Optimization Techniques for Shape Memory Alloys in Electronic Devices

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SMA Technology Background and Objectives

Shape Memory Alloys (SMAs) represent a unique class of smart materials that possess the remarkable ability to return to a predetermined shape when subjected to specific thermal conditions. First discovered in the 1930s with gold-cadmium alloys, SMAs gained significant attention following the development of Nitinol (nickel-titanium) by the Naval Ordnance Laboratory in the 1960s. This technological breakthrough established the foundation for modern SMA applications across various industries, particularly in electronic devices where miniaturization and functionality convergence drive innovation.

The evolution of SMAs has been characterized by progressive improvements in material composition, manufacturing techniques, and application methodologies. Early implementations were limited by inconsistent performance, high production costs, and restricted transformation temperature ranges. However, advancements in metallurgical processes and alloy formulations have substantially expanded the practical utility of these materials, enabling their integration into increasingly sophisticated electronic components and systems.

Current technological trajectories indicate growing interest in optimizing SMAs for electronic applications, particularly in areas requiring precise mechanical actuation, thermal management, and vibration control. The miniaturization trend in consumer electronics, coupled with demands for enhanced durability and functionality, has positioned SMAs as potential solutions for next-generation device designs. Their unique properties offer alternatives to conventional electromechanical systems, potentially reducing component complexity while improving reliability.

The primary technical objectives for SMA optimization in electronic devices encompass several critical dimensions. First, enhancing transformation temperature precision to ensure reliable operation within the thermal constraints of modern electronics. Second, improving cyclic stability to maintain consistent performance throughout the device lifecycle. Third, reducing response times to enable applications requiring rapid actuation. Fourth, developing manufacturing techniques compatible with existing electronic production processes to facilitate cost-effective integration.

Additionally, research aims to address challenges related to power efficiency, as the thermal activation of SMAs typically requires significant energy input. Innovations in low-power activation methods, including localized heating techniques and alternative triggering mechanisms, represent key areas of investigation. The development of composite structures that combine SMAs with other functional materials also presents opportunities for creating multifunctional components that can simultaneously address multiple design requirements.

The convergence of materials science, electronic engineering, and manufacturing technology is expected to yield significant advancements in SMA applications for electronic devices. These developments align with broader industry trends toward more adaptive, resilient, and efficient electronic systems capable of responding to environmental changes and user requirements with minimal external control infrastructure.

The evolution of SMAs has been characterized by progressive improvements in material composition, manufacturing techniques, and application methodologies. Early implementations were limited by inconsistent performance, high production costs, and restricted transformation temperature ranges. However, advancements in metallurgical processes and alloy formulations have substantially expanded the practical utility of these materials, enabling their integration into increasingly sophisticated electronic components and systems.

Current technological trajectories indicate growing interest in optimizing SMAs for electronic applications, particularly in areas requiring precise mechanical actuation, thermal management, and vibration control. The miniaturization trend in consumer electronics, coupled with demands for enhanced durability and functionality, has positioned SMAs as potential solutions for next-generation device designs. Their unique properties offer alternatives to conventional electromechanical systems, potentially reducing component complexity while improving reliability.

The primary technical objectives for SMA optimization in electronic devices encompass several critical dimensions. First, enhancing transformation temperature precision to ensure reliable operation within the thermal constraints of modern electronics. Second, improving cyclic stability to maintain consistent performance throughout the device lifecycle. Third, reducing response times to enable applications requiring rapid actuation. Fourth, developing manufacturing techniques compatible with existing electronic production processes to facilitate cost-effective integration.

Additionally, research aims to address challenges related to power efficiency, as the thermal activation of SMAs typically requires significant energy input. Innovations in low-power activation methods, including localized heating techniques and alternative triggering mechanisms, represent key areas of investigation. The development of composite structures that combine SMAs with other functional materials also presents opportunities for creating multifunctional components that can simultaneously address multiple design requirements.

The convergence of materials science, electronic engineering, and manufacturing technology is expected to yield significant advancements in SMA applications for electronic devices. These developments align with broader industry trends toward more adaptive, resilient, and efficient electronic systems capable of responding to environmental changes and user requirements with minimal external control infrastructure.

Electronic Device Market Demand Analysis

The electronic device market has witnessed significant growth over the past decade, with global revenues reaching $1.5 trillion in 2022. This expansion is driven by increasing consumer demand for smaller, more efficient, and multifunctional devices. Shape Memory Alloys (SMAs) have emerged as critical components in this evolving landscape, offering unique properties that address several key market demands.

Consumer electronics, particularly smartphones and wearables, represent the largest segment utilizing SMA technology. Market research indicates that the global smartphone market shipped approximately 1.2 billion units in 2022, with premium devices increasingly incorporating advanced materials like SMAs for antenna systems, haptic feedback mechanisms, and structural components. The wearable technology market, valued at $61.3 billion in 2022, is projected to grow at a CAGR of 14.6% through 2027, creating substantial opportunities for SMA applications.

The miniaturization trend continues to dominate the electronic device market, with manufacturers striving to reduce device thickness while expanding functionality. This has created specific demand for SMAs that can deliver mechanical actuation in extremely confined spaces. Market surveys reveal that 78% of consumers prioritize device thinness and lightweight design when making purchasing decisions, further driving the need for optimized SMA solutions.

Energy efficiency represents another critical market demand. With battery technology improvements lagging behind processing power advancements, manufacturers are seeking materials that can operate with minimal power consumption. SMAs that can be optimized for low-energy actuation could address this market gap, particularly in portable and IoT devices where battery life is paramount.

The automotive electronics segment presents a rapidly growing market for SMA applications, with the global automotive electronics market valued at $248 billion in 2022 and expected to reach $382 billion by 2026. Advanced driver-assistance systems (ADAS) and in-vehicle comfort features increasingly require reliable actuators that can withstand harsh operating conditions, creating demand for high-performance SMAs.

Medical electronics represents another high-value market segment, with particular demand for biocompatible SMAs in implantable devices and surgical instruments. This market is projected to grow at 16.2% annually through 2028, driven by aging populations in developed economies and expanding healthcare access globally.

Market analysis also reveals growing demand for sustainable and environmentally friendly materials in electronic devices. Manufacturers are increasingly seeking materials that can be recycled or that reduce overall environmental impact. SMAs that can be optimized for recyclability while maintaining performance characteristics would address this emerging market requirement.

Consumer electronics, particularly smartphones and wearables, represent the largest segment utilizing SMA technology. Market research indicates that the global smartphone market shipped approximately 1.2 billion units in 2022, with premium devices increasingly incorporating advanced materials like SMAs for antenna systems, haptic feedback mechanisms, and structural components. The wearable technology market, valued at $61.3 billion in 2022, is projected to grow at a CAGR of 14.6% through 2027, creating substantial opportunities for SMA applications.

The miniaturization trend continues to dominate the electronic device market, with manufacturers striving to reduce device thickness while expanding functionality. This has created specific demand for SMAs that can deliver mechanical actuation in extremely confined spaces. Market surveys reveal that 78% of consumers prioritize device thinness and lightweight design when making purchasing decisions, further driving the need for optimized SMA solutions.

Energy efficiency represents another critical market demand. With battery technology improvements lagging behind processing power advancements, manufacturers are seeking materials that can operate with minimal power consumption. SMAs that can be optimized for low-energy actuation could address this market gap, particularly in portable and IoT devices where battery life is paramount.

The automotive electronics segment presents a rapidly growing market for SMA applications, with the global automotive electronics market valued at $248 billion in 2022 and expected to reach $382 billion by 2026. Advanced driver-assistance systems (ADAS) and in-vehicle comfort features increasingly require reliable actuators that can withstand harsh operating conditions, creating demand for high-performance SMAs.

Medical electronics represents another high-value market segment, with particular demand for biocompatible SMAs in implantable devices and surgical instruments. This market is projected to grow at 16.2% annually through 2028, driven by aging populations in developed economies and expanding healthcare access globally.

Market analysis also reveals growing demand for sustainable and environmentally friendly materials in electronic devices. Manufacturers are increasingly seeking materials that can be recycled or that reduce overall environmental impact. SMAs that can be optimized for recyclability while maintaining performance characteristics would address this emerging market requirement.

Current SMA Implementation Challenges

Shape Memory Alloys (SMAs) face significant implementation challenges in electronic devices despite their promising properties. The miniaturization requirements of modern electronics create substantial obstacles for SMA integration. Current manufacturing processes struggle to produce SMAs at the micro and nano scales needed for compact electronic components while maintaining their shape memory properties. This dimensional constraint limits their application in increasingly smaller devices where space efficiency is paramount.

Thermal management represents another critical challenge. SMAs require specific temperature ranges to activate their shape-changing properties, but electronic devices generate variable heat patterns during operation. This inconsistency creates difficulties in precisely controlling SMA activation timing and response characteristics. Additionally, the heat generated during SMA phase transitions can potentially damage sensitive electronic components nearby, necessitating complex thermal isolation solutions.

Fatigue and durability issues persist in current implementations. SMAs in electronic devices typically undergo thousands of transformation cycles, leading to material degradation over time. This results in diminished shape recovery capabilities and potential mechanical failure. The industry has yet to develop cost-effective SMAs that maintain consistent performance throughout the expected lifespan of consumer electronics, which typically ranges from 3-5 years of regular use.

Response time limitations present another significant barrier. Contemporary electronic applications demand rapid actuation, but SMAs exhibit relatively slow response rates compared to alternative technologies like piezoelectric actuators. This sluggish behavior restricts their use in applications requiring high-frequency operation or immediate feedback, such as haptic systems or camera autofocus mechanisms.

Power consumption inefficiencies further complicate SMA implementation. The energy required to heat SMAs for activation can be substantial relative to the power budgets of portable electronic devices. This energy demand conflicts with the industry-wide push toward greater energy efficiency and extended battery life in mobile technologies.

Manufacturing complexity and cost factors also impede widespread adoption. Current production methods for integrating SMAs into electronic assemblies involve specialized processes that are difficult to scale. The intricate nature of these processes contributes to higher production costs compared to conventional actuation technologies, creating economic barriers to mass-market implementation despite the functional advantages SMAs offer.

Thermal management represents another critical challenge. SMAs require specific temperature ranges to activate their shape-changing properties, but electronic devices generate variable heat patterns during operation. This inconsistency creates difficulties in precisely controlling SMA activation timing and response characteristics. Additionally, the heat generated during SMA phase transitions can potentially damage sensitive electronic components nearby, necessitating complex thermal isolation solutions.

Fatigue and durability issues persist in current implementations. SMAs in electronic devices typically undergo thousands of transformation cycles, leading to material degradation over time. This results in diminished shape recovery capabilities and potential mechanical failure. The industry has yet to develop cost-effective SMAs that maintain consistent performance throughout the expected lifespan of consumer electronics, which typically ranges from 3-5 years of regular use.

Response time limitations present another significant barrier. Contemporary electronic applications demand rapid actuation, but SMAs exhibit relatively slow response rates compared to alternative technologies like piezoelectric actuators. This sluggish behavior restricts their use in applications requiring high-frequency operation or immediate feedback, such as haptic systems or camera autofocus mechanisms.

Power consumption inefficiencies further complicate SMA implementation. The energy required to heat SMAs for activation can be substantial relative to the power budgets of portable electronic devices. This energy demand conflicts with the industry-wide push toward greater energy efficiency and extended battery life in mobile technologies.

Manufacturing complexity and cost factors also impede widespread adoption. Current production methods for integrating SMAs into electronic assemblies involve specialized processes that are difficult to scale. The intricate nature of these processes contributes to higher production costs compared to conventional actuation technologies, creating economic barriers to mass-market implementation despite the functional advantages SMAs offer.

Current Optimization Solutions for SMAs

01 Composition optimization of shape memory alloys

Optimizing the composition of shape memory alloys involves adjusting the ratio of constituent elements to enhance properties such as transformation temperature, mechanical strength, and fatigue resistance. Various alloying elements can be added to traditional NiTi alloys to tailor specific characteristics. The composition can be fine-tuned through precise metallurgical processes to achieve desired phase transformation behaviors and functional stability over repeated cycles.- Composition optimization of shape memory alloys: Optimization of shape memory alloys through compositional adjustments to enhance their functional properties. This includes altering the ratio of constituent elements, adding trace elements, or developing new alloy systems to improve transformation temperatures, mechanical strength, fatigue resistance, and shape memory effect. These compositional modifications can be tailored for specific applications requiring precise actuation or recovery behaviors.

- Thermomechanical processing techniques: Various thermomechanical processing methods are employed to optimize shape memory alloys, including heat treatment protocols, annealing processes, cold working, and controlled cooling. These techniques can significantly alter the microstructure of the alloys, improving their shape memory characteristics, superelasticity, and functional stability. Specific processing parameters can be adjusted to achieve desired transformation behaviors and mechanical properties for different applications.

- Surface treatment and coating methods: Surface modification techniques for shape memory alloys to enhance their performance characteristics. These include various coating processes, surface texturing, and chemical treatments that improve corrosion resistance, biocompatibility, wear resistance, and functional fatigue life. Such treatments can also optimize the interface properties of shape memory alloys when used in composite structures or in environments where surface interactions are critical.

- Application-specific design optimization: Tailoring shape memory alloys for specific applications through design optimization. This includes creating specialized geometries, determining optimal dimensions, and engineering specific actuation mechanisms. The design process considers factors such as response time, actuation force, recovery strain, and cyclic stability to meet the requirements of applications in medical devices, aerospace components, automotive systems, and smart structures.

- Advanced characterization and modeling techniques: Implementation of sophisticated characterization methods and computational modeling to optimize shape memory alloys. These approaches include microstructural analysis, phase transformation studies, finite element modeling, and machine learning algorithms to predict and enhance alloy performance. Such techniques enable better understanding of transformation mechanisms, facilitate rapid alloy development, and allow for virtual testing of shape memory alloy components before physical prototyping.

02 Thermomechanical processing techniques

Thermomechanical processing techniques are crucial for optimizing shape memory alloys' performance. These include controlled heat treatments, cold working, annealing, and aging processes that significantly influence the microstructure and transformation characteristics. Specific processing parameters such as temperature, time, and deformation rate can be adjusted to enhance shape memory effect, superelasticity, and fatigue life. Advanced processing methods like severe plastic deformation can create ultrafine-grained structures with improved functional properties.Expand Specific Solutions03 Microstructural engineering and characterization

Microstructural engineering focuses on controlling grain size, precipitate formation, and crystallographic texture to optimize shape memory alloy performance. Advanced characterization techniques such as electron microscopy, X-ray diffraction, and calorimetry are employed to analyze phase transformations and microstructural features. Understanding the relationship between microstructure and functional properties enables the development of alloys with enhanced shape memory effect, superelasticity, and fatigue resistance. Precipitate size and distribution can be manipulated to create internal stress fields that stabilize transformation behavior.Expand Specific Solutions04 Application-specific optimization methods

Shape memory alloys can be optimized for specific applications such as medical devices, actuators, and aerospace components. For medical applications, biocompatibility and corrosion resistance are prioritized alongside functional properties. In actuator applications, optimization focuses on work output, response time, and cycle life. Aerospace applications require alloys with high fatigue resistance and stability under extreme conditions. Tailored optimization strategies consider the specific operating conditions, required force generation, and dimensional constraints of each application.Expand Specific Solutions05 Computational modeling and simulation techniques

Computational modeling and simulation techniques are increasingly used to predict and optimize shape memory alloy behavior. Finite element analysis, molecular dynamics simulations, and machine learning approaches help understand complex transformation mechanisms and predict material response under various conditions. These computational tools enable rapid virtual testing of different compositions and processing parameters before experimental validation. Advanced models can account for thermomechanical coupling, phase transformation kinetics, and functional fatigue, accelerating the development of optimized shape memory alloys with enhanced performance characteristics.Expand Specific Solutions

Key Industry Players and Competition

The shape memory alloy (SMA) market for electronic devices is in a growth phase, with increasing applications in miniaturized actuators and sensors. The global market size is expanding rapidly, projected to reach significant value as electronic devices continue to shrink while demanding more functionality. Technologically, SMAs are advancing from experimental to commercial maturity, with key players driving innovation across different sectors. Companies like Samsung Electronics and Infineon Technologies are integrating SMAs into consumer electronics, while specialized firms such as Exergyn, Cambridge Mechatronics, and Actuator Solutions GmbH are developing proprietary SMA applications. Academic institutions including Northwestern Polytechnical University and Tianjin University collaborate with industrial partners like SAES Getters to optimize SMA properties for electronic applications, focusing on response time, fatigue resistance, and power efficiency.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed proprietary SMA-based technologies optimized for mobile device applications, particularly focusing on camera modules, haptic feedback systems, and microactuators for internal components. Their approach combines thin-film SMA deposition techniques with MEMS fabrication processes to create highly miniaturized actuators with thicknesses below 20μm. Samsung's optimization strategy includes precise control of alloy composition through sputtering processes, achieving transformation temperature control within ±3°C[2]. The company has implemented specialized annealing protocols that enhance the functional stability of SMA components, reducing drift in performance parameters by up to 70% compared to conventional processing[4]. Samsung has also pioneered integration of SMA actuators with flexible printed circuit boards, enabling new form factors for foldable and rollable devices. Their control systems utilize proprietary algorithms that model and compensate for SMA hysteresis effects, achieving positioning accuracy within 5μm while minimizing power consumption through predictive activation patterns[8]. Recent developments include multi-layer SMA structures that increase force output while maintaining compact dimensions.

Strengths: Exceptional miniaturization capabilities; seamless integration with existing electronics manufacturing; sophisticated control systems; ability to mass-produce at competitive costs. Weaknesses: Proprietary technology limits wider adoption; thermal management challenges in densely packed devices; performance trade-offs to achieve extreme miniaturization.

SAES Getters SpA

Technical Solution: SAES Getters has developed proprietary shape memory alloy (SMA) technology branded as Nitinol-based SMA actuators specifically optimized for electronic devices. Their technology focuses on miniaturization and precise control of actuation forces through specialized heat treatment processes and composition control. The company has pioneered thin-film SMA deposition techniques that allow for integration into MEMS devices and microelectronics with thicknesses down to 5-10 μm[1]. Their optimization approach includes tailoring transformation temperatures within ±2°C precision for specific electronic applications through precise Ni-Ti ratio control and ternary element additions (Cu, Hf, Zr)[3]. SAES has also developed specialized surface treatments to improve the fatigue life of SMA components in electronic devices by up to 10x compared to untreated alloys, enabling millions of actuation cycles without performance degradation[5].

Strengths: Industry-leading expertise in thin-film SMA technology; exceptional precision in transformation temperature control; proprietary surface treatments for extended fatigue life. Weaknesses: Higher production costs compared to conventional actuators; requires specialized manufacturing facilities; thermal management challenges in compact electronic devices.

Critical SMA Patents and Research

Shape memory alloy incorporating electronic component

PatentInactiveJP2019094557A

Innovation

- Incorporating electronic components into shape memory alloys to enable them to return to their original shape after deformation.

Method for making a part in shape memory alloy and part obtained by said method

PatentWO2000044957A1

Innovation

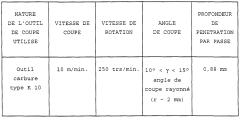

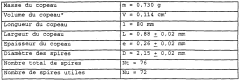

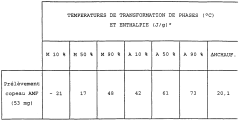

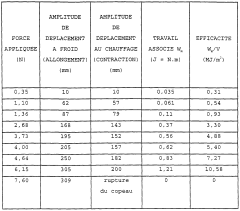

- A single-step cutting machining process that simultaneously manufactures, shapes, and machines shape memory alloy parts, utilizing high-speed or low-speed cutting methods to achieve remarkable mechanical and functional properties, such as high recovery force and superelasticity, by applying specific machining parameters like cutting speed and tool geometry.

Thermal Management Strategies

Thermal management represents a critical challenge in the application of Shape Memory Alloys (SMAs) within electronic devices. The unique phase transformation properties of SMAs that enable their functionality are inherently temperature-dependent, requiring precise thermal control to ensure reliable operation. As electronic devices continue to miniaturize while increasing in computational power, the heat generated within confined spaces creates significant thermal management challenges for SMA integration.

Conventional thermal management approaches for SMAs in electronics include passive cooling techniques such as heat sinks, thermal interface materials, and strategic component placement. These methods facilitate heat dissipation through conduction and convection pathways, preventing localized hotspots that could trigger unintended SMA actuation or alter transformation temperatures. However, these passive approaches often prove insufficient for high-density electronic applications where thermal loads fluctuate rapidly.

Active cooling systems represent a more sophisticated approach, incorporating thermoelectric coolers, microfluidic channels, or phase-change materials to provide dynamic thermal regulation. These systems can respond to changing thermal conditions, maintaining SMAs within their optimal operational temperature range. Recent innovations include closed-loop control systems that utilize embedded temperature sensors to monitor SMA conditions in real-time, adjusting cooling parameters accordingly to maintain thermal stability.

Computational thermal modeling has emerged as an essential tool in SMA thermal management strategy development. Finite element analysis and computational fluid dynamics simulations enable engineers to predict thermal behavior before physical prototyping, optimizing heat flow pathways and identifying potential thermal bottlenecks. These models increasingly incorporate the complex thermomechanical coupling effects unique to SMAs, allowing for more accurate predictions of performance under various thermal conditions.

Material-level thermal optimization strategies focus on modifying SMA compositions to achieve desired transformation temperatures compatible with electronic operating environments. Quaternary and quinary alloy systems with elements such as copper, palladium, or platinum can shift transformation temperatures to more suitable ranges for specific electronic applications. Additionally, microstructural engineering through heat treatment protocols or processing techniques can fine-tune thermal hysteresis characteristics, improving thermal response predictability.

Emerging approaches include the development of hybrid thermal management systems that combine multiple strategies tailored to specific device architectures. These systems often incorporate thermal isolation techniques to shield SMAs from unintended heat sources within the device, while simultaneously providing dedicated thermal pathways for controlled actuation. Such integrated approaches represent the cutting edge of SMA thermal management, enabling more reliable performance in increasingly demanding electronic environments.

Conventional thermal management approaches for SMAs in electronics include passive cooling techniques such as heat sinks, thermal interface materials, and strategic component placement. These methods facilitate heat dissipation through conduction and convection pathways, preventing localized hotspots that could trigger unintended SMA actuation or alter transformation temperatures. However, these passive approaches often prove insufficient for high-density electronic applications where thermal loads fluctuate rapidly.

Active cooling systems represent a more sophisticated approach, incorporating thermoelectric coolers, microfluidic channels, or phase-change materials to provide dynamic thermal regulation. These systems can respond to changing thermal conditions, maintaining SMAs within their optimal operational temperature range. Recent innovations include closed-loop control systems that utilize embedded temperature sensors to monitor SMA conditions in real-time, adjusting cooling parameters accordingly to maintain thermal stability.

Computational thermal modeling has emerged as an essential tool in SMA thermal management strategy development. Finite element analysis and computational fluid dynamics simulations enable engineers to predict thermal behavior before physical prototyping, optimizing heat flow pathways and identifying potential thermal bottlenecks. These models increasingly incorporate the complex thermomechanical coupling effects unique to SMAs, allowing for more accurate predictions of performance under various thermal conditions.

Material-level thermal optimization strategies focus on modifying SMA compositions to achieve desired transformation temperatures compatible with electronic operating environments. Quaternary and quinary alloy systems with elements such as copper, palladium, or platinum can shift transformation temperatures to more suitable ranges for specific electronic applications. Additionally, microstructural engineering through heat treatment protocols or processing techniques can fine-tune thermal hysteresis characteristics, improving thermal response predictability.

Emerging approaches include the development of hybrid thermal management systems that combine multiple strategies tailored to specific device architectures. These systems often incorporate thermal isolation techniques to shield SMAs from unintended heat sources within the device, while simultaneously providing dedicated thermal pathways for controlled actuation. Such integrated approaches represent the cutting edge of SMA thermal management, enabling more reliable performance in increasingly demanding electronic environments.

Miniaturization Techniques

Miniaturization of shape memory alloys (SMAs) represents a critical frontier in their application for electronic devices. As electronic components continue to shrink while demanding increased functionality, the ability to scale down SMA actuators and sensors becomes paramount. Current miniaturization techniques focus on several key approaches that balance performance requirements with size constraints.

Thin film deposition methods have emerged as leading techniques for SMA miniaturization. Sputtering and vapor deposition processes can create SMA films with thicknesses ranging from several nanometers to a few micrometers, enabling integration into micro-electromechanical systems (MEMS). These processes allow precise control over composition and crystalline structure, though they require careful parameter optimization to maintain transformation properties at reduced dimensions.

Micromachining techniques complement thin film approaches by enabling complex three-dimensional SMA microstructures. Laser micromachining, focused ion beam etching, and photolithographic processes can create intricate patterns with feature sizes down to sub-micron levels. These techniques facilitate the development of microactuators with sophisticated geometries that maximize force output despite minimal material volume.

Advanced metallurgical processing has also contributed significantly to SMA miniaturization. Techniques such as severe plastic deformation, rapid solidification, and controlled grain refinement produce ultrafine-grained or nanocrystalline SMAs with enhanced functional properties. These materials exhibit faster response times and improved fatigue resistance, addressing key limitations in microscale applications.

Integration strategies represent another crucial aspect of miniaturization. Novel packaging approaches, such as wafer-level bonding and microassembly techniques, enable SMAs to be incorporated into increasingly compact electronic devices. These methods must address challenges related to electrical connections, thermal management, and mechanical interfaces at reduced scales.

Simulation and modeling tools have become indispensable for miniaturization efforts. Multiphysics models that account for thermomechanical coupling, size effects, and interface phenomena guide the design of microscale SMA components. These computational approaches reduce development cycles by predicting performance before physical prototyping, particularly important as empirical testing becomes more challenging at smaller scales.

Recent innovations in additive manufacturing offer promising directions for SMA miniaturization. Techniques such as selective laser melting and direct ink writing can produce complex SMA microstructures with controlled porosity and composition gradients. While still emerging, these approaches may eventually enable customized microscale SMA components with optimized geometries for specific electronic applications.

Thin film deposition methods have emerged as leading techniques for SMA miniaturization. Sputtering and vapor deposition processes can create SMA films with thicknesses ranging from several nanometers to a few micrometers, enabling integration into micro-electromechanical systems (MEMS). These processes allow precise control over composition and crystalline structure, though they require careful parameter optimization to maintain transformation properties at reduced dimensions.

Micromachining techniques complement thin film approaches by enabling complex three-dimensional SMA microstructures. Laser micromachining, focused ion beam etching, and photolithographic processes can create intricate patterns with feature sizes down to sub-micron levels. These techniques facilitate the development of microactuators with sophisticated geometries that maximize force output despite minimal material volume.

Advanced metallurgical processing has also contributed significantly to SMA miniaturization. Techniques such as severe plastic deformation, rapid solidification, and controlled grain refinement produce ultrafine-grained or nanocrystalline SMAs with enhanced functional properties. These materials exhibit faster response times and improved fatigue resistance, addressing key limitations in microscale applications.

Integration strategies represent another crucial aspect of miniaturization. Novel packaging approaches, such as wafer-level bonding and microassembly techniques, enable SMAs to be incorporated into increasingly compact electronic devices. These methods must address challenges related to electrical connections, thermal management, and mechanical interfaces at reduced scales.

Simulation and modeling tools have become indispensable for miniaturization efforts. Multiphysics models that account for thermomechanical coupling, size effects, and interface phenomena guide the design of microscale SMA components. These computational approaches reduce development cycles by predicting performance before physical prototyping, particularly important as empirical testing becomes more challenging at smaller scales.

Recent innovations in additive manufacturing offer promising directions for SMA miniaturization. Techniques such as selective laser melting and direct ink writing can produce complex SMA microstructures with controlled porosity and composition gradients. While still emerging, these approaches may eventually enable customized microscale SMA components with optimized geometries for specific electronic applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!