Regulatory Frameworks Affecting the Use of Shape Memory Alloys in Medical Devices

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SMA Medical Device Regulatory Background and Objectives

Shape Memory Alloys (SMAs) have emerged as revolutionary materials in the medical device industry since their discovery in the 1960s. These unique metallic compounds, primarily Nitinol (nickel-titanium alloy), possess remarkable properties including superelasticity and shape memory effect, allowing them to return to predetermined shapes when subjected to specific temperature changes. The evolution of SMA technology in medical applications has accelerated significantly over the past three decades, transitioning from experimental usage to mainstream implementation in critical medical devices.

The regulatory landscape governing SMAs in medical devices has evolved in parallel with technological advancements. Initially, regulatory frameworks were minimal, focusing primarily on basic material biocompatibility. However, as applications expanded into implantable devices, vascular stents, orthodontic wires, and surgical instruments, regulatory bodies worldwide developed increasingly sophisticated oversight mechanisms to ensure patient safety while enabling innovation.

Currently, SMAs in medical devices fall under the jurisdiction of multiple regulatory authorities, including the FDA in the United States, the European Medicines Agency through the Medical Device Regulation (MDR) in Europe, and the Pharmaceuticals and Medical Devices Agency (PMDA) in Japan. These frameworks have progressively incorporated specific requirements for SMA-based devices, addressing unique considerations such as fatigue resistance, corrosion behavior, and nickel leaching potential.

The primary objective of this technical research is to comprehensively analyze the current global regulatory frameworks affecting SMA implementation in medical devices. This includes identifying regulatory convergence and divergence across major markets, evaluating how existing frameworks address the unique properties of SMAs, and assessing regulatory gaps that may impede innovation or compromise safety.

Secondary objectives include mapping the evolution of SMA-specific regulatory requirements over time, identifying emerging regulatory trends that may impact future development, and evaluating how regulatory considerations influence material selection and device design processes. This analysis aims to provide actionable insights for manufacturers navigating the complex regulatory landscape while developing next-generation SMA-based medical technologies.

The technological trajectory suggests continued expansion of SMA applications in increasingly complex medical devices, including active implantables and combination products. This evolution necessitates forward-looking regulatory approaches that balance innovation enablement with rigorous safety standards. Understanding this regulatory ecosystem is essential for strategic planning and efficient product development pathways in the medical device industry.

The regulatory landscape governing SMAs in medical devices has evolved in parallel with technological advancements. Initially, regulatory frameworks were minimal, focusing primarily on basic material biocompatibility. However, as applications expanded into implantable devices, vascular stents, orthodontic wires, and surgical instruments, regulatory bodies worldwide developed increasingly sophisticated oversight mechanisms to ensure patient safety while enabling innovation.

Currently, SMAs in medical devices fall under the jurisdiction of multiple regulatory authorities, including the FDA in the United States, the European Medicines Agency through the Medical Device Regulation (MDR) in Europe, and the Pharmaceuticals and Medical Devices Agency (PMDA) in Japan. These frameworks have progressively incorporated specific requirements for SMA-based devices, addressing unique considerations such as fatigue resistance, corrosion behavior, and nickel leaching potential.

The primary objective of this technical research is to comprehensively analyze the current global regulatory frameworks affecting SMA implementation in medical devices. This includes identifying regulatory convergence and divergence across major markets, evaluating how existing frameworks address the unique properties of SMAs, and assessing regulatory gaps that may impede innovation or compromise safety.

Secondary objectives include mapping the evolution of SMA-specific regulatory requirements over time, identifying emerging regulatory trends that may impact future development, and evaluating how regulatory considerations influence material selection and device design processes. This analysis aims to provide actionable insights for manufacturers navigating the complex regulatory landscape while developing next-generation SMA-based medical technologies.

The technological trajectory suggests continued expansion of SMA applications in increasingly complex medical devices, including active implantables and combination products. This evolution necessitates forward-looking regulatory approaches that balance innovation enablement with rigorous safety standards. Understanding this regulatory ecosystem is essential for strategic planning and efficient product development pathways in the medical device industry.

Market Analysis for SMA-Based Medical Devices

The global market for Shape Memory Alloy (SMA) medical devices continues to expand rapidly, with a current valuation exceeding $12 billion and projected annual growth rates of 8-10% through 2028. This growth is primarily driven by increasing prevalence of minimally invasive surgeries and the rising demand for advanced implantable devices across cardiovascular, orthopedic, and neurological applications.

Cardiovascular applications represent the largest market segment, accounting for approximately 45% of SMA medical device usage. Stents and heart valve frames dominate this category, with North America holding the largest market share at 38%. The orthopedic segment follows at 30% market share, with bone plates, staples, and spinal correction devices showing particularly strong growth trajectories in aging populations.

Regional analysis reveals North America as the dominant market for SMA medical devices, followed by Europe and Asia-Pacific. However, the Asia-Pacific region demonstrates the highest growth rate at 12% annually, driven by improving healthcare infrastructure, increasing medical tourism, and growing adoption of advanced medical technologies in China, Japan, and India.

Key market drivers include the aging global population, increasing prevalence of chronic diseases requiring implantable devices, and growing preference for minimally invasive procedures. The unique properties of SMAs—particularly nitinol's superelasticity and biocompatibility—position these materials ideally for next-generation medical applications where traditional materials fall short.

Market barriers primarily center around stringent regulatory frameworks, with FDA and EU MDR requirements creating significant hurdles for new entrants. The average approval timeline for SMA-based devices spans 3-5 years, with associated costs ranging from $5-25 million depending on device classification and intended use. These regulatory challenges have contributed to market consolidation, with five major manufacturers controlling approximately 70% of the global SMA medical device market.

Pricing trends show moderate pressure, with average selling prices decreasing 2-3% annually due to increased competition and manufacturing efficiencies. However, premium pricing remains sustainable for novel applications with demonstrated clinical advantages over conventional alternatives.

Consumer adoption patterns indicate strong physician preference for SMA-based devices in procedures requiring precise deployment and reduced trauma. Patient awareness of device materials remains limited, with purchasing decisions primarily driven by physician recommendations and insurance coverage rather than specific material preferences.

AI-powered analytics project continued market expansion, with particular growth opportunities in neurovascular applications, drug delivery systems, and robotic surgical instruments incorporating SMA actuators. These emerging applications could potentially add $3-4 billion to the market by 2030.

Cardiovascular applications represent the largest market segment, accounting for approximately 45% of SMA medical device usage. Stents and heart valve frames dominate this category, with North America holding the largest market share at 38%. The orthopedic segment follows at 30% market share, with bone plates, staples, and spinal correction devices showing particularly strong growth trajectories in aging populations.

Regional analysis reveals North America as the dominant market for SMA medical devices, followed by Europe and Asia-Pacific. However, the Asia-Pacific region demonstrates the highest growth rate at 12% annually, driven by improving healthcare infrastructure, increasing medical tourism, and growing adoption of advanced medical technologies in China, Japan, and India.

Key market drivers include the aging global population, increasing prevalence of chronic diseases requiring implantable devices, and growing preference for minimally invasive procedures. The unique properties of SMAs—particularly nitinol's superelasticity and biocompatibility—position these materials ideally for next-generation medical applications where traditional materials fall short.

Market barriers primarily center around stringent regulatory frameworks, with FDA and EU MDR requirements creating significant hurdles for new entrants. The average approval timeline for SMA-based devices spans 3-5 years, with associated costs ranging from $5-25 million depending on device classification and intended use. These regulatory challenges have contributed to market consolidation, with five major manufacturers controlling approximately 70% of the global SMA medical device market.

Pricing trends show moderate pressure, with average selling prices decreasing 2-3% annually due to increased competition and manufacturing efficiencies. However, premium pricing remains sustainable for novel applications with demonstrated clinical advantages over conventional alternatives.

Consumer adoption patterns indicate strong physician preference for SMA-based devices in procedures requiring precise deployment and reduced trauma. Patient awareness of device materials remains limited, with purchasing decisions primarily driven by physician recommendations and insurance coverage rather than specific material preferences.

AI-powered analytics project continued market expansion, with particular growth opportunities in neurovascular applications, drug delivery systems, and robotic surgical instruments incorporating SMA actuators. These emerging applications could potentially add $3-4 billion to the market by 2030.

Current Regulatory Challenges for SMA Medical Applications

The regulatory landscape for Shape Memory Alloys (SMAs) in medical devices presents significant challenges for manufacturers and innovators. Currently, the FDA in the United States classifies most SMA-containing medical devices as Class II or Class III, requiring either 510(k) clearance or premarket approval (PMA), depending on the risk profile and intended use. This classification system creates a substantial regulatory burden, particularly for novel applications where predicate devices may not exist.

European regulations under the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) have introduced more stringent requirements for clinical evidence and post-market surveillance. For SMA devices, this translates to comprehensive technical documentation demonstrating biocompatibility, fatigue resistance, and long-term stability of the alloy properties under physiological conditions. The transition period from the previous Medical Device Directive (MDD) to MDR has created additional compliance challenges for existing SMA devices.

Biocompatibility testing represents a particular regulatory hurdle for SMA applications. Current standards such as ISO 10993 require extensive testing to ensure that nickel leaching from Nitinol (the most common SMA) remains below threshold levels. The variability in surface treatments and processing methods for SMAs complicates standardization of these tests, often resulting in case-by-case evaluation by regulatory bodies.

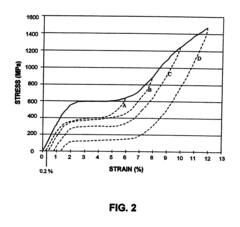

Material characterization requirements present another significant challenge. Regulatory agencies increasingly demand comprehensive data on transformation temperatures, superelastic properties, and fatigue behavior across the full range of physiological conditions. The complex thermomechanical behavior of SMAs makes standardized testing protocols difficult to establish, leading to regulatory inconsistencies across different jurisdictions.

International harmonization efforts through the International Medical Device Regulators Forum (IMDRF) have made progress but significant regional differences persist. Japan's Pharmaceuticals and Medical Devices Agency (PMDA) and China's National Medical Products Administration (NMPA) maintain distinct requirements for SMA devices, creating compliance complexities for global manufacturers.

Emerging applications of SMAs in active implantable medical devices face particularly complex regulatory pathways. The combination of electrical, mechanical, and material properties in these devices triggers multiple regulatory frameworks simultaneously. Software components that control SMA actuation introduce additional regulatory considerations under cybersecurity and software validation requirements.

Post-market surveillance regulations have also intensified, with requirements for long-term monitoring of SMA device performance. Manufacturers must implement robust systems for tracking device failures, material degradation, and unexpected biological responses, adding to the overall regulatory burden for bringing SMA medical technologies to market.

European regulations under the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) have introduced more stringent requirements for clinical evidence and post-market surveillance. For SMA devices, this translates to comprehensive technical documentation demonstrating biocompatibility, fatigue resistance, and long-term stability of the alloy properties under physiological conditions. The transition period from the previous Medical Device Directive (MDD) to MDR has created additional compliance challenges for existing SMA devices.

Biocompatibility testing represents a particular regulatory hurdle for SMA applications. Current standards such as ISO 10993 require extensive testing to ensure that nickel leaching from Nitinol (the most common SMA) remains below threshold levels. The variability in surface treatments and processing methods for SMAs complicates standardization of these tests, often resulting in case-by-case evaluation by regulatory bodies.

Material characterization requirements present another significant challenge. Regulatory agencies increasingly demand comprehensive data on transformation temperatures, superelastic properties, and fatigue behavior across the full range of physiological conditions. The complex thermomechanical behavior of SMAs makes standardized testing protocols difficult to establish, leading to regulatory inconsistencies across different jurisdictions.

International harmonization efforts through the International Medical Device Regulators Forum (IMDRF) have made progress but significant regional differences persist. Japan's Pharmaceuticals and Medical Devices Agency (PMDA) and China's National Medical Products Administration (NMPA) maintain distinct requirements for SMA devices, creating compliance complexities for global manufacturers.

Emerging applications of SMAs in active implantable medical devices face particularly complex regulatory pathways. The combination of electrical, mechanical, and material properties in these devices triggers multiple regulatory frameworks simultaneously. Software components that control SMA actuation introduce additional regulatory considerations under cybersecurity and software validation requirements.

Post-market surveillance regulations have also intensified, with requirements for long-term monitoring of SMA device performance. Manufacturers must implement robust systems for tracking device failures, material degradation, and unexpected biological responses, adding to the overall regulatory burden for bringing SMA medical technologies to market.

Current Compliance Strategies for SMA Medical Devices

01 Composition and manufacturing of shape memory alloys

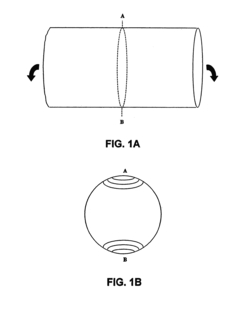

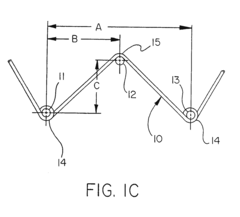

Shape memory alloys (SMAs) can be manufactured with specific compositions to achieve desired transformation temperatures and mechanical properties. These alloys typically contain nickel-titanium (Nitinol) or copper-based compositions. The manufacturing process involves precise control of melting, casting, and heat treatment to ensure proper phase transformation characteristics. Advanced processing techniques can enhance the shape memory effect and superelasticity of these materials.- Composition and manufacturing of shape memory alloys: Shape memory alloys can be manufactured with specific compositions to achieve desired properties. These alloys undergo phase transformations that enable them to return to their original shape after deformation when heated above a certain temperature. The manufacturing process involves precise control of alloying elements, heat treatment, and processing conditions to achieve the desired transformation temperatures and mechanical properties.

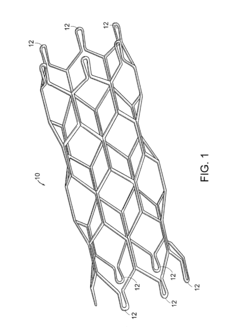

- Applications in medical devices: Shape memory alloys are widely used in medical devices due to their biocompatibility and unique mechanical properties. These alloys can be designed to activate at body temperature, making them ideal for implantable devices such as stents, orthodontic wires, and surgical instruments. The superelasticity of certain shape memory alloys allows for minimally invasive procedures where devices can be compressed for insertion and then expand to their functional shape once deployed in the body.

- Actuators and mechanical systems: Shape memory alloys are utilized as actuators in various mechanical systems due to their ability to generate significant force during shape recovery. These actuators can convert thermal energy directly into mechanical work, offering advantages such as silent operation, compact design, and high power-to-weight ratio. Applications include automotive systems, aerospace components, robotics, and consumer electronics where conventional motors or hydraulic systems may be impractical.

- Thermal processing and heat treatment techniques: Specific thermal processing and heat treatment techniques are crucial for optimizing the properties of shape memory alloys. These processes include annealing, aging, quenching, and controlled cooling, which affect the transformation temperatures, hysteresis, and fatigue life of the alloys. The microstructural changes during heat treatment determine the shape memory effect and superelastic behavior, allowing engineers to tailor the material properties for specific applications.

- Smart materials and responsive structures: Shape memory alloys are integrated into smart materials and responsive structures that can adapt to environmental changes. These materials can be designed to respond to temperature variations, stress conditions, or magnetic fields, enabling self-healing, self-adjusting, or self-regulating capabilities. Applications include smart textiles, adaptive architecture, vibration damping systems, and safety devices that automatically respond to environmental triggers.

02 Applications in medical devices and implants

Shape memory alloys are widely used in medical applications due to their biocompatibility and unique mechanical properties. These materials are employed in stents, orthodontic wires, surgical instruments, and implantable devices. The superelastic behavior allows for minimally invasive procedures, while the shape memory effect enables self-expanding implants that can be deployed at body temperature. These alloys provide excellent fatigue resistance and can withstand repeated deformation cycles in physiological environments.Expand Specific Solutions03 Actuators and mechanical systems using shape memory alloys

Shape memory alloys function as effective actuators in various mechanical systems due to their ability to generate significant force during shape recovery. These actuators can be designed for applications ranging from automotive components to aerospace mechanisms. The temperature-induced phase transformation allows for controlled movement without conventional motors or hydraulics. SMA actuators offer advantages including compact size, silent operation, and high power-to-weight ratios, making them suitable for space-constrained applications.Expand Specific Solutions04 Heat treatment and processing techniques for shape memory alloys

Heat treatment processes significantly influence the performance of shape memory alloys by controlling their microstructure and transformation characteristics. Techniques such as annealing, aging, and quenching can optimize properties like transformation temperature, hysteresis, and recovery stress. Advanced processing methods including thermomechanical treatments and grain refinement can enhance functional stability and fatigue life. Proper heat treatment is essential for achieving reliable and repeatable shape memory behavior in practical applications.Expand Specific Solutions05 Smart materials and composite systems incorporating shape memory alloys

Shape memory alloys can be integrated into composite structures and smart material systems to create adaptive and responsive components. These composites combine the shape memory effect with conventional materials to achieve unique functionalities such as self-healing, vibration damping, and structural morphing. The integration methods include embedding SMA wires or particles within polymer matrices or attaching SMA elements to structural components. These smart material systems find applications in civil engineering, aerospace structures, and consumer products.Expand Specific Solutions

Key Regulatory Bodies and Industry Players

The regulatory landscape for shape memory alloys (SMAs) in medical devices is evolving within a maturing industry characterized by stringent oversight and growing market demand. Currently valued at approximately $12-15 billion globally, the SMA medical device market is experiencing steady growth as these materials gain acceptance in cardiovascular, orthopedic, and neurological applications. Leading companies like Medtronic, Boston Scientific, Abbott Laboratories, and W.L. Gore & Associates have established strong regulatory expertise, while emerging players such as Shape Memory Medical, MedShape, and Smarter Alloys are advancing innovative applications. The regulatory framework varies significantly across regions, with FDA's 510(k) and PMA pathways in the US, MDR in Europe, and PMDA in Japan creating a complex compliance environment that influences development timelines and market entry strategies.

Boston Scientific Scimed, Inc.

Technical Solution: Boston Scientific Scimed has developed a sophisticated regulatory framework specifically tailored to their extensive portfolio of nitinol-based medical devices. Their approach integrates material science expertise with regulatory strategy, focusing on the unique challenges posed by shape memory alloys in medical applications [1]. The company has established specialized testing protocols that address the FDA's concerns regarding nickel leaching, fatigue resistance, and corrosion behavior of nitinol components, particularly for their stent platforms and structural heart devices [2]. Boston Scientific's regulatory strategy includes comprehensive documentation of the entire nitinol processing chain, from raw material sourcing through final heat treatment, addressing the FDA's increased scrutiny on manufacturing controls for SMA devices [3]. They have pioneered advanced computational modeling approaches to predict nitinol component performance under physiological conditions, which has been accepted by regulatory bodies as supporting evidence for safety and effectiveness claims. The company maintains dedicated regulatory affairs specialists focused on navigating the evolving global regulatory landscape for SMA devices, with particular expertise in addressing the heightened requirements under EU MDR for implantable devices containing nickel, including specialized clinical evaluation reports and post-market surveillance protocols specific to SMA device performance characteristics.

Strengths: Extensive experience with high-risk Class III SMA devices; sophisticated material characterization capabilities that satisfy stringent regulatory requirements; established relationships with regulatory bodies across global markets. Weaknesses: Their regulatory approach is heavily resource-intensive and creates high barriers to entry; primarily focused on cardiovascular applications with less established pathways for other therapeutic areas.

Abbott Laboratories

Technical Solution: Abbott Laboratories has implemented a multi-tiered regulatory compliance strategy for their shape memory alloy medical devices, particularly focusing on their vascular intervention portfolio. Their approach centers on a comprehensive Quality Management System that addresses the specific regulatory challenges of nitinol-based implantable devices across global markets [1]. Abbott has developed specialized verification and validation protocols for SMA components that address the FDA's concerns regarding fatigue resistance, corrosion behavior, and nickel ion release in physiological environments [2]. Their regulatory strategy includes extensive mechanical characterization of nitinol components under simulated in-vivo conditions, with particular attention to thermomechanical processing history documentation as required by both FDA and EU MDR frameworks [3]. Abbott has pioneered accelerated aging protocols specifically designed for SMA devices to demonstrate long-term stability and performance, which has been accepted by multiple regulatory bodies. The company maintains dedicated regulatory affairs teams specialized in navigating the complex and evolving requirements for SMA medical devices across different international jurisdictions, with particular expertise in addressing the heightened scrutiny applied to implantable devices containing nickel under EU MDR.

Strengths: Global regulatory expertise spanning FDA, EU MDR, and Asian markets; sophisticated quality systems specifically adapted for SMA materials; strong track record of successful regulatory submissions for high-risk SMA devices. Weaknesses: Their regulatory approach is highly resource-intensive and may not be scalable for smaller product lines; heavy focus on cardiovascular applications with less established pathways for orthopedic or neurological SMA applications.

Critical Regulatory Standards and Guidelines Analysis

Medical Devices Utilizing Modified Shape Memory Alloy

PatentInactiveUS20080058859A1

Innovation

- The development of medical devices with portions having different recovery forces by selectively altering the recovery force characteristics through techniques like direct heating, laser treatment, mechanical cycling, or ion treatment, allowing for softer or stiffer sections in specific areas to reduce trauma during deployment and interaction with tissues.

Shape memory alloy articles with improved fatigue performance and methods therefore

PatentInactiveUS20100331946A1

Innovation

- The method involves controlled pre-straining of shape memory alloy articles, specifically nitinol, to induce non-recoverable tensile strains greater than 0.20% at targeted surface regions, creating residual compressive stresses that enhance fatigue resistance, while maintaining the superelastic properties of the subsurface area, thereby improving the overall fatigue performance of medical devices.

International Harmonization of SMA Medical Device Regulations

The global landscape of medical device regulations presents significant challenges for manufacturers utilizing shape memory alloys (SMAs), as they must navigate diverse regulatory frameworks across different markets. Currently, three major regulatory systems dominate: the FDA in the United States, the EU MDR in Europe, and the PMDA in Japan. These systems, while sharing common safety and efficacy goals, differ substantially in their specific requirements, documentation processes, and approval pathways for SMA-based devices.

Recent initiatives toward international harmonization have gained momentum through organizations like the International Medical Device Regulators Forum (IMDRF), which evolved from the Global Harmonization Task Force (GHTF). The IMDRF has developed several guidance documents specifically addressing novel materials like SMAs, aiming to standardize testing protocols and risk assessment methodologies across regulatory jurisdictions.

The Medical Device Single Audit Program (MDSAP) represents another significant step toward harmonization, allowing manufacturers to undergo a single regulatory audit acceptable in multiple countries including the US, Canada, Japan, Australia, and Brazil. For SMA device manufacturers, this program reduces redundant inspections and streamlines compliance processes across these markets.

ISO 13485:2016 has emerged as a globally recognized standard for medical device quality management systems, providing a unified framework for SMA device manufacturers to demonstrate regulatory compliance across multiple markets. Similarly, the harmonization of technical standards through ISO 14155 for clinical investigations and ISO 10993 for biocompatibility testing has created more consistent evaluation criteria for SMA materials.

Despite progress, significant challenges remain in achieving full regulatory harmonization. Different regions maintain unique requirements for clinical evidence, with the EU generally demanding more extensive clinical data than the US for certain SMA applications. Post-market surveillance requirements also vary considerably, with the EU MDR implementing more stringent vigilance reporting compared to other jurisdictions.

Economic and political factors continue to influence harmonization efforts, with trade agreements sometimes accelerating regulatory alignment while protectionist policies may impede progress. The COVID-19 pandemic has both highlighted the need for harmonized emergency approval pathways and demonstrated how regulatory systems can adapt quickly when necessary.

For SMA device manufacturers, a strategic approach to navigating this evolving landscape includes developing modular technical documentation that can be adapted to different regulatory submissions and engaging early with regulatory authorities across target markets to anticipate requirements.

Recent initiatives toward international harmonization have gained momentum through organizations like the International Medical Device Regulators Forum (IMDRF), which evolved from the Global Harmonization Task Force (GHTF). The IMDRF has developed several guidance documents specifically addressing novel materials like SMAs, aiming to standardize testing protocols and risk assessment methodologies across regulatory jurisdictions.

The Medical Device Single Audit Program (MDSAP) represents another significant step toward harmonization, allowing manufacturers to undergo a single regulatory audit acceptable in multiple countries including the US, Canada, Japan, Australia, and Brazil. For SMA device manufacturers, this program reduces redundant inspections and streamlines compliance processes across these markets.

ISO 13485:2016 has emerged as a globally recognized standard for medical device quality management systems, providing a unified framework for SMA device manufacturers to demonstrate regulatory compliance across multiple markets. Similarly, the harmonization of technical standards through ISO 14155 for clinical investigations and ISO 10993 for biocompatibility testing has created more consistent evaluation criteria for SMA materials.

Despite progress, significant challenges remain in achieving full regulatory harmonization. Different regions maintain unique requirements for clinical evidence, with the EU generally demanding more extensive clinical data than the US for certain SMA applications. Post-market surveillance requirements also vary considerably, with the EU MDR implementing more stringent vigilance reporting compared to other jurisdictions.

Economic and political factors continue to influence harmonization efforts, with trade agreements sometimes accelerating regulatory alignment while protectionist policies may impede progress. The COVID-19 pandemic has both highlighted the need for harmonized emergency approval pathways and demonstrated how regulatory systems can adapt quickly when necessary.

For SMA device manufacturers, a strategic approach to navigating this evolving landscape includes developing modular technical documentation that can be adapted to different regulatory submissions and engaging early with regulatory authorities across target markets to anticipate requirements.

Risk Management and Safety Considerations for SMA Medical Devices

The implementation of Shape Memory Alloys (SMAs) in medical devices necessitates comprehensive risk management strategies to ensure patient safety and regulatory compliance. Medical device manufacturers must establish robust risk management processes aligned with ISO 14971, which provides a framework for identifying, evaluating, and controlling risks associated with medical devices throughout their lifecycle.

Risk identification for SMA-based devices requires particular attention to unique failure modes such as fatigue, corrosion, and unexpected shape recovery. These materials exhibit distinctive stress-strain behaviors and transformation characteristics that must be thoroughly understood and documented. Manufacturers should conduct Failure Mode and Effects Analysis (FMEA) specifically tailored to SMA components, considering both mechanical and thermal activation scenarios.

Biocompatibility testing represents a critical safety consideration for SMAs in medical applications. Nickel release from Nitinol, the most commonly used SMA, poses potential allergic reactions in sensitive patients. Manufacturers must conduct extensive biocompatibility testing according to ISO 10993 standards, with particular emphasis on cytotoxicity, sensitization, and long-term implantation effects.

Fatigue resistance evaluation is essential for SMA devices subjected to cyclic loading, especially for long-term implants like stents and heart valve frames. Testing protocols should simulate physiological conditions, including temperature fluctuations and mechanical stresses that might trigger phase transformations. Accelerated aging tests must be designed to predict device performance throughout its intended service life.

Manufacturing process validation plays a significant role in risk management for SMA devices. Process parameters such as heat treatment temperatures, cooling rates, and surface finishing techniques directly impact material properties and performance. Manufacturers must implement stringent quality control measures with appropriate acceptance criteria for critical characteristics like transformation temperatures and superelastic behavior.

Post-market surveillance systems should be established to monitor the real-world performance of SMA medical devices. This includes tracking adverse events, analyzing explanted devices, and conducting periodic safety reviews. The data collected should feed back into the risk management process, enabling continuous improvement of device safety and performance.

Clinical risk-benefit analysis must balance the unique advantages of SMAs against their potential risks. This analysis should consider patient populations, alternative treatments, and the severity of the medical condition being addressed. Manufacturers should document this analysis as part of their regulatory submissions and update it as new safety information becomes available.

Risk identification for SMA-based devices requires particular attention to unique failure modes such as fatigue, corrosion, and unexpected shape recovery. These materials exhibit distinctive stress-strain behaviors and transformation characteristics that must be thoroughly understood and documented. Manufacturers should conduct Failure Mode and Effects Analysis (FMEA) specifically tailored to SMA components, considering both mechanical and thermal activation scenarios.

Biocompatibility testing represents a critical safety consideration for SMAs in medical applications. Nickel release from Nitinol, the most commonly used SMA, poses potential allergic reactions in sensitive patients. Manufacturers must conduct extensive biocompatibility testing according to ISO 10993 standards, with particular emphasis on cytotoxicity, sensitization, and long-term implantation effects.

Fatigue resistance evaluation is essential for SMA devices subjected to cyclic loading, especially for long-term implants like stents and heart valve frames. Testing protocols should simulate physiological conditions, including temperature fluctuations and mechanical stresses that might trigger phase transformations. Accelerated aging tests must be designed to predict device performance throughout its intended service life.

Manufacturing process validation plays a significant role in risk management for SMA devices. Process parameters such as heat treatment temperatures, cooling rates, and surface finishing techniques directly impact material properties and performance. Manufacturers must implement stringent quality control measures with appropriate acceptance criteria for critical characteristics like transformation temperatures and superelastic behavior.

Post-market surveillance systems should be established to monitor the real-world performance of SMA medical devices. This includes tracking adverse events, analyzing explanted devices, and conducting periodic safety reviews. The data collected should feed back into the risk management process, enabling continuous improvement of device safety and performance.

Clinical risk-benefit analysis must balance the unique advantages of SMAs against their potential risks. This analysis should consider patient populations, alternative treatments, and the severity of the medical condition being addressed. Manufacturers should document this analysis as part of their regulatory submissions and update it as new safety information becomes available.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!