Patents and Innovations in Shape Memory Alloys for Wearable Technology

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SMA Technology Evolution and Objectives

Shape Memory Alloys (SMAs) have evolved significantly since their discovery in the 1930s, with the first commercially viable SMA, Nitinol (a nickel-titanium alloy), being developed at the Naval Ordnance Laboratory in the 1960s. Initially, SMAs were primarily utilized in aerospace and medical applications due to their unique properties of shape recovery and superelasticity. The technological evolution of SMAs has been characterized by continuous improvements in material composition, processing techniques, and application methodologies.

The 1980s and 1990s witnessed the expansion of SMA applications into various industries, including automotive and robotics. However, it was not until the early 2000s that researchers began exploring the potential of SMAs in wearable technology. This shift was driven by the growing demand for flexible, adaptable, and comfortable wearable devices that could seamlessly integrate with the human body.

Recent advancements in SMA technology have focused on enhancing their responsiveness, durability, and energy efficiency. Innovations in nano-structured SMAs and composite materials have led to improved performance characteristics, making them increasingly suitable for wearable applications. Patent activities in this domain have surged over the past decade, with significant contributions from both academic institutions and industry leaders.

The current technological trajectory of SMAs in wearable technology is oriented towards addressing several key challenges, including reducing activation energy requirements, improving cyclic stability, and enhancing biocompatibility. These improvements are essential for the widespread adoption of SMAs in next-generation wearable devices.

The primary objectives of SMA technology development for wearable applications include creating materials with faster response times, greater force generation capabilities, and improved fatigue resistance. Additionally, there is a growing emphasis on developing SMAs that can be activated through various stimuli beyond temperature changes, such as electrical, magnetic, or light-based triggers, which would significantly expand their functionality in wearable devices.

Another critical objective is the miniaturization of SMA components to facilitate their integration into increasingly compact wearable form factors. This includes the development of thin-film SMAs and micro-actuators that can provide mechanical functionality without adding substantial bulk or weight to wearable devices.

The long-term vision for SMA technology in wearables encompasses the creation of "smart fabrics" and "second-skin" interfaces that can dynamically adapt to user needs and environmental conditions. This vision aligns with broader trends in wearable technology towards more intuitive, responsive, and personalized user experiences.

The 1980s and 1990s witnessed the expansion of SMA applications into various industries, including automotive and robotics. However, it was not until the early 2000s that researchers began exploring the potential of SMAs in wearable technology. This shift was driven by the growing demand for flexible, adaptable, and comfortable wearable devices that could seamlessly integrate with the human body.

Recent advancements in SMA technology have focused on enhancing their responsiveness, durability, and energy efficiency. Innovations in nano-structured SMAs and composite materials have led to improved performance characteristics, making them increasingly suitable for wearable applications. Patent activities in this domain have surged over the past decade, with significant contributions from both academic institutions and industry leaders.

The current technological trajectory of SMAs in wearable technology is oriented towards addressing several key challenges, including reducing activation energy requirements, improving cyclic stability, and enhancing biocompatibility. These improvements are essential for the widespread adoption of SMAs in next-generation wearable devices.

The primary objectives of SMA technology development for wearable applications include creating materials with faster response times, greater force generation capabilities, and improved fatigue resistance. Additionally, there is a growing emphasis on developing SMAs that can be activated through various stimuli beyond temperature changes, such as electrical, magnetic, or light-based triggers, which would significantly expand their functionality in wearable devices.

Another critical objective is the miniaturization of SMA components to facilitate their integration into increasingly compact wearable form factors. This includes the development of thin-film SMAs and micro-actuators that can provide mechanical functionality without adding substantial bulk or weight to wearable devices.

The long-term vision for SMA technology in wearables encompasses the creation of "smart fabrics" and "second-skin" interfaces that can dynamically adapt to user needs and environmental conditions. This vision aligns with broader trends in wearable technology towards more intuitive, responsive, and personalized user experiences.

Wearable Market Demand for Shape Memory Alloys

The wearable technology market has witnessed significant growth in recent years, with a compound annual growth rate exceeding 15% between 2018 and 2022. This expansion has created substantial opportunities for advanced materials like shape memory alloys (SMAs), which offer unique properties particularly suited to wearable applications. Consumer demand for more comfortable, adaptable, and functional wearable devices is driving innovation in this space.

Healthcare wearables represent the largest segment demanding SMA integration, with applications ranging from smart compression garments to orthopedic supports that can adjust pressure or support based on body movement or temperature. The aging global population has intensified demand for rehabilitation devices and mobility aids that incorporate SMAs to provide personalized support while maintaining comfort during extended wear periods.

Fitness and sports performance wearables constitute another rapidly growing market segment. Athletes and fitness enthusiasts increasingly seek garments and accessories that can adapt to body temperature, movement patterns, and environmental conditions. SMAs enable the development of smart compression wear that can adjust pressure during different activity phases, enhancing both performance and recovery.

Consumer electronics manufacturers are exploring SMAs for next-generation wearable devices that can conform to body contours while maintaining functional integrity. The demand for flexible displays, self-adjusting earbuds, and adaptive wristbands has created new application opportunities for these materials. Market research indicates consumers are willing to pay premium prices for wearables that offer enhanced comfort through adaptive materials.

Fashion technology represents an emerging but potentially significant market for SMA applications. Smart clothing that can adjust to environmental conditions, change appearance, or modify fit based on user preferences is gaining traction among early adopters and luxury consumers. Industry analysts project this segment could grow substantially as manufacturing costs decrease and design capabilities expand.

Industrial and military applications for SMA-enhanced wearables show strong demand growth, particularly for exoskeletons, smart protective gear, and environmental adaptation systems. These specialized markets value the durability, reliability, and functional advantages that SMAs provide in demanding operational environments.

Market barriers include manufacturing complexity, cost considerations, and integration challenges. However, as production techniques improve and economies of scale develop, these constraints are gradually diminishing. Consumer education remains critical, as many potential users are unfamiliar with the benefits and capabilities of SMA-enhanced wearables.

Healthcare wearables represent the largest segment demanding SMA integration, with applications ranging from smart compression garments to orthopedic supports that can adjust pressure or support based on body movement or temperature. The aging global population has intensified demand for rehabilitation devices and mobility aids that incorporate SMAs to provide personalized support while maintaining comfort during extended wear periods.

Fitness and sports performance wearables constitute another rapidly growing market segment. Athletes and fitness enthusiasts increasingly seek garments and accessories that can adapt to body temperature, movement patterns, and environmental conditions. SMAs enable the development of smart compression wear that can adjust pressure during different activity phases, enhancing both performance and recovery.

Consumer electronics manufacturers are exploring SMAs for next-generation wearable devices that can conform to body contours while maintaining functional integrity. The demand for flexible displays, self-adjusting earbuds, and adaptive wristbands has created new application opportunities for these materials. Market research indicates consumers are willing to pay premium prices for wearables that offer enhanced comfort through adaptive materials.

Fashion technology represents an emerging but potentially significant market for SMA applications. Smart clothing that can adjust to environmental conditions, change appearance, or modify fit based on user preferences is gaining traction among early adopters and luxury consumers. Industry analysts project this segment could grow substantially as manufacturing costs decrease and design capabilities expand.

Industrial and military applications for SMA-enhanced wearables show strong demand growth, particularly for exoskeletons, smart protective gear, and environmental adaptation systems. These specialized markets value the durability, reliability, and functional advantages that SMAs provide in demanding operational environments.

Market barriers include manufacturing complexity, cost considerations, and integration challenges. However, as production techniques improve and economies of scale develop, these constraints are gradually diminishing. Consumer education remains critical, as many potential users are unfamiliar with the benefits and capabilities of SMA-enhanced wearables.

SMA Technical Challenges in Wearable Applications

Despite the promising potential of Shape Memory Alloys (SMAs) in wearable technology, several significant technical challenges impede their widespread adoption. The primary obstacle remains the relatively slow response time of SMAs compared to other actuation technologies. While conventional actuators can respond in milliseconds, SMAs typically require seconds to complete their shape transformation cycle, limiting their application in scenarios demanding rapid response.

Thermal management presents another critical challenge. The phase transformation in SMAs is temperature-dependent, requiring precise heating and cooling control. In wearable applications, this becomes particularly problematic as the human body acts as a heat sink with variable thermal conditions. The inconsistent thermal environment can lead to unpredictable actuation behavior and reduced performance reliability.

Power consumption poses a substantial hurdle for SMA integration in wearable devices. The joule heating mechanism commonly used to activate SMAs demands significant energy, which contradicts the low-power requirements of most wearable technologies. This energy demand restricts operational duration and necessitates larger batteries, compromising the compactness and comfort of wearable devices.

Fatigue and degradation over repeated actuation cycles represent another technical limitation. Current commercial SMAs typically demonstrate functional degradation after 10^5-10^6 cycles, falling short of the durability requirements for many wearable applications that may demand millions of consistent actuation cycles throughout their operational lifetime.

Miniaturization challenges also persist in SMA technology. While SMAs offer excellent power-to-weight ratios, developing reliable micro-scale SMA actuators with consistent performance remains difficult. Manufacturing processes for creating precise, microscale SMA components with uniform properties have not yet reached maturity for mass production.

Biocompatibility concerns arise when SMAs are used in direct contact with skin. Nickel, a primary component in Nitinol (the most common SMA), can cause allergic reactions in approximately 10-20% of the population. Although surface treatments and coatings can mitigate this issue, they add complexity and cost to the manufacturing process.

Control precision represents perhaps the most significant technical barrier. The non-linear behavior of SMAs makes precise position control challenging, particularly in the intermediate states between fully austenitic and fully martensitic phases. This hysteresis effect complicates the development of accurate control algorithms necessary for sophisticated wearable applications requiring fine movement control.

Thermal management presents another critical challenge. The phase transformation in SMAs is temperature-dependent, requiring precise heating and cooling control. In wearable applications, this becomes particularly problematic as the human body acts as a heat sink with variable thermal conditions. The inconsistent thermal environment can lead to unpredictable actuation behavior and reduced performance reliability.

Power consumption poses a substantial hurdle for SMA integration in wearable devices. The joule heating mechanism commonly used to activate SMAs demands significant energy, which contradicts the low-power requirements of most wearable technologies. This energy demand restricts operational duration and necessitates larger batteries, compromising the compactness and comfort of wearable devices.

Fatigue and degradation over repeated actuation cycles represent another technical limitation. Current commercial SMAs typically demonstrate functional degradation after 10^5-10^6 cycles, falling short of the durability requirements for many wearable applications that may demand millions of consistent actuation cycles throughout their operational lifetime.

Miniaturization challenges also persist in SMA technology. While SMAs offer excellent power-to-weight ratios, developing reliable micro-scale SMA actuators with consistent performance remains difficult. Manufacturing processes for creating precise, microscale SMA components with uniform properties have not yet reached maturity for mass production.

Biocompatibility concerns arise when SMAs are used in direct contact with skin. Nickel, a primary component in Nitinol (the most common SMA), can cause allergic reactions in approximately 10-20% of the population. Although surface treatments and coatings can mitigate this issue, they add complexity and cost to the manufacturing process.

Control precision represents perhaps the most significant technical barrier. The non-linear behavior of SMAs makes precise position control challenging, particularly in the intermediate states between fully austenitic and fully martensitic phases. This hysteresis effect complicates the development of accurate control algorithms necessary for sophisticated wearable applications requiring fine movement control.

Current SMA Solutions in Wearable Devices

01 Composition and manufacturing of shape memory alloys

Shape memory alloys (SMAs) can be manufactured with specific compositions to achieve desired properties. These alloys undergo phase transformations that enable them to return to their original shape after deformation when heated above a certain temperature. The manufacturing process involves precise control of alloying elements, heat treatment, and processing conditions to achieve the desired transformation temperatures and mechanical properties.- Composition and manufacturing of shape memory alloys: Shape memory alloys can be manufactured with specific compositions to achieve desired properties. These alloys undergo phase transformations that enable them to return to their original shape after deformation when heated above a certain temperature. The manufacturing process involves precise control of alloying elements, heat treatment, and processing conditions to achieve the desired transformation temperatures and mechanical properties.

- Applications in medical devices: Shape memory alloys are widely used in medical devices due to their biocompatibility and unique mechanical properties. These applications include stents, guidewires, orthodontic arches, and surgical instruments. The superelasticity and shape memory effect allow for minimally invasive procedures where devices can be inserted in a compact form and then expand to their functional shape when deployed in the body.

- Actuators and mechanical systems: Shape memory alloys are utilized as actuators in various mechanical systems due to their ability to generate significant force during shape recovery. These actuators can be designed to respond to temperature changes, creating motion or force without the need for complex mechanical assemblies. Applications include automotive systems, aerospace components, and robotic devices where compact, silent operation is desired.

- Advanced processing techniques: Various advanced processing techniques are employed to enhance the properties of shape memory alloys. These include specialized heat treatments, thermomechanical processing, surface modifications, and microstructural engineering. These techniques can improve fatigue resistance, corrosion resistance, transformation temperatures, and overall performance of the alloys for specific applications.

- Smart materials and responsive structures: Shape memory alloys are integrated into smart materials and responsive structures that can adapt to environmental changes. These materials can be designed to respond to temperature, stress, or other stimuli, enabling self-healing, self-adjusting, or self-regulating capabilities. Applications include smart textiles, adaptive structures, vibration damping systems, and temperature-responsive safety devices.

02 Applications in medical devices and implants

Shape memory alloys are widely used in medical applications due to their biocompatibility and unique mechanical properties. They are particularly valuable in implantable devices, stents, orthodontic wires, and surgical instruments. The superelasticity and shape memory effect allow for minimally invasive procedures where devices can be inserted in a compact form and then expand to their functional shape when deployed in the body.Expand Specific Solutions03 Actuators and mechanical systems

Shape memory alloys serve as effective actuators in various mechanical systems due to their ability to generate significant force during shape recovery. These actuators can be activated by temperature changes, making them suitable for applications where electrical motors would be impractical. They are used in automotive, aerospace, robotics, and consumer electronics industries for functions such as valves, switches, and positioning devices.Expand Specific Solutions04 Thermal processing and heat treatment techniques

The performance of shape memory alloys is highly dependent on proper thermal processing and heat treatment. Specific annealing, aging, and quenching protocols are essential to establish the crystallographic structures necessary for the shape memory effect. These thermal treatments control transformation temperatures, hysteresis, and fatigue properties of the alloys, allowing customization for specific applications.Expand Specific Solutions05 Novel shape memory alloy systems and composites

Research continues to develop new shape memory alloy systems beyond the traditional nickel-titanium (Nitinol) compositions. These include copper-based alloys, iron-based alloys, and high-temperature shape memory alloys. Additionally, shape memory alloy composites combine the unique properties of SMAs with other materials to create hybrid systems with enhanced functionality, such as improved damping, sensing capabilities, or multifunctional responses.Expand Specific Solutions

Key SMA Patent Holders and Industry Leaders

The shape memory alloys (SMAs) market for wearable technology is currently in a growth phase, with increasing applications across healthcare, fitness, and consumer electronics sectors. The global market size is estimated to reach $20-25 billion by 2025, driven by demand for miniaturized, flexible components. Technologically, the field shows varying maturity levels, with companies like Johnson & Johnson Vision Care and W.L. Gore & Associates leading commercial applications, while research institutions such as MIT and Northwestern Polytechnical University focus on fundamental innovations. Industrial players including 3M, Toyota, and Boeing are developing specialized applications, while materials specialists like SAES Getters and QuesTek Innovations are advancing alloy formulations. The competitive landscape features collaboration between academic institutions and industry partners to overcome challenges in biocompatibility, durability, and manufacturing scalability.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed proprietary shape memory alloy (SMA) technologies for wearable applications leveraging their extensive experience in aerospace and industrial automation. Their patented "high-cycle SMA" materials feature specialized compositions and processing techniques that achieve exceptional fatigue resistance, maintaining consistent actuation performance for over 10 million cycles - a critical requirement for reliable wearable devices. Honeywell's innovations include precision-engineered SMA wire systems with tailored transformation temperatures specifically optimized for body-temperature activation, enabling responsive wearable devices that react to the user's physiological state. Their "variable force" SMA technology allows dynamic adjustment of actuation force based on applied current, creating adaptive support systems for medical and performance wearables. Honeywell has also patented advanced manufacturing processes for creating ultra-thin SMA components with thickness down to 20 microns while maintaining uniform transformation properties, enabling integration into flexible wearable form factors. Their "smart textile" technology incorporates SMA filaments directly into fabric structures during the weaving process, creating seamless actuating textiles that maintain comfort and flexibility while providing mechanical functionality.

Strengths: Exceptional reliability derived from aerospace engineering heritage with documented performance exceeding 10 million cycles; sophisticated manufacturing capabilities enabling consistent production of miniaturized SMA components. Weaknesses: Technologies primarily developed for industrial and aerospace applications may require significant adaptation for consumer wearable markets; higher production costs compared to conventional actuator technologies may limit applications to premium wearable segments.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has developed pioneering shape memory alloy (SMA) technologies specifically engineered for wearable applications through their specialized materials science research programs. Their patented "ultra-low power SMA" technology features unique alloy compositions that can achieve complete shape transformation with minimal energy input, addressing a critical limitation in battery-powered wearable devices. Michigan researchers have created innovative "bidirectional" SMA actuators that can actively move in two directions without requiring external bias forces, enabling more compact and efficient wearable mechanisms. Their work includes advanced SMA processing techniques that significantly improve transformation speed, achieving response times up to 10 times faster than conventional SMAs through microstructural engineering. The university has patented several biocompatible SMA compositions specifically designed for medical wearables, featuring specialized surface treatments that prevent nickel leaching while maintaining transformation properties. Their "gradient SMA" technology creates components with varying transformation properties across their structure, enabling complex mechanical responses from simple actuation inputs. Michigan has also developed novel SMA-elastomer composites that combine the actuation capabilities of shape memory alloys with the comfort and flexibility of elastomeric materials, creating platforms ideal for skin-interfacing wearable devices.

Strengths: Superior energy efficiency compared to conventional SMAs, enabling longer battery life in wearable applications; advanced biocompatibility innovations specifically addressing medical wearable requirements. Weaknesses: Some technologies remain in research phase with limited commercial implementation; complex manufacturing requirements for advanced compositions may present challenges for mass production and cost-effective scaling.

Critical Patents Analysis in SMA Wearable Technology

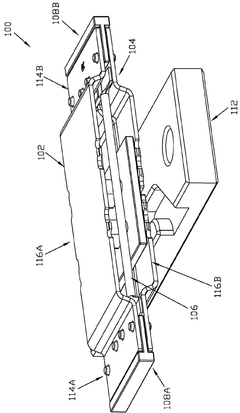

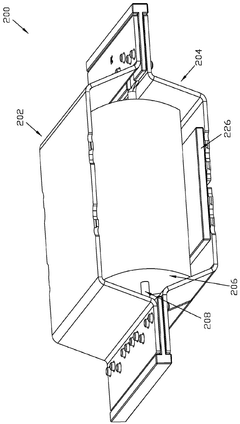

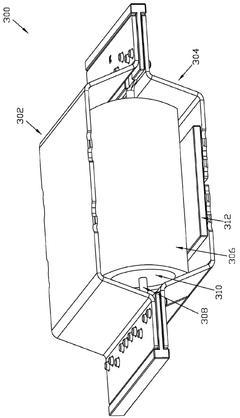

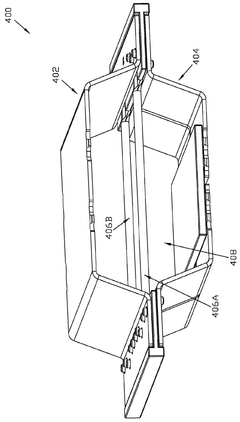

Shape memory alloy haptics designs

PatentWO2025175046A1

Innovation

- The use of shape memory alloy (SMA) elements in haptics devices, combined with a fixed and moving bow structure, spacers for electrical isolation, and cooling mechanisms such as sheaths, fluids, and thermally conductive greases to manage heat and enhance mechanical performance.

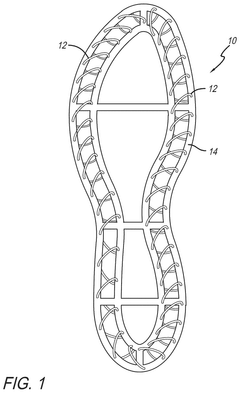

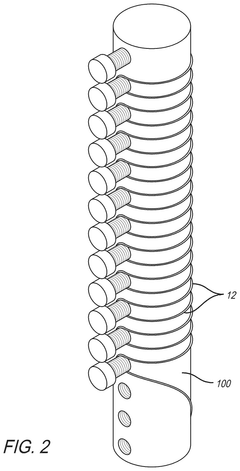

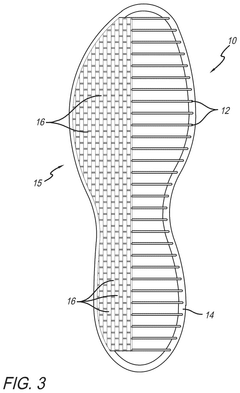

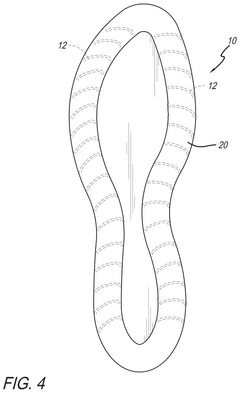

Footwear assembly including shape memory alloy elements

PatentPendingUS20240423320A1

Innovation

- Integration of superelastic shape memory alloys (SMAs) within footwear components, such as the midsole, insole, or outersole, encapsulated in polymers, which provide enhanced rebound energy, resistance to compression set, and improved mechanical properties at higher temperatures.

Material Science Advancements Supporting SMA Development

The evolution of Shape Memory Alloys (SMAs) for wearable technology applications has been significantly influenced by advancements in materials science over the past decades. Traditional NiTi (Nitinol) alloys, while effective in their shape memory and superelastic properties, initially presented limitations in terms of transformation temperatures, fatigue resistance, and biocompatibility—critical factors for wearable applications.

Recent breakthroughs in metallurgical processing techniques have enabled the development of ternary and quaternary SMA systems with enhanced functional properties. The addition of elements such as copper, palladium, and platinum to NiTi has resulted in alloys with more precisely controlled transformation temperatures, which is essential for wearable devices that operate in close contact with human skin.

Nanoscale engineering has revolutionized SMA development through the creation of nanostructured SMAs with significantly improved mechanical properties. These materials exhibit faster response times and greater energy density compared to conventional SMAs, making them ideal for compact wearable applications. Electron microscopy studies have revealed that controlling precipitate size and distribution at the nanoscale can dramatically enhance functional fatigue resistance—a previous limitation in wearable SMA applications.

Surface modification technologies have addressed biocompatibility concerns, which are paramount for wearable devices. Techniques such as plasma immersion ion implantation, diamond-like carbon coating, and titanium nitride deposition have been employed to create protective layers that prevent nickel ion leaching while maintaining the alloy's functional properties. These advancements have expanded the potential for SMAs in direct-contact wearable applications.

Thin film SMA technology represents another significant materials science breakthrough, enabling the integration of SMAs into flexible electronic platforms. Magnetron sputtering and vacuum deposition techniques have allowed for the creation of SMA films with thicknesses in the micrometer range that retain excellent shape memory properties. These films can be patterned using photolithography techniques, facilitating their incorporation into complex microelectromechanical systems (MEMS) for wearable sensors and actuators.

Computational materials science has accelerated SMA development through predictive modeling of phase transformations and mechanical behaviors. Machine learning algorithms applied to materials databases have identified promising new SMA compositions with optimized properties for specific wearable applications. These computational approaches have significantly reduced development time and costs compared to traditional trial-and-error methods.

Additive manufacturing techniques have enabled the fabrication of complex SMA geometries previously impossible with conventional manufacturing methods. Selective laser melting and electron beam melting processes can now produce porous SMA structures with tailored mechanical properties and enhanced heat transfer characteristics, addressing thermal management challenges in wearable SMA applications.

Recent breakthroughs in metallurgical processing techniques have enabled the development of ternary and quaternary SMA systems with enhanced functional properties. The addition of elements such as copper, palladium, and platinum to NiTi has resulted in alloys with more precisely controlled transformation temperatures, which is essential for wearable devices that operate in close contact with human skin.

Nanoscale engineering has revolutionized SMA development through the creation of nanostructured SMAs with significantly improved mechanical properties. These materials exhibit faster response times and greater energy density compared to conventional SMAs, making them ideal for compact wearable applications. Electron microscopy studies have revealed that controlling precipitate size and distribution at the nanoscale can dramatically enhance functional fatigue resistance—a previous limitation in wearable SMA applications.

Surface modification technologies have addressed biocompatibility concerns, which are paramount for wearable devices. Techniques such as plasma immersion ion implantation, diamond-like carbon coating, and titanium nitride deposition have been employed to create protective layers that prevent nickel ion leaching while maintaining the alloy's functional properties. These advancements have expanded the potential for SMAs in direct-contact wearable applications.

Thin film SMA technology represents another significant materials science breakthrough, enabling the integration of SMAs into flexible electronic platforms. Magnetron sputtering and vacuum deposition techniques have allowed for the creation of SMA films with thicknesses in the micrometer range that retain excellent shape memory properties. These films can be patterned using photolithography techniques, facilitating their incorporation into complex microelectromechanical systems (MEMS) for wearable sensors and actuators.

Computational materials science has accelerated SMA development through predictive modeling of phase transformations and mechanical behaviors. Machine learning algorithms applied to materials databases have identified promising new SMA compositions with optimized properties for specific wearable applications. These computational approaches have significantly reduced development time and costs compared to traditional trial-and-error methods.

Additive manufacturing techniques have enabled the fabrication of complex SMA geometries previously impossible with conventional manufacturing methods. Selective laser melting and electron beam melting processes can now produce porous SMA structures with tailored mechanical properties and enhanced heat transfer characteristics, addressing thermal management challenges in wearable SMA applications.

Regulatory Framework for SMA in Medical Wearables

The regulatory landscape for Shape Memory Alloys (SMAs) in medical wearable devices presents a complex framework that manufacturers and innovators must navigate carefully. In the United States, the FDA classifies most SMA-containing wearable medical devices under Class II, requiring premarket notification (510(k)) or in some cases, premarket approval (PMA) for devices with novel applications. The regulatory pathway depends significantly on the intended use, with devices claiming therapeutic benefits facing more stringent requirements than those marketed for wellness purposes.

European regulations have evolved substantially with the implementation of the Medical Device Regulation (MDR 2017/745), which replaced the previous Medical Device Directive. Under this framework, SMA-based wearables typically fall under Class IIa or IIb, depending on their invasiveness and duration of use. The MDR places increased emphasis on clinical evidence and post-market surveillance, creating additional compliance burdens for manufacturers.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) oversees a regulatory system that categorizes SMA medical wearables based on risk classification similar to international standards, though with distinct approval pathways that often require local clinical data. China's National Medical Products Administration (NMPA) has also established specific requirements for SMA-containing devices, with particular attention to material biocompatibility and fatigue resistance documentation.

Biocompatibility testing represents a critical regulatory requirement across all major markets. ISO 10993 series standards provide the framework for biological evaluation, with particular attention to cytotoxicity, sensitization, and irritation for devices with skin contact. For SMA components, additional testing for nickel leaching is typically required due to potential allergenic concerns, especially in the EU where the Nickel Directive imposes strict limits.

Material fatigue and durability testing presents another regulatory challenge specific to SMA applications. ASTM F2063 for wrought nickel-titanium shape memory alloys provides testing standards, but regulatory bodies increasingly require device-specific cyclic testing that simulates real-world use conditions over the product's expected lifetime.

Electromagnetic compatibility (EMC) testing becomes particularly relevant for SMA wearables with electronic components, as required by IEC 60601-1-2 for medical electrical equipment. The unique properties of SMAs can sometimes create unexpected electromagnetic interactions that must be characterized during the regulatory approval process.

Recent regulatory trends indicate movement toward harmonization of international standards for novel materials in medical devices, potentially streamlining the approval process for SMA wearables across multiple markets. However, country-specific requirements for clinical validation and post-market surveillance continue to present challenges for global commercialization strategies.

European regulations have evolved substantially with the implementation of the Medical Device Regulation (MDR 2017/745), which replaced the previous Medical Device Directive. Under this framework, SMA-based wearables typically fall under Class IIa or IIb, depending on their invasiveness and duration of use. The MDR places increased emphasis on clinical evidence and post-market surveillance, creating additional compliance burdens for manufacturers.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) oversees a regulatory system that categorizes SMA medical wearables based on risk classification similar to international standards, though with distinct approval pathways that often require local clinical data. China's National Medical Products Administration (NMPA) has also established specific requirements for SMA-containing devices, with particular attention to material biocompatibility and fatigue resistance documentation.

Biocompatibility testing represents a critical regulatory requirement across all major markets. ISO 10993 series standards provide the framework for biological evaluation, with particular attention to cytotoxicity, sensitization, and irritation for devices with skin contact. For SMA components, additional testing for nickel leaching is typically required due to potential allergenic concerns, especially in the EU where the Nickel Directive imposes strict limits.

Material fatigue and durability testing presents another regulatory challenge specific to SMA applications. ASTM F2063 for wrought nickel-titanium shape memory alloys provides testing standards, but regulatory bodies increasingly require device-specific cyclic testing that simulates real-world use conditions over the product's expected lifetime.

Electromagnetic compatibility (EMC) testing becomes particularly relevant for SMA wearables with electronic components, as required by IEC 60601-1-2 for medical electrical equipment. The unique properties of SMAs can sometimes create unexpected electromagnetic interactions that must be characterized during the regulatory approval process.

Recent regulatory trends indicate movement toward harmonization of international standards for novel materials in medical devices, potentially streamlining the approval process for SMA wearables across multiple markets. However, country-specific requirements for clinical validation and post-market surveillance continue to present challenges for global commercialization strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!