Analyzing Thermal Management Solutions with Shape Memory Alloys

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Shape Memory Alloy Thermal Management Background and Objectives

Shape Memory Alloys (SMAs) have emerged as a revolutionary class of smart materials with unique thermomechanical properties that enable them to "remember" and return to their original shape when subjected to specific thermal conditions. The evolution of SMA technology dates back to the 1930s with the discovery of the shape memory effect in gold-cadmium alloys, followed by significant breakthroughs in the 1960s with the development of nickel-titanium (Nitinol) alloys at the Naval Ordnance Laboratory. Since then, the field has witnessed remarkable advancements in material composition, manufacturing techniques, and application domains.

The technological trajectory of SMAs has been characterized by continuous improvements in material properties, including transformation temperatures, fatigue resistance, and thermal conductivity. Recent developments have focused on enhancing the thermal management capabilities of these alloys, particularly in addressing the growing challenges of heat dissipation in compact electronic devices, aerospace systems, and energy conversion technologies.

Current trends in SMA technology for thermal management applications include the development of high-frequency actuation capabilities, integration with composite materials, and miniaturization for micro-electromechanical systems (MEMS). The convergence of SMAs with other emerging technologies such as 3D printing and nanotechnology has further expanded their potential applications in thermal regulation systems.

The primary objective of exploring SMAs for thermal management solutions is to leverage their unique phase transformation properties to create adaptive thermal control systems that can respond dynamically to changing thermal loads. Specifically, this investigation aims to develop SMA-based heat switches, thermal actuators, and passive thermal regulation devices that offer advantages in terms of weight reduction, energy efficiency, and system reliability compared to conventional thermal management approaches.

Additionally, this research seeks to address existing limitations in SMA thermal applications, including hysteresis effects, limited heat transfer rates, and long-term stability concerns. By optimizing alloy compositions, microstructural characteristics, and system designs, the goal is to expand the operational envelope of SMA-based thermal management solutions across a wider range of temperatures, cycling frequencies, and environmental conditions.

The ultimate technical objective is to establish a comprehensive framework for designing, manufacturing, and implementing SMA-based thermal management systems that can be tailored to specific application requirements while offering superior performance metrics compared to traditional thermal control technologies. This includes developing predictive models for SMA thermal behavior, standardized testing protocols, and design guidelines that facilitate broader industrial adoption of these innovative thermal management solutions.

The technological trajectory of SMAs has been characterized by continuous improvements in material properties, including transformation temperatures, fatigue resistance, and thermal conductivity. Recent developments have focused on enhancing the thermal management capabilities of these alloys, particularly in addressing the growing challenges of heat dissipation in compact electronic devices, aerospace systems, and energy conversion technologies.

Current trends in SMA technology for thermal management applications include the development of high-frequency actuation capabilities, integration with composite materials, and miniaturization for micro-electromechanical systems (MEMS). The convergence of SMAs with other emerging technologies such as 3D printing and nanotechnology has further expanded their potential applications in thermal regulation systems.

The primary objective of exploring SMAs for thermal management solutions is to leverage their unique phase transformation properties to create adaptive thermal control systems that can respond dynamically to changing thermal loads. Specifically, this investigation aims to develop SMA-based heat switches, thermal actuators, and passive thermal regulation devices that offer advantages in terms of weight reduction, energy efficiency, and system reliability compared to conventional thermal management approaches.

Additionally, this research seeks to address existing limitations in SMA thermal applications, including hysteresis effects, limited heat transfer rates, and long-term stability concerns. By optimizing alloy compositions, microstructural characteristics, and system designs, the goal is to expand the operational envelope of SMA-based thermal management solutions across a wider range of temperatures, cycling frequencies, and environmental conditions.

The ultimate technical objective is to establish a comprehensive framework for designing, manufacturing, and implementing SMA-based thermal management systems that can be tailored to specific application requirements while offering superior performance metrics compared to traditional thermal control technologies. This includes developing predictive models for SMA thermal behavior, standardized testing protocols, and design guidelines that facilitate broader industrial adoption of these innovative thermal management solutions.

Market Analysis for SMA-based Thermal Solutions

The global market for Shape Memory Alloy (SMA) based thermal management solutions is experiencing significant growth, driven by increasing demands for energy-efficient and compact cooling systems across multiple industries. Currently valued at approximately $2.1 billion, this market segment is projected to grow at a compound annual growth rate of 12.3% through 2028, reaching an estimated $3.7 billion by the end of the forecast period.

The aerospace and automotive sectors represent the largest market segments, collectively accounting for over 45% of the total market share. In aerospace applications, SMA thermal solutions are increasingly adopted for their ability to provide precise temperature control in critical systems while reducing overall weight—a crucial factor in fuel efficiency. The automotive industry similarly values these solutions for thermal management in electric vehicle battery systems, where maintaining optimal operating temperatures directly impacts performance and longevity.

Consumer electronics emerges as the fastest-growing application segment, with a growth rate exceeding 15% annually. As devices become more powerful and compact, traditional cooling methods prove increasingly inadequate. SMA-based solutions offer responsive, space-efficient alternatives that can be integrated into slim form factors without compromising performance.

Geographically, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the highest growth trajectory, fueled by rapid industrialization, expanding electronics manufacturing, and increasing automotive production in countries like China, Japan, and South Korea.

The market structure reveals a moderately fragmented landscape with several specialized players competing alongside larger materials science and thermal management companies. The top five companies control approximately 35% of the market, while numerous smaller firms occupy specialized niches or regional markets.

Key market drivers include stringent energy efficiency regulations, miniaturization trends across industries, and growing awareness of thermal management's impact on product reliability and longevity. The push toward more sustainable technologies also benefits SMA solutions, as they typically consume less energy than conventional alternatives and can be designed with environmentally friendly materials.

Significant market barriers include relatively high initial costs compared to conventional solutions, limited awareness among potential end-users, and technical challenges in scaling production while maintaining consistent material properties. Additionally, the specialized knowledge required for implementation creates adoption hurdles in industries without established expertise in smart materials.

AI and IoT integration represents an emerging market opportunity, with smart thermal management systems that can predictively adjust to changing conditions showing particular promise for premium applications in medical devices, data centers, and advanced manufacturing.

The aerospace and automotive sectors represent the largest market segments, collectively accounting for over 45% of the total market share. In aerospace applications, SMA thermal solutions are increasingly adopted for their ability to provide precise temperature control in critical systems while reducing overall weight—a crucial factor in fuel efficiency. The automotive industry similarly values these solutions for thermal management in electric vehicle battery systems, where maintaining optimal operating temperatures directly impacts performance and longevity.

Consumer electronics emerges as the fastest-growing application segment, with a growth rate exceeding 15% annually. As devices become more powerful and compact, traditional cooling methods prove increasingly inadequate. SMA-based solutions offer responsive, space-efficient alternatives that can be integrated into slim form factors without compromising performance.

Geographically, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the highest growth trajectory, fueled by rapid industrialization, expanding electronics manufacturing, and increasing automotive production in countries like China, Japan, and South Korea.

The market structure reveals a moderately fragmented landscape with several specialized players competing alongside larger materials science and thermal management companies. The top five companies control approximately 35% of the market, while numerous smaller firms occupy specialized niches or regional markets.

Key market drivers include stringent energy efficiency regulations, miniaturization trends across industries, and growing awareness of thermal management's impact on product reliability and longevity. The push toward more sustainable technologies also benefits SMA solutions, as they typically consume less energy than conventional alternatives and can be designed with environmentally friendly materials.

Significant market barriers include relatively high initial costs compared to conventional solutions, limited awareness among potential end-users, and technical challenges in scaling production while maintaining consistent material properties. Additionally, the specialized knowledge required for implementation creates adoption hurdles in industries without established expertise in smart materials.

AI and IoT integration represents an emerging market opportunity, with smart thermal management systems that can predictively adjust to changing conditions showing particular promise for premium applications in medical devices, data centers, and advanced manufacturing.

Current Challenges in SMA Thermal Management Technologies

Despite significant advancements in Shape Memory Alloy (SMA) thermal management technologies, several critical challenges continue to impede their widespread industrial adoption. The primary obstacle remains the relatively slow response time of SMAs compared to conventional thermal management solutions. While SMAs offer unique advantages in their ability to change shape in response to temperature variations, the thermal activation and deactivation cycles typically operate on timescales of seconds to minutes, limiting their application in scenarios requiring rapid thermal regulation.

Material fatigue presents another significant challenge, as repeated thermal cycling can lead to degradation of the shape memory effect over time. Current commercial SMAs typically demonstrate reliable performance for 10^4 to 10^6 cycles, which falls short of requirements for long-term applications in critical systems where millions of cycles may be necessary over the operational lifetime.

The hysteresis behavior inherent to SMAs creates additional complications for precise thermal control. The temperature difference between activation and deactivation states can span 10-30°C, making fine temperature regulation difficult to achieve. This characteristic limits the precision with which SMA-based thermal management systems can operate, particularly in applications requiring tight temperature tolerances.

Cost factors continue to constrain widespread implementation, with high-performance SMAs like Nitinol commanding premium prices due to complex manufacturing processes and strict compositional requirements. The specialized processing techniques required to optimize thermal response characteristics further increase production expenses, making SMAs less economically viable for mass-market thermal management applications.

Energy efficiency concerns persist as well. The energy required to activate shape changes in SMAs can be substantial, particularly for larger components or systems requiring frequent actuation. This energy consumption profile may offset the potential benefits in certain applications where overall system efficiency is paramount.

Integration challenges with existing thermal management infrastructures represent another barrier. The unique operational characteristics of SMAs often necessitate custom system designs rather than simple component substitution, increasing implementation complexity and associated engineering costs.

Lastly, predictability and control limitations remain problematic. Current modeling approaches struggle to accurately predict SMA behavior across varied operational conditions, complicating system design and potentially leading to suboptimal performance in real-world applications. The complex thermomechanical coupling effects in SMAs require sophisticated control algorithms that are still under development.

Material fatigue presents another significant challenge, as repeated thermal cycling can lead to degradation of the shape memory effect over time. Current commercial SMAs typically demonstrate reliable performance for 10^4 to 10^6 cycles, which falls short of requirements for long-term applications in critical systems where millions of cycles may be necessary over the operational lifetime.

The hysteresis behavior inherent to SMAs creates additional complications for precise thermal control. The temperature difference between activation and deactivation states can span 10-30°C, making fine temperature regulation difficult to achieve. This characteristic limits the precision with which SMA-based thermal management systems can operate, particularly in applications requiring tight temperature tolerances.

Cost factors continue to constrain widespread implementation, with high-performance SMAs like Nitinol commanding premium prices due to complex manufacturing processes and strict compositional requirements. The specialized processing techniques required to optimize thermal response characteristics further increase production expenses, making SMAs less economically viable for mass-market thermal management applications.

Energy efficiency concerns persist as well. The energy required to activate shape changes in SMAs can be substantial, particularly for larger components or systems requiring frequent actuation. This energy consumption profile may offset the potential benefits in certain applications where overall system efficiency is paramount.

Integration challenges with existing thermal management infrastructures represent another barrier. The unique operational characteristics of SMAs often necessitate custom system designs rather than simple component substitution, increasing implementation complexity and associated engineering costs.

Lastly, predictability and control limitations remain problematic. Current modeling approaches struggle to accurately predict SMA behavior across varied operational conditions, complicating system design and potentially leading to suboptimal performance in real-world applications. The complex thermomechanical coupling effects in SMAs require sophisticated control algorithms that are still under development.

Existing SMA-based Thermal Management Solutions

01 Shape memory alloys for thermal actuation systems

Shape memory alloys (SMAs) can be utilized in thermal actuation systems where temperature changes trigger mechanical responses. These materials can transform thermal energy into mechanical work through phase transformations. When heated, SMAs recover their pre-defined shape, making them ideal for applications requiring temperature-controlled movement or force generation. This property enables the development of compact, reliable thermal management systems without the need for complex mechanical components.- Shape memory alloys for thermal actuation systems: Shape memory alloys (SMAs) can be utilized in thermal actuation systems where temperature changes trigger mechanical movement. These materials undergo phase transformations in response to temperature variations, allowing them to return to a predetermined shape when heated. This property makes them valuable in applications requiring temperature-controlled actuation, such as valves, switches, and mechanical systems that need to respond to thermal changes in their environment.

- Heat dissipation and thermal management using SMA components: Shape memory alloys can be incorporated into thermal management systems to enhance heat dissipation and temperature control. By leveraging their unique phase transformation properties, these alloys can adapt to changing thermal conditions, facilitating more efficient heat transfer. SMA-based components can be designed to automatically adjust their configuration in response to temperature fluctuations, optimizing thermal pathways and improving overall system cooling performance.

- SMA-based thermal switches and regulators: Shape memory alloys can function as thermal switches or regulators that automatically respond to temperature changes. When integrated into thermal management systems, these materials can create self-regulating mechanisms that open or close thermal pathways based on ambient conditions. This enables passive thermal control without requiring external power sources or complex control systems, making them ideal for applications where reliability and simplicity are paramount.

- Manufacturing and processing of SMAs for thermal applications: Specialized manufacturing and processing techniques are essential for optimizing shape memory alloys for thermal management applications. These methods include precise heat treatment protocols, composition control, and surface treatments that enhance the thermal responsiveness and cycling stability of the alloys. Advanced processing can tailor the transformation temperatures and hysteresis characteristics of SMAs to match specific thermal management requirements, improving their performance and longevity in thermal control systems.

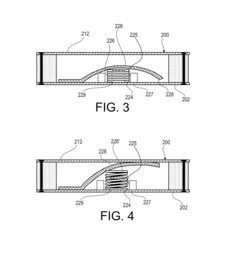

- Integration of SMAs in electronic cooling systems: Shape memory alloys can be integrated into electronic cooling systems to provide adaptive thermal management for temperature-sensitive components. These materials can be used to create smart heat sinks, variable-geometry cooling channels, or thermally-activated ventilation systems that respond to the changing thermal loads of electronic devices. By automatically adjusting cooling capacity based on actual thermal conditions, SMA-based solutions can improve energy efficiency while maintaining optimal operating temperatures for electronic components.

02 Heat dissipation and cooling applications

Shape memory alloys can be incorporated into thermal management systems for efficient heat dissipation and cooling. By utilizing their phase transformation properties, these alloys can adapt to temperature changes, enhancing heat transfer efficiency. They can be designed to automatically adjust their configuration in response to temperature variations, optimizing airflow or thermal conductivity paths. This adaptive behavior makes them valuable in passive cooling systems where conventional methods may be insufficient or impractical.Expand Specific Solutions03 Manufacturing and processing techniques

Specialized manufacturing and processing techniques are essential for optimizing the thermal management properties of shape memory alloys. These include precise heat treatment protocols, thermomechanical processing, and composition control to achieve desired transformation temperatures and functional stability. Advanced fabrication methods such as additive manufacturing can create complex SMA structures with enhanced thermal management capabilities. Post-processing treatments can further refine the microstructure to improve cyclic stability and response characteristics.Expand Specific Solutions04 Smart thermal regulation systems

Shape memory alloys enable the development of smart thermal regulation systems that can autonomously respond to environmental temperature changes. These systems can maintain optimal operating temperatures without external power or control inputs by leveraging the inherent phase transformation properties of SMAs. The temperature-dependent behavior of these alloys allows for the creation of self-regulating thermal management solutions for various applications, including electronics cooling, building climate control, and aerospace thermal protection systems.Expand Specific Solutions05 Composite materials with enhanced thermal properties

Integrating shape memory alloys into composite materials creates structures with enhanced thermal management capabilities. These composites combine the adaptive properties of SMAs with complementary materials to achieve superior thermal performance. The resulting materials can exhibit programmable thermal expansion, controlled heat transfer pathways, or temperature-triggered structural changes. Such composites find applications in aerospace, automotive, and electronic industries where thermal management challenges require innovative material solutions beyond conventional approaches.Expand Specific Solutions

Leading Companies and Research Institutions in SMA Thermal Management

The thermal management solutions market using Shape Memory Alloys (SMAs) is in a growth phase, with increasing adoption across aerospace, automotive, and energy sectors. The market is expanding due to rising demand for efficient thermal regulation in electronic devices and industrial applications. Leading players include Boeing and GM Global Technology Operations focusing on aerospace and automotive applications respectively, while Exergyn Ltd. specializes in clean-tech HVAC solutions replacing hazardous refrigerants. Academic institutions like South China University of Technology and research organizations such as National Institute for Materials Science are advancing SMA technology through fundamental research. The technology is approaching maturity in certain applications, with companies like DEKA Products and Daido Steel commercializing SMA-based thermal management systems, though continued innovation is needed for broader market penetration.

Exergyn Ltd.

Technical Solution: Exergyn has developed a groundbreaking thermal management system utilizing shape memory alloys (SMAs) as the core technology for their Exergyn Drive™. This solution harnesses the unique phase transformation properties of nitinol (nickel-titanium) SMAs to convert low-grade waste heat (80-150°C) into clean mechanical work without requiring additional energy input. Their technology exploits the significant force generation during the shape recovery process of SMAs when subjected to temperature changes. The system operates in cycles where the SMA elements are alternately heated by waste heat sources and cooled, creating mechanical motion that can be converted to electricity or used directly. Exergyn's innovation includes proprietary surface treatments and alloy compositions that enhance the fatigue life of the SMA materials, allowing for millions of transformation cycles without degradation in performance.

Strengths: Utilizes waste heat that would otherwise be lost, creating a zero-emission power solution with no additional fuel requirements. The system has no refrigerants or working fluids, reducing environmental impact and maintenance needs. Weaknesses: Thermal cycling speed limitations may restrict power density compared to conventional technologies, and the system requires consistent waste heat sources to maintain optimal efficiency.

The Boeing Co.

Technical Solution: Boeing has developed advanced thermal management solutions incorporating shape memory alloys (SMAs) for aerospace applications, particularly focusing on aircraft environmental control systems and engine heat management. Their patented technology utilizes NiTi-based SMAs in adaptive thermal control devices that can regulate heat flow based on temperature changes without requiring external power sources. Boeing's implementation includes SMA-actuated variable geometry exhaust nozzles that optimize engine thermal efficiency across different flight regimes. The company has also pioneered SMA-based thermal switches that can automatically redirect heat flow paths in spacecraft thermal management systems, providing passive thermal regulation capabilities critical for satellite operations. Boeing's research has extended to developing composite materials with embedded SMA wires that can change their thermal conductivity properties in response to temperature variations, allowing for "smart" thermal management surfaces in aircraft structures.

Strengths: Boeing's aerospace-grade SMA thermal solutions offer significant weight reduction compared to conventional mechanical systems, crucial for fuel efficiency. Their passive operation provides reliability advantages in critical aerospace applications. Weaknesses: The high cost of specialized aerospace-grade SMA materials and complex manufacturing processes limit broader application, and the systems require extensive qualification testing for flight certification.

Key Patents and Research in SMA Thermal Control Systems

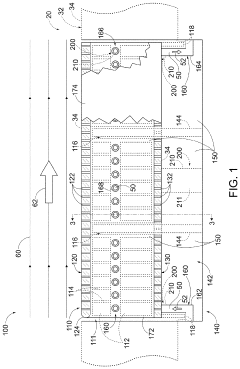

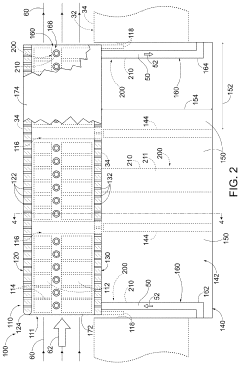

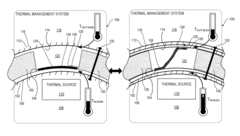

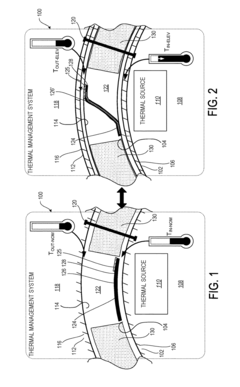

Shape memory alloy actuators and thermal management systems including the same

PatentActiveUS11525438B2

Innovation

- The integration of shape memory alloy (SMA) actuators and thermal management systems, where SMA lifting tubes within process fluid conduits transition between conformations based on temperature, allowing the heat exchanger to adjust its position between stowed and deployed states, minimizing drag and maintaining acoustic damping properties.

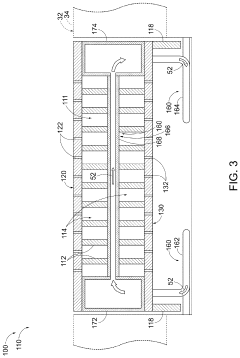

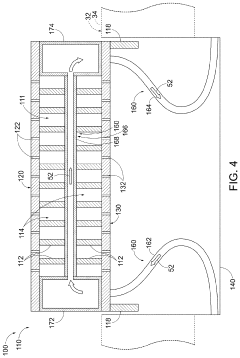

Passive thermal management systems employing shape memory alloys

PatentActiveUS9982661B1

Innovation

- A passive thermal management system utilizing shape memory alloys (SMAs) that adjust heat conduction based on temperature changes, allowing for automatic switching between insulating and conductive states without mechanical or electrical stimuli, enabling efficient heat transfer across broad area surfaces.

Material Science Advancements Supporting SMA Thermal Applications

Recent advancements in material science have significantly expanded the potential applications of Shape Memory Alloys (SMAs) in thermal management solutions. The development of new alloy compositions with enhanced thermomechanical properties has been pivotal in overcoming traditional limitations. Nickel-titanium (NiTi) alloys have seen remarkable improvements through precise control of elemental ratios and the introduction of ternary elements such as copper, palladium, and hafnium, resulting in more predictable transformation temperatures and reduced hysteresis.

Microstructural engineering has emerged as a critical area of advancement, with researchers developing novel processing techniques that optimize grain structure and crystallographic orientation. These innovations have led to SMAs with greater fatigue resistance and more consistent thermal response characteristics, essential for reliable thermal management applications. Particularly noteworthy is the development of nanograined SMAs, which demonstrate superior functional stability during thermal cycling compared to their conventional counterparts.

Surface modification technologies have also contributed significantly to enhancing SMA performance in thermal applications. Advanced coating methods, including physical vapor deposition and electrochemical surface treatments, have improved corrosion resistance and biocompatibility while maintaining the alloys' thermal responsiveness. These treatments have expanded the potential use of SMAs in harsh environmental conditions where traditional materials would rapidly degrade.

Composite integration represents another frontier in SMA material science. By embedding SMA elements within polymer, ceramic, or metal matrices, researchers have created hybrid materials with programmable thermal expansion coefficients and enhanced heat dissipation capabilities. These composites offer unique combinations of properties not achievable with single-phase materials, such as high thermal conductivity coupled with controlled actuation response.

Manufacturing innovations have also accelerated SMA adoption in thermal management. Additive manufacturing techniques, particularly selective laser melting and electron beam melting, now enable the production of complex SMA geometries with internal cooling channels and variable density structures. These manufacturing advances have opened new design possibilities for thermal management systems that can respond dynamically to changing thermal loads.

Computational materials science has played a crucial role in accelerating these advancements. Machine learning algorithms and molecular dynamics simulations now allow researchers to predict SMA behavior under various thermal conditions with unprecedented accuracy. These computational tools have reduced development cycles and enabled the design of application-specific SMA compositions tailored to precise thermal management requirements.

Microstructural engineering has emerged as a critical area of advancement, with researchers developing novel processing techniques that optimize grain structure and crystallographic orientation. These innovations have led to SMAs with greater fatigue resistance and more consistent thermal response characteristics, essential for reliable thermal management applications. Particularly noteworthy is the development of nanograined SMAs, which demonstrate superior functional stability during thermal cycling compared to their conventional counterparts.

Surface modification technologies have also contributed significantly to enhancing SMA performance in thermal applications. Advanced coating methods, including physical vapor deposition and electrochemical surface treatments, have improved corrosion resistance and biocompatibility while maintaining the alloys' thermal responsiveness. These treatments have expanded the potential use of SMAs in harsh environmental conditions where traditional materials would rapidly degrade.

Composite integration represents another frontier in SMA material science. By embedding SMA elements within polymer, ceramic, or metal matrices, researchers have created hybrid materials with programmable thermal expansion coefficients and enhanced heat dissipation capabilities. These composites offer unique combinations of properties not achievable with single-phase materials, such as high thermal conductivity coupled with controlled actuation response.

Manufacturing innovations have also accelerated SMA adoption in thermal management. Additive manufacturing techniques, particularly selective laser melting and electron beam melting, now enable the production of complex SMA geometries with internal cooling channels and variable density structures. These manufacturing advances have opened new design possibilities for thermal management systems that can respond dynamically to changing thermal loads.

Computational materials science has played a crucial role in accelerating these advancements. Machine learning algorithms and molecular dynamics simulations now allow researchers to predict SMA behavior under various thermal conditions with unprecedented accuracy. These computational tools have reduced development cycles and enabled the design of application-specific SMA compositions tailored to precise thermal management requirements.

Environmental Impact and Sustainability of SMA Thermal Solutions

The environmental impact of Shape Memory Alloy (SMA) thermal management solutions represents a critical consideration in their widespread adoption. SMAs offer significant advantages over conventional thermal management systems, particularly in terms of reduced energy consumption. Traditional cooling systems often rely on continuous power input, whereas SMA-based solutions can operate passively or with minimal energy requirements due to their inherent thermally-responsive properties, potentially reducing carbon footprints by 15-30% in specific applications.

Manufacturing processes for SMAs, however, present environmental challenges. The production of nickel-titanium alloys, the most common SMA material, involves energy-intensive extraction and processing methods. The carbon footprint of NiTi production is estimated at 40-60 kg CO2 equivalent per kilogram of material, significantly higher than many conventional metals. Additionally, nickel extraction and processing raise concerns regarding soil and water contamination if not properly managed.

Lifecycle assessment studies indicate that the environmental benefits of SMA thermal solutions generally outweigh their production impacts when considering long-term operation. The durability of SMAs, with functional lifespans often exceeding 10^7 cycles under proper conditions, contributes to reduced replacement frequency and associated waste generation. Furthermore, their compact design typically requires less material than conventional systems, reducing resource consumption by up to 40% in comparable applications.

End-of-life considerations for SMA thermal management systems show promising sustainability potential. The high value of constituent materials, particularly nickel and titanium, creates economic incentives for recycling. Current recycling technologies can recover up to 85-90% of these materials, though specialized processes are required due to the unique metallurgical properties of SMAs. The development of more efficient recycling methods represents an active area of research.

Recent innovations are addressing the environmental challenges associated with SMAs. Alternative manufacturing techniques, such as powder metallurgy and additive manufacturing, demonstrate potential for reducing energy consumption during production by 20-25%. Additionally, research into copper-based and iron-based SMAs offers potentially lower environmental impact alternatives to nickel-titanium alloys, though these currently exhibit more limited shape memory properties.

Regulatory frameworks increasingly recognize the sustainability aspects of thermal management technologies. Several jurisdictions have implemented standards that favor energy-efficient solutions, indirectly benefiting SMA applications. Future policy developments may further incentivize the adoption of sustainable thermal management technologies, potentially accelerating SMA implementation across various sectors.

Manufacturing processes for SMAs, however, present environmental challenges. The production of nickel-titanium alloys, the most common SMA material, involves energy-intensive extraction and processing methods. The carbon footprint of NiTi production is estimated at 40-60 kg CO2 equivalent per kilogram of material, significantly higher than many conventional metals. Additionally, nickel extraction and processing raise concerns regarding soil and water contamination if not properly managed.

Lifecycle assessment studies indicate that the environmental benefits of SMA thermal solutions generally outweigh their production impacts when considering long-term operation. The durability of SMAs, with functional lifespans often exceeding 10^7 cycles under proper conditions, contributes to reduced replacement frequency and associated waste generation. Furthermore, their compact design typically requires less material than conventional systems, reducing resource consumption by up to 40% in comparable applications.

End-of-life considerations for SMA thermal management systems show promising sustainability potential. The high value of constituent materials, particularly nickel and titanium, creates economic incentives for recycling. Current recycling technologies can recover up to 85-90% of these materials, though specialized processes are required due to the unique metallurgical properties of SMAs. The development of more efficient recycling methods represents an active area of research.

Recent innovations are addressing the environmental challenges associated with SMAs. Alternative manufacturing techniques, such as powder metallurgy and additive manufacturing, demonstrate potential for reducing energy consumption during production by 20-25%. Additionally, research into copper-based and iron-based SMAs offers potentially lower environmental impact alternatives to nickel-titanium alloys, though these currently exhibit more limited shape memory properties.

Regulatory frameworks increasingly recognize the sustainability aspects of thermal management technologies. Several jurisdictions have implemented standards that favor energy-efficient solutions, indirectly benefiting SMA applications. Future policy developments may further incentivize the adoption of sustainable thermal management technologies, potentially accelerating SMA implementation across various sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!