive fundamental innovations. Thyssenkrupp and Toyota are advancing automotive applications, while Boeing and Intel explore aerospace and electronics implementations respectively. The industry faces challenges in enhancing cycle life and sustainability, with collaborative efforts between academic institutions and industrial players focusing on developing more durable and environmentally friendly SMA solutions.

Exergyn Ltd.

Technical Solution: Exergyn has developed innovative shape memory alloy-based thermal energy harvesting systems with enhanced cycle life for sustainable energy applications. Their technology centers on a proprietary SMA formulation optimized specifically for thermal cycling applications with improved functional stability. Exergyn's approach includes a specialized thermomechanical treatment process that creates a "trained" microstructure with stabilized transformation behavior, enabling their materials to withstand millions of thermal cycles without significant degradation. Their innovation includes a unique mechanical system design that limits strain during transformation to below critical thresholds, significantly extending operational lifespan. Exergyn has pioneered the application of SMAs for waste heat recovery, developing systems that can convert low-grade thermal energy (80-150°C) into mechanical work with reported efficiencies up to 8%. Their manufacturing process incorporates precision control of oxygen and carbon content during melting, as these interstitial elements significantly impact transformation stability. Additionally, Exergyn has developed environmentally friendly surface treatments that enhance corrosion resistance without hazardous chemicals, supporting their focus on sustainability.

Strengths: Focused application in renewable energy sector; practical system-level implementation; demonstrated commercial viability; strong sustainability credentials. Weaknesses: Limited material composition range; technology optimized for specific temperature ranges; relatively new market entrant with less established track record.

SAES Getters SpA

Technical Solution: SAES Getters has developed proprietary Nitinol-based shape memory alloys with enhanced functional fatigue resistance through innovative processing techniques. Their technology involves precise control of material composition with specific ratios of nickel and titanium, combined with proprietary thermomechanical treatments that optimize grain structure and precipitate distribution. The company has pioneered a "training" protocol that conditions the alloy through controlled cycling under specific temperature and stress conditions, resulting in stabilized transformation behavior and significantly improved cycle life exceeding 10 million cycles for certain applications. SAES has also developed surface treatment technologies that enhance corrosion resistance and biocompatibility while maintaining transformation properties. Their sustainable manufacturing processes include closed-loop material recycling systems that recover over 90% of scrap material, reducing environmental impact and resource consumption.

Strengths: Industry-leading cycle life performance; established manufacturing infrastructure; comprehensive material characterization capabilities; strong intellectual property portfolio. Weaknesses: Higher production costs compared to conventional alloys; limited application in high-temperature environments; requires specialized processing equipment.

Key Patents and Research in SMA Fatigue Resistance

Shape memory device having two-way cyclical shape memory effect due to compositional gradient and method of manufacture

PatentInactiveUS20060289295A1

Innovation

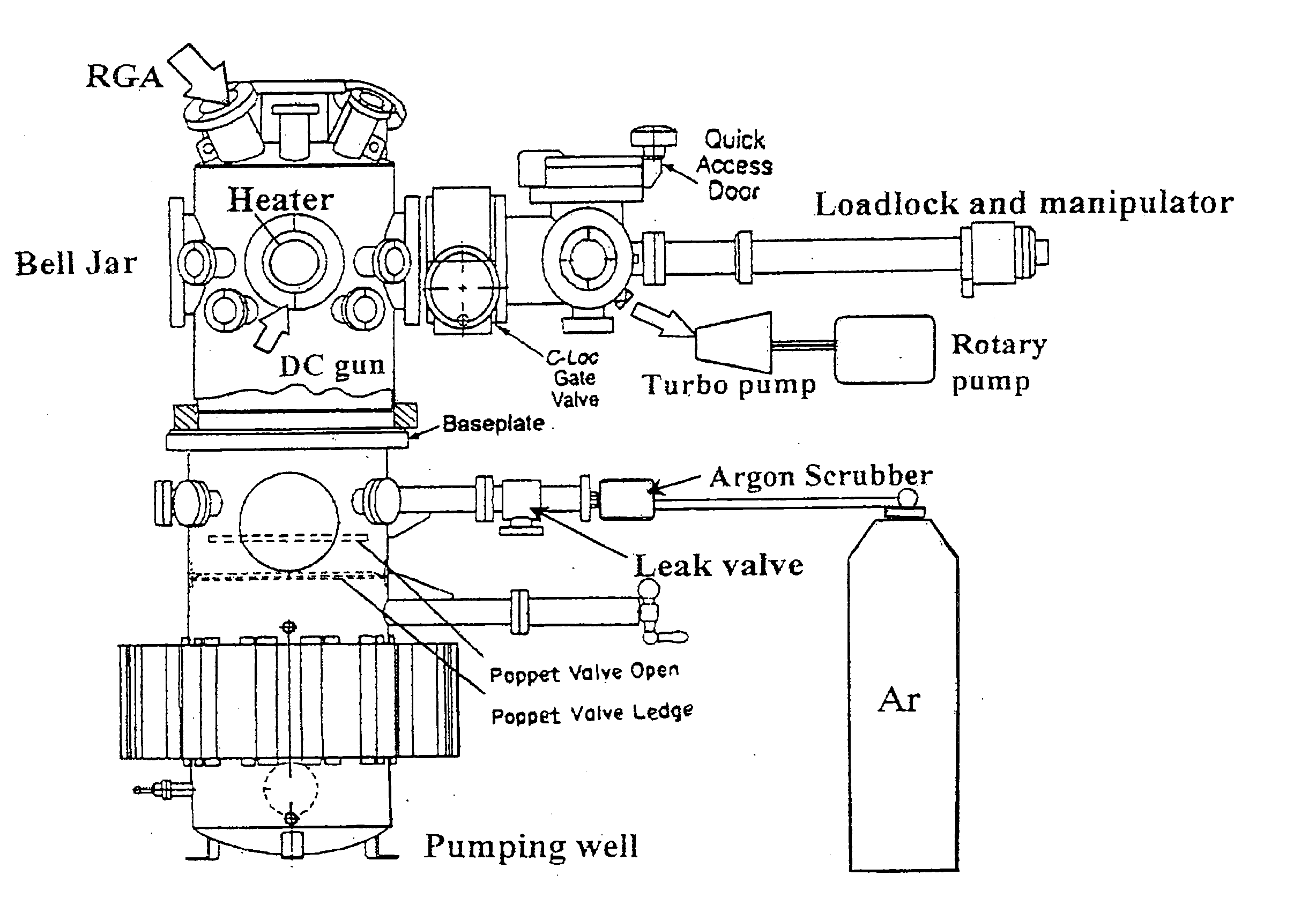

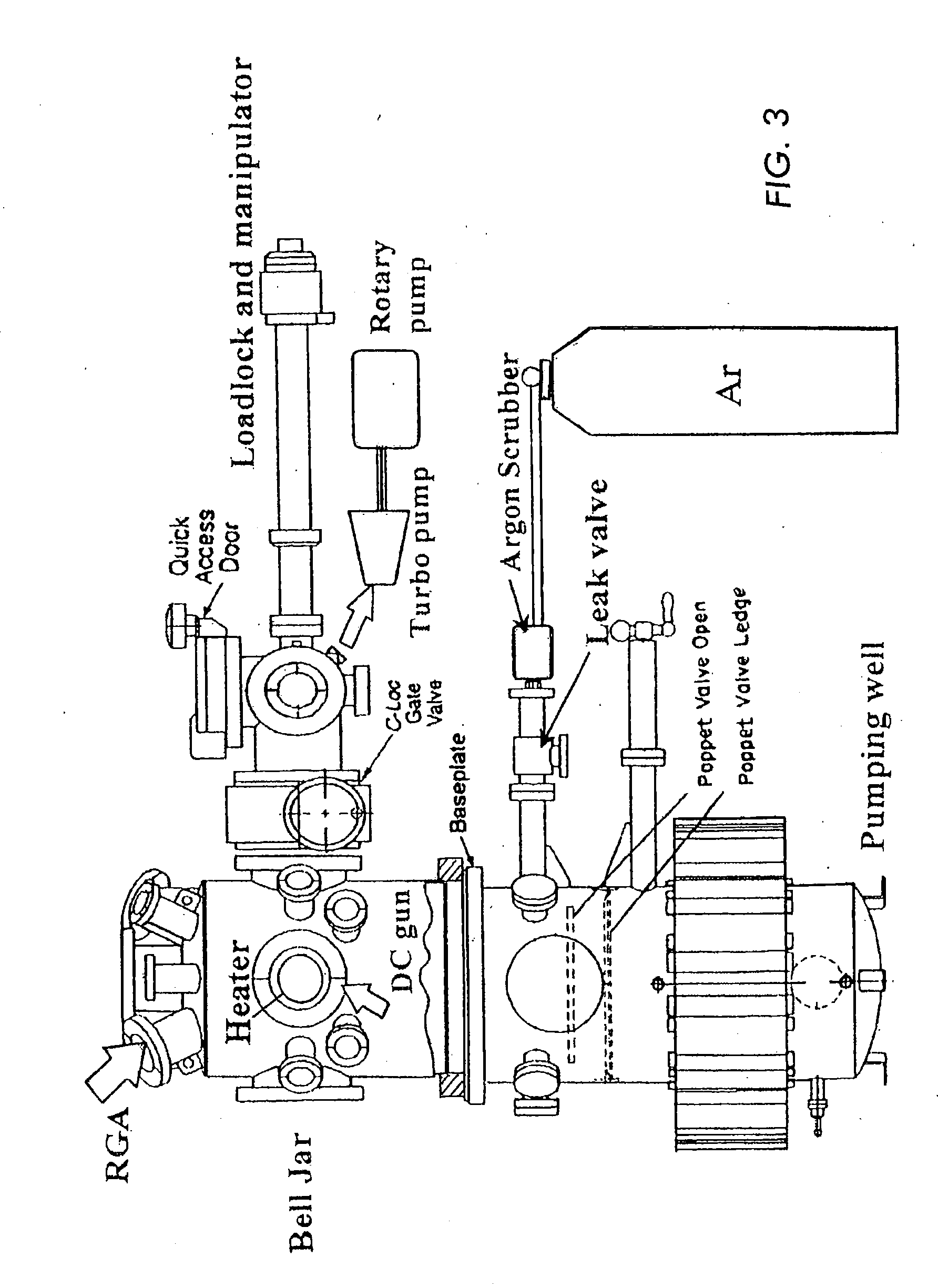

- The use of binary, ternary, and higher-order alloys such as Au:Cd, Fe:Mn:Si, Cu:Zn:Al, and Cu:Ni:Al allows for the production of shape memory films that can exhibit a two-way shape memory effect at higher vacuum pressures, reducing reactivity with contaminants and enabling the deposition of thicker films with compositional gradients, thus eliminating the need for external biasing and simplifying the manufacturing process.

Shape memory alloys made of an iron-cobalt-aluminum system

PatentWO2018060085A1

Innovation

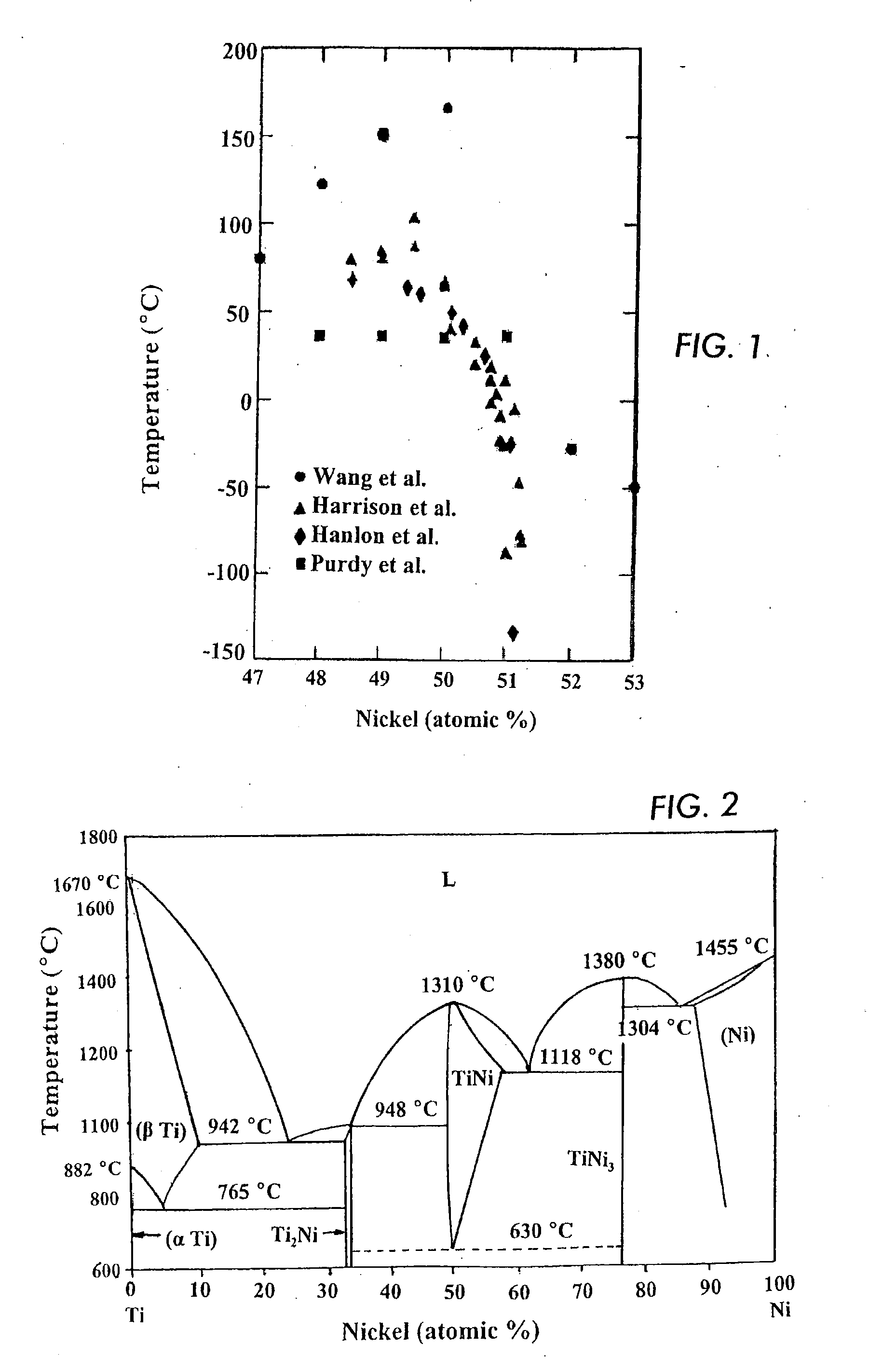

- A shape memory alloy composition of 30-53% cobalt, 18-35% aluminum, and 22-40% iron, with specific ratios optimizing transformation temperatures and cycle numbers, enabling higher reversibility and broader applicability.

Environmental Impact and Recyclability of SMAs

The environmental footprint of Shape Memory Alloys (SMAs) represents a critical consideration in their lifecycle assessment. Traditional manufacturing processes for SMAs, particularly those involving nickel-titanium (Nitinol) alloys, consume significant energy during melting, casting, and subsequent thermomechanical treatments. These energy-intensive processes contribute to greenhouse gas emissions, with estimates suggesting that producing one kilogram of Nitinol generates approximately 40-50 kg of CO2 equivalent emissions.

Water usage and chemical waste also present environmental challenges in SMA production. Acid pickling and surface treatments generate hazardous effluents containing heavy metals and acidic compounds that require specialized treatment before disposal. Recent advancements in cleaner production technologies have shown promise in reducing these impacts, with vacuum induction melting and electron beam melting offering more environmentally friendly alternatives to conventional methods.

The recyclability of SMAs presents both opportunities and challenges. On the positive side, the high value of constituent elements like nickel and titanium provides economic incentives for recovery. Studies indicate that recycled Nitinol can retain up to 90% of its shape memory properties when properly processed, suggesting a viable circular economy approach. However, the complex composition of these alloys, often including trace elements for property enhancement, complicates separation and purification processes.

Several innovative recycling methodologies have emerged in recent years. Electrochemical dissolution techniques allow for selective recovery of constituent elements while maintaining high purity levels. Hydrogen decrepitation offers another promising approach, utilizing hydrogen-induced embrittlement to facilitate mechanical separation of alloy components. These methods demonstrate significantly lower environmental impacts compared to primary production, with energy savings of 40-60% and corresponding reductions in carbon emissions.

Life cycle assessment (LCA) studies comparing virgin and recycled SMAs reveal substantial sustainability benefits. A comprehensive cradle-to-gate analysis shows that recycled Nitinol production can reduce global warming potential by approximately 65% compared to virgin material production. Water consumption and ecotoxicity impacts similarly decrease by 50-70% when implementing closed-loop recycling systems.

The medical device industry, a major consumer of SMAs, has begun implementing take-back programs for explanted devices, creating pathways for material recovery. Automotive and aerospace sectors are following suit with design-for-disassembly approaches that facilitate the eventual recovery of SMA components. These initiatives, coupled with emerging regulatory frameworks promoting extended producer responsibility, are gradually shifting the SMA value chain toward greater circularity and environmental sustainability.

Water usage and chemical waste also present environmental challenges in SMA production. Acid pickling and surface treatments generate hazardous effluents containing heavy metals and acidic compounds that require specialized treatment before disposal. Recent advancements in cleaner production technologies have shown promise in reducing these impacts, with vacuum induction melting and electron beam melting offering more environmentally friendly alternatives to conventional methods.

The recyclability of SMAs presents both opportunities and challenges. On the positive side, the high value of constituent elements like nickel and titanium provides economic incentives for recovery. Studies indicate that recycled Nitinol can retain up to 90% of its shape memory properties when properly processed, suggesting a viable circular economy approach. However, the complex composition of these alloys, often including trace elements for property enhancement, complicates separation and purification processes.

Several innovative recycling methodologies have emerged in recent years. Electrochemical dissolution techniques allow for selective recovery of constituent elements while maintaining high purity levels. Hydrogen decrepitation offers another promising approach, utilizing hydrogen-induced embrittlement to facilitate mechanical separation of alloy components. These methods demonstrate significantly lower environmental impacts compared to primary production, with energy savings of 40-60% and corresponding reductions in carbon emissions.

Life cycle assessment (LCA) studies comparing virgin and recycled SMAs reveal substantial sustainability benefits. A comprehensive cradle-to-gate analysis shows that recycled Nitinol production can reduce global warming potential by approximately 65% compared to virgin material production. Water consumption and ecotoxicity impacts similarly decrease by 50-70% when implementing closed-loop recycling systems.

The medical device industry, a major consumer of SMAs, has begun implementing take-back programs for explanted devices, creating pathways for material recovery. Automotive and aerospace sectors are following suit with design-for-disassembly approaches that facilitate the eventual recovery of SMA components. These initiatives, coupled with emerging regulatory frameworks promoting extended producer responsibility, are gradually shifting the SMA value chain toward greater circularity and environmental sustainability.

Standardization and Testing Protocols for SMA Lifecycle Assessment

The development of standardized testing protocols for Shape Memory Alloys (SMAs) represents a critical step toward ensuring reliable performance assessment and industry-wide adoption. Currently, the SMA field suffers from fragmented testing methodologies, making cross-study comparisons and lifecycle predictions challenging. ASTM International and ISO have established preliminary standards for certain SMA applications, but comprehensive lifecycle assessment protocols remain underdeveloped.

A robust standardization framework must address multiple performance dimensions including thermomechanical cycling, functional fatigue, structural fatigue, and environmental degradation mechanisms. Testing protocols should incorporate both accelerated aging tests and real-time degradation monitoring to establish meaningful correlations between laboratory results and field performance. The temperature range, stress levels, and cycling frequencies must be carefully calibrated to reflect actual application conditions.

For medical applications, additional biocompatibility and corrosion resistance testing standards are essential. The FDA has published guidance documents for SMA-based implantable devices, requiring specific testing for nickel leaching and tissue response. Similarly, aerospace applications demand rigorous vibration and thermal cycling tests that simulate extreme environmental conditions.

Digital twins and physics-based modeling approaches are emerging as valuable tools for standardizing virtual testing environments. These computational frameworks enable the prediction of SMA behavior under various conditions without extensive physical testing, potentially accelerating the standardization process. However, validation protocols for these virtual testing environments themselves require standardization.

Round-robin testing involving multiple laboratories has proven effective in establishing reproducible protocols. Recent initiatives by the International Association for SMA Standardization have coordinated cross-laboratory validation studies, resulting in more consistent measurement techniques for transformation temperatures and mechanical properties. These collaborative efforts have reduced inter-laboratory variation from approximately 15% to under 5% for critical performance metrics.

Sustainability considerations must be integrated into lifecycle assessment protocols, including recyclability evaluation, energy consumption during manufacturing, and end-of-life material recovery efficiency. The development of standardized environmental impact metrics specific to SMAs would facilitate more meaningful sustainability comparisons across different alloy systems and manufacturing processes.

Certification programs based on these standardized protocols would provide manufacturers and end-users with greater confidence in SMA component reliability. Such certification would particularly benefit emerging applications in soft robotics, adaptive structures, and energy harvesting systems where long-term performance data remains limited.

A robust standardization framework must address multiple performance dimensions including thermomechanical cycling, functional fatigue, structural fatigue, and environmental degradation mechanisms. Testing protocols should incorporate both accelerated aging tests and real-time degradation monitoring to establish meaningful correlations between laboratory results and field performance. The temperature range, stress levels, and cycling frequencies must be carefully calibrated to reflect actual application conditions.

For medical applications, additional biocompatibility and corrosion resistance testing standards are essential. The FDA has published guidance documents for SMA-based implantable devices, requiring specific testing for nickel leaching and tissue response. Similarly, aerospace applications demand rigorous vibration and thermal cycling tests that simulate extreme environmental conditions.

Digital twins and physics-based modeling approaches are emerging as valuable tools for standardizing virtual testing environments. These computational frameworks enable the prediction of SMA behavior under various conditions without extensive physical testing, potentially accelerating the standardization process. However, validation protocols for these virtual testing environments themselves require standardization.

Round-robin testing involving multiple laboratories has proven effective in establishing reproducible protocols. Recent initiatives by the International Association for SMA Standardization have coordinated cross-laboratory validation studies, resulting in more consistent measurement techniques for transformation temperatures and mechanical properties. These collaborative efforts have reduced inter-laboratory variation from approximately 15% to under 5% for critical performance metrics.

Sustainability considerations must be integrated into lifecycle assessment protocols, including recyclability evaluation, energy consumption during manufacturing, and end-of-life material recovery efficiency. The development of standardized environmental impact metrics specific to SMAs would facilitate more meaningful sustainability comparisons across different alloy systems and manufacturing processes.

Certification programs based on these standardized protocols would provide manufacturers and end-users with greater confidence in SMA component reliability. Such certification would particularly benefit emerging applications in soft robotics, adaptive structures, and energy harvesting systems where long-term performance data remains limited.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!