Shape Memory Alloys: Challenges in Qualification and Certification Processes

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SMA Technology Background and Objectives

Shape Memory Alloys (SMAs) represent a unique class of functional materials that possess the remarkable ability to recover their original shape after deformation when subjected to specific thermal or mechanical stimuli. First discovered in the 1930s with gold-cadmium alloys, SMAs gained significant attention following William Buehler's discovery of nickel-titanium (Nitinol) at the Naval Ordnance Laboratory in 1962. This discovery marked a pivotal moment in SMA development, establishing Nitinol as the most commercially viable and widely studied shape memory alloy due to its superior properties and biocompatibility.

The technological evolution of SMAs has progressed through several distinct phases. The initial discovery phase (1930s-1960s) focused on fundamental material characterization. The exploration phase (1970s-1990s) saw the first commercial applications emerge, primarily in medical devices and aerospace components. The current expansion phase (2000s-present) has witnessed diversification into numerous sectors including automotive, robotics, civil engineering, and consumer electronics, driven by advances in material processing and control mechanisms.

Despite their growing adoption, SMAs face significant challenges in qualification and certification processes that limit their broader implementation. These materials exhibit complex thermomechanical behaviors that are highly sensitive to processing conditions, composition, and operational environments. This complexity creates substantial hurdles for establishing standardized testing protocols and certification frameworks necessary for critical applications.

The primary technical objective in this domain is to develop robust, universally accepted qualification and certification methodologies that can accurately predict and validate SMA performance across diverse application environments. This includes establishing standardized testing procedures, defining performance metrics, and creating comprehensive material databases that capture the unique properties of various SMA compositions under different conditions.

Current research trends focus on advanced characterization techniques, computational modeling approaches, and accelerated testing methodologies to address these challenges. The integration of digital twins and machine learning algorithms represents a promising direction for predicting long-term material behavior and reliability, potentially streamlining certification processes.

The global market for SMAs is projected to reach $20 billion by 2025, with a compound annual growth rate exceeding 12%. This growth trajectory underscores the urgent need for streamlined qualification and certification processes to facilitate broader industrial adoption and unlock the full potential of these remarkable materials across emerging application domains.

The technological evolution of SMAs has progressed through several distinct phases. The initial discovery phase (1930s-1960s) focused on fundamental material characterization. The exploration phase (1970s-1990s) saw the first commercial applications emerge, primarily in medical devices and aerospace components. The current expansion phase (2000s-present) has witnessed diversification into numerous sectors including automotive, robotics, civil engineering, and consumer electronics, driven by advances in material processing and control mechanisms.

Despite their growing adoption, SMAs face significant challenges in qualification and certification processes that limit their broader implementation. These materials exhibit complex thermomechanical behaviors that are highly sensitive to processing conditions, composition, and operational environments. This complexity creates substantial hurdles for establishing standardized testing protocols and certification frameworks necessary for critical applications.

The primary technical objective in this domain is to develop robust, universally accepted qualification and certification methodologies that can accurately predict and validate SMA performance across diverse application environments. This includes establishing standardized testing procedures, defining performance metrics, and creating comprehensive material databases that capture the unique properties of various SMA compositions under different conditions.

Current research trends focus on advanced characterization techniques, computational modeling approaches, and accelerated testing methodologies to address these challenges. The integration of digital twins and machine learning algorithms represents a promising direction for predicting long-term material behavior and reliability, potentially streamlining certification processes.

The global market for SMAs is projected to reach $20 billion by 2025, with a compound annual growth rate exceeding 12%. This growth trajectory underscores the urgent need for streamlined qualification and certification processes to facilitate broader industrial adoption and unlock the full potential of these remarkable materials across emerging application domains.

Market Demand Analysis for SMA Applications

The global market for Shape Memory Alloys (SMAs) has been experiencing steady growth, driven primarily by increasing applications in medical devices, aerospace, automotive, and consumer electronics sectors. The market size was valued at approximately $10.5 billion in 2022 and is projected to reach $18.7 billion by 2028, representing a compound annual growth rate (CAGR) of 10.1% during the forecast period.

In the medical sector, which accounts for nearly 60% of the total SMA market, demand is particularly strong for minimally invasive surgical devices, orthodontic appliances, and cardiovascular stents. The aging global population and increasing prevalence of chronic diseases are key factors driving this demand. Hospitals and medical device manufacturers are increasingly seeking SMA-based solutions that can reduce patient recovery time and improve treatment outcomes.

The aerospace industry represents the second-largest market for SMAs, with applications in aircraft structural components, vibration damping systems, and deployable structures. Major aerospace manufacturers are investing heavily in SMA research to develop lighter, more fuel-efficient aircraft. Market analysis indicates that SMA adoption in aerospace could reduce aircraft weight by up to 15%, translating to significant fuel savings and reduced emissions.

Consumer electronics manufacturers are also showing growing interest in SMAs for applications such as actuators in smartphones, cameras, and wearable devices. The miniaturization trend in electronics has created demand for compact actuation mechanisms that SMAs can uniquely provide. Industry forecasts suggest that this segment could grow at a CAGR of 12.5% over the next five years.

Despite this promising market outlook, significant barriers to widespread adoption remain. The qualification and certification processes for SMAs are complex and time-consuming, often taking 3-5 years for aerospace applications and 2-3 years for medical devices. This extended timeline creates market entry barriers and slows innovation cycles. A survey of industry stakeholders revealed that 78% consider certification challenges as the primary obstacle to broader SMA implementation.

Regional analysis shows North America leading the market with a 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth due to increasing industrialization, healthcare infrastructure development, and government initiatives supporting advanced materials research in countries like China, Japan, and South Korea.

The market is also witnessing a shift toward customized SMA solutions tailored to specific application requirements. This trend is creating opportunities for specialized material suppliers and engineering firms that can provide application-specific SMA formulations and processing techniques.

In the medical sector, which accounts for nearly 60% of the total SMA market, demand is particularly strong for minimally invasive surgical devices, orthodontic appliances, and cardiovascular stents. The aging global population and increasing prevalence of chronic diseases are key factors driving this demand. Hospitals and medical device manufacturers are increasingly seeking SMA-based solutions that can reduce patient recovery time and improve treatment outcomes.

The aerospace industry represents the second-largest market for SMAs, with applications in aircraft structural components, vibration damping systems, and deployable structures. Major aerospace manufacturers are investing heavily in SMA research to develop lighter, more fuel-efficient aircraft. Market analysis indicates that SMA adoption in aerospace could reduce aircraft weight by up to 15%, translating to significant fuel savings and reduced emissions.

Consumer electronics manufacturers are also showing growing interest in SMAs for applications such as actuators in smartphones, cameras, and wearable devices. The miniaturization trend in electronics has created demand for compact actuation mechanisms that SMAs can uniquely provide. Industry forecasts suggest that this segment could grow at a CAGR of 12.5% over the next five years.

Despite this promising market outlook, significant barriers to widespread adoption remain. The qualification and certification processes for SMAs are complex and time-consuming, often taking 3-5 years for aerospace applications and 2-3 years for medical devices. This extended timeline creates market entry barriers and slows innovation cycles. A survey of industry stakeholders revealed that 78% consider certification challenges as the primary obstacle to broader SMA implementation.

Regional analysis shows North America leading the market with a 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth due to increasing industrialization, healthcare infrastructure development, and government initiatives supporting advanced materials research in countries like China, Japan, and South Korea.

The market is also witnessing a shift toward customized SMA solutions tailored to specific application requirements. This trend is creating opportunities for specialized material suppliers and engineering firms that can provide application-specific SMA formulations and processing techniques.

Current Qualification Challenges and Limitations

The qualification and certification of Shape Memory Alloys (SMAs) face significant challenges that impede their broader industrial adoption. Current standardization frameworks remain inadequate for these unique materials, with most existing standards developed for conventional alloys failing to address the distinctive thermomechanical properties of SMAs. This creates a regulatory gap where certification bodies lack clear guidelines for evaluating SMA components, particularly for critical applications in aerospace and medical sectors.

Testing methodologies present another major limitation. Traditional mechanical testing protocols do not adequately capture the superelastic behavior and shape memory effects that define SMAs. The complex phase transformation mechanisms require specialized testing equipment and procedures that many certification laboratories are not equipped to perform. Furthermore, the cyclic loading response and fatigue characteristics of SMAs differ substantially from conventional materials, necessitating new test standards that can reliably predict long-term performance.

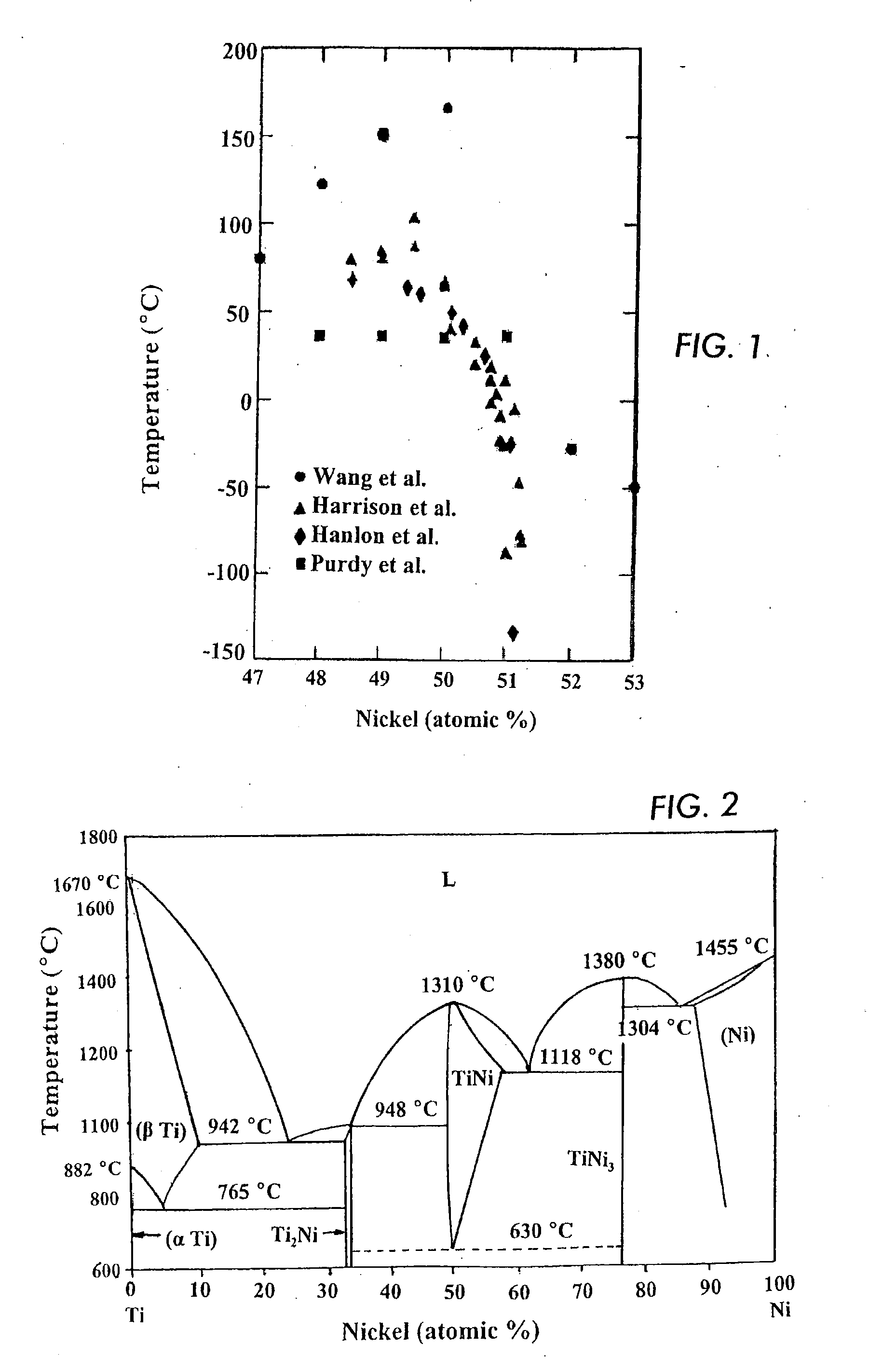

Material consistency poses a significant challenge in qualification processes. The functional properties of SMAs are highly sensitive to minor variations in composition and processing conditions. Even small deviations in nickel content in Nitinol, for example, can dramatically alter transformation temperatures and mechanical response. This sensitivity makes it difficult to establish acceptable tolerance ranges for material specifications and creates challenges for quality control in manufacturing.

The application-specific nature of SMA certification further complicates qualification efforts. Medical device applications require biocompatibility testing and long-term implantation studies, while aerospace applications demand certification under extreme environmental conditions. This diversity of requirements prevents the development of universal qualification protocols, forcing case-by-case certification approaches that increase costs and development timelines.

Accelerated aging and lifetime prediction represent perhaps the most significant technical barrier. Unlike conventional materials where established models can predict service life, the complex degradation mechanisms of SMAs—including functional fatigue, microstructural evolution during cycling, and potential hydrogen embrittlement—are not fully understood. Current qualification processes lack validated methods to extrapolate short-term test results to predict decades of in-service performance, creating uncertainty for end-users and regulatory bodies alike.

Computational modeling capabilities also remain limited for qualification purposes. While finite element models have advanced significantly, they still struggle to accurately capture the non-linear behavior of SMAs across their full operating range. This gap between simulation and physical testing creates additional verification requirements, further extending the qualification timeline and increasing associated costs.

Testing methodologies present another major limitation. Traditional mechanical testing protocols do not adequately capture the superelastic behavior and shape memory effects that define SMAs. The complex phase transformation mechanisms require specialized testing equipment and procedures that many certification laboratories are not equipped to perform. Furthermore, the cyclic loading response and fatigue characteristics of SMAs differ substantially from conventional materials, necessitating new test standards that can reliably predict long-term performance.

Material consistency poses a significant challenge in qualification processes. The functional properties of SMAs are highly sensitive to minor variations in composition and processing conditions. Even small deviations in nickel content in Nitinol, for example, can dramatically alter transformation temperatures and mechanical response. This sensitivity makes it difficult to establish acceptable tolerance ranges for material specifications and creates challenges for quality control in manufacturing.

The application-specific nature of SMA certification further complicates qualification efforts. Medical device applications require biocompatibility testing and long-term implantation studies, while aerospace applications demand certification under extreme environmental conditions. This diversity of requirements prevents the development of universal qualification protocols, forcing case-by-case certification approaches that increase costs and development timelines.

Accelerated aging and lifetime prediction represent perhaps the most significant technical barrier. Unlike conventional materials where established models can predict service life, the complex degradation mechanisms of SMAs—including functional fatigue, microstructural evolution during cycling, and potential hydrogen embrittlement—are not fully understood. Current qualification processes lack validated methods to extrapolate short-term test results to predict decades of in-service performance, creating uncertainty for end-users and regulatory bodies alike.

Computational modeling capabilities also remain limited for qualification purposes. While finite element models have advanced significantly, they still struggle to accurately capture the non-linear behavior of SMAs across their full operating range. This gap between simulation and physical testing creates additional verification requirements, further extending the qualification timeline and increasing associated costs.

Current Qualification and Testing Methodologies

01 Testing and certification methods for shape memory alloys

Various testing and certification methods are employed to validate the properties and performance of shape memory alloys. These methods include mechanical testing, thermal cycling tests, and fatigue resistance evaluations to ensure the alloys meet specific industry standards. The certification process often involves documenting the alloy's transformation temperatures, mechanical strength, and shape recovery capabilities under different conditions.- Testing and certification methods for shape memory alloys: Various testing and certification methods are employed to validate the properties and performance of shape memory alloys. These methods include mechanical testing, thermal cycling tests, and fatigue resistance evaluations to ensure the alloys meet specific industry standards. The certification process typically involves documenting the alloy's transformation temperatures, mechanical strength, and shape recovery capabilities under different conditions.

- Manufacturing processes and quality control for shape memory alloys: Manufacturing processes for shape memory alloys require strict quality control measures to ensure consistent performance. These processes include precise heat treatment protocols, composition control, and surface finishing techniques that directly impact the functional properties of the alloys. Quality control systems monitor key parameters throughout production to verify that the alloys will exhibit reliable shape memory effects and superelasticity in their intended applications.

- Standards and specifications for aerospace and medical applications: Shape memory alloys used in aerospace and medical applications must meet rigorous standards and specifications due to the critical nature of these fields. These standards address biocompatibility, corrosion resistance, fatigue life, and reliability under extreme conditions. Certification for these applications typically involves extensive documentation, traceability of materials, and compliance with regulatory frameworks such as those established by aviation authorities and medical device regulations.

- Characterization techniques for shape memory properties: Advanced characterization techniques are essential for qualifying shape memory alloys and verifying their transformation behavior. These techniques include differential scanning calorimetry to determine transformation temperatures, X-ray diffraction for crystallographic analysis, and in-situ mechanical testing to observe phase transformations. Electron microscopy and spectroscopic methods are also employed to analyze microstructure and composition, which are critical factors affecting the shape memory effect and superelastic behavior.

- Security and authentication applications of certified shape memory alloys: Shape memory alloys are increasingly being used in security and authentication applications, requiring specialized certification processes. These applications leverage the unique properties of shape memory alloys to create tamper-evident seals, secure fasteners, and authentication devices that respond to specific thermal or mechanical triggers. Certification for these applications focuses on the repeatability of the shape memory effect, resistance to counterfeiting, and long-term stability under various environmental conditions.

02 Manufacturing processes and quality control for shape memory alloys

Manufacturing processes for shape memory alloys require strict quality control measures to ensure consistent performance. These processes include precise heat treatment protocols, composition control, and surface finishing techniques that significantly impact the functional properties of the alloys. Quality control systems monitor key parameters throughout production to maintain the specific transformation characteristics and mechanical properties required for certification.Expand Specific Solutions03 Standards and specifications for aerospace and medical applications

Shape memory alloys used in aerospace and medical applications must meet rigorous standards and specifications due to the critical nature of these fields. Certification requirements include biocompatibility testing for medical implants, corrosion resistance verification, and performance validation under extreme environmental conditions for aerospace components. These standards ensure reliability and safety in high-stakes applications where material failure could have severe consequences.Expand Specific Solutions04 Characterization techniques for shape memory properties

Advanced characterization techniques are essential for qualifying shape memory alloys by accurately measuring their unique properties. These techniques include differential scanning calorimetry to determine transformation temperatures, X-ray diffraction for crystallographic analysis, and specialized mechanical testing to evaluate superelasticity and shape memory effect. The data collected through these characterization methods forms the foundation of certification documentation and helps predict the alloy's behavior in actual applications.Expand Specific Solutions05 Qualification protocols for specific industrial applications

Different industrial applications require specialized qualification protocols tailored to the specific operating conditions and performance requirements of shape memory alloys. These protocols may include cyclic loading tests, environmental exposure assessments, and accelerated aging studies to predict long-term reliability. Certification for automotive, civil engineering, and consumer electronics applications often involves demonstrating consistent performance across production batches and validating the alloy's response to the unique stresses encountered in each field.Expand Specific Solutions

Key Industry Players and Certification Bodies

Shape Memory Alloys (SMAs) are currently in a growth phase, with the global market expected to reach $20 billion by 2025, expanding at a CAGR of approximately 12%. The technology maturity varies across applications, with medical devices representing the most mature sector. Key industry players demonstrate different specialization levels: SAES Getters leads in getter technology integration with SMAs, while Honda Motor and Boeing have advanced aerospace and automotive applications. Research institutions like National Institute for Materials Science and Lawrence Livermore National Security are driving fundamental innovations. Cambridge Mechatronics and QinetiQ focus on mechatronic applications, while Nippon Steel and thyssenkrupp are developing industrial-scale manufacturing processes. The qualification and certification challenges remain significant barriers to wider adoption, particularly in safety-critical applications.

SAES Getters SpA

Technical Solution: SAES Getters has developed a comprehensive qualification framework for shape memory alloys (SMAs) that addresses the unique challenges in certification processes. Their approach includes standardized testing protocols for thermomechanical fatigue, which is critical for SMA applications. The company has pioneered a three-tier qualification system that evaluates material properties, component performance, and system integration aspects separately[1]. Their NiTiNOL-based alloys undergo rigorous characterization using differential scanning calorimetry and dynamic mechanical analysis to establish transformation temperatures and mechanical properties with statistical significance[3]. SAES has also developed specialized accelerated aging protocols that simulate decades of operational cycles within compressed timeframes, allowing for more efficient certification processes while maintaining reliability standards required for aerospace and medical applications.

Strengths: Industry-leading expertise in high-purity SMA production with exceptional batch-to-batch consistency; established relationships with certification bodies that streamline approval processes. Weaknesses: Their qualification protocols are often proprietary and expensive, potentially limiting accessibility for smaller manufacturers; certification processes are optimized for medical and aerospace applications but may require adaptation for emerging sectors.

United States Army

Technical Solution: The United States Army has established a comprehensive qualification framework for shape memory alloys intended for military applications, with particular emphasis on durability under extreme conditions. Their approach integrates traditional metallurgical testing with battlefield-relevant environmental exposures to ensure SMA components maintain functionality in combat scenarios. The Army's certification protocol includes ballistic impact resistance testing, chemical warfare agent exposure evaluation, and electromagnetic interference assessment - factors not typically addressed in commercial certification processes[5]. Their qualification methodology employs accelerated aging in desert, arctic, and high-humidity environments to validate long-term performance across global deployment scenarios. The Army Research Laboratory has developed specialized non-destructive evaluation techniques using acoustic emission and infrared thermography to detect microstructural changes in SMAs that might compromise performance before mechanical failure occurs[6]. This approach allows for more accurate prediction of service life and establishes clearer recertification intervals for critical components.

Strengths: Unparalleled testing capabilities for extreme environmental conditions; established protocols for qualifying materials for mission-critical applications where failure is not an option. Weaknesses: Certification processes are often classified or restricted, limiting knowledge transfer to commercial applications; qualification requirements frequently exceed commercial necessity, potentially increasing costs unnecessarily for non-military applications.

Critical Standards and Certification Protocols

Shape memory device having two-way cyclical shape memory effect due to compositional gradient and method of manufacture

PatentInactiveUS20060289295A1

Innovation

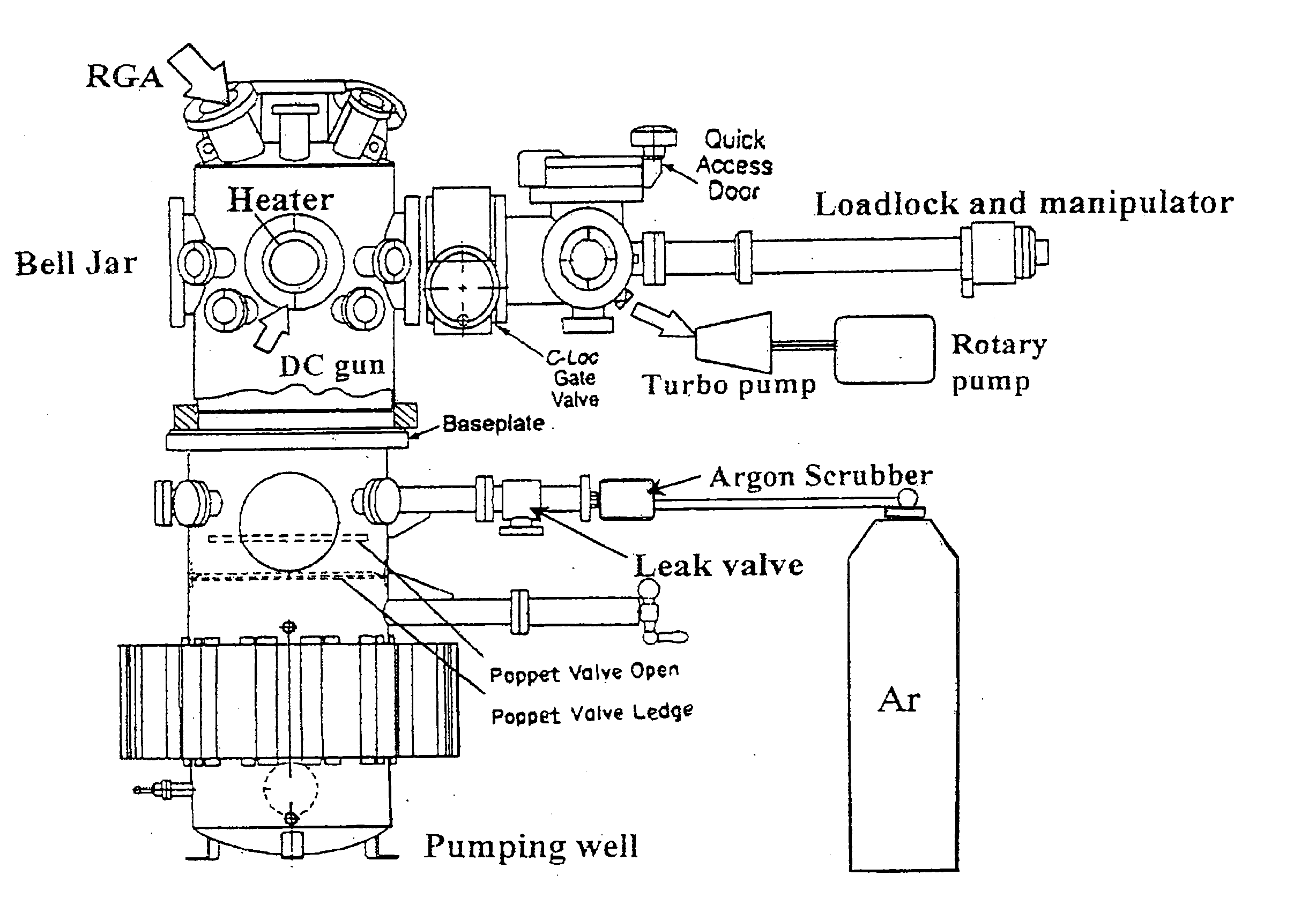

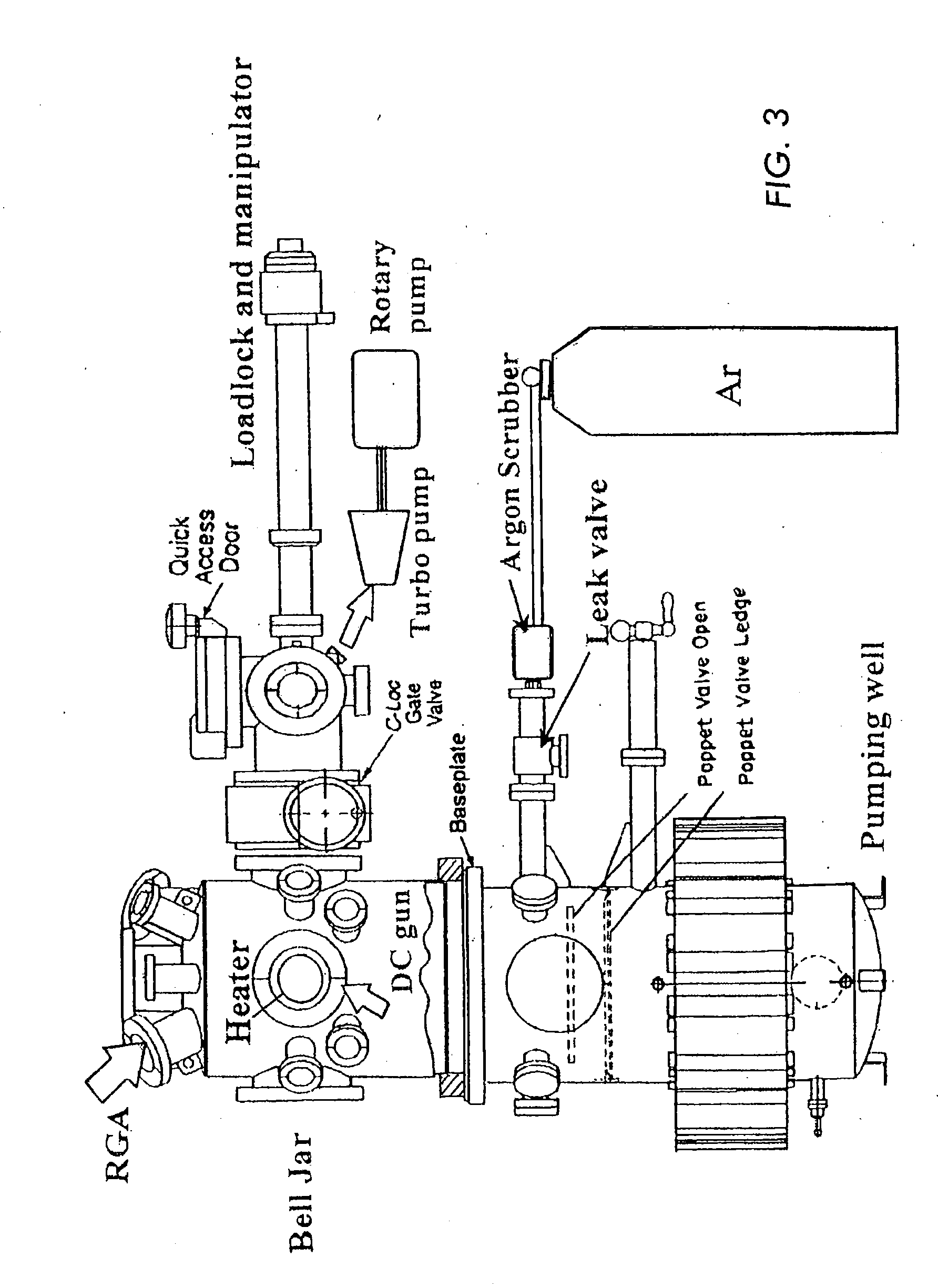

- The use of binary, ternary, and higher-order alloys such as Au:Cd, Fe:Mn:Si, Cu:Zn:Al, and Cu:Ni:Al allows for the production of shape memory films that can exhibit a two-way shape memory effect at higher vacuum pressures, reducing reactivity with contaminants and enabling the deposition of thicker films with compositional gradients, thus eliminating the need for external biasing and simplifying the manufacturing process.

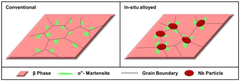

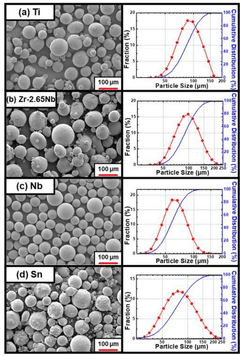

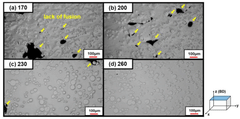

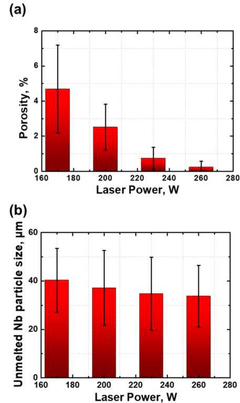

Shape memory alloy using laser-based additive manufacturing process and method for preparing thereof

PatentActiveKR1020230139065A

Innovation

- A laser-based additive manufacturing process is used to disperse inclusions in a metal mixed powder, inducing phase transformations at specific locations to create a non-toxic shape memory alloy with improved ductility and tensile strength, utilizing a composition of titanium, zirconium, tin, and niobium, and incorporating unmelted niobium powder to enhance mechanical properties.

International Regulatory Framework for SMAs

The international regulatory landscape for Shape Memory Alloys (SMAs) presents a complex framework that varies significantly across regions and application domains. Currently, there is no unified global standard specifically dedicated to SMAs, which creates challenges for manufacturers and end-users seeking to implement these advanced materials in regulated industries.

In the medical device sector, the U.S. Food and Drug Administration (FDA) has established specific guidelines for nitinol-based implantable devices, requiring extensive biocompatibility testing, fatigue resistance evaluation, and corrosion resistance assessment. The FDA's guidance document "Technical Considerations for Non-Traditional Device Materials" addresses SMAs among other novel materials, emphasizing the need for comprehensive characterization of transformation temperatures and mechanical properties.

The European Union, through its Medical Device Regulation (MDR) and the harmonized standards system, imposes stringent requirements for SMA-based medical devices. Manufacturers must demonstrate compliance with ISO 14971 for risk management and ISO 10993 series for biocompatibility, with additional emphasis on the unique properties of SMAs such as superelasticity and shape memory effect.

In aerospace applications, the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have developed certification protocols for SMA components in non-critical applications. However, for critical structural applications, the regulatory pathway remains challenging due to the lack of established certification standards specifically addressing the unique fatigue and degradation mechanisms of SMAs.

The automotive industry faces similar regulatory challenges, with varying requirements across different markets. While Japan's automotive standards organization has developed preliminary guidelines for SMA actuators in vehicles, most regions rely on general material qualification standards that may not adequately address the unique characteristics of SMAs.

International standards organizations have begun addressing this gap, with ASTM International developing ASTM F2063 for wrought nickel-titanium shape memory alloys for medical applications and ISO/TC 261 working on standards for additive manufacturing of SMA components. However, these efforts remain fragmented and application-specific rather than providing a comprehensive regulatory framework.

The lack of harmonized international standards creates significant barriers to market entry for SMA-based innovations, particularly in highly regulated sectors. Companies must navigate different regulatory requirements across regions, often conducting redundant testing to satisfy various authorities, which increases development costs and time-to-market.

In the medical device sector, the U.S. Food and Drug Administration (FDA) has established specific guidelines for nitinol-based implantable devices, requiring extensive biocompatibility testing, fatigue resistance evaluation, and corrosion resistance assessment. The FDA's guidance document "Technical Considerations for Non-Traditional Device Materials" addresses SMAs among other novel materials, emphasizing the need for comprehensive characterization of transformation temperatures and mechanical properties.

The European Union, through its Medical Device Regulation (MDR) and the harmonized standards system, imposes stringent requirements for SMA-based medical devices. Manufacturers must demonstrate compliance with ISO 14971 for risk management and ISO 10993 series for biocompatibility, with additional emphasis on the unique properties of SMAs such as superelasticity and shape memory effect.

In aerospace applications, the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have developed certification protocols for SMA components in non-critical applications. However, for critical structural applications, the regulatory pathway remains challenging due to the lack of established certification standards specifically addressing the unique fatigue and degradation mechanisms of SMAs.

The automotive industry faces similar regulatory challenges, with varying requirements across different markets. While Japan's automotive standards organization has developed preliminary guidelines for SMA actuators in vehicles, most regions rely on general material qualification standards that may not adequately address the unique characteristics of SMAs.

International standards organizations have begun addressing this gap, with ASTM International developing ASTM F2063 for wrought nickel-titanium shape memory alloys for medical applications and ISO/TC 261 working on standards for additive manufacturing of SMA components. However, these efforts remain fragmented and application-specific rather than providing a comprehensive regulatory framework.

The lack of harmonized international standards creates significant barriers to market entry for SMA-based innovations, particularly in highly regulated sectors. Companies must navigate different regulatory requirements across regions, often conducting redundant testing to satisfy various authorities, which increases development costs and time-to-market.

Risk Assessment Strategies for SMA Implementation

Implementing Shape Memory Alloys (SMAs) in critical applications necessitates comprehensive risk assessment strategies to ensure safety, reliability, and regulatory compliance. The qualification and certification processes for SMAs present unique challenges due to their complex thermomechanical behavior and sensitivity to processing conditions.

A systematic risk assessment framework begins with hazard identification specific to SMA applications. This includes potential failure modes such as functional fatigue, structural fatigue, overheating, unexpected phase transformations, and environmental degradation. Each identified hazard must be categorized according to severity and likelihood, creating a prioritized risk matrix tailored to the intended application environment.

Probabilistic risk assessment (PRA) methodologies offer particular value for SMA implementation. These approaches incorporate uncertainty quantification to account for the variable performance characteristics of SMAs across different batches and processing conditions. Monte Carlo simulations and Bayesian networks can model the propagation of uncertainties through the system, providing statistical confidence levels for certification decisions.

Accelerated life testing protocols represent another critical component of SMA risk assessment. These must be carefully designed to capture the unique degradation mechanisms of shape memory materials, including functional fatigue during cyclic actuation and microstructural changes during extended service. Correlation between accelerated test results and real-world performance requires validation through field data collection and analysis.

Digital twin modeling emerges as an advanced risk mitigation strategy for SMA components. By creating virtual representations that simulate the thermomechanical behavior of specific SMA implementations, engineers can predict performance under various operating conditions and identify potential failure scenarios before physical deployment. These models must incorporate material constitutive laws that accurately capture the superelastic and shape memory effects.

Failure Mode and Effects Analysis (FMEA) tailored to SMA characteristics provides a structured approach to risk evaluation. This includes consideration of unique SMA failure modes such as transformation temperature drift, incomplete shape recovery, and stress relaxation during constrained recovery. Critical Process Parameters (CPPs) must be identified and monitored throughout manufacturing to ensure consistent material properties.

Regulatory pathway mapping constitutes the final element of effective risk assessment. This involves early engagement with certification authorities to establish acceptable evidence requirements for novel SMA applications. Creating a qualification roadmap that addresses material characterization, component testing, system integration validation, and long-term reliability demonstration helps navigate the complex certification landscape for these advanced materials.

A systematic risk assessment framework begins with hazard identification specific to SMA applications. This includes potential failure modes such as functional fatigue, structural fatigue, overheating, unexpected phase transformations, and environmental degradation. Each identified hazard must be categorized according to severity and likelihood, creating a prioritized risk matrix tailored to the intended application environment.

Probabilistic risk assessment (PRA) methodologies offer particular value for SMA implementation. These approaches incorporate uncertainty quantification to account for the variable performance characteristics of SMAs across different batches and processing conditions. Monte Carlo simulations and Bayesian networks can model the propagation of uncertainties through the system, providing statistical confidence levels for certification decisions.

Accelerated life testing protocols represent another critical component of SMA risk assessment. These must be carefully designed to capture the unique degradation mechanisms of shape memory materials, including functional fatigue during cyclic actuation and microstructural changes during extended service. Correlation between accelerated test results and real-world performance requires validation through field data collection and analysis.

Digital twin modeling emerges as an advanced risk mitigation strategy for SMA components. By creating virtual representations that simulate the thermomechanical behavior of specific SMA implementations, engineers can predict performance under various operating conditions and identify potential failure scenarios before physical deployment. These models must incorporate material constitutive laws that accurately capture the superelastic and shape memory effects.

Failure Mode and Effects Analysis (FMEA) tailored to SMA characteristics provides a structured approach to risk evaluation. This includes consideration of unique SMA failure modes such as transformation temperature drift, incomplete shape recovery, and stress relaxation during constrained recovery. Critical Process Parameters (CPPs) must be identified and monitored throughout manufacturing to ensure consistent material properties.

Regulatory pathway mapping constitutes the final element of effective risk assessment. This involves early engagement with certification authorities to establish acceptable evidence requirements for novel SMA applications. Creating a qualification roadmap that addresses material characterization, component testing, system integration validation, and long-term reliability demonstration helps navigate the complex certification landscape for these advanced materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!