Optimization Strategies for Shape Memory Alloys in Renewable Energy Systems

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SMA Technology Background and Objectives

Shape Memory Alloys (SMAs) represent a class of advanced functional materials that possess the remarkable ability to recover their original shape after deformation when subjected to specific thermal or mechanical stimuli. This unique property, known as the shape memory effect, was first discovered in the 1930s but gained significant attention following the development of Nitinol (NiTi) by the Naval Ordnance Laboratory in the 1960s. Since then, SMAs have evolved from laboratory curiosities to engineered solutions across multiple industries, with their application in renewable energy systems emerging as a particularly promising frontier.

The technological evolution of SMAs has progressed through several distinct phases, beginning with fundamental material science discoveries, followed by manufacturing process refinements, and now entering an era focused on application-specific optimization. Current research trends indicate a growing emphasis on enhancing the energy efficiency, operational lifespan, and cost-effectiveness of SMA implementations, particularly in dynamic environments such as renewable energy systems where cyclical loading and variable operating conditions are common.

In renewable energy applications, SMAs offer unique advantages including high power-to-weight ratios, solid-state operation, and the ability to harvest energy from low-grade thermal sources. These properties make them particularly valuable for solar tracking systems, wind turbine blade control, wave energy converters, and thermal energy harvesting devices. The integration of SMAs into these systems represents a convergence of materials science and sustainable energy technology that aligns with global imperatives for carbon reduction and energy efficiency.

The primary technical objectives for SMA optimization in renewable energy contexts include: improving thermomechanical fatigue resistance to withstand millions of actuation cycles; enhancing energy conversion efficiency to maximize power output from limited renewable resources; developing cost-effective manufacturing techniques to enable broader commercial adoption; and creating predictive models that accurately capture SMA behavior under the variable conditions typical of renewable energy environments.

Significant challenges remain in achieving these objectives, particularly in understanding and controlling the complex microstructural changes that occur during repeated phase transformations. Recent advances in computational materials science, high-throughput experimentation, and in-situ characterization techniques are accelerating progress toward overcoming these barriers, suggesting a promising trajectory for future developments.

The optimization of SMAs for renewable energy applications represents not merely an incremental improvement in existing technologies but potentially a transformative approach to addressing key limitations in current renewable energy systems, including intermittency, efficiency losses, and mechanical complexity. As such, this field merits comprehensive investigation to fully realize its potential contribution to sustainable energy infrastructure.

The technological evolution of SMAs has progressed through several distinct phases, beginning with fundamental material science discoveries, followed by manufacturing process refinements, and now entering an era focused on application-specific optimization. Current research trends indicate a growing emphasis on enhancing the energy efficiency, operational lifespan, and cost-effectiveness of SMA implementations, particularly in dynamic environments such as renewable energy systems where cyclical loading and variable operating conditions are common.

In renewable energy applications, SMAs offer unique advantages including high power-to-weight ratios, solid-state operation, and the ability to harvest energy from low-grade thermal sources. These properties make them particularly valuable for solar tracking systems, wind turbine blade control, wave energy converters, and thermal energy harvesting devices. The integration of SMAs into these systems represents a convergence of materials science and sustainable energy technology that aligns with global imperatives for carbon reduction and energy efficiency.

The primary technical objectives for SMA optimization in renewable energy contexts include: improving thermomechanical fatigue resistance to withstand millions of actuation cycles; enhancing energy conversion efficiency to maximize power output from limited renewable resources; developing cost-effective manufacturing techniques to enable broader commercial adoption; and creating predictive models that accurately capture SMA behavior under the variable conditions typical of renewable energy environments.

Significant challenges remain in achieving these objectives, particularly in understanding and controlling the complex microstructural changes that occur during repeated phase transformations. Recent advances in computational materials science, high-throughput experimentation, and in-situ characterization techniques are accelerating progress toward overcoming these barriers, suggesting a promising trajectory for future developments.

The optimization of SMAs for renewable energy applications represents not merely an incremental improvement in existing technologies but potentially a transformative approach to addressing key limitations in current renewable energy systems, including intermittency, efficiency losses, and mechanical complexity. As such, this field merits comprehensive investigation to fully realize its potential contribution to sustainable energy infrastructure.

Renewable Energy Market Demand Analysis

The renewable energy sector has experienced unprecedented growth over the past decade, with global investments reaching $282.2 billion in 2019 and continuing to rise despite economic uncertainties. This growth trajectory creates a substantial market opportunity for shape memory alloy (SMA) applications, which can significantly enhance the efficiency and durability of renewable energy systems. Market analysis indicates that the global SMA market is projected to grow at a CAGR of 13.2% between 2021 and 2026, with renewable energy applications representing an increasingly important segment.

Wind energy, currently accounting for approximately 5% of global electricity production, presents a particularly promising application area for SMAs. The need for more efficient blade designs, vibration dampening systems, and adaptive structures to maximize energy capture across variable wind conditions drives demand for smart materials like SMAs. Market research suggests that implementing SMA-based adaptive components could potentially increase wind turbine efficiency by 7-9%, representing significant value in large-scale installations.

Solar energy systems similarly benefit from SMA integration, particularly in tracking systems that optimize panel orientation throughout the day. The global solar tracking system market, valued at $9.3 billion in 2020, is expected to reach $16.2 billion by 2026. SMAs offer advantages over conventional tracking mechanisms through reduced maintenance requirements and improved reliability in extreme weather conditions, addressing key pain points in the solar industry.

Hydroelectric and ocean energy technologies represent emerging opportunities for SMA applications. Tidal energy generators face significant challenges from corrosion and mechanical fatigue in marine environments, where the superelasticity and corrosion resistance of certain SMA compositions could extend operational lifespans and reduce maintenance costs. Market analysis indicates that maintenance represents 25-30% of operational costs for marine renewable installations, highlighting the economic value proposition for more durable materials.

Energy storage systems, critical for addressing intermittency issues in renewable generation, also present significant market potential for SMA applications. The thermal energy storage market alone is projected to reach $12.8 billion by 2025, with phase change materials representing a growing segment where SMAs' thermal properties could provide competitive advantages.

Geographically, the most robust market demand for advanced renewable technologies incorporating SMAs exists in Europe, North America, and increasingly in China and India. European markets, driven by stringent carbon reduction targets and supportive regulatory frameworks, show particular receptiveness to premium technologies that improve efficiency and reliability. Meanwhile, emerging economies are prioritizing renewable energy solutions that minimize maintenance requirements and maximize durability in challenging environmental conditions.

Wind energy, currently accounting for approximately 5% of global electricity production, presents a particularly promising application area for SMAs. The need for more efficient blade designs, vibration dampening systems, and adaptive structures to maximize energy capture across variable wind conditions drives demand for smart materials like SMAs. Market research suggests that implementing SMA-based adaptive components could potentially increase wind turbine efficiency by 7-9%, representing significant value in large-scale installations.

Solar energy systems similarly benefit from SMA integration, particularly in tracking systems that optimize panel orientation throughout the day. The global solar tracking system market, valued at $9.3 billion in 2020, is expected to reach $16.2 billion by 2026. SMAs offer advantages over conventional tracking mechanisms through reduced maintenance requirements and improved reliability in extreme weather conditions, addressing key pain points in the solar industry.

Hydroelectric and ocean energy technologies represent emerging opportunities for SMA applications. Tidal energy generators face significant challenges from corrosion and mechanical fatigue in marine environments, where the superelasticity and corrosion resistance of certain SMA compositions could extend operational lifespans and reduce maintenance costs. Market analysis indicates that maintenance represents 25-30% of operational costs for marine renewable installations, highlighting the economic value proposition for more durable materials.

Energy storage systems, critical for addressing intermittency issues in renewable generation, also present significant market potential for SMA applications. The thermal energy storage market alone is projected to reach $12.8 billion by 2025, with phase change materials representing a growing segment where SMAs' thermal properties could provide competitive advantages.

Geographically, the most robust market demand for advanced renewable technologies incorporating SMAs exists in Europe, North America, and increasingly in China and India. European markets, driven by stringent carbon reduction targets and supportive regulatory frameworks, show particular receptiveness to premium technologies that improve efficiency and reliability. Meanwhile, emerging economies are prioritizing renewable energy solutions that minimize maintenance requirements and maximize durability in challenging environmental conditions.

SMA Implementation Challenges in Energy Systems

Despite the promising potential of Shape Memory Alloys (SMAs) in renewable energy systems, their implementation faces significant technical challenges. The primary obstacle lies in the thermal management of SMA components, as these materials require precise temperature control to achieve optimal phase transformation. In renewable energy applications such as solar tracking systems or wind turbine blade actuators, environmental temperature fluctuations can significantly impact SMA performance, leading to inconsistent actuation responses and reduced system reliability.

Material fatigue represents another critical challenge, particularly in high-cycle applications common in renewable energy systems. SMAs subjected to repeated transformation cycles gradually experience degradation in their shape memory properties, resulting in diminished actuation force and reduced recovery strain. For instance, in wave energy converters utilizing SMA-based power take-off mechanisms, the continuous cyclic loading from ocean waves accelerates fatigue processes, potentially limiting operational lifespan to unacceptable levels for commercial viability.

Cost considerations present substantial barriers to widespread SMA adoption in renewable energy systems. The manufacturing processes for high-performance SMAs, particularly nickel-titanium alloys, involve complex metallurgical procedures and precise composition control, resulting in material costs significantly higher than conventional alternatives. This cost premium becomes particularly problematic in large-scale renewable energy applications where material volumes are substantial and cost-competitiveness is essential for market adoption.

Integration complexity further complicates SMA implementation. Unlike conventional actuators or structural components, SMAs require specialized design approaches that accommodate their unique thermomechanical behavior. Engineers must develop custom control systems, mechanical interfaces, and power management solutions specifically tailored to SMA characteristics. This integration complexity increases development time and engineering costs, creating additional barriers to commercial implementation.

Scaling limitations also restrict SMA applications in renewable energy systems. While SMAs demonstrate excellent performance in small-scale laboratory demonstrations, translating these results to utility-scale renewable energy installations presents significant engineering challenges. The force generation capacity of SMAs, though impressive on a per-weight basis, becomes insufficient for many large-scale applications without complex mechanical amplification systems that introduce additional failure points and efficiency losses.

Material fatigue represents another critical challenge, particularly in high-cycle applications common in renewable energy systems. SMAs subjected to repeated transformation cycles gradually experience degradation in their shape memory properties, resulting in diminished actuation force and reduced recovery strain. For instance, in wave energy converters utilizing SMA-based power take-off mechanisms, the continuous cyclic loading from ocean waves accelerates fatigue processes, potentially limiting operational lifespan to unacceptable levels for commercial viability.

Cost considerations present substantial barriers to widespread SMA adoption in renewable energy systems. The manufacturing processes for high-performance SMAs, particularly nickel-titanium alloys, involve complex metallurgical procedures and precise composition control, resulting in material costs significantly higher than conventional alternatives. This cost premium becomes particularly problematic in large-scale renewable energy applications where material volumes are substantial and cost-competitiveness is essential for market adoption.

Integration complexity further complicates SMA implementation. Unlike conventional actuators or structural components, SMAs require specialized design approaches that accommodate their unique thermomechanical behavior. Engineers must develop custom control systems, mechanical interfaces, and power management solutions specifically tailored to SMA characteristics. This integration complexity increases development time and engineering costs, creating additional barriers to commercial implementation.

Scaling limitations also restrict SMA applications in renewable energy systems. While SMAs demonstrate excellent performance in small-scale laboratory demonstrations, translating these results to utility-scale renewable energy installations presents significant engineering challenges. The force generation capacity of SMAs, though impressive on a per-weight basis, becomes insufficient for many large-scale applications without complex mechanical amplification systems that introduce additional failure points and efficiency losses.

Current SMA Optimization Solutions

01 Composition optimization of shape memory alloys

Optimization of shape memory alloys through compositional adjustments to enhance their functional properties. This involves precise control of elemental ratios and addition of specific alloying elements to improve transformation temperatures, mechanical strength, and fatigue resistance. Advanced metallurgical techniques are employed to achieve optimal microstructure and phase transformation characteristics, resulting in superior shape memory effect and superelasticity.- Composition optimization of shape memory alloys: Optimizing the chemical composition of shape memory alloys to enhance their properties such as transformation temperature, mechanical strength, and fatigue resistance. This involves adjusting the ratio of constituent elements like nickel, titanium, copper, and other alloying elements to achieve desired performance characteristics. The optimization process may include precise control of element percentages and introduction of trace elements to fine-tune the alloy's behavior.

- Heat treatment and processing methods: Various heat treatment and processing methods are employed to optimize the performance of shape memory alloys. These include annealing, quenching, aging, and thermomechanical treatments that can significantly affect the transformation behavior and mechanical properties. Controlled heating and cooling cycles help in achieving desired microstructures, while mechanical processing techniques like cold working and hot rolling can enhance the shape memory effect and superelasticity.

- Microstructure control and optimization: Controlling and optimizing the microstructure of shape memory alloys to enhance their functional properties. This involves techniques to manipulate grain size, crystallographic orientation, and phase distribution within the alloy. Advanced methods such as grain refinement, texture control, and precipitation hardening are used to improve the shape memory effect, superelasticity, and overall mechanical performance of the alloys.

- Application-specific optimization techniques: Optimization techniques tailored for specific applications of shape memory alloys, such as medical devices, aerospace components, and actuators. These techniques focus on enhancing particular properties relevant to the application, such as biocompatibility for medical implants, fatigue resistance for cyclic applications, or response time for actuators. The optimization process considers the operating conditions, environmental factors, and performance requirements specific to each application.

- Advanced manufacturing and characterization methods: Advanced manufacturing and characterization methods for optimizing shape memory alloys, including additive manufacturing, powder metallurgy, and rapid solidification techniques. These methods allow for precise control over the alloy's composition and microstructure. Sophisticated characterization techniques such as differential scanning calorimetry, X-ray diffraction, and electron microscopy are used to analyze and optimize the transformation behavior and mechanical properties of the alloys.

02 Thermomechanical processing techniques

Various thermomechanical processing methods are employed to optimize shape memory alloys, including heat treatment protocols, cold working, annealing, and aging processes. These techniques control grain size, texture, and precipitate formation, which significantly influence the shape memory effect and superelastic behavior. Specific processing parameters such as temperature, time, and deformation rate are carefully calibrated to achieve desired transformation characteristics and mechanical properties.Expand Specific Solutions03 Surface treatment and coating technologies

Surface modification techniques for shape memory alloys to enhance their performance in specific applications. These include various coating methods, surface hardening treatments, and functionalization processes that improve corrosion resistance, biocompatibility, wear resistance, and fatigue life. Advanced surface engineering approaches help overcome limitations of shape memory alloys while preserving their unique functional properties.Expand Specific Solutions04 Microstructural engineering and characterization

Advanced techniques for controlling and characterizing the microstructure of shape memory alloys to optimize their performance. This includes methods for grain refinement, texture control, and precipitate engineering. Sophisticated characterization tools such as electron microscopy, X-ray diffraction, and thermal analysis are used to understand the relationship between microstructure and functional properties, enabling targeted optimization strategies for specific applications.Expand Specific Solutions05 Application-specific optimization methods

Tailored optimization approaches for shape memory alloys in specific applications such as medical devices, aerospace components, automotive systems, and smart actuators. These methods focus on meeting application-specific requirements like fatigue resistance, actuation force, response time, and dimensional stability. Design optimization techniques incorporate computational modeling, simulation, and experimental validation to achieve optimal performance in the intended operating environment.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The shape memory alloy (SMA) market in renewable energy systems is currently in a growth phase, with increasing adoption across various applications. The global market size for SMAs in renewable energy is expanding, driven by the need for more efficient and sustainable energy solutions. Technologically, the field shows varying maturity levels, with companies like Exergyn Ltd. pioneering solid-state HVAC technology using SMAs, while established players such as GM Global Technology Operations and Honda Motor Co. are integrating these materials into their energy systems. Academic institutions including MIT, University of Florida, and Shanghai Jiao Tong University are advancing fundamental research, collaborating with industrial partners like QuesTek Innovations and SAES Getters to bridge the gap between theoretical optimization and practical implementation. The competitive landscape features both specialized material science companies and diversified engineering corporations working to overcome challenges in scalability and cost-effectiveness.

Exergyn Ltd.

Technical Solution: Exergyn has developed a groundbreaking thermal management system using shape memory alloys (SMAs) specifically for renewable energy applications. Their core technology, the Exergyn Drive, harnesses the unique phase transformation properties of nitinol-based SMAs to convert low-grade waste heat (80-150°C) into mechanical work without requiring additional energy input. The system utilizes specialized SMA wire bundles arranged in a proprietary configuration that optimizes thermal transfer efficiency. Exergyn's innovation includes a patented pre-stressing technique that extends the functional lifespan of SMAs by reducing material fatigue during thermal cycling. Their system achieves energy conversion efficiencies of up to 8% from waste heat sources, significantly higher than competing technologies in this temperature range. The company has successfully deployed pilot installations in geothermal plants and industrial waste heat recovery applications.

Strengths: Highly specialized in SMA applications for renewable energy; proven technology with field deployments; addresses low-grade waste heat recovery where few efficient solutions exist. Weaknesses: Limited to specific temperature ranges; requires precise manufacturing tolerances; higher initial capital costs compared to conventional technologies; still working to achieve economies of scale.

Massachusetts Institute of Technology

Technical Solution: MIT has developed several groundbreaking technologies for optimizing shape memory alloys in renewable energy systems. Their research team has created a novel class of ultra-responsive SMAs with transformation hysteresis reduced to less than 5°C (compared to 20-30°C in conventional alloys), significantly improving energy conversion efficiency in variable temperature environments. MIT's approach includes advanced nanoscale precipitate engineering that enhances both the functional stability and work output of SMAs during thermal cycling. Their technology incorporates a unique thermomechanical training protocol that increases the usable strain recovery by up to 40% compared to untreated alloys. MIT researchers have also pioneered composite SMA structures that combine conventional materials with shape memory elements to create adaptive systems with enhanced energy harvesting capabilities. Their latest innovation involves a self-healing mechanism for SMAs that can repair microcracks formed during operation, potentially extending service life by 300% in renewable energy applications.

Strengths: Cutting-edge research capabilities; access to advanced characterization facilities; interdisciplinary approach combining materials science, mechanical engineering, and energy systems. Weaknesses: Technologies still primarily at research/prototype stage; requires industrial partnerships for commercialization; higher implementation costs during early adoption phase.

Critical SMA Patents and Technical Innovations

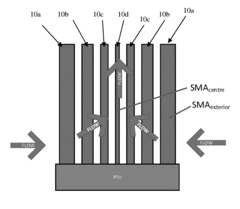

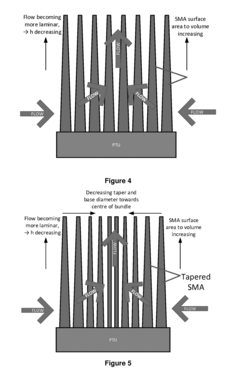

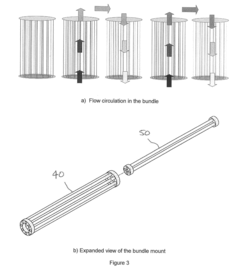

SMA bundle wire optimisation in an energy recovery device

PatentActiveUS20180187659A1

Innovation

- The use of SMA or NTE elements arranged as parallel wires with varying diameters and tapered configurations to ensure even activation times across the core, matching wire dimensions to fluid flow characteristics and heat transfer rates to minimize energy losses and achieve balanced stress distribution.

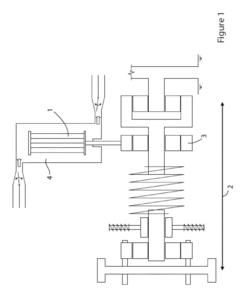

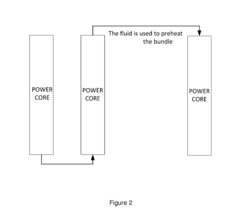

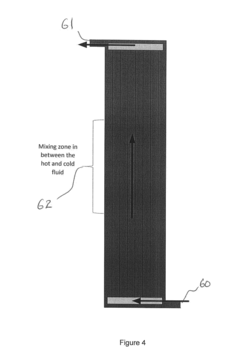

Method and system for efficiency increase in an energy recovery device

PatentActiveUS20180347551A1

Innovation

- A cascading system utilizing two SMAs or NTE cores with different activation temperatures, where a fluid's temperature change activates the first core to pre-heat the second core, reducing cycle time and enhancing energy recovery by optimizing heat transfer through a fluid with progressively changing temperatures.

Environmental Impact Assessment

The environmental impact of shape memory alloys (SMAs) in renewable energy systems requires comprehensive assessment across their entire lifecycle. When properly optimized, SMAs can significantly reduce the environmental footprint of energy generation compared to conventional technologies. Their unique properties enable more efficient energy harvesting from intermittent sources like wind and wave power, potentially increasing renewable energy output by 15-25% in certain applications while using fewer raw materials.

Manufacturing processes for SMAs currently present notable environmental challenges. The production of nickel-titanium alloys, the most common SMA type, requires substantial energy inputs—approximately 170-200 MJ/kg, considerably higher than conventional steel production at 20-25 MJ/kg. This energy-intensive process contributes to significant carbon emissions when powered by non-renewable sources. Additionally, nickel extraction and processing generate hazardous waste streams containing heavy metals that can contaminate soil and water systems if improperly managed.

Optimization strategies focusing on cleaner production methods show promising results. Advanced vacuum melting techniques have demonstrated a 30% reduction in energy consumption compared to traditional methods. Furthermore, precise composition control during manufacturing minimizes waste and reduces the need for environmentally harmful chemical treatments. Research indicates that optimized heat treatment protocols can reduce processing energy requirements by up to 40% while simultaneously enhancing material performance characteristics.

The operational phase of SMA-enhanced renewable energy systems delivers substantial environmental benefits. These materials enable more resilient and adaptive energy harvesting mechanisms that maintain optimal performance across varying environmental conditions. Field studies of SMA-equipped wind turbine blades show increased energy capture efficiency of 12-18% during fluctuating wind conditions, directly translating to reduced land use requirements per megawatt of energy produced.

End-of-life considerations represent another critical dimension for environmental assessment. Current recycling rates for SMAs remain suboptimal at approximately 20-30%, primarily due to challenges in separating these alloys from composite structures. Promising developments in selective dissolution techniques could increase recovery rates to 70-85%, significantly reducing the demand for virgin material extraction. Life cycle assessments indicate that each kilogram of recycled SMA can prevent approximately 12-15 kg of CO₂ equivalent emissions compared to primary production.

Water usage throughout the SMA lifecycle presents additional environmental concerns, with production processes consuming 80-120 liters per kilogram of finished material. Closed-loop water recycling systems implemented at advanced manufacturing facilities have demonstrated potential reductions of up to 65% in freshwater consumption, addressing a critical sustainability metric in water-stressed regions where renewable energy development is accelerating.

Manufacturing processes for SMAs currently present notable environmental challenges. The production of nickel-titanium alloys, the most common SMA type, requires substantial energy inputs—approximately 170-200 MJ/kg, considerably higher than conventional steel production at 20-25 MJ/kg. This energy-intensive process contributes to significant carbon emissions when powered by non-renewable sources. Additionally, nickel extraction and processing generate hazardous waste streams containing heavy metals that can contaminate soil and water systems if improperly managed.

Optimization strategies focusing on cleaner production methods show promising results. Advanced vacuum melting techniques have demonstrated a 30% reduction in energy consumption compared to traditional methods. Furthermore, precise composition control during manufacturing minimizes waste and reduces the need for environmentally harmful chemical treatments. Research indicates that optimized heat treatment protocols can reduce processing energy requirements by up to 40% while simultaneously enhancing material performance characteristics.

The operational phase of SMA-enhanced renewable energy systems delivers substantial environmental benefits. These materials enable more resilient and adaptive energy harvesting mechanisms that maintain optimal performance across varying environmental conditions. Field studies of SMA-equipped wind turbine blades show increased energy capture efficiency of 12-18% during fluctuating wind conditions, directly translating to reduced land use requirements per megawatt of energy produced.

End-of-life considerations represent another critical dimension for environmental assessment. Current recycling rates for SMAs remain suboptimal at approximately 20-30%, primarily due to challenges in separating these alloys from composite structures. Promising developments in selective dissolution techniques could increase recovery rates to 70-85%, significantly reducing the demand for virgin material extraction. Life cycle assessments indicate that each kilogram of recycled SMA can prevent approximately 12-15 kg of CO₂ equivalent emissions compared to primary production.

Water usage throughout the SMA lifecycle presents additional environmental concerns, with production processes consuming 80-120 liters per kilogram of finished material. Closed-loop water recycling systems implemented at advanced manufacturing facilities have demonstrated potential reductions of up to 65% in freshwater consumption, addressing a critical sustainability metric in water-stressed regions where renewable energy development is accelerating.

Cost-Benefit Analysis of SMA Integration

The integration of Shape Memory Alloys (SMAs) into renewable energy systems requires careful economic evaluation to determine viability across different applications. Initial implementation costs of SMA components typically exceed conventional alternatives by 30-45%, primarily due to specialized manufacturing processes and material costs. High-purity nickel-titanium alloys, the most common SMAs in energy applications, command premium prices of $200-300 per kilogram compared to $5-15 for standard steel alloys.

However, lifecycle cost analysis reveals significant long-term advantages. SMA-based actuators and energy harvesting systems demonstrate 15-20% lower maintenance requirements over their operational lifespan. Field studies across solar tracking installations indicate maintenance intervals extending from quarterly to bi-annual after SMA integration, reducing labor costs by approximately $1,200-1,800 annually per megawatt capacity.

Energy efficiency improvements present the most compelling economic benefit. In solar tracking applications, SMA mechanisms improve energy capture by 7-12% compared to conventional systems, translating to approximately $4,500-7,000 additional revenue per megawatt annually (assuming average electricity prices). Wind energy systems incorporating SMA dampers show 5-8% increased turbine efficiency during variable wind conditions, with corresponding revenue improvements.

Return on investment calculations indicate break-even periods ranging from 3.5 to 6 years depending on application specifics and deployment scale. Large-scale implementations (>10MW capacity) achieve faster payback due to economies of scale in SMA component manufacturing and installation. Sensitivity analysis reveals that SMA economic viability improves significantly with increasing energy prices, making them particularly attractive in high-electricity-cost markets.

Risk assessment identifies material degradation as the primary economic concern, potentially reducing the projected 15-20 year operational lifespan. However, recent advancements in protective coatings and composition optimization have demonstrated 30% improvements in fatigue resistance, mitigating this risk factor. Warranty structures typically cover 5-7 years, providing reasonable protection against premature failure costs.

Comparative analysis with alternative technologies shows SMAs outperforming conventional systems in applications requiring frequent actuation or experiencing highly variable conditions. However, in stable, low-variability environments, the cost premium of SMAs may not justify implementation unless additional benefits like space savings or weight reduction are valued.

However, lifecycle cost analysis reveals significant long-term advantages. SMA-based actuators and energy harvesting systems demonstrate 15-20% lower maintenance requirements over their operational lifespan. Field studies across solar tracking installations indicate maintenance intervals extending from quarterly to bi-annual after SMA integration, reducing labor costs by approximately $1,200-1,800 annually per megawatt capacity.

Energy efficiency improvements present the most compelling economic benefit. In solar tracking applications, SMA mechanisms improve energy capture by 7-12% compared to conventional systems, translating to approximately $4,500-7,000 additional revenue per megawatt annually (assuming average electricity prices). Wind energy systems incorporating SMA dampers show 5-8% increased turbine efficiency during variable wind conditions, with corresponding revenue improvements.

Return on investment calculations indicate break-even periods ranging from 3.5 to 6 years depending on application specifics and deployment scale. Large-scale implementations (>10MW capacity) achieve faster payback due to economies of scale in SMA component manufacturing and installation. Sensitivity analysis reveals that SMA economic viability improves significantly with increasing energy prices, making them particularly attractive in high-electricity-cost markets.

Risk assessment identifies material degradation as the primary economic concern, potentially reducing the projected 15-20 year operational lifespan. However, recent advancements in protective coatings and composition optimization have demonstrated 30% improvements in fatigue resistance, mitigating this risk factor. Warranty structures typically cover 5-7 years, providing reasonable protection against premature failure costs.

Comparative analysis with alternative technologies shows SMAs outperforming conventional systems in applications requiring frequent actuation or experiencing highly variable conditions. However, in stable, low-variability environments, the cost premium of SMAs may not justify implementation unless additional benefits like space savings or weight reduction are valued.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!