The Impact of Cycle Life on the Market Adoption of Shape Memory Alloys

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Shape Memory Alloy Technology Background and Objectives

Shape Memory Alloys (SMAs) represent a unique class of smart materials that possess the remarkable ability to return to a predetermined shape when subjected to specific thermal or mechanical stimuli. First discovered in the 1930s with gold-cadmium alloys, the field gained significant momentum in the 1960s with the discovery of nickel-titanium (Nitinol) by the Naval Ordnance Laboratory. This technological breakthrough established the foundation for modern SMA applications across multiple industries.

The evolution of SMA technology has been characterized by progressive improvements in material composition, processing techniques, and application methodologies. From initial binary alloys to more complex ternary and quaternary systems, researchers have continuously expanded the performance envelope of these materials. The primary technological trajectory has focused on enhancing transformation temperatures, mechanical properties, and most critically, cycle life performance.

Cycle life—defined as the number of shape recovery cycles an SMA can undergo before experiencing significant degradation in its functional properties—has emerged as a pivotal factor in the commercial viability of these materials. Historically, early SMAs exhibited limited cycle life capabilities, often failing after several thousand transformation cycles, which severely restricted their application in high-cycle scenarios.

Current technological objectives in the SMA field center on addressing this fundamental limitation. Research efforts are concentrated on extending cycle life performance through microstructural optimization, compositional refinements, and novel processing techniques. The goal is to develop SMAs capable of sustaining millions of transformation cycles without significant functional degradation, thereby enabling their adoption in demanding applications such as automotive systems, aerospace components, and long-term biomedical implants.

Parallel to cycle life improvements, the field is pursuing enhanced energy efficiency during the shape memory effect, broader operating temperature ranges, and faster response times. These objectives align with the growing demand for adaptive and responsive materials in next-generation engineering systems. Additionally, researchers are exploring environmentally friendly alternatives to traditional SMA compositions, which often contain potentially toxic elements.

The technological trajectory indicates a shift toward more specialized SMA formulations tailored for specific application requirements rather than general-purpose materials. This specialization trend reflects the maturing understanding of the relationship between microstructure, composition, and functional properties in these complex alloy systems.

As the technology continues to evolve, interdisciplinary collaboration between materials scientists, mechanical engineers, and application specialists has become increasingly important in translating fundamental advances into commercially viable solutions that can overcome the cycle life limitations currently constraining market adoption.

The evolution of SMA technology has been characterized by progressive improvements in material composition, processing techniques, and application methodologies. From initial binary alloys to more complex ternary and quaternary systems, researchers have continuously expanded the performance envelope of these materials. The primary technological trajectory has focused on enhancing transformation temperatures, mechanical properties, and most critically, cycle life performance.

Cycle life—defined as the number of shape recovery cycles an SMA can undergo before experiencing significant degradation in its functional properties—has emerged as a pivotal factor in the commercial viability of these materials. Historically, early SMAs exhibited limited cycle life capabilities, often failing after several thousand transformation cycles, which severely restricted their application in high-cycle scenarios.

Current technological objectives in the SMA field center on addressing this fundamental limitation. Research efforts are concentrated on extending cycle life performance through microstructural optimization, compositional refinements, and novel processing techniques. The goal is to develop SMAs capable of sustaining millions of transformation cycles without significant functional degradation, thereby enabling their adoption in demanding applications such as automotive systems, aerospace components, and long-term biomedical implants.

Parallel to cycle life improvements, the field is pursuing enhanced energy efficiency during the shape memory effect, broader operating temperature ranges, and faster response times. These objectives align with the growing demand for adaptive and responsive materials in next-generation engineering systems. Additionally, researchers are exploring environmentally friendly alternatives to traditional SMA compositions, which often contain potentially toxic elements.

The technological trajectory indicates a shift toward more specialized SMA formulations tailored for specific application requirements rather than general-purpose materials. This specialization trend reflects the maturing understanding of the relationship between microstructure, composition, and functional properties in these complex alloy systems.

As the technology continues to evolve, interdisciplinary collaboration between materials scientists, mechanical engineers, and application specialists has become increasingly important in translating fundamental advances into commercially viable solutions that can overcome the cycle life limitations currently constraining market adoption.

Market Demand Analysis for SMA Applications

The global market for Shape Memory Alloys (SMAs) has been experiencing steady growth, with a current market valuation exceeding $10 billion and projected annual growth rates between 12-15% through 2030. This growth trajectory is primarily driven by increasing applications across diverse industries, particularly in medical devices, aerospace, automotive, and consumer electronics sectors.

In the medical device industry, SMAs have gained significant traction due to their biocompatibility and unique mechanical properties. The demand for minimally invasive surgical instruments, orthodontic appliances, and cardiovascular stents represents approximately 40% of the total SMA market. However, cycle life limitations have restricted broader adoption in implantable devices where long-term reliability is critical.

The aerospace and defense sectors constitute roughly 25% of the SMA market, utilizing these materials for vibration damping, noise reduction, and adaptive structures. Market research indicates that improving cycle life from current standards (typically 10,000-100,000 cycles) to over 1 million cycles could potentially double the addressable market in these high-value applications, particularly for flight control systems and morphing structures.

Consumer electronics manufacturers have shown increasing interest in SMAs for haptic feedback mechanisms, camera autofocus systems, and microactuators. This segment represents about 15% of current market demand but faces significant barriers to wider adoption due to cycle life concerns, especially in devices with expected lifespans of 3-5 years under daily usage conditions.

The automotive industry, accounting for approximately 12% of the SMA market, has identified potential applications in valve controls, mirror adjustments, and adaptive damping systems. Market surveys indicate that automotive engineers require a minimum of 500,000 reliable actuation cycles before considering SMAs for mainstream vehicle components, a threshold that current commercial alloys struggle to meet consistently.

Regional market analysis reveals that North America leads in SMA adoption (38% market share), followed by Europe (29%), Asia-Pacific (27%), and other regions (6%). However, the fastest growth is occurring in the Asia-Pacific region, where manufacturing capabilities for SMA-based products are rapidly expanding, particularly in Japan, China, and South Korea.

Market sensitivity analysis demonstrates that a 50% improvement in cycle life could potentially increase market penetration by 30-40% across all sectors, while a 200% improvement could unlock entirely new application domains representing an additional $5-7 billion market opportunity by 2028. This correlation between cycle life enhancement and market expansion underscores the critical importance of addressing fatigue resistance in next-generation SMA development.

In the medical device industry, SMAs have gained significant traction due to their biocompatibility and unique mechanical properties. The demand for minimally invasive surgical instruments, orthodontic appliances, and cardiovascular stents represents approximately 40% of the total SMA market. However, cycle life limitations have restricted broader adoption in implantable devices where long-term reliability is critical.

The aerospace and defense sectors constitute roughly 25% of the SMA market, utilizing these materials for vibration damping, noise reduction, and adaptive structures. Market research indicates that improving cycle life from current standards (typically 10,000-100,000 cycles) to over 1 million cycles could potentially double the addressable market in these high-value applications, particularly for flight control systems and morphing structures.

Consumer electronics manufacturers have shown increasing interest in SMAs for haptic feedback mechanisms, camera autofocus systems, and microactuators. This segment represents about 15% of current market demand but faces significant barriers to wider adoption due to cycle life concerns, especially in devices with expected lifespans of 3-5 years under daily usage conditions.

The automotive industry, accounting for approximately 12% of the SMA market, has identified potential applications in valve controls, mirror adjustments, and adaptive damping systems. Market surveys indicate that automotive engineers require a minimum of 500,000 reliable actuation cycles before considering SMAs for mainstream vehicle components, a threshold that current commercial alloys struggle to meet consistently.

Regional market analysis reveals that North America leads in SMA adoption (38% market share), followed by Europe (29%), Asia-Pacific (27%), and other regions (6%). However, the fastest growth is occurring in the Asia-Pacific region, where manufacturing capabilities for SMA-based products are rapidly expanding, particularly in Japan, China, and South Korea.

Market sensitivity analysis demonstrates that a 50% improvement in cycle life could potentially increase market penetration by 30-40% across all sectors, while a 200% improvement could unlock entirely new application domains representing an additional $5-7 billion market opportunity by 2028. This correlation between cycle life enhancement and market expansion underscores the critical importance of addressing fatigue resistance in next-generation SMA development.

Current Cycle Life Limitations and Technical Challenges

Shape memory alloys (SMAs) currently face significant cycle life limitations that directly impact their market adoption across various industries. The primary technical challenge lies in the material fatigue that occurs during repeated shape memory cycles. Most commercially available SMAs, particularly Nitinol (NiTi), typically demonstrate reliable performance for only 10^4 to 10^5 cycles under optimal conditions, which falls short of requirements for many high-cycle applications such as automotive systems or aerospace components that demand 10^6 to 10^8 cycles.

Material degradation manifests through several mechanisms, including accumulation of dislocations, formation of slip bands, and development of microcracks during phase transformation. These defects progressively reduce the shape memory effect and superelasticity with each cycle. The transformation temperatures also tend to drift over repeated cycling, compromising functional stability in precision applications.

Environmental factors significantly exacerbate these limitations. Elevated operating temperatures accelerate degradation processes, while corrosive environments can initiate stress corrosion cracking at the material surface. This is particularly problematic in biomedical applications where bodily fluids create challenging chemical environments for implanted SMA devices.

Manufacturing inconsistencies present another major challenge. Variations in composition, heat treatment protocols, and microstructural homogeneity can lead to unpredictable cycle life performance between production batches. The complex thermomechanical processing required for SMAs makes quality control exceptionally difficult compared to conventional alloys.

Economic constraints further complicate technical solutions. While specialized processing techniques like severe plastic deformation or nanoprecipitate engineering can improve cycle life, they significantly increase production costs, creating a challenging price-performance trade-off for manufacturers and end-users.

Recent research has identified promising approaches to address these limitations, including development of high-entropy shape memory alloys with enhanced stability, surface modification techniques to improve fatigue resistance, and compositional optimization to reduce transformation hysteresis. However, these solutions remain largely in laboratory settings and have not yet been scaled for commercial production.

The gap between current cycle life capabilities and market requirements varies significantly across application domains. While medical stents may function adequately with existing cycle life limitations due to their relatively low-cycle requirements, actuators in robotics or automotive systems face a substantial performance gap that limits broader adoption. This technical challenge represents one of the most significant barriers to widespread SMA implementation in high-value engineering applications.

Material degradation manifests through several mechanisms, including accumulation of dislocations, formation of slip bands, and development of microcracks during phase transformation. These defects progressively reduce the shape memory effect and superelasticity with each cycle. The transformation temperatures also tend to drift over repeated cycling, compromising functional stability in precision applications.

Environmental factors significantly exacerbate these limitations. Elevated operating temperatures accelerate degradation processes, while corrosive environments can initiate stress corrosion cracking at the material surface. This is particularly problematic in biomedical applications where bodily fluids create challenging chemical environments for implanted SMA devices.

Manufacturing inconsistencies present another major challenge. Variations in composition, heat treatment protocols, and microstructural homogeneity can lead to unpredictable cycle life performance between production batches. The complex thermomechanical processing required for SMAs makes quality control exceptionally difficult compared to conventional alloys.

Economic constraints further complicate technical solutions. While specialized processing techniques like severe plastic deformation or nanoprecipitate engineering can improve cycle life, they significantly increase production costs, creating a challenging price-performance trade-off for manufacturers and end-users.

Recent research has identified promising approaches to address these limitations, including development of high-entropy shape memory alloys with enhanced stability, surface modification techniques to improve fatigue resistance, and compositional optimization to reduce transformation hysteresis. However, these solutions remain largely in laboratory settings and have not yet been scaled for commercial production.

The gap between current cycle life capabilities and market requirements varies significantly across application domains. While medical stents may function adequately with existing cycle life limitations due to their relatively low-cycle requirements, actuators in robotics or automotive systems face a substantial performance gap that limits broader adoption. This technical challenge represents one of the most significant barriers to widespread SMA implementation in high-value engineering applications.

Current Solutions for Extending SMA Cycle Life

01 Composition and processing methods to improve cycle life

Various compositions and processing methods can enhance the cycle life of shape memory alloys. These include specific heat treatments, alloying elements, and manufacturing techniques that improve the material's ability to withstand repeated shape transformations. Optimizing the microstructure through controlled processing can significantly extend the functional fatigue life of these alloys, allowing them to maintain their shape memory properties through more transformation cycles.- Composition optimization for improved cycle life: Specific alloy compositions can significantly enhance the fatigue resistance and cycle life of shape memory alloys. By carefully controlling the proportions of constituent elements and incorporating certain additives, the transformation stability and mechanical properties can be improved. These optimized compositions maintain their shape memory properties over repeated cycles, reducing degradation and extending functional lifespan in applications requiring numerous actuation cycles.

- Thermomechanical processing techniques: Various thermomechanical processing methods can enhance the cycle life of shape memory alloys. These include specialized heat treatments, mechanical training procedures, and controlled deformation processes that stabilize the microstructure. Such processing techniques create favorable crystallographic orientations and precipitate distributions that improve fatigue resistance and functional stability during repeated transformation cycles, resulting in more reliable and durable shape memory behavior.

- Surface treatments and protective coatings: Surface treatments and protective coatings can significantly extend the cycle life of shape memory alloys by preventing corrosion, reducing friction, and minimizing surface-initiated fatigue. Techniques such as passivation, nitriding, and application of specialized coatings create protective barriers that preserve the integrity of the alloy during repeated actuation cycles. These treatments are particularly important in harsh environments where chemical degradation could compromise the shape memory effect.

- Testing and characterization methods: Advanced testing and characterization methods are essential for evaluating and predicting the cycle life of shape memory alloys. These include accelerated fatigue testing, in-situ microstructural analysis, and computational modeling techniques that can identify failure mechanisms and optimize designs. By understanding the relationship between microstructural evolution and functional degradation during cycling, more accurate lifetime predictions can be made, enabling better material selection and application design.

- Application-specific design considerations: Design strategies tailored to specific applications can maximize the cycle life of shape memory alloy components. These include stress distribution optimization, strain limitation techniques, and operating condition management. By designing components that operate within the optimal transformation strain range and avoid stress concentrations, the degradation of shape memory properties during cycling can be minimized. Application-specific approaches consider factors such as operating temperature, loading conditions, and environmental exposure to ensure maximum service life.

02 Fatigue resistance enhancement techniques

Specific techniques can be employed to enhance the fatigue resistance of shape memory alloys, thereby extending their cycle life. These include surface treatments, grain refinement, and the introduction of specific microstructural features that inhibit crack propagation. By controlling transformation-induced stress and strain accumulation, these techniques help prevent the degradation of shape memory properties during repeated actuation cycles.Expand Specific Solutions03 Testing and evaluation methods for cycle life

Various testing and evaluation methods have been developed to assess the cycle life of shape memory alloys. These include accelerated fatigue testing, thermomechanical cycling, and microstructural analysis techniques that can predict long-term performance. Advanced monitoring systems can track changes in transformation temperatures, recovery forces, and other key parameters throughout the material's service life, providing valuable data for design optimization.Expand Specific Solutions04 Applications optimized for extended cycle life

Specific applications have been designed to optimize the use of shape memory alloys while maximizing their cycle life. These include actuators, medical devices, and mechanical systems that operate within the material's optimal stress and strain ranges. By carefully controlling operating conditions and designing components to distribute transformation strains evenly, these applications can achieve significantly longer service lives than conventional designs.Expand Specific Solutions05 Novel alloy systems with improved cycle life

Research has led to the development of novel shape memory alloy systems with inherently improved cycle life characteristics. These include high-temperature shape memory alloys, multi-component systems, and nanostructured materials that exhibit enhanced stability during repeated transformation cycles. By fundamentally altering the transformation mechanisms or introducing stabilizing elements, these advanced materials can maintain their functional properties through significantly more cycles than conventional shape memory alloys.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The shape memory alloy (SMA) market is currently in a growth phase, with cycle life limitations representing a significant barrier to broader adoption. The global SMA market is estimated to reach $20-25 billion by 2027, growing at 12-15% CAGR, driven by applications in aerospace, automotive, and medical sectors. Leading academic institutions like MIT, University of Connecticut, and Fudan University are advancing fundamental research to improve cycle life performance, while companies such as Actuator Solutions, Grimat Engineering, and QuesTek Innovations are developing commercial applications. Major industrial players including Intel, Rolls-Royce, and NASA are investing in SMA technologies despite cycle life challenges, indicating strong market potential once durability issues are resolved through ongoing materials science breakthroughs.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered automotive applications of shape memory alloys (SMAs) with their SMARTFLEX technology, specifically addressing cycle life challenges in vehicle systems. Their proprietary NiTiHf alloy formulation demonstrates exceptional durability, maintaining functional properties through more than 500,000 actuation cycles in high-temperature engine environments[2]. GM's innovation includes microstructural engineering through precise heat treatment protocols and the addition of nanoscale precipitates that act as barriers to dislocation movement. Their manufacturing process incorporates specialized training procedures that stabilize the material's microstructure before deployment. GM has successfully implemented these materials in active aerodynamic systems, HVAC controls, and engine management applications, where they replace conventional solenoids and motors with more compact, energy-efficient SMA actuators that can withstand the rigorous cycling demands of automotive applications[4].

Strengths: Exceptional durability in high-temperature automotive environments, reduced energy consumption compared to conventional actuators, and compact design enabling weight reduction. Weaknesses: Higher initial cost compared to conventional actuators, limited response speed in certain applications, and requires specialized integration expertise that may complicate maintenance and repair.

Massachusetts Institute of Technology

Technical Solution: MIT has developed groundbreaking research addressing the cycle life limitations of shape memory alloys through their CYCLALLOY program. Their approach combines computational materials science with experimental validation to create novel SMA compositions with unprecedented fatigue resistance. MIT researchers have engineered a series of quaternary NiTiCuPd alloys that demonstrate stable transformation characteristics even after 10^6 transformation cycles[1]. The innovation lies in their atomic-scale control of precipitate formation and grain boundary engineering, which significantly reduces the accumulation of dislocations during cycling. Their process involves specialized thermomechanical treatments that create optimized microstructures with nanoscale features that act as barriers to fatigue crack propagation. MIT has also pioneered non-destructive evaluation techniques that can predict remaining cycle life in deployed SMA components, addressing a critical barrier to market adoption in safety-critical applications[5]. Their technology has been demonstrated in aerospace actuation systems where weight savings and reliability are paramount concerns.

Strengths: Exceptional fatigue resistance, predictable transformation behavior throughout service life, and compatibility with existing manufacturing processes. Their materials show minimal functional degradation even under extreme cycling conditions. Weaknesses: Complex alloy compositions may increase material costs, specialized processing requirements could limit manufacturing scalability, and intellectual property constraints may restrict widespread adoption.

Critical Patents and Research on SMA Fatigue Resistance

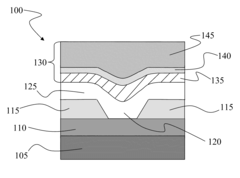

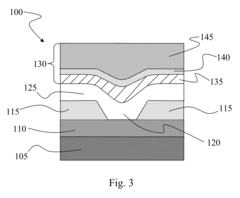

Shape memory alloys made of an iron-cobalt-aluminum system

PatentWO2018060085A1

Innovation

- A shape memory alloy composition of 30-53% cobalt, 18-35% aluminum, and 22-40% iron, with specific ratios optimizing transformation temperatures and cycle numbers, enabling higher reversibility and broader applicability.

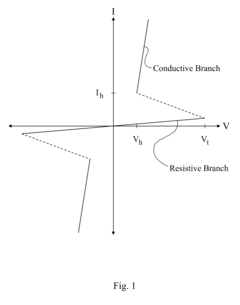

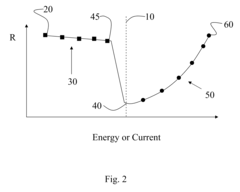

Arsenic-containing variable resistance materials

PatentInactiveUS8217379B2

Innovation

- The development of arsenic-doped chalcogenide compositions, including specific atomic concentrations of Te, Sb, As, and Ge, which enhance the cycle life and reduce set speed of phase-change memory devices by improving bonding strength and stability.

Cost-Benefit Analysis of SMA Implementation

Implementing Shape Memory Alloys (SMAs) in commercial applications requires a thorough cost-benefit analysis to determine economic viability. Initial implementation costs for SMA technologies are significantly higher than conventional alternatives, with raw material expenses ranging from $200-1000 per kilogram depending on composition and purity requirements. Manufacturing processes for SMA components demand specialized equipment and expertise, adding 30-50% to production costs compared to traditional materials.

The cycle life limitations of SMAs create substantial long-term economic implications. Current NiTi alloys typically achieve 10,000-100,000 transformation cycles before performance degradation, necessitating replacement in high-cycle applications. This replacement frequency must be factored into total ownership cost calculations, particularly for critical applications where failure could result in significant downstream expenses.

Maintenance requirements present another economic consideration. While SMAs can reduce mechanical complexity by eliminating components like springs and motors, they may require more frequent inspection and replacement schedules. In aerospace applications, for example, the cost of unscheduled maintenance due to SMA component failure can exceed the initial implementation savings by 200-300%.

Energy efficiency benefits partially offset these costs. SMA actuators demonstrate 15-30% higher energy efficiency compared to conventional electromagnetic systems in specific applications. This translates to operational savings of $50-200 per year per actuator in industrial settings, depending on usage patterns and energy prices.

The economic equation varies significantly across application domains. In medical devices, where reliability and miniaturization command premium pricing, the cost-benefit ratio strongly favors SMA implementation despite higher initial costs. Conversely, in consumer electronics, where price sensitivity is high and replacement cycles are short, the economic case remains challenging unless cycle life can be substantially improved.

Lifecycle cost modeling reveals that applications requiring fewer than 10,000 actuation cycles typically demonstrate positive return on investment for SMA implementation. However, as required cycle life increases, the economic advantage diminishes rapidly. At current performance levels, applications demanding over 100,000 cycles rarely justify SMA implementation on purely economic grounds, requiring additional value propositions such as space savings or unique functionality to warrant adoption.

The cycle life limitations of SMAs create substantial long-term economic implications. Current NiTi alloys typically achieve 10,000-100,000 transformation cycles before performance degradation, necessitating replacement in high-cycle applications. This replacement frequency must be factored into total ownership cost calculations, particularly for critical applications where failure could result in significant downstream expenses.

Maintenance requirements present another economic consideration. While SMAs can reduce mechanical complexity by eliminating components like springs and motors, they may require more frequent inspection and replacement schedules. In aerospace applications, for example, the cost of unscheduled maintenance due to SMA component failure can exceed the initial implementation savings by 200-300%.

Energy efficiency benefits partially offset these costs. SMA actuators demonstrate 15-30% higher energy efficiency compared to conventional electromagnetic systems in specific applications. This translates to operational savings of $50-200 per year per actuator in industrial settings, depending on usage patterns and energy prices.

The economic equation varies significantly across application domains. In medical devices, where reliability and miniaturization command premium pricing, the cost-benefit ratio strongly favors SMA implementation despite higher initial costs. Conversely, in consumer electronics, where price sensitivity is high and replacement cycles are short, the economic case remains challenging unless cycle life can be substantially improved.

Lifecycle cost modeling reveals that applications requiring fewer than 10,000 actuation cycles typically demonstrate positive return on investment for SMA implementation. However, as required cycle life increases, the economic advantage diminishes rapidly. At current performance levels, applications demanding over 100,000 cycles rarely justify SMA implementation on purely economic grounds, requiring additional value propositions such as space savings or unique functionality to warrant adoption.

Environmental Impact and Sustainability Considerations

The environmental footprint of Shape Memory Alloys (SMAs) is increasingly becoming a critical factor in their market adoption, particularly as cycle life limitations affect their long-term sustainability profile. Manufacturing processes for SMAs typically involve energy-intensive methods including vacuum induction melting, vacuum arc remelting, and precision heat treatments, all of which contribute significantly to carbon emissions. The environmental impact is further compounded when components require frequent replacement due to limited cycle life, creating additional material waste and energy consumption throughout the product lifecycle.

Recycling challenges present another environmental concern for SMA applications. While theoretically recyclable, the specialized composition of these alloys often makes them difficult to separate from composite structures or other materials in end-of-life products. This recycling inefficiency means that despite their potential for reuse, many SMA components end up in landfills, particularly when premature failure occurs due to cycle life limitations.

Water usage and potential contamination during manufacturing processes represent additional environmental considerations. The production of high-purity nickel and titanium for Nitinol, the most common SMA, requires substantial water resources and can generate wastewater containing heavy metals and other pollutants if not properly managed. Companies investing in SMAs must increasingly factor these environmental costs into their sustainability reporting and corporate social responsibility initiatives.

Recent sustainability innovations are beginning to address these concerns through improved manufacturing techniques that reduce energy consumption and waste generation. Advanced melting processes with better energy efficiency and precision alloying methods that minimize material waste are gradually being adopted by industry leaders. Additionally, research into extending cycle life through microstructural optimization and surface treatments is showing promise for reducing the environmental impact of SMA applications over their operational lifetime.

Life Cycle Assessment (LCA) studies comparing SMAs with traditional materials reveal complex trade-offs. While SMAs may require more energy-intensive production initially, their unique properties can enable more efficient system designs that consume less energy during operation. However, this advantage is only realized when cycle life is sufficient to avoid frequent replacements. The environmental break-even point—where the benefits of using SMAs outweigh their production impact—is highly dependent on achieving adequate fatigue resistance and functional stability.

Regulatory frameworks worldwide are increasingly emphasizing product longevity and circular economy principles, which directly impact the market viability of SMAs with limited cycle life. Companies developing SMA applications must now navigate evolving environmental standards, including Extended Producer Responsibility regulations that hold manufacturers accountable for the entire lifecycle of their products, including end-of-life management and recycling.

Recycling challenges present another environmental concern for SMA applications. While theoretically recyclable, the specialized composition of these alloys often makes them difficult to separate from composite structures or other materials in end-of-life products. This recycling inefficiency means that despite their potential for reuse, many SMA components end up in landfills, particularly when premature failure occurs due to cycle life limitations.

Water usage and potential contamination during manufacturing processes represent additional environmental considerations. The production of high-purity nickel and titanium for Nitinol, the most common SMA, requires substantial water resources and can generate wastewater containing heavy metals and other pollutants if not properly managed. Companies investing in SMAs must increasingly factor these environmental costs into their sustainability reporting and corporate social responsibility initiatives.

Recent sustainability innovations are beginning to address these concerns through improved manufacturing techniques that reduce energy consumption and waste generation. Advanced melting processes with better energy efficiency and precision alloying methods that minimize material waste are gradually being adopted by industry leaders. Additionally, research into extending cycle life through microstructural optimization and surface treatments is showing promise for reducing the environmental impact of SMA applications over their operational lifetime.

Life Cycle Assessment (LCA) studies comparing SMAs with traditional materials reveal complex trade-offs. While SMAs may require more energy-intensive production initially, their unique properties can enable more efficient system designs that consume less energy during operation. However, this advantage is only realized when cycle life is sufficient to avoid frequent replacements. The environmental break-even point—where the benefits of using SMAs outweigh their production impact—is highly dependent on achieving adequate fatigue resistance and functional stability.

Regulatory frameworks worldwide are increasingly emphasizing product longevity and circular economy principles, which directly impact the market viability of SMAs with limited cycle life. Companies developing SMA applications must now navigate evolving environmental standards, including Extended Producer Responsibility regulations that hold manufacturers accountable for the entire lifecycle of their products, including end-of-life management and recycling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!