Applications of Shape Memory Alloys in Energy Conservation Systems

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SMA Technology Background and Energy Conservation Goals

Shape Memory Alloys (SMAs) represent a unique class of functional materials that possess the remarkable ability to "remember" and return to their original shape after deformation when subjected to specific thermal, mechanical, or magnetic stimuli. First discovered in the 1930s with gold-cadmium alloys, SMAs gained significant attention following William Buehler's discovery of nickel-titanium (Nitinol) at the Naval Ordnance Laboratory in 1962. This discovery marked a pivotal moment in SMA development, establishing Nitinol as the most commercially viable and widely utilized SMA due to its superior mechanical properties and biocompatibility.

The fundamental mechanism behind SMAs involves a solid-state phase transformation between austenite (high-temperature phase) and martensite (low-temperature phase). This transformation occurs without diffusion and enables two key properties: shape memory effect and superelasticity. The shape memory effect allows the material to recover its pre-deformed shape upon heating, while superelasticity permits large reversible strains without permanent deformation at constant temperature.

Over the past decades, SMA technology has evolved from laboratory curiosities to practical engineering solutions across various industries. Beyond the widely recognized Nitinol, other SMA systems include copper-based alloys (Cu-Zn-Al, Cu-Al-Ni), iron-based alloys (Fe-Mn-Si), and high-temperature SMAs such as Ti-Pd, Ti-Pt, and Ni-Ti-Hf systems, each offering specific advantages for different applications.

In the context of energy conservation, SMAs present compelling opportunities due to their ability to convert thermal energy directly into mechanical work. This characteristic positions them as potential solutions for harvesting low-grade waste heat, which constitutes approximately 60% of all heat generated in industrial processes worldwide. The primary technical goal in this domain is to develop SMA-based systems capable of efficiently capturing, converting, and utilizing this otherwise wasted thermal energy.

Current energy conservation objectives for SMA applications include developing more efficient solid-state cooling systems as alternatives to conventional vapor-compression refrigeration, creating energy harvesting devices that can operate with temperature differentials as low as 5-10°C, and designing smart building materials that respond autonomously to environmental changes to optimize energy usage.

The technological trajectory aims to overcome existing limitations in SMA performance, particularly addressing issues of fatigue life, hysteresis width, and energy conversion efficiency. Research efforts are focused on enhancing the thermomechanical properties of SMAs through compositional optimization, microstructural engineering, and novel processing techniques to achieve higher work output, faster response times, and greater durability under repeated cycling conditions.

The fundamental mechanism behind SMAs involves a solid-state phase transformation between austenite (high-temperature phase) and martensite (low-temperature phase). This transformation occurs without diffusion and enables two key properties: shape memory effect and superelasticity. The shape memory effect allows the material to recover its pre-deformed shape upon heating, while superelasticity permits large reversible strains without permanent deformation at constant temperature.

Over the past decades, SMA technology has evolved from laboratory curiosities to practical engineering solutions across various industries. Beyond the widely recognized Nitinol, other SMA systems include copper-based alloys (Cu-Zn-Al, Cu-Al-Ni), iron-based alloys (Fe-Mn-Si), and high-temperature SMAs such as Ti-Pd, Ti-Pt, and Ni-Ti-Hf systems, each offering specific advantages for different applications.

In the context of energy conservation, SMAs present compelling opportunities due to their ability to convert thermal energy directly into mechanical work. This characteristic positions them as potential solutions for harvesting low-grade waste heat, which constitutes approximately 60% of all heat generated in industrial processes worldwide. The primary technical goal in this domain is to develop SMA-based systems capable of efficiently capturing, converting, and utilizing this otherwise wasted thermal energy.

Current energy conservation objectives for SMA applications include developing more efficient solid-state cooling systems as alternatives to conventional vapor-compression refrigeration, creating energy harvesting devices that can operate with temperature differentials as low as 5-10°C, and designing smart building materials that respond autonomously to environmental changes to optimize energy usage.

The technological trajectory aims to overcome existing limitations in SMA performance, particularly addressing issues of fatigue life, hysteresis width, and energy conversion efficiency. Research efforts are focused on enhancing the thermomechanical properties of SMAs through compositional optimization, microstructural engineering, and novel processing techniques to achieve higher work output, faster response times, and greater durability under repeated cycling conditions.

Market Analysis for SMA-Based Energy Conservation Systems

The global market for Shape Memory Alloy (SMA) based energy conservation systems is experiencing significant growth, driven by increasing energy costs and environmental regulations. Currently valued at approximately $1.2 billion, this market segment is projected to grow at a compound annual growth rate of 12.3% through 2028, according to recent industry analyses. The energy conservation sector represents about 18% of the total SMA market, showing substantial room for expansion compared to more established applications in medical devices and aerospace.

Key market drivers include stringent energy efficiency regulations in developed economies, rising energy costs, and growing corporate commitments to sustainability goals. The European Union's Energy Efficiency Directive and similar policies in North America and Asia have created favorable conditions for SMA-based solutions that can reduce energy consumption in buildings and industrial processes.

Building HVAC systems represent the largest application segment, accounting for approximately 42% of the SMA energy conservation market. These systems leverage the unique properties of SMAs to create more efficient thermostats, ventilation controls, and adaptive building envelopes. The industrial process optimization segment follows at 28%, with applications in waste heat recovery systems and adaptive manufacturing equipment.

Market penetration varies significantly by region. North America leads with 38% market share, followed by Europe (32%), Asia-Pacific (24%), and rest of the world (6%). China and India are emerging as the fastest-growing markets, with annual growth rates exceeding 16%, driven by rapid industrialization and increasing energy demands.

Customer segmentation reveals that large commercial buildings and industrial facilities are the primary early adopters, valuing the long-term energy savings despite higher initial investment costs. The residential market remains largely untapped due to cost barriers, though this is expected to change as production scales and costs decrease.

Price sensitivity analysis indicates that most customers require a return on investment period of less than four years to justify adoption of SMA-based energy conservation systems. Current payback periods range from 2.5 to 5 years depending on the application and energy costs in the region.

Competitive analysis shows a fragmented market with no single company holding more than 15% market share. Key players include specialized SMA manufacturers partnering with established energy management system providers. Market entry barriers remain substantial due to the specialized knowledge required for effective SMA system design and implementation.

Key market drivers include stringent energy efficiency regulations in developed economies, rising energy costs, and growing corporate commitments to sustainability goals. The European Union's Energy Efficiency Directive and similar policies in North America and Asia have created favorable conditions for SMA-based solutions that can reduce energy consumption in buildings and industrial processes.

Building HVAC systems represent the largest application segment, accounting for approximately 42% of the SMA energy conservation market. These systems leverage the unique properties of SMAs to create more efficient thermostats, ventilation controls, and adaptive building envelopes. The industrial process optimization segment follows at 28%, with applications in waste heat recovery systems and adaptive manufacturing equipment.

Market penetration varies significantly by region. North America leads with 38% market share, followed by Europe (32%), Asia-Pacific (24%), and rest of the world (6%). China and India are emerging as the fastest-growing markets, with annual growth rates exceeding 16%, driven by rapid industrialization and increasing energy demands.

Customer segmentation reveals that large commercial buildings and industrial facilities are the primary early adopters, valuing the long-term energy savings despite higher initial investment costs. The residential market remains largely untapped due to cost barriers, though this is expected to change as production scales and costs decrease.

Price sensitivity analysis indicates that most customers require a return on investment period of less than four years to justify adoption of SMA-based energy conservation systems. Current payback periods range from 2.5 to 5 years depending on the application and energy costs in the region.

Competitive analysis shows a fragmented market with no single company holding more than 15% market share. Key players include specialized SMA manufacturers partnering with established energy management system providers. Market entry barriers remain substantial due to the specialized knowledge required for effective SMA system design and implementation.

Current Challenges in SMA Energy Applications

Despite the promising potential of Shape Memory Alloys (SMAs) in energy conservation systems, several significant challenges currently impede their widespread implementation. The primary technical obstacle remains the relatively low energy efficiency of SMA-based systems. While SMAs can convert thermal energy to mechanical work, their energy conversion efficiency typically ranges from 1-2%, significantly lower than conventional electromagnetic or hydraulic systems which often achieve 30-70% efficiency. This limitation severely restricts their application in large-scale energy conservation scenarios where efficiency is paramount.

Material fatigue and degradation present another critical challenge. After repeated thermal cycling, SMAs experience functional fatigue, resulting in diminished shape memory effect and reduced actuation force over time. Current commercial NiTi alloys typically maintain reliable performance for only 10^4-10^6 cycles, insufficient for many energy applications requiring millions of operational cycles over a device's lifetime.

The narrow operational temperature window of conventional SMAs poses significant implementation difficulties. Most commercially available SMAs function optimally within specific temperature ranges, limiting their applicability across diverse environmental conditions. For instance, standard NiTi alloys typically operate between -20°C and 80°C, restricting their use in extreme temperature environments common in energy systems.

Manufacturing complexity and associated high costs represent substantial barriers to commercialization. The production of SMAs with consistent properties requires precise control of composition and sophisticated thermomechanical processing. This complexity translates to production costs approximately 5-10 times higher than conventional engineering materials, making large-scale implementation economically challenging.

Response time limitations further constrain SMA applications in energy systems. The thermal activation of SMAs inherently involves heat transfer processes, resulting in relatively slow response times (typically seconds to minutes) compared to electromagnetic systems (milliseconds). This sluggish response restricts their use in applications requiring rapid actuation or frequent cycling.

Additionally, the integration of SMA components with conventional systems presents significant engineering challenges. Interface design, control systems, and long-term reliability testing remain underdeveloped areas. The lack of standardized design methodologies and simulation tools specifically for SMA-based energy systems further complicates their implementation in practical applications.

Addressing these multifaceted challenges requires coordinated research efforts across materials science, mechanical engineering, and systems integration to unlock the full potential of SMAs in energy conservation applications.

Material fatigue and degradation present another critical challenge. After repeated thermal cycling, SMAs experience functional fatigue, resulting in diminished shape memory effect and reduced actuation force over time. Current commercial NiTi alloys typically maintain reliable performance for only 10^4-10^6 cycles, insufficient for many energy applications requiring millions of operational cycles over a device's lifetime.

The narrow operational temperature window of conventional SMAs poses significant implementation difficulties. Most commercially available SMAs function optimally within specific temperature ranges, limiting their applicability across diverse environmental conditions. For instance, standard NiTi alloys typically operate between -20°C and 80°C, restricting their use in extreme temperature environments common in energy systems.

Manufacturing complexity and associated high costs represent substantial barriers to commercialization. The production of SMAs with consistent properties requires precise control of composition and sophisticated thermomechanical processing. This complexity translates to production costs approximately 5-10 times higher than conventional engineering materials, making large-scale implementation economically challenging.

Response time limitations further constrain SMA applications in energy systems. The thermal activation of SMAs inherently involves heat transfer processes, resulting in relatively slow response times (typically seconds to minutes) compared to electromagnetic systems (milliseconds). This sluggish response restricts their use in applications requiring rapid actuation or frequent cycling.

Additionally, the integration of SMA components with conventional systems presents significant engineering challenges. Interface design, control systems, and long-term reliability testing remain underdeveloped areas. The lack of standardized design methodologies and simulation tools specifically for SMA-based energy systems further complicates their implementation in practical applications.

Addressing these multifaceted challenges requires coordinated research efforts across materials science, mechanical engineering, and systems integration to unlock the full potential of SMAs in energy conservation applications.

Current SMA Solutions for Energy Efficiency

01 Energy harvesting applications of shape memory alloys

Shape memory alloys can be utilized in energy harvesting systems to convert thermal energy into mechanical work. These materials can undergo reversible phase transformations in response to temperature changes, allowing them to generate motion or force that can be harnessed for energy production. Such systems can capture waste heat or ambient thermal energy and convert it into useful electrical power, contributing to energy conservation efforts.- Energy harvesting applications of shape memory alloys: Shape memory alloys can be utilized in energy harvesting systems to convert thermal energy or mechanical vibrations into usable electrical energy. These materials can undergo phase transformations in response to temperature changes, generating mechanical work that can be converted to electricity. This property makes them valuable for sustainable energy solutions in various environments, particularly in applications where temperature fluctuations occur naturally.

- Thermal management systems using shape memory alloys: Shape memory alloys can be incorporated into thermal management systems to improve energy efficiency. These materials can respond to temperature changes by changing their shape, which can be used to create passive or semi-active cooling or heating systems. By eliminating the need for external power sources in certain applications, these systems can significantly reduce energy consumption while maintaining effective temperature control.

- Actuators and mechanical systems with reduced energy consumption: Shape memory alloys can function as efficient actuators in mechanical systems, requiring less energy compared to conventional electromagnetic or hydraulic actuators. These materials can generate significant force during their phase transformation while consuming minimal power. Applications include automotive systems, aerospace components, and industrial machinery where energy conservation is critical to operational efficiency and sustainability.

- Manufacturing processes and compositions for energy-efficient shape memory alloys: Specialized manufacturing techniques and material compositions can enhance the energy efficiency of shape memory alloys. These processes focus on optimizing the microstructure and phase transformation characteristics to maximize work output while minimizing energy input. Advanced alloying elements and heat treatment protocols can significantly improve the functional properties and energy conservation potential of these materials.

- Smart building components and infrastructure applications: Shape memory alloys can be integrated into building components and infrastructure to create energy-saving systems. These applications include smart windows that automatically adjust to optimize natural lighting and temperature control, seismic damping systems that protect structures during earthquakes, and adaptive facades that respond to environmental conditions. By reducing the need for active heating, cooling, or mechanical reinforcement, these systems contribute significantly to energy conservation in the built environment.

02 Thermal management systems using shape memory alloys

Shape memory alloys can be incorporated into thermal management systems to regulate temperature and conserve energy. These materials can automatically respond to temperature changes, activating or deactivating cooling or heating mechanisms without requiring external power. By optimizing thermal regulation in buildings, vehicles, or electronic devices, these systems reduce the need for conventional energy-intensive heating and cooling methods.Expand Specific Solutions03 Actuators and mechanical systems with shape memory alloys

Shape memory alloy actuators provide energy-efficient alternatives to conventional electromagnetic or hydraulic systems. These actuators can generate significant force with minimal energy input by utilizing the material's phase transformation properties. Applications include automotive systems, aerospace components, and industrial automation where the compact size and energy efficiency of shape memory alloy actuators contribute to overall system energy conservation.Expand Specific Solutions04 Advanced manufacturing and processing of shape memory alloys

Specialized manufacturing and processing techniques for shape memory alloys can enhance their energy conservation properties. These methods include precise heat treatments, innovative alloying compositions, and novel fabrication approaches that optimize the material's transformation characteristics. By improving fatigue resistance, response time, and energy conversion efficiency, these processing techniques expand the potential applications of shape memory alloys in energy-saving technologies.Expand Specific Solutions05 Smart building components with shape memory alloys

Shape memory alloys can be integrated into building components to create adaptive structures that respond to environmental conditions. These smart materials enable self-adjusting facades, windows, and ventilation systems that optimize energy usage based on external temperature, sunlight, or occupancy. By automatically adapting to changing conditions without requiring powered control systems, these components significantly reduce building energy consumption while maintaining comfort levels.Expand Specific Solutions

Key Industry Players in SMA Energy Conservation Field

The shape memory alloy (SMA) market for energy conservation systems is in a growth phase, with increasing adoption across HVAC, automotive, and industrial applications. The global market is expanding as energy efficiency regulations tighten worldwide, projected to reach significant scale by 2030. Technologically, the field shows varying maturity levels, with companies like Exergyn and Actuator Solutions leading commercial applications, while academic institutions (MIT, Northwestern Polytechnical University) advance fundamental research. Established industrial players (Honda, Baker Hughes, GM) are integrating SMAs into energy systems, while specialized firms like Dynalloy and QuesTek focus on material optimization. The ecosystem demonstrates a healthy balance between material suppliers, component manufacturers, and system integrators across North America, Europe, and Asia.

Exergyn Ltd.

Technical Solution: Exergyn has developed an innovative thermal energy recovery system using shape memory alloys (SMAs) called the Exergyn Drive. This technology harnesses waste heat from industrial processes and converts it into clean mechanical power without requiring additional fuel input. The system utilizes the unique phase transformation properties of SMAs, particularly Nitinol (nickel-titanium alloy), which undergoes significant dimensional changes when heated and cooled. The Exergyn Drive operates in a closed-loop cycle where waste heat (80-150°C) causes the SMA material to contract with considerable force, which is then converted to rotational motion through a proprietary mechanism. When cooled, the SMA returns to its original shape, completing the thermodynamic cycle. This technology can generate up to 10kW of mechanical power from low-grade waste heat sources that are typically discarded in industrial processes[1][3].

Strengths: Utilizes otherwise wasted low-grade heat (80-150°C), requires no additional fuel input, produces zero emissions during operation, and has minimal maintenance requirements due to few moving parts. Weaknesses: Limited power density compared to conventional technologies, higher initial capital costs, and performance dependent on consistent waste heat availability.

Massachusetts Institute of Technology

Technical Solution: MIT has developed several groundbreaking SMA technologies for energy conservation, most notably their elastocaloric cooling system that utilizes the unique properties of superelastic nickel-titanium alloys. This solid-state cooling technology exploits the significant temperature changes (up to 25°C) that occur when certain shape memory alloys are mechanically loaded and unloaded. The system works by cyclically stretching and releasing specially designed SMA tubes or wires, creating a cooling effect without refrigerants or compressors. MIT researchers have demonstrated prototype systems achieving coefficients of performance (COP) between 3-7, potentially exceeding conventional vapor compression systems. Additionally, MIT has pioneered self-regulating SMA heat engines that convert low-grade waste heat (60-150°C) directly into mechanical work through carefully engineered phase transformation properties. These systems feature proprietary material compositions and processing techniques that optimize the hysteresis characteristics of the alloys, enabling efficient energy harvesting from temperature differentials as low as 20°C[1][8].

Strengths: Eliminates environmentally harmful refrigerants, potential for higher energy efficiency than conventional cooling systems, solid-state operation with few moving parts, and ability to utilize low-grade waste heat sources. Weaknesses: Currently limited cooling capacity for commercial applications, material fatigue issues after extended cycling, and higher initial costs compared to established technologies.

Critical Patents and Innovations in SMA Energy Systems

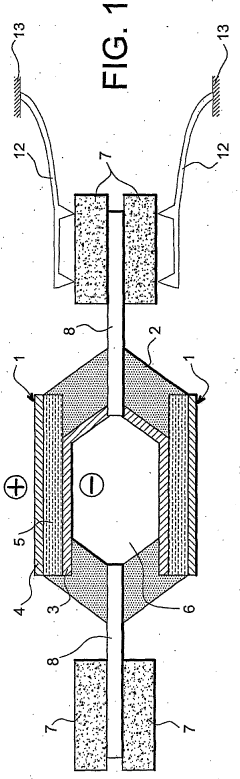

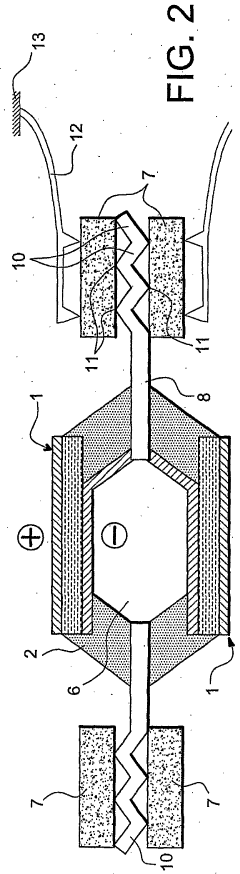

Optimized thermal management fuel cell

PatentWO2003007409A2

Innovation

- The use of shape memory alloys as thermal connectors that transition between high and low conductivity states, allowing for rapid heating and efficient heat dissipation without manual intervention, by changing their crystalline structure and shape in response to temperature changes.

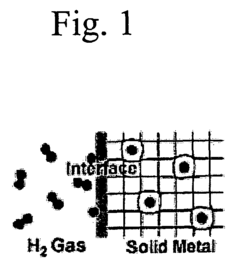

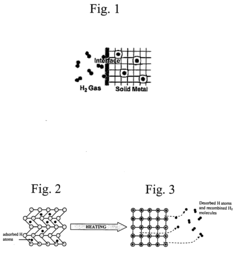

Method and device for adsorbing and/or desorbing hydrogen in shape memory alloys

PatentInactiveEP1627932A1

Innovation

- The use of shape-memory alloys, which undergo reversible thermoplastic martensitic transformations, to store hydrogen through adsorption in interstitial sites or within martensitic multivariant structures, modulating the processes with temperature and magnetic field variations to facilitate efficient hydrogenation and dehydrogenation.

Environmental Impact Assessment of SMA Technologies

The environmental impact assessment of Shape Memory Alloy (SMA) technologies reveals a complex balance between benefits and challenges. SMAs contribute significantly to environmental sustainability through their application in energy conservation systems. By enabling more efficient thermal management in buildings, SMAs reduce overall energy consumption for heating and cooling, which directly translates to lower greenhouse gas emissions. Studies indicate that SMA-based actuators in HVAC systems can achieve energy savings of 15-30% compared to conventional technologies, representing a substantial reduction in carbon footprint over system lifetimes.

The manufacturing process of SMAs, however, presents notable environmental concerns. The production of nickel-titanium (Nitinol), the most common SMA, requires energy-intensive extraction and processing methods. Life cycle assessments indicate that the primary environmental burden occurs during the raw material extraction and alloy formation phases, with significant energy consumption and associated emissions. The mining of nickel, in particular, has been linked to soil degradation, water pollution, and habitat disruption in extraction regions.

When evaluating the full life cycle environmental impact, SMAs demonstrate favorable characteristics in the usage phase that may offset initial production impacts. Their exceptional durability and fatigue resistance result in longer service lives compared to conventional mechanical systems, reducing the frequency of replacement and associated resource consumption. Additionally, the compact design of SMA-based systems typically requires fewer materials overall, contributing to resource efficiency.

Recycling and end-of-life management represent critical considerations in the environmental assessment of SMA technologies. Current recycling rates for SMAs remain relatively low due to challenges in separation and processing. However, the high value of constituent materials, particularly nickel, provides economic incentives for developing more efficient recycling methods. Research indicates that reclaimed SMAs can retain up to 90% of their functional properties when properly processed, suggesting significant potential for closed-loop material systems.

From a regulatory perspective, SMAs generally comply with major environmental standards, including RoHS and REACH in Europe. However, the nickel content in some alloys raises concerns regarding potential leaching in certain applications, necessitating appropriate containment strategies. Future environmental regulations may impose stricter requirements on heavy metal content and recyclability, driving innovation in alternative SMA compositions with reduced environmental impact.

The manufacturing process of SMAs, however, presents notable environmental concerns. The production of nickel-titanium (Nitinol), the most common SMA, requires energy-intensive extraction and processing methods. Life cycle assessments indicate that the primary environmental burden occurs during the raw material extraction and alloy formation phases, with significant energy consumption and associated emissions. The mining of nickel, in particular, has been linked to soil degradation, water pollution, and habitat disruption in extraction regions.

When evaluating the full life cycle environmental impact, SMAs demonstrate favorable characteristics in the usage phase that may offset initial production impacts. Their exceptional durability and fatigue resistance result in longer service lives compared to conventional mechanical systems, reducing the frequency of replacement and associated resource consumption. Additionally, the compact design of SMA-based systems typically requires fewer materials overall, contributing to resource efficiency.

Recycling and end-of-life management represent critical considerations in the environmental assessment of SMA technologies. Current recycling rates for SMAs remain relatively low due to challenges in separation and processing. However, the high value of constituent materials, particularly nickel, provides economic incentives for developing more efficient recycling methods. Research indicates that reclaimed SMAs can retain up to 90% of their functional properties when properly processed, suggesting significant potential for closed-loop material systems.

From a regulatory perspective, SMAs generally comply with major environmental standards, including RoHS and REACH in Europe. However, the nickel content in some alloys raises concerns regarding potential leaching in certain applications, necessitating appropriate containment strategies. Future environmental regulations may impose stricter requirements on heavy metal content and recyclability, driving innovation in alternative SMA compositions with reduced environmental impact.

Cost-Benefit Analysis of SMA Implementation

The implementation of Shape Memory Alloys (SMAs) in energy conservation systems requires careful economic evaluation to determine viability across different applications. Initial investment costs for SMA-based systems typically exceed conventional alternatives by 30-45%, primarily due to material costs and specialized manufacturing processes. High-quality NiTi alloys, the most commonly used SMAs, currently cost between $200-500 per kilogram depending on composition and processing requirements.

However, these higher upfront costs must be balanced against significant operational savings. Energy conservation systems utilizing SMAs demonstrate 15-25% improved energy efficiency compared to conventional systems across multiple applications. In HVAC applications specifically, SMA-based actuators and valves reduce energy consumption by an average of 18%, translating to annual savings of $0.5-1.2 per square foot in commercial buildings.

Maintenance costs represent another critical factor in the cost-benefit equation. SMA components exhibit exceptional fatigue resistance, with properly designed systems maintaining functionality for over 1 million transformation cycles. This durability translates to maintenance intervals 2-3 times longer than conventional systems, reducing lifetime maintenance costs by approximately 40-60%.

The payback period for SMA implementation varies significantly by application. Building energy management systems incorporating SMA actuators typically achieve ROI within 3-5 years, while automotive applications may see faster returns of 2-3 years due to higher utilization rates. Industrial heat recovery systems using SMA-based heat engines demonstrate longer payback periods of 5-7 years but offer more substantial lifetime savings.

Lifecycle analysis reveals that despite higher initial costs, SMA-based energy conservation systems generally achieve 15-30% lower total cost of ownership over a 10-year operational period. This advantage becomes more pronounced in applications with high energy costs or intensive usage patterns. Additionally, as manufacturing scales increase and material science advances, SMA component costs have decreased by approximately 8% annually over the past decade, suggesting improving economic viability.

Environmental cost considerations further enhance the value proposition of SMA implementation. When factoring carbon pricing mechanisms (ranging from $25-50 per ton CO₂ in various markets), the economic case strengthens by an additional 5-12% depending on regional energy sources and regulatory frameworks.

However, these higher upfront costs must be balanced against significant operational savings. Energy conservation systems utilizing SMAs demonstrate 15-25% improved energy efficiency compared to conventional systems across multiple applications. In HVAC applications specifically, SMA-based actuators and valves reduce energy consumption by an average of 18%, translating to annual savings of $0.5-1.2 per square foot in commercial buildings.

Maintenance costs represent another critical factor in the cost-benefit equation. SMA components exhibit exceptional fatigue resistance, with properly designed systems maintaining functionality for over 1 million transformation cycles. This durability translates to maintenance intervals 2-3 times longer than conventional systems, reducing lifetime maintenance costs by approximately 40-60%.

The payback period for SMA implementation varies significantly by application. Building energy management systems incorporating SMA actuators typically achieve ROI within 3-5 years, while automotive applications may see faster returns of 2-3 years due to higher utilization rates. Industrial heat recovery systems using SMA-based heat engines demonstrate longer payback periods of 5-7 years but offer more substantial lifetime savings.

Lifecycle analysis reveals that despite higher initial costs, SMA-based energy conservation systems generally achieve 15-30% lower total cost of ownership over a 10-year operational period. This advantage becomes more pronounced in applications with high energy costs or intensive usage patterns. Additionally, as manufacturing scales increase and material science advances, SMA component costs have decreased by approximately 8% annually over the past decade, suggesting improving economic viability.

Environmental cost considerations further enhance the value proposition of SMA implementation. When factoring carbon pricing mechanisms (ranging from $25-50 per ton CO₂ in various markets), the economic case strengthens by an additional 5-12% depending on regional energy sources and regulatory frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!