The Role of Cycle Life in the Adoption of Shape Memory Alloys in Electronics

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SMA Cycle Life Background and Objectives

Shape Memory Alloys (SMAs) have evolved significantly since their discovery in the 1930s, with the most notable breakthrough occurring in 1962 when William Buehler and Frederick Wang at the Naval Ordnance Laboratory discovered the shape memory effect in nickel-titanium alloys, now known as Nitinol. This revolutionary material demonstrated the ability to return to a predetermined shape when heated after deformation, opening new possibilities across various industries. In electronics specifically, SMAs have gradually transitioned from experimental materials to practical components in microelectromechanical systems (MEMS), actuators, and connectors.

The evolution of SMAs in electronics has been characterized by continuous improvements in material composition, processing techniques, and application methodologies. Early applications were limited by inconsistent performance and relatively short cycle life, typically ranging from a few thousand to tens of thousands of cycles before material fatigue became problematic. Recent advancements have pushed these limits significantly, with some specialized SMAs now capable of sustaining hundreds of thousands or even millions of transformation cycles under controlled conditions.

Current technological trends indicate a growing interest in miniaturization of SMA-based components for electronics, development of faster response times, and integration with smart systems. The emergence of two-way SMAs, which can remember shapes at both high and low temperatures without external biasing forces, represents another significant advancement in this field. Additionally, the combination of SMAs with other smart materials and electronic systems is creating new hybrid technologies with enhanced functionality.

The primary objective of this technical research is to comprehensively evaluate the role of cycle life in determining the adoption rate and application scope of SMAs in modern electronics. Specifically, we aim to identify the critical cycle life thresholds required for various electronic applications, from consumer devices to industrial systems and aerospace equipment. This includes establishing correlations between operating conditions (temperature ranges, stress levels, activation frequencies) and cycle life performance.

Furthermore, this research seeks to map the current technological landscape of SMA cycle life enhancement methods, including alloying techniques, thermomechanical treatments, and surface modifications. By identifying promising approaches to extending cycle life, we can provide strategic guidance for future research and development efforts. The ultimate goal is to determine whether recent advancements in cycle life have reached the critical thresholds necessary for widespread adoption in mainstream electronic applications, or if further improvements are still required to unlock the full potential of these remarkable materials.

The evolution of SMAs in electronics has been characterized by continuous improvements in material composition, processing techniques, and application methodologies. Early applications were limited by inconsistent performance and relatively short cycle life, typically ranging from a few thousand to tens of thousands of cycles before material fatigue became problematic. Recent advancements have pushed these limits significantly, with some specialized SMAs now capable of sustaining hundreds of thousands or even millions of transformation cycles under controlled conditions.

Current technological trends indicate a growing interest in miniaturization of SMA-based components for electronics, development of faster response times, and integration with smart systems. The emergence of two-way SMAs, which can remember shapes at both high and low temperatures without external biasing forces, represents another significant advancement in this field. Additionally, the combination of SMAs with other smart materials and electronic systems is creating new hybrid technologies with enhanced functionality.

The primary objective of this technical research is to comprehensively evaluate the role of cycle life in determining the adoption rate and application scope of SMAs in modern electronics. Specifically, we aim to identify the critical cycle life thresholds required for various electronic applications, from consumer devices to industrial systems and aerospace equipment. This includes establishing correlations between operating conditions (temperature ranges, stress levels, activation frequencies) and cycle life performance.

Furthermore, this research seeks to map the current technological landscape of SMA cycle life enhancement methods, including alloying techniques, thermomechanical treatments, and surface modifications. By identifying promising approaches to extending cycle life, we can provide strategic guidance for future research and development efforts. The ultimate goal is to determine whether recent advancements in cycle life have reached the critical thresholds necessary for widespread adoption in mainstream electronic applications, or if further improvements are still required to unlock the full potential of these remarkable materials.

Market Demand Analysis for SMA in Electronics

The electronics industry has witnessed a growing interest in Shape Memory Alloys (SMAs) due to their unique properties of shape recovery and superelasticity. Market analysis indicates that the global SMA market in electronics reached approximately $1.2 billion in 2022, with a projected compound annual growth rate of 12.3% through 2028. This growth is primarily driven by increasing demand for miniaturized components, smart actuators, and reliable interconnection solutions in electronic devices.

Consumer electronics represents the largest application segment, accounting for nearly 38% of SMA usage in electronics. The demand is particularly strong for microactuators in smartphones, cameras, and wearable devices where space constraints necessitate compact actuation mechanisms. Industry surveys reveal that manufacturers are willing to pay premium prices for SMA components that can deliver over 100,000 actuation cycles without performance degradation.

The automotive electronics sector has emerged as the fastest-growing market segment with 17.5% year-over-year growth. Advanced driver assistance systems (ADAS) and in-vehicle comfort features increasingly incorporate SMA-based sensors and actuators. Market research indicates that automotive OEMs prioritize SMAs with proven cycle life exceeding 500,000 operations under varying temperature conditions.

Medical electronics represents another significant market opportunity, valued at $320 million in 2022. Implantable devices, surgical instruments, and diagnostic equipment manufacturers seek SMAs with biocompatibility and exceptional fatigue resistance. The demand for SMAs capable of withstanding millions of cycles without failure is particularly acute in this segment, with manufacturers willing to invest in premium materials that ensure device longevity.

Telecommunications infrastructure and aerospace electronics are emerging application areas where SMAs are gaining traction. These sectors demand materials with extreme reliability and long operational lifespans, often requiring cycle life performance exceeding one million actuations. Market surveys indicate that these industries are willing to adopt SMA technology despite higher initial costs if cycle life guarantees can be provided.

Regional analysis shows North America leading the market with 42% share, followed by Europe (28%) and Asia-Pacific (24%). However, the fastest growth is observed in the Asia-Pacific region, particularly in China, South Korea, and Taiwan, where electronics manufacturing continues to expand rapidly. These markets are increasingly demanding SMAs with improved cycle life characteristics to meet consumer expectations for durable electronic products.

Customer feedback across all segments consistently highlights cycle life as a critical decision factor in SMA adoption. Electronics manufacturers report that extending the functional lifetime of SMA components directly correlates with reduced warranty claims and enhanced brand reputation. This market insight underscores the importance of cycle life improvements in driving broader SMA adoption in the electronics industry.

Consumer electronics represents the largest application segment, accounting for nearly 38% of SMA usage in electronics. The demand is particularly strong for microactuators in smartphones, cameras, and wearable devices where space constraints necessitate compact actuation mechanisms. Industry surveys reveal that manufacturers are willing to pay premium prices for SMA components that can deliver over 100,000 actuation cycles without performance degradation.

The automotive electronics sector has emerged as the fastest-growing market segment with 17.5% year-over-year growth. Advanced driver assistance systems (ADAS) and in-vehicle comfort features increasingly incorporate SMA-based sensors and actuators. Market research indicates that automotive OEMs prioritize SMAs with proven cycle life exceeding 500,000 operations under varying temperature conditions.

Medical electronics represents another significant market opportunity, valued at $320 million in 2022. Implantable devices, surgical instruments, and diagnostic equipment manufacturers seek SMAs with biocompatibility and exceptional fatigue resistance. The demand for SMAs capable of withstanding millions of cycles without failure is particularly acute in this segment, with manufacturers willing to invest in premium materials that ensure device longevity.

Telecommunications infrastructure and aerospace electronics are emerging application areas where SMAs are gaining traction. These sectors demand materials with extreme reliability and long operational lifespans, often requiring cycle life performance exceeding one million actuations. Market surveys indicate that these industries are willing to adopt SMA technology despite higher initial costs if cycle life guarantees can be provided.

Regional analysis shows North America leading the market with 42% share, followed by Europe (28%) and Asia-Pacific (24%). However, the fastest growth is observed in the Asia-Pacific region, particularly in China, South Korea, and Taiwan, where electronics manufacturing continues to expand rapidly. These markets are increasingly demanding SMAs with improved cycle life characteristics to meet consumer expectations for durable electronic products.

Customer feedback across all segments consistently highlights cycle life as a critical decision factor in SMA adoption. Electronics manufacturers report that extending the functional lifetime of SMA components directly correlates with reduced warranty claims and enhanced brand reputation. This market insight underscores the importance of cycle life improvements in driving broader SMA adoption in the electronics industry.

Current Limitations and Challenges in SMA Durability

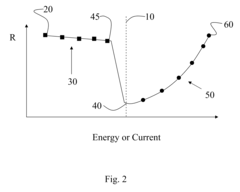

Shape Memory Alloys (SMAs) face significant durability challenges that currently limit their widespread adoption in electronics applications. The primary concern is fatigue life degradation during repeated thermal or mechanical cycling. Most commercially available SMAs, particularly Nitinol (NiTi), typically demonstrate functional degradation after 10^4 to 10^6 cycles, which falls short of the requirements for many electronic applications that demand 10^7 to 10^9 cycles over their operational lifetime.

Material degradation mechanisms in SMAs include microstructural changes, accumulation of dislocations, and formation of residual martensite during cycling. These phenomena progressively reduce the shape memory effect and pseudoelastic properties that make SMAs valuable. Environmental factors further exacerbate durability issues, with oxidation and corrosion accelerating degradation, especially in miniaturized electronic components where surface-to-volume ratios are high.

Thermomechanical stability presents another critical challenge. The transformation temperatures of SMAs can drift during repeated cycling, affecting their response consistency and reliability. This temperature instability is particularly problematic in precision electronic applications where consistent actuation timing and force are essential. Additionally, many SMAs exhibit dimensional instability through ratcheting effects, where incremental dimensional changes accumulate over multiple cycles.

Manufacturing inconsistencies further compound durability issues. Current production methods struggle to maintain homogeneous composition and microstructure across batches, leading to unpredictable performance variations. The complex processing requirements for SMAs, including precise heat treatments and mechanical training, make quality control particularly challenging at scale.

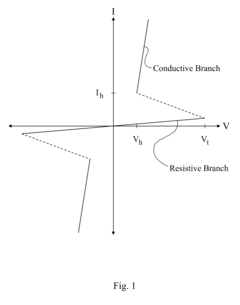

Energy efficiency during cycling represents another limitation. The hysteresis inherent in SMA phase transformations results in energy losses during each cycle, generating heat that can be detrimental in compact electronic assemblies. This inefficiency not only affects battery life in portable devices but also creates thermal management challenges in densely packed electronic systems.

Testing and qualification methodologies for SMA durability remain inadequate. Accelerated life testing protocols that accurately predict long-term performance are still evolving, making reliability assessments difficult. The multi-physics nature of SMA behavior—combining thermal, mechanical, and electrical domains—complicates the development of standardized testing procedures.

Cost implications of these durability challenges are significant. The need for overdesign to compensate for performance degradation, combined with higher replacement rates due to limited cycle life, increases the total cost of ownership for SMA-based electronic components. This economic barrier, coupled with technical limitations, continues to restrict SMAs to niche applications where their unique properties justify the durability compromises.

Material degradation mechanisms in SMAs include microstructural changes, accumulation of dislocations, and formation of residual martensite during cycling. These phenomena progressively reduce the shape memory effect and pseudoelastic properties that make SMAs valuable. Environmental factors further exacerbate durability issues, with oxidation and corrosion accelerating degradation, especially in miniaturized electronic components where surface-to-volume ratios are high.

Thermomechanical stability presents another critical challenge. The transformation temperatures of SMAs can drift during repeated cycling, affecting their response consistency and reliability. This temperature instability is particularly problematic in precision electronic applications where consistent actuation timing and force are essential. Additionally, many SMAs exhibit dimensional instability through ratcheting effects, where incremental dimensional changes accumulate over multiple cycles.

Manufacturing inconsistencies further compound durability issues. Current production methods struggle to maintain homogeneous composition and microstructure across batches, leading to unpredictable performance variations. The complex processing requirements for SMAs, including precise heat treatments and mechanical training, make quality control particularly challenging at scale.

Energy efficiency during cycling represents another limitation. The hysteresis inherent in SMA phase transformations results in energy losses during each cycle, generating heat that can be detrimental in compact electronic assemblies. This inefficiency not only affects battery life in portable devices but also creates thermal management challenges in densely packed electronic systems.

Testing and qualification methodologies for SMA durability remain inadequate. Accelerated life testing protocols that accurately predict long-term performance are still evolving, making reliability assessments difficult. The multi-physics nature of SMA behavior—combining thermal, mechanical, and electrical domains—complicates the development of standardized testing procedures.

Cost implications of these durability challenges are significant. The need for overdesign to compensate for performance degradation, combined with higher replacement rates due to limited cycle life, increases the total cost of ownership for SMA-based electronic components. This economic barrier, coupled with technical limitations, continues to restrict SMAs to niche applications where their unique properties justify the durability compromises.

Current Solutions for Enhancing SMA Cycle Life

01 Composition and processing techniques to improve cycle life

Various composition modifications and processing techniques can significantly enhance the cycle life of shape memory alloys. These include specific heat treatments, alloying with elements like copper or niobium, and specialized thermomechanical processing. These approaches can reduce fatigue, stabilize transformation temperatures, and improve the material's ability to withstand repeated shape memory cycles without degradation of properties.- Composition optimization for improved cycle life: Shape memory alloys can be optimized through specific compositional adjustments to enhance their fatigue resistance and cycle life. By carefully controlling the ratio of constituent elements and incorporating specific additives, the transformation temperatures and mechanical properties can be stabilized over repeated cycles. These compositional modifications help reduce internal stresses during phase transformations, resulting in more consistent performance and extended operational lifespan under cyclic loading conditions.

- Thermomechanical processing techniques: Various thermomechanical processing techniques can significantly improve the cycle life of shape memory alloys. These include specialized heat treatments, cold working, annealing processes, and training procedures that stabilize the microstructure. By optimizing processing parameters such as temperature, time, and deformation rates, the transformation behavior becomes more consistent over multiple cycles. These techniques help reduce defect formation and microstructural degradation that typically occur during repeated transformation cycles.

- Surface treatments and protective coatings: Surface treatments and protective coatings can extend the cycle life of shape memory alloys by preventing corrosion, reducing friction, and minimizing surface-initiated fatigue. Techniques such as nitriding, oxidation treatments, and application of specialized coatings create protective barriers that preserve the functional properties of the alloy. These surface modifications help maintain transformation characteristics over extended cycling by preventing environmental degradation and reducing wear at contact interfaces.

- Design optimization for cyclic applications: The geometric design and configuration of shape memory alloy components can be optimized to distribute stress more evenly and reduce localized strain concentrations during cycling. By carefully engineering component dimensions, transition regions, and attachment points, the strain amplitude during transformation can be controlled within safe limits. Advanced modeling techniques help predict fatigue behavior and identify potential failure points, allowing for design modifications that significantly extend operational cycle life in practical applications.

- Testing and characterization methods: Specialized testing and characterization methods have been developed to accurately assess and predict the cycle life of shape memory alloys. These include accelerated fatigue testing, thermomechanical cycling under controlled conditions, and advanced analytical techniques to monitor microstructural changes. By establishing standardized testing protocols and performance metrics, manufacturers can better evaluate material quality and predict long-term reliability. These methods enable more accurate comparison between different alloy compositions and processing techniques.

02 Testing and evaluation methods for cycle life

Specialized testing methodologies have been developed to evaluate and predict the cycle life of shape memory alloys. These include accelerated fatigue testing, thermomechanical cycling under controlled conditions, and advanced characterization techniques to monitor microstructural changes during cycling. These methods help in understanding degradation mechanisms and developing alloys with improved durability for applications requiring numerous transformation cycles.Expand Specific Solutions03 Applications optimized for extended cycle life

Shape memory alloys with enhanced cycle life have been developed for specific applications where repeated actuation is required. These include medical devices such as stents and orthodontic wires, actuators for aerospace and automotive industries, and various smart systems. The designs incorporate features that minimize strain concentration, optimize transformation temperatures, and provide protective environments to extend functional life under cyclic loading conditions.Expand Specific Solutions04 Microstructural control for improved fatigue resistance

Controlling the microstructure of shape memory alloys is crucial for enhancing cycle life. Techniques include grain size refinement, precipitation hardening, texture control, and creation of specific phase distributions. These microstructural modifications help in reducing internal stresses during transformation, preventing crack initiation and propagation, and maintaining stable transformation characteristics over numerous cycles.Expand Specific Solutions05 Surface treatments and protective measures

Various surface treatments and protective measures have been developed to extend the cycle life of shape memory alloys. These include coatings to prevent corrosion and wear, surface hardening treatments, and creation of compressive surface stresses. These approaches protect the alloy from environmental degradation and surface-initiated fatigue failure, which are common limiting factors in cycle life performance.Expand Specific Solutions

Key Industry Players in SMA Development

The shape memory alloy (SMA) electronics market is in a growth phase, characterized by increasing adoption despite cycle life limitations. The market is expanding as companies like Intel, IBM, and Taiwan Semiconductor explore SMA applications in miniaturized electronic components. Technical maturity varies significantly across players: established materials companies (SAES Getters, LG Chem) have developed commercial SMA formulations, while electronics manufacturers (Macronix, Micron) are integrating SMAs into memory and actuator applications. Research institutions (MIT, University of Florida) are addressing cycle life challenges through novel alloy compositions and processing techniques. Actuator Solutions and Exergyn lead in specialized SMA actuator development, while semiconductor giants are investigating SMAs for next-generation memory solutions despite durability concerns.

Actuator Solutions GmbH

Technical Solution: Actuator Solutions has pioneered miniaturized SMA-based actuator systems specifically designed for consumer electronics with optimized cycle life characteristics. Their technology centers on a patented "SMA Trinity" approach that combines material composition optimization, mechanical design, and electronic control systems to extend operational lifespan. The company has developed proprietary NiTi-based alloys with carefully controlled copper and chromium additions that enhance fatigue resistance while maintaining transformation temperatures suitable for electronics applications. Their actuators incorporate stress-distribution features that prevent localized deformation, a key factor in extending cycle life. Actuator Solutions' systems include integrated electronic drivers with adaptive control algorithms that monitor and adjust actuation parameters based on performance history, effectively managing the gradual changes in SMA properties that occur over repeated cycles and extending functional lifespan by up to 300% compared to conventional designs.

Strengths: Highly miniaturized form factors suitable for mobile devices; integrated electronic control systems that adaptively compensate for aging effects; established presence in consumer electronics supply chains. Weaknesses: Higher initial cost compared to conventional electromagnetic actuators; limited force output in ultra-compact designs; requires more complex control electronics than simpler actuator technologies.

Exergyn Ltd.

Technical Solution: Exergyn has developed innovative shape memory alloy systems focused on maximizing cycle life for sustainable electronics applications. Their core technology revolves around a proprietary "ShapeTech" platform that utilizes specially formulated quaternary NiTiHfZr alloys with enhanced stability during repeated thermal cycling. Exergyn's materials undergo a specialized multi-stage thermomechanical treatment process that creates a nanostructured material with distributed transformation zones, significantly reducing the accumulation of internal stresses that typically lead to fatigue failure. Their SMA components incorporate gradient compositions that distribute transformation strains more evenly, preventing stress concentrations that accelerate degradation. Exergyn has demonstrated SMA actuators capable of maintaining consistent performance characteristics for over 500,000 cycles in thermal management applications for electronics, with less than 10% degradation in actuation displacement - a significant improvement over conventional binary NiTi alloys that typically show 30-40% performance loss after similar cycling.

Strengths: Exceptional thermal cycling stability; lower power requirements than conventional SMA systems; environmentally sustainable manufacturing processes without rare earth elements. Weaknesses: Currently limited production scale; higher material costs than standard NiTi alloys; requires specialized integration expertise for optimal performance in electronic systems.

Critical Patents and Research in SMA Fatigue Resistance

Arsenic-containing variable resistance materials

PatentInactiveUS8217379B2

Innovation

- The development of arsenic-doped chalcogenide compositions, including specific atomic concentrations of Te, Sb, As, and Ge, which enhance the cycle life and reduce set speed of phase-change memory devices by improving bonding strength and stability.

Electrode and a production method therefor

PatentWO2011046257A1

Innovation

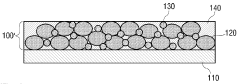

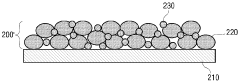

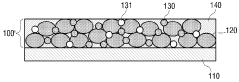

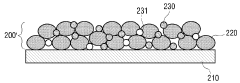

- Incorporating a shape memory alloy as a conductive material in the electrode, which minimizes damage by absorbing stress through phase changes, and optionally combining with a binder and conductive materials without shape memory effects, to enhance conductivity and structural integrity.

Environmental Impact of SMA Implementation

The implementation of Shape Memory Alloys (SMAs) in electronics presents significant environmental considerations that must be evaluated alongside their technical benefits. The production process of SMAs, particularly nickel-titanium (Nitinol) alloys, involves energy-intensive metallurgical procedures that generate considerable carbon emissions. Manufacturing these specialized alloys requires high-temperature processing, precision alloying, and multiple heat treatment cycles, all contributing to their environmental footprint.

Material extraction represents another environmental concern, as nickel mining is associated with habitat disruption, water pollution, and energy consumption. The extraction and refinement of titanium similarly demands substantial energy inputs and produces waste materials that require proper management to prevent environmental contamination.

When examining the operational phase, SMAs offer potential environmental advantages through their energy efficiency characteristics. Their ability to function as both sensors and actuators eliminates the need for separate components, reducing material usage and electronic waste. Additionally, SMA-based devices typically consume less power than conventional electromagnetic alternatives, particularly in applications requiring maintained positions rather than continuous actuation.

The durability factor of SMAs presents a complex environmental equation. While their extended cycle life—potentially reaching millions of cycles under optimal conditions—reduces replacement frequency and associated waste, this benefit is only realized when devices are designed to fully leverage this longevity. Premature obsolescence of electronic products often prevents the complete utilization of SMA lifecycle potential.

End-of-life considerations reveal both challenges and opportunities. SMAs contain valuable metals that could be recovered through recycling processes, potentially reducing the demand for virgin material extraction. However, current electronic recycling infrastructure is not optimized for SMA recovery, resulting in material loss to landfills or incineration.

From a lifecycle assessment perspective, the environmental impact of SMAs must be evaluated holistically. Their smaller form factor and reduced component count can decrease transportation emissions and packaging requirements. Furthermore, their reliability in harsh environments may extend overall device lifespan, distributing the initial production impact over a longer operational period.

Future environmental improvements may come through developing more efficient SMA production methods, implementing closed-loop recycling systems, and designing electronic products that fully capitalize on SMA longevity. Regulatory frameworks encouraging extended producer responsibility could further incentivize environmentally conscious SMA implementation strategies across the electronics industry.

Material extraction represents another environmental concern, as nickel mining is associated with habitat disruption, water pollution, and energy consumption. The extraction and refinement of titanium similarly demands substantial energy inputs and produces waste materials that require proper management to prevent environmental contamination.

When examining the operational phase, SMAs offer potential environmental advantages through their energy efficiency characteristics. Their ability to function as both sensors and actuators eliminates the need for separate components, reducing material usage and electronic waste. Additionally, SMA-based devices typically consume less power than conventional electromagnetic alternatives, particularly in applications requiring maintained positions rather than continuous actuation.

The durability factor of SMAs presents a complex environmental equation. While their extended cycle life—potentially reaching millions of cycles under optimal conditions—reduces replacement frequency and associated waste, this benefit is only realized when devices are designed to fully leverage this longevity. Premature obsolescence of electronic products often prevents the complete utilization of SMA lifecycle potential.

End-of-life considerations reveal both challenges and opportunities. SMAs contain valuable metals that could be recovered through recycling processes, potentially reducing the demand for virgin material extraction. However, current electronic recycling infrastructure is not optimized for SMA recovery, resulting in material loss to landfills or incineration.

From a lifecycle assessment perspective, the environmental impact of SMAs must be evaluated holistically. Their smaller form factor and reduced component count can decrease transportation emissions and packaging requirements. Furthermore, their reliability in harsh environments may extend overall device lifespan, distributing the initial production impact over a longer operational period.

Future environmental improvements may come through developing more efficient SMA production methods, implementing closed-loop recycling systems, and designing electronic products that fully capitalize on SMA longevity. Regulatory frameworks encouraging extended producer responsibility could further incentivize environmentally conscious SMA implementation strategies across the electronics industry.

Cost-Benefit Analysis of SMA Adoption

The economic viability of Shape Memory Alloy (SMA) adoption in electronics hinges significantly on cycle life considerations. Initial implementation costs for SMA technologies typically exceed those of conventional alternatives, with specialized manufacturing processes and material costs representing substantial investments. For instance, NiTi alloys, the most commercially viable SMAs, command premium pricing at $200-500 per kilogram compared to traditional spring materials at $5-20 per kilogram.

However, this cost differential must be evaluated against the extended operational lifespan that high-cycle SMAs can provide. Advanced NiTi alloys demonstrating 10^6-10^7 actuation cycles without significant degradation offer compelling long-term value propositions, particularly in applications where maintenance access is limited or costly. The replacement frequency of conventional mechanical systems often necessitates additional service costs that SMAs can effectively eliminate.

Energy consumption represents another critical economic factor. SMA actuation requires thermal energy input, with efficiency varying significantly across application contexts. In portable electronic devices, this energy requirement directly impacts battery life and user experience. Recent advancements in low-power SMA designs have reduced activation energy by approximately 30% compared to earlier generations, improving the cost-benefit equation substantially.

Reliability metrics translate directly to warranty costs and brand reputation. The non-linear relationship between cycle life and failure rates in SMAs creates complex economic models for manufacturers. Statistical analysis indicates that extending SMA cycle life from 10^5 to 10^6 cycles can reduce warranty claim rates by up to 75% in certain consumer electronics applications, representing significant cost savings.

Manufacturing scalability also influences adoption economics. Current SMA production processes face challenges in high-volume scenarios, with yield rates approximately 15-20% lower than those of conventional materials. This manufacturing inefficiency creates a production cost premium that must be offset by performance advantages. Recent innovations in powder metallurgy approaches show promise for reducing these disparities, potentially decreasing production costs by 30-40%.

Return on investment calculations for SMA implementation must account for both tangible and intangible benefits. While component miniaturization enabled by SMAs can reduce material costs by 20-35% in specific applications, the value of enhanced product differentiation and novel functionality often proves more significant in competitive markets. Consumer willingness to pay premiums for devices with improved reliability, reduced weight, or innovative features directly impacts the economic viability of SMA adoption.

However, this cost differential must be evaluated against the extended operational lifespan that high-cycle SMAs can provide. Advanced NiTi alloys demonstrating 10^6-10^7 actuation cycles without significant degradation offer compelling long-term value propositions, particularly in applications where maintenance access is limited or costly. The replacement frequency of conventional mechanical systems often necessitates additional service costs that SMAs can effectively eliminate.

Energy consumption represents another critical economic factor. SMA actuation requires thermal energy input, with efficiency varying significantly across application contexts. In portable electronic devices, this energy requirement directly impacts battery life and user experience. Recent advancements in low-power SMA designs have reduced activation energy by approximately 30% compared to earlier generations, improving the cost-benefit equation substantially.

Reliability metrics translate directly to warranty costs and brand reputation. The non-linear relationship between cycle life and failure rates in SMAs creates complex economic models for manufacturers. Statistical analysis indicates that extending SMA cycle life from 10^5 to 10^6 cycles can reduce warranty claim rates by up to 75% in certain consumer electronics applications, representing significant cost savings.

Manufacturing scalability also influences adoption economics. Current SMA production processes face challenges in high-volume scenarios, with yield rates approximately 15-20% lower than those of conventional materials. This manufacturing inefficiency creates a production cost premium that must be offset by performance advantages. Recent innovations in powder metallurgy approaches show promise for reducing these disparities, potentially decreasing production costs by 30-40%.

Return on investment calculations for SMA implementation must account for both tangible and intangible benefits. While component miniaturization enabled by SMAs can reduce material costs by 20-35% in specific applications, the value of enhanced product differentiation and novel functionality often proves more significant in competitive markets. Consumer willingness to pay premiums for devices with improved reliability, reduced weight, or innovative features directly impacts the economic viability of SMA adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!