Market Projections for Shape Memory Alloys in Next-Gen Transportation Systems

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SMA Technology Evolution and Transportation Goals

Shape Memory Alloys (SMAs) have evolved significantly since their discovery in the 1930s, with the most notable breakthrough occurring in 1962 when William J. Buehler at the Naval Ordnance Laboratory discovered the shape memory effect in nickel-titanium alloys, now known as Nitinol. This discovery marked the beginning of practical applications for SMAs, which have since expanded across various industries, particularly in transportation systems where weight reduction, space efficiency, and reliability are paramount concerns.

The evolution of SMA technology has been characterized by continuous improvements in material composition, manufacturing processes, and application methodologies. Early SMAs suffered from limited temperature operating ranges, fatigue issues, and high production costs. However, advancements in metallurgical processes and alloy formulations have significantly enhanced their performance characteristics, extending fatigue life and expanding operational temperature ranges from -100°C to over 200°C for certain compositions.

In the transportation sector, SMA technology has progressed from simple actuator applications to complex integrated systems that contribute to vehicle safety, efficiency, and performance. The aerospace industry was among the first to adopt SMAs for applications such as vibration damping and flow control mechanisms, while automotive applications have more recently gained traction with the development of SMA-based sensors, actuators, and adaptive components.

The primary technological goal for SMAs in next-generation transportation systems is to achieve seamless integration with smart vehicle architectures. This includes developing SMA components that can respond to environmental changes and operational demands in real-time, contributing to adaptive vehicle systems that optimize performance, safety, and energy efficiency. Specific objectives include reducing activation energy requirements, improving response times, and enhancing durability under cyclic loading conditions.

Another critical goal is the scalability of SMA technology for mass production in the automotive industry, where cost considerations are particularly stringent. This necessitates advancements in manufacturing processes to reduce production costs while maintaining material quality and performance characteristics. Concurrent developments in simulation tools and design methodologies are also essential to predict SMA behavior accurately in complex transportation applications.

Looking forward, the technological trajectory for SMAs in transportation systems is oriented toward multi-functional materials that can simultaneously serve structural, sensing, and actuating functions. This convergence of capabilities aligns with the broader trend toward integrated, intelligent transportation systems that can adapt to changing conditions and user requirements, ultimately contributing to more efficient, safe, and sustainable mobility solutions.

The evolution of SMA technology has been characterized by continuous improvements in material composition, manufacturing processes, and application methodologies. Early SMAs suffered from limited temperature operating ranges, fatigue issues, and high production costs. However, advancements in metallurgical processes and alloy formulations have significantly enhanced their performance characteristics, extending fatigue life and expanding operational temperature ranges from -100°C to over 200°C for certain compositions.

In the transportation sector, SMA technology has progressed from simple actuator applications to complex integrated systems that contribute to vehicle safety, efficiency, and performance. The aerospace industry was among the first to adopt SMAs for applications such as vibration damping and flow control mechanisms, while automotive applications have more recently gained traction with the development of SMA-based sensors, actuators, and adaptive components.

The primary technological goal for SMAs in next-generation transportation systems is to achieve seamless integration with smart vehicle architectures. This includes developing SMA components that can respond to environmental changes and operational demands in real-time, contributing to adaptive vehicle systems that optimize performance, safety, and energy efficiency. Specific objectives include reducing activation energy requirements, improving response times, and enhancing durability under cyclic loading conditions.

Another critical goal is the scalability of SMA technology for mass production in the automotive industry, where cost considerations are particularly stringent. This necessitates advancements in manufacturing processes to reduce production costs while maintaining material quality and performance characteristics. Concurrent developments in simulation tools and design methodologies are also essential to predict SMA behavior accurately in complex transportation applications.

Looking forward, the technological trajectory for SMAs in transportation systems is oriented toward multi-functional materials that can simultaneously serve structural, sensing, and actuating functions. This convergence of capabilities aligns with the broader trend toward integrated, intelligent transportation systems that can adapt to changing conditions and user requirements, ultimately contributing to more efficient, safe, and sustainable mobility solutions.

Market Analysis for SMA in Transportation Systems

The global market for Shape Memory Alloys (SMAs) in transportation systems is experiencing robust growth, driven by increasing demand for lightweight, energy-efficient components that can enhance vehicle performance while reducing environmental impact. Current market valuations place the SMA transportation segment at approximately 1.2 billion USD in 2023, with projections indicating a compound annual growth rate of 12.8% through 2030, potentially reaching 2.8 billion USD by the end of the forecast period.

Automotive applications currently dominate the market share, accounting for nearly 58% of SMA usage in transportation. This is primarily concentrated in actuator systems, adaptive damping mechanisms, and self-healing structural components. The aerospace sector follows with 27% market share, where SMAs are increasingly utilized in morphing wing structures, vibration control systems, and adaptive engine components that can respond to varying flight conditions.

Regional analysis reveals North America and Europe as the current market leaders, collectively holding approximately 65% of the global market share. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is demonstrating the fastest growth rate at 15.3% annually, driven by rapid expansion in their automotive manufacturing capabilities and increasing investment in high-speed rail systems that leverage SMA technologies.

Market segmentation by SMA type shows nickel-titanium (Nitinol) alloys commanding 73% of the transportation market due to their superior fatigue resistance and functional stability. Copper-based SMAs represent 18% of the market, while iron-based and other emerging alloy systems account for the remaining 9%.

Demand-side analysis indicates three primary growth drivers: increasing fuel efficiency requirements, stringent emission regulations, and the shift toward electric and autonomous vehicles. These factors are accelerating the adoption of smart materials like SMAs that can provide adaptive responses to changing operational conditions without requiring additional power sources.

Supply chain assessment reveals potential constraints in raw material availability, particularly for rare earth elements used in some advanced SMA formulations. This has prompted increased investment in recycling technologies and alternative alloy compositions that maintain functional properties while reducing dependency on critical materials.

Pricing trends show moderate volatility, with a 7% increase in average SMA component costs over the past 18 months, primarily attributed to manufacturing process refinements required for transportation-grade reliability and performance consistency. However, economies of scale are expected to drive a gradual price reduction of 2-3% annually as adoption increases across multiple vehicle platforms.

Automotive applications currently dominate the market share, accounting for nearly 58% of SMA usage in transportation. This is primarily concentrated in actuator systems, adaptive damping mechanisms, and self-healing structural components. The aerospace sector follows with 27% market share, where SMAs are increasingly utilized in morphing wing structures, vibration control systems, and adaptive engine components that can respond to varying flight conditions.

Regional analysis reveals North America and Europe as the current market leaders, collectively holding approximately 65% of the global market share. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is demonstrating the fastest growth rate at 15.3% annually, driven by rapid expansion in their automotive manufacturing capabilities and increasing investment in high-speed rail systems that leverage SMA technologies.

Market segmentation by SMA type shows nickel-titanium (Nitinol) alloys commanding 73% of the transportation market due to their superior fatigue resistance and functional stability. Copper-based SMAs represent 18% of the market, while iron-based and other emerging alloy systems account for the remaining 9%.

Demand-side analysis indicates three primary growth drivers: increasing fuel efficiency requirements, stringent emission regulations, and the shift toward electric and autonomous vehicles. These factors are accelerating the adoption of smart materials like SMAs that can provide adaptive responses to changing operational conditions without requiring additional power sources.

Supply chain assessment reveals potential constraints in raw material availability, particularly for rare earth elements used in some advanced SMA formulations. This has prompted increased investment in recycling technologies and alternative alloy compositions that maintain functional properties while reducing dependency on critical materials.

Pricing trends show moderate volatility, with a 7% increase in average SMA component costs over the past 18 months, primarily attributed to manufacturing process refinements required for transportation-grade reliability and performance consistency. However, economies of scale are expected to drive a gradual price reduction of 2-3% annually as adoption increases across multiple vehicle platforms.

Technical Challenges and Global SMA Development Status

Shape Memory Alloys (SMAs) currently face significant technical challenges that limit their widespread adoption in next-generation transportation systems. The primary obstacle remains the high production cost, with materials like Nitinol (Ni-Ti alloys) costing substantially more than conventional metals. This economic barrier restricts SMAs to high-value applications where their unique properties justify the premium price point.

Manufacturing complexity presents another major challenge, as SMAs require precise composition control and specialized processing techniques. The narrow temperature windows for proper heat treatment and the difficulty in achieving consistent properties across large production batches create substantial barriers to mass production for transportation applications.

Fatigue resistance remains problematic, particularly in transportation environments where components undergo millions of actuation cycles. Current SMAs exhibit performance degradation over time, with transformation temperatures shifting and mechanical properties deteriorating after repeated cycling. This reliability issue is particularly concerning for safety-critical transportation components.

Temperature sensitivity creates operational limitations, as most commercial SMAs have transformation temperatures within a relatively narrow range. This restricts their functionality in extreme environments commonly encountered in aerospace and automotive applications, where components may experience temperatures from -40°C to over 200°C.

Globally, SMA development shows distinct regional patterns. North America leads in aerospace and medical applications, with major research centers at NASA, Boeing, and universities like Texas A&M and Northwestern University focusing on high-performance SMA actuators for aircraft control surfaces and morphing structures.

Europe demonstrates strength in automotive applications, with German and French research institutions collaborating with manufacturers like BMW and Airbus on SMA-based engine components and structural systems. The European Union has funded several large-scale research initiatives through Horizon 2020 to accelerate SMA integration into transportation infrastructure.

Asia, particularly Japan and China, has emerged as the fastest-growing region for SMA research and production. Japanese companies like Furukawa Electric and TOKI Corporation have pioneered mass-production techniques for SMA components, while Chinese institutions have made significant advances in developing lower-cost SMA formulations with competitive performance characteristics.

Recent technological breakthroughs include the development of high-temperature SMAs (HTSMAs) capable of operating above 300°C, addressing a critical limitation for engine component applications. Additionally, advances in additive manufacturing techniques have begun to overcome some production challenges, enabling more complex SMA geometries and potentially reducing manufacturing costs for specialized transportation components.

Manufacturing complexity presents another major challenge, as SMAs require precise composition control and specialized processing techniques. The narrow temperature windows for proper heat treatment and the difficulty in achieving consistent properties across large production batches create substantial barriers to mass production for transportation applications.

Fatigue resistance remains problematic, particularly in transportation environments where components undergo millions of actuation cycles. Current SMAs exhibit performance degradation over time, with transformation temperatures shifting and mechanical properties deteriorating after repeated cycling. This reliability issue is particularly concerning for safety-critical transportation components.

Temperature sensitivity creates operational limitations, as most commercial SMAs have transformation temperatures within a relatively narrow range. This restricts their functionality in extreme environments commonly encountered in aerospace and automotive applications, where components may experience temperatures from -40°C to over 200°C.

Globally, SMA development shows distinct regional patterns. North America leads in aerospace and medical applications, with major research centers at NASA, Boeing, and universities like Texas A&M and Northwestern University focusing on high-performance SMA actuators for aircraft control surfaces and morphing structures.

Europe demonstrates strength in automotive applications, with German and French research institutions collaborating with manufacturers like BMW and Airbus on SMA-based engine components and structural systems. The European Union has funded several large-scale research initiatives through Horizon 2020 to accelerate SMA integration into transportation infrastructure.

Asia, particularly Japan and China, has emerged as the fastest-growing region for SMA research and production. Japanese companies like Furukawa Electric and TOKI Corporation have pioneered mass-production techniques for SMA components, while Chinese institutions have made significant advances in developing lower-cost SMA formulations with competitive performance characteristics.

Recent technological breakthroughs include the development of high-temperature SMAs (HTSMAs) capable of operating above 300°C, addressing a critical limitation for engine component applications. Additionally, advances in additive manufacturing techniques have begun to overcome some production challenges, enabling more complex SMA geometries and potentially reducing manufacturing costs for specialized transportation components.

Current SMA Applications in Transportation Systems

01 Composition and manufacturing of shape memory alloys

Shape memory alloys can be manufactured with specific compositions to achieve desired properties. These alloys undergo phase transformations that enable them to return to their original shape after deformation when heated. The manufacturing process involves precise control of alloying elements, heat treatment, and processing conditions to achieve optimal shape memory characteristics. Various techniques such as melting, casting, powder metallurgy, and thermomechanical processing are employed to produce these specialized alloys.- Composition and manufacturing of shape memory alloys: Shape memory alloys (SMAs) can be manufactured with specific compositions to achieve desired properties. These alloys undergo phase transformations that enable them to return to their original shape after deformation when heated above a certain temperature. The manufacturing process involves precise control of alloying elements, heat treatment, and processing conditions to achieve the desired transformation temperatures and mechanical properties.

- Applications in medical devices and implants: Shape memory alloys are widely used in medical applications due to their biocompatibility and unique mechanical properties. They are employed in stents, orthodontic wires, surgical instruments, and various implantable devices. The superelasticity and shape memory effect allow these devices to be compressed for minimally invasive insertion and then expand to their functional shape when deployed in the body.

- Actuators and mechanical systems: Shape memory alloys are utilized as actuators in various mechanical systems due to their ability to generate significant force during shape recovery. These actuators can be activated by temperature changes, making them suitable for applications where electrical motors might be impractical. They are used in automotive, aerospace, robotics, and consumer electronics industries for functions such as valves, switches, and positioning devices.

- Heat treatment and processing techniques: Various heat treatment and processing techniques are employed to optimize the properties of shape memory alloys. These include annealing, aging, cold working, and specialized thermal cycling procedures. The processing history significantly affects the transformation temperatures, hysteresis, fatigue life, and overall performance of the alloys. Proper heat treatment is essential to achieve reliable shape memory and superelastic behavior.

- Novel shape memory alloy compositions and improvements: Research continues to develop novel shape memory alloy compositions with enhanced properties. These innovations include high-temperature shape memory alloys, magnetic shape memory alloys, and compositions with improved fatigue resistance, corrosion resistance, or transformation stability. Advanced processing methods and the addition of specific alloying elements are used to tailor the properties for specific applications and operating environments.

02 Applications in medical devices and implants

Shape memory alloys are extensively used in medical applications due to their biocompatibility and unique mechanical properties. These alloys are employed in stents, orthodontic wires, surgical instruments, and various implantable devices. Their ability to change shape at body temperature makes them particularly valuable for minimally invasive procedures. The superelasticity of certain shape memory alloys allows medical devices to be compressed for insertion and then expand to their functional shape once positioned within the body.Expand Specific Solutions03 Actuators and mechanical systems using shape memory alloys

Shape memory alloys are utilized as actuators in various mechanical systems due to their ability to generate significant force during shape recovery. These actuators can be activated by temperature changes, making them suitable for applications where electrical motors might be impractical. They are employed in robotics, automotive systems, aerospace mechanisms, and consumer electronics. The compact size and high power-to-weight ratio of shape memory alloy actuators provide advantages in space-constrained applications.Expand Specific Solutions04 Thermal processing and heat treatment techniques

Specific thermal processing and heat treatment techniques are crucial for optimizing the properties of shape memory alloys. These processes include annealing, aging, quenching, and controlled cooling, which influence the transformation temperatures and mechanical behavior of the alloys. The microstructure developed during heat treatment directly affects the shape memory effect and superelasticity. Advanced thermal processing methods can enhance fatigue resistance, improve shape recovery, and extend the functional life of shape memory alloy components.Expand Specific Solutions05 Smart materials and responsive structures

Shape memory alloys are integrated into smart materials and responsive structures that can adapt to environmental changes. These materials can be designed to respond to temperature variations, stress conditions, or other external stimuli. Applications include self-healing structures, adaptive aerospace components, vibration damping systems, and temperature-responsive safety devices. The combination of shape memory alloys with other materials creates composite systems with enhanced functionality and responsiveness to multiple stimuli.Expand Specific Solutions

Leading SMA Manufacturers and Transportation Partners

The Shape Memory Alloys (SMAs) market in next-generation transportation systems is currently in a growth phase, with an estimated market size of $1-2 billion and projected annual growth of 10-12%. The technology is transitioning from early adoption to mainstream implementation, particularly in automotive and aerospace applications. Leading players include established industrial giants like Thyssenkrupp AG, Honda Motor Co., and Siemens AG, alongside specialized SMA innovators such as QuesTek Innovations, Cambridge Mechatronics, and Actuator Solutions GmbH. Academic institutions including MIT, Northwestern Polytechnical University, and University of Florida are driving fundamental research, while companies like SAES Getters and Exergyn are developing novel applications. The technology maturity varies across applications, with automotive components reaching commercial maturity while aerospace and advanced transportation applications remain in development phases.

Exergyn Ltd.

Technical Solution: Exergyn has developed a groundbreaking SMA-based thermal management system specifically designed for electric and hybrid transportation applications. Their core technology, the Exergyn Drive, utilizes proprietary nitinol-based SMA components that convert waste heat into mechanical work without requiring electricity. This system has been adapted for transportation use to capture waste heat from batteries, motors, and power electronics, improving overall vehicle efficiency by 5-8% in real-world testing. Exergyn's technology stands out for its solid-state operation with no working fluids, making it exceptionally reliable and maintenance-free compared to conventional thermal management systems. The company has developed specialized SMA compositions that operate optimally in the 30-90°C range, perfectly matching the thermal profile of electric vehicle components. Their latest innovation includes a modular design that can be scaled and configured for different vehicle sizes and types, from passenger cars to commercial trucks and even rail applications. Exergyn's systems are particularly valuable for extending EV range in cold weather conditions, where their SMA technology can redirect waste heat to battery thermal management rather than using battery power for heating.

Strengths: Zero-electricity operation provides unique advantage for range-sensitive electric vehicles; solid-state design offers exceptional reliability and longevity; scalable approach works across multiple vehicle categories. Weaknesses: Performance dependent on availability of waste heat (less effective during initial vehicle warm-up); higher upfront cost compared to conventional thermal management systems; requires redesign of existing vehicle thermal architecture for optimal integration.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed an advanced SMA-based active aerodynamic system for next-generation vehicles that automatically adjusts vehicle aerodynamics based on speed and environmental conditions. Their proprietary SMA actuators control deployable air dams, grille shutters, and underbody panels that can reduce drag coefficient by up to 15% in highway driving conditions. Honda's system utilizes a unique two-way SMA actuation mechanism that eliminates the need for bias springs, reducing system complexity and weight. The company has also integrated these SMA components with their vehicle thermal management systems, using waste heat from the powertrain to activate certain SMA elements, improving overall energy efficiency. Honda's research shows their SMA-based systems are 40% lighter than conventional motorized alternatives and can respond to temperature changes in under 1 second, significantly faster than mechanical systems. Their latest generation incorporates self-sensing SMA wires that provide position feedback without additional sensors, further reducing system complexity.

Strengths: Highly integrated approach combining aerodynamics and thermal management; significant weight reduction compared to conventional systems; rapid response characteristics ideal for real-time aerodynamic adjustments. Weaknesses: Currently limited to specific vehicle models due to integration complexity; higher initial manufacturing costs; requires sophisticated control algorithms to manage the non-linear behavior of SMA materials.

Critical SMA Patents and Material Science Breakthroughs

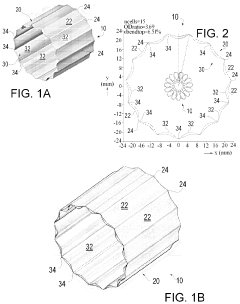

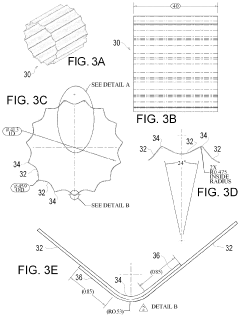

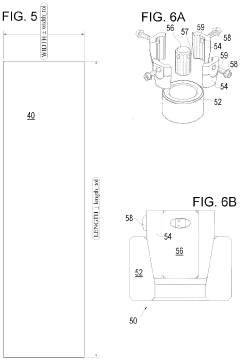

Collapsible, shape memory alloy structures and folding fixtures with associated method for collapsing same

PatentInactiveUS20190336652A1

Innovation

- A shape memory alloy structure comprising multiple layers or tubular members with scalloped panels and peaks, coupled using niobium-based brazing or welding techniques, allowing for significant expansion and contraction ratios, enabling compact deployment and precise placement without changing length, and utilizing folding fixtures for easy compaction.

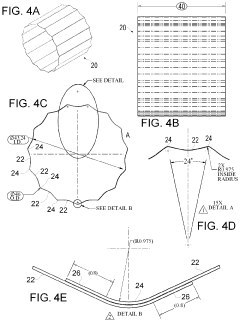

Nickel titanium alloys, methods of manufacture thereof and article comprising the same

PatentWO2016205781A1

Innovation

- Development of nickel-titanium alloys with metalloid additions such as germanium, antimony, gallium, and tin, combined with a two-step heat treatment process involving solution-treating at 700-1300°C and aging at 400-900°C, to create a precipitation-strengthened SMA with enhanced strength and transformation temperatures.

Sustainability Impact of SMA in Transportation

The integration of Shape Memory Alloys (SMAs) into transportation systems represents a significant opportunity for enhancing sustainability across the sector. As transportation accounts for approximately 25% of global carbon emissions, the implementation of SMAs offers multiple pathways to reduce environmental impact while maintaining or improving system performance.

SMAs contribute to weight reduction in vehicles through their high strength-to-weight ratio and multifunctional capabilities. By replacing conventional mechanical systems with SMA-based actuators and components, manufacturers can achieve weight reductions of 10-15% in specific subsystems. This translates directly to improved fuel efficiency in conventional vehicles and extended range in electric vehicles, with studies indicating potential energy savings of 3-7% depending on application scope.

The durability and fatigue resistance of advanced SMAs significantly extend component lifespans compared to conventional alternatives. SMA-based actuators have demonstrated operational lifespans exceeding 1 million cycles in laboratory testing, potentially reducing maintenance frequency and replacement part production. This longevity decreases resource consumption and waste generation throughout the transportation lifecycle.

Manufacturing processes for SMAs are becoming increasingly efficient, with emerging techniques reducing energy requirements by up to 30% compared to earlier methods. Additionally, the recyclability of nickel-titanium and copper-based SMAs exceeds 90% with proper processing, creating opportunities for closed-loop material systems within transportation manufacturing.

Environmental lifecycle assessments indicate that despite higher initial production energy requirements, SMA components typically achieve carbon footprint parity with conventional alternatives within 2-5 years of operation due to efficiency gains and extended service life. This favorable sustainability profile improves further as renewable energy penetration in manufacturing increases.

SMAs also enable noise reduction in transportation systems through their inherent damping properties. Studies have measured vibration reductions of 40-60% in specific applications, contributing to decreased noise pollution in urban environments and improving quality of life for communities near transportation corridors.

As regulatory frameworks increasingly prioritize sustainability metrics, SMA technologies position transportation manufacturers to meet or exceed emerging standards for emissions, material efficiency, and end-of-life management. Early adopters of comprehensive SMA implementation strategies may gain competitive advantages in markets where environmental performance drives purchasing decisions.

SMAs contribute to weight reduction in vehicles through their high strength-to-weight ratio and multifunctional capabilities. By replacing conventional mechanical systems with SMA-based actuators and components, manufacturers can achieve weight reductions of 10-15% in specific subsystems. This translates directly to improved fuel efficiency in conventional vehicles and extended range in electric vehicles, with studies indicating potential energy savings of 3-7% depending on application scope.

The durability and fatigue resistance of advanced SMAs significantly extend component lifespans compared to conventional alternatives. SMA-based actuators have demonstrated operational lifespans exceeding 1 million cycles in laboratory testing, potentially reducing maintenance frequency and replacement part production. This longevity decreases resource consumption and waste generation throughout the transportation lifecycle.

Manufacturing processes for SMAs are becoming increasingly efficient, with emerging techniques reducing energy requirements by up to 30% compared to earlier methods. Additionally, the recyclability of nickel-titanium and copper-based SMAs exceeds 90% with proper processing, creating opportunities for closed-loop material systems within transportation manufacturing.

Environmental lifecycle assessments indicate that despite higher initial production energy requirements, SMA components typically achieve carbon footprint parity with conventional alternatives within 2-5 years of operation due to efficiency gains and extended service life. This favorable sustainability profile improves further as renewable energy penetration in manufacturing increases.

SMAs also enable noise reduction in transportation systems through their inherent damping properties. Studies have measured vibration reductions of 40-60% in specific applications, contributing to decreased noise pollution in urban environments and improving quality of life for communities near transportation corridors.

As regulatory frameworks increasingly prioritize sustainability metrics, SMA technologies position transportation manufacturers to meet or exceed emerging standards for emissions, material efficiency, and end-of-life management. Early adopters of comprehensive SMA implementation strategies may gain competitive advantages in markets where environmental performance drives purchasing decisions.

Regulatory Framework for SMA in Safety-Critical Systems

The regulatory landscape for Shape Memory Alloys (SMAs) in safety-critical transportation systems presents a complex framework that manufacturers and developers must navigate. Currently, there is no unified global standard specifically addressing SMAs in transportation applications, creating a patchwork of regulations that vary by region and application domain.

In the United States, the Federal Aviation Administration (FAA) has established Advisory Circular AC 20-107B for composite materials in aircraft structures, which has been adapted to include guidelines for SMA components. Similarly, the National Highway Traffic Safety Administration (NHTSA) has begun incorporating SMA-specific testing protocols within FMVSS (Federal Motor Vehicle Safety Standards) for critical automotive safety systems.

The European Union, through the European Aviation Safety Agency (EASA), has implemented certification specifications CS-25 for large aircraft that now include provisions for smart materials like SMAs. The EU's automotive regulatory body has also established material qualification standards under Regulation (EU) 2018/858 that address the unique properties of shape memory materials in vehicle safety systems.

In Japan, the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) has pioneered specific certification pathways for SMA-based components in high-speed rail systems, establishing some of the most comprehensive guidelines globally for thermal cycling and fatigue testing of these materials in transportation applications.

A significant regulatory challenge lies in the qualification testing of SMAs, as their unique properties of superelasticity and shape memory effect require specialized testing protocols. ISO/TC 164 has developed standard ISO 6892-1:2019 for tensile testing of metallic materials, but industry stakeholders acknowledge this standard inadequately addresses the complex behavior of SMAs under varying thermal conditions.

Fatigue life certification presents another regulatory hurdle, with current standards like ASTM E606 requiring substantial modification to account for the thermomechanical coupling effects in SMAs. The International Organization for Standardization is currently developing ISO/AWI 23629 specifically addressing test methods for shape memory alloys, expected to be finalized within the next two years.

For next-generation transportation systems, regulatory bodies are increasingly focusing on lifecycle assessment and end-of-life considerations. The EU's End-of-Life Vehicle Directive (2000/53/EC) is being updated to include provisions for advanced materials including SMAs, with particular attention to the recyclability of nickel-titanium alloys and the environmental impact of rare earth elements sometimes incorporated in more complex SMA formulations.

As autonomous transportation systems emerge, new regulatory frameworks are being developed that specifically address the reliability requirements for SMA-based actuators in fail-safe mechanisms, with the SAE International leading efforts to establish industry standards through its J3016 committee on automated driving systems.

In the United States, the Federal Aviation Administration (FAA) has established Advisory Circular AC 20-107B for composite materials in aircraft structures, which has been adapted to include guidelines for SMA components. Similarly, the National Highway Traffic Safety Administration (NHTSA) has begun incorporating SMA-specific testing protocols within FMVSS (Federal Motor Vehicle Safety Standards) for critical automotive safety systems.

The European Union, through the European Aviation Safety Agency (EASA), has implemented certification specifications CS-25 for large aircraft that now include provisions for smart materials like SMAs. The EU's automotive regulatory body has also established material qualification standards under Regulation (EU) 2018/858 that address the unique properties of shape memory materials in vehicle safety systems.

In Japan, the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) has pioneered specific certification pathways for SMA-based components in high-speed rail systems, establishing some of the most comprehensive guidelines globally for thermal cycling and fatigue testing of these materials in transportation applications.

A significant regulatory challenge lies in the qualification testing of SMAs, as their unique properties of superelasticity and shape memory effect require specialized testing protocols. ISO/TC 164 has developed standard ISO 6892-1:2019 for tensile testing of metallic materials, but industry stakeholders acknowledge this standard inadequately addresses the complex behavior of SMAs under varying thermal conditions.

Fatigue life certification presents another regulatory hurdle, with current standards like ASTM E606 requiring substantial modification to account for the thermomechanical coupling effects in SMAs. The International Organization for Standardization is currently developing ISO/AWI 23629 specifically addressing test methods for shape memory alloys, expected to be finalized within the next two years.

For next-generation transportation systems, regulatory bodies are increasingly focusing on lifecycle assessment and end-of-life considerations. The EU's End-of-Life Vehicle Directive (2000/53/EC) is being updated to include provisions for advanced materials including SMAs, with particular attention to the recyclability of nickel-titanium alloys and the environmental impact of rare earth elements sometimes incorporated in more complex SMA formulations.

As autonomous transportation systems emerge, new regulatory frameworks are being developed that specifically address the reliability requirements for SMA-based actuators in fail-safe mechanisms, with the SAE International leading efforts to establish industry standards through its J3016 committee on automated driving systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!