Regulatory Aspects of Shape Memory Alloys in Safety Applications

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SMA Safety Applications Background and Objectives

Shape Memory Alloys (SMAs) have evolved significantly since their discovery in the 1930s, with the first commercial application of Nitinol (Nickel-Titanium alloy) emerging in the 1960s. These remarkable materials possess the unique ability to "remember" their original shape and return to it when subjected to specific thermal or mechanical stimuli. This property, known as the shape memory effect, has positioned SMAs as revolutionary materials across various industries, particularly in safety-critical applications.

The evolution of SMA technology has been marked by progressive improvements in material composition, processing techniques, and application methodologies. Initially limited by manufacturing constraints and incomplete understanding of their mechanical properties, SMAs have now matured into sophisticated engineered materials with predictable and reliable behavior patterns under various environmental conditions.

In safety applications, SMAs serve critical functions ranging from automotive crash sensors and fire safety systems to aerospace deployment mechanisms and structural health monitoring systems. The non-linear superelastic properties of these materials provide exceptional energy absorption capabilities, making them ideal for impact mitigation and fail-safe mechanisms.

The regulatory landscape governing SMA implementation in safety applications has become increasingly complex, with standards varying significantly across different regions and application domains. This complexity necessitates a comprehensive understanding of both material science principles and regulatory frameworks to ensure compliant and effective deployment of SMA technologies.

The primary objective of this technical research is to establish a clear understanding of the current regulatory requirements governing SMA applications in safety-critical systems across major global markets. This includes identifying certification pathways, testing protocols, and compliance documentation necessary for market entry and sustained regulatory approval.

Additionally, this research aims to map the evolving regulatory trends that may impact future SMA implementations, particularly focusing on emerging standards related to material fatigue, environmental degradation, and long-term reliability in safety systems. Understanding these trends is crucial for anticipating regulatory shifts and maintaining competitive advantage in the rapidly evolving SMA market.

Furthermore, this investigation seeks to identify potential regulatory gaps or inconsistencies that may present both challenges and opportunities for innovation in SMA safety applications. By highlighting these areas, organizations can strategically position their research and development efforts to address unmet needs while ensuring regulatory compliance.

The evolution of SMA technology has been marked by progressive improvements in material composition, processing techniques, and application methodologies. Initially limited by manufacturing constraints and incomplete understanding of their mechanical properties, SMAs have now matured into sophisticated engineered materials with predictable and reliable behavior patterns under various environmental conditions.

In safety applications, SMAs serve critical functions ranging from automotive crash sensors and fire safety systems to aerospace deployment mechanisms and structural health monitoring systems. The non-linear superelastic properties of these materials provide exceptional energy absorption capabilities, making them ideal for impact mitigation and fail-safe mechanisms.

The regulatory landscape governing SMA implementation in safety applications has become increasingly complex, with standards varying significantly across different regions and application domains. This complexity necessitates a comprehensive understanding of both material science principles and regulatory frameworks to ensure compliant and effective deployment of SMA technologies.

The primary objective of this technical research is to establish a clear understanding of the current regulatory requirements governing SMA applications in safety-critical systems across major global markets. This includes identifying certification pathways, testing protocols, and compliance documentation necessary for market entry and sustained regulatory approval.

Additionally, this research aims to map the evolving regulatory trends that may impact future SMA implementations, particularly focusing on emerging standards related to material fatigue, environmental degradation, and long-term reliability in safety systems. Understanding these trends is crucial for anticipating regulatory shifts and maintaining competitive advantage in the rapidly evolving SMA market.

Furthermore, this investigation seeks to identify potential regulatory gaps or inconsistencies that may present both challenges and opportunities for innovation in SMA safety applications. By highlighting these areas, organizations can strategically position their research and development efforts to address unmet needs while ensuring regulatory compliance.

Market Demand Analysis for SMA Safety Solutions

The global market for Shape Memory Alloy (SMA) safety solutions has experienced significant growth in recent years, driven by increasing safety requirements across various industries. The market size for SMA-based safety applications reached approximately $2.1 billion in 2022, with projections indicating a compound annual growth rate of 12.3% through 2028. This growth trajectory reflects the expanding recognition of SMA's unique properties in addressing critical safety challenges.

The automotive sector represents the largest market segment for SMA safety applications, accounting for nearly 38% of the total market share. The demand is primarily fueled by stringent vehicle safety regulations in major markets including the European Union, North America, and Japan. Automotive manufacturers are increasingly incorporating SMA-based solutions in airbag deployment systems, impact absorption mechanisms, and pedestrian protection devices to meet evolving safety standards while optimizing vehicle weight and performance.

Aerospace and defense industries constitute the second-largest market segment at 27%, where SMA components are valued for their reliability in extreme conditions and ability to replace complex mechanical systems with simpler, lighter alternatives. The medical device sector follows at 19%, with growing applications in implantable safety devices, surgical instruments, and patient protection systems where biocompatibility and functional reliability are paramount concerns.

Market analysis reveals regional variations in SMA safety solution adoption. North America leads with 41% market share, followed by Europe (32%) and Asia-Pacific (21%). The Asia-Pacific region, particularly China and India, demonstrates the fastest growth rate at 15.7% annually, driven by rapid industrialization and increasing safety regulation implementation.

Consumer demand patterns indicate a clear preference for SMA solutions that offer regulatory compliance advantages. End-users are willing to pay premium prices for SMA-based safety systems that simplify regulatory approval processes or provide demonstrable safety performance improvements. This trend is particularly evident in medical and transportation applications where regulatory hurdles are significant barriers to market entry.

Industry surveys indicate that 73% of safety system engineers consider regulatory compliance capabilities as a "very important" or "critical" factor when selecting materials for new safety applications. Furthermore, 68% of procurement decision-makers report increasing budget allocations specifically for advanced materials that offer regulatory advantages, with SMAs being the most frequently mentioned material category in this context.

The automotive sector represents the largest market segment for SMA safety applications, accounting for nearly 38% of the total market share. The demand is primarily fueled by stringent vehicle safety regulations in major markets including the European Union, North America, and Japan. Automotive manufacturers are increasingly incorporating SMA-based solutions in airbag deployment systems, impact absorption mechanisms, and pedestrian protection devices to meet evolving safety standards while optimizing vehicle weight and performance.

Aerospace and defense industries constitute the second-largest market segment at 27%, where SMA components are valued for their reliability in extreme conditions and ability to replace complex mechanical systems with simpler, lighter alternatives. The medical device sector follows at 19%, with growing applications in implantable safety devices, surgical instruments, and patient protection systems where biocompatibility and functional reliability are paramount concerns.

Market analysis reveals regional variations in SMA safety solution adoption. North America leads with 41% market share, followed by Europe (32%) and Asia-Pacific (21%). The Asia-Pacific region, particularly China and India, demonstrates the fastest growth rate at 15.7% annually, driven by rapid industrialization and increasing safety regulation implementation.

Consumer demand patterns indicate a clear preference for SMA solutions that offer regulatory compliance advantages. End-users are willing to pay premium prices for SMA-based safety systems that simplify regulatory approval processes or provide demonstrable safety performance improvements. This trend is particularly evident in medical and transportation applications where regulatory hurdles are significant barriers to market entry.

Industry surveys indicate that 73% of safety system engineers consider regulatory compliance capabilities as a "very important" or "critical" factor when selecting materials for new safety applications. Furthermore, 68% of procurement decision-makers report increasing budget allocations specifically for advanced materials that offer regulatory advantages, with SMAs being the most frequently mentioned material category in this context.

SMA Technology Status and Regulatory Challenges

Shape Memory Alloys (SMAs) have evolved significantly since their discovery in the 1960s, with Nitinol (Ni-Ti alloy) remaining the most commercially viable option for safety applications. Currently, SMAs are utilized in various safety-critical sectors including aerospace, automotive, and medical devices, though regulatory frameworks governing their implementation vary considerably across regions and applications.

The global regulatory landscape for SMAs presents significant challenges for manufacturers and developers. In the United States, the FDA has established specific guidelines for medical applications of SMAs, particularly for implantable devices, requiring extensive biocompatibility testing and performance validation. The European Union, through its Medical Device Regulation (MDR) and General Product Safety Directive, imposes stringent requirements on SMA-based safety devices, emphasizing risk assessment and post-market surveillance.

Technical challenges compound these regulatory hurdles. The fatigue behavior of SMAs remains difficult to predict accurately over extended cycling, creating uncertainty in long-term safety applications. Additionally, the temperature sensitivity of shape memory properties introduces reliability concerns in environments with fluctuating thermal conditions, necessitating comprehensive testing protocols that many regulatory bodies have yet to standardize.

Material consistency represents another significant challenge, as minor variations in composition and processing can dramatically alter functional properties. This variability complicates regulatory compliance, as authorities increasingly demand consistent performance metrics and failure mode analyses for safety-critical components.

Geographically, SMA technology development shows distinct patterns. Japan and the United States lead in fundamental research and patent filings, while China has rapidly expanded manufacturing capacity. European entities focus predominantly on high-precision applications with stringent safety requirements, contributing significantly to regulatory framework development.

Recent advancements in characterization techniques have improved understanding of SMA microstructural dynamics, though these insights have not yet been fully incorporated into regulatory standards. The gap between cutting-edge research and regulatory frameworks creates uncertainty for innovators seeking to implement novel SMA solutions in safety applications.

Cross-border regulatory harmonization efforts are underway through organizations like ASTM International and ISO, which are developing standardized testing methodologies for SMA components. However, these initiatives remain in nascent stages, with significant disparities persisting between regional approaches to certification and approval processes.

The global regulatory landscape for SMAs presents significant challenges for manufacturers and developers. In the United States, the FDA has established specific guidelines for medical applications of SMAs, particularly for implantable devices, requiring extensive biocompatibility testing and performance validation. The European Union, through its Medical Device Regulation (MDR) and General Product Safety Directive, imposes stringent requirements on SMA-based safety devices, emphasizing risk assessment and post-market surveillance.

Technical challenges compound these regulatory hurdles. The fatigue behavior of SMAs remains difficult to predict accurately over extended cycling, creating uncertainty in long-term safety applications. Additionally, the temperature sensitivity of shape memory properties introduces reliability concerns in environments with fluctuating thermal conditions, necessitating comprehensive testing protocols that many regulatory bodies have yet to standardize.

Material consistency represents another significant challenge, as minor variations in composition and processing can dramatically alter functional properties. This variability complicates regulatory compliance, as authorities increasingly demand consistent performance metrics and failure mode analyses for safety-critical components.

Geographically, SMA technology development shows distinct patterns. Japan and the United States lead in fundamental research and patent filings, while China has rapidly expanded manufacturing capacity. European entities focus predominantly on high-precision applications with stringent safety requirements, contributing significantly to regulatory framework development.

Recent advancements in characterization techniques have improved understanding of SMA microstructural dynamics, though these insights have not yet been fully incorporated into regulatory standards. The gap between cutting-edge research and regulatory frameworks creates uncertainty for innovators seeking to implement novel SMA solutions in safety applications.

Cross-border regulatory harmonization efforts are underway through organizations like ASTM International and ISO, which are developing standardized testing methodologies for SMA components. However, these initiatives remain in nascent stages, with significant disparities persisting between regional approaches to certification and approval processes.

Current SMA Safety Compliance Solutions

01 Composition and manufacturing of shape memory alloys

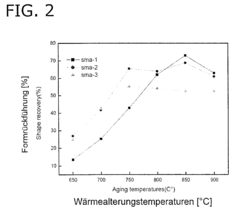

Shape memory alloys (SMAs) can be manufactured with specific compositions to achieve desired transformation temperatures and mechanical properties. These alloys typically contain nickel-titanium (Nitinol) or copper-based compositions. The manufacturing process involves precise control of alloying elements, heat treatment protocols, and thermomechanical processing to ensure the shape memory effect is properly developed. Advanced processing techniques can enhance the functional properties and performance characteristics of these materials.- Composition and manufacturing of shape memory alloys: Shape memory alloys (SMAs) can be manufactured with specific compositions to achieve desired transformation temperatures and mechanical properties. These alloys typically contain nickel-titanium (Nitinol) or copper-based compositions. The manufacturing process involves precise control of alloying elements, heat treatment, and thermomechanical processing to achieve the shape memory effect. Various techniques such as melting, casting, powder metallurgy, and heat treatment are employed to produce SMAs with optimal properties.

- Medical applications of shape memory alloys: Shape memory alloys are widely used in medical devices due to their biocompatibility and unique mechanical properties. Applications include stents, orthodontic wires, surgical instruments, and implantable devices. The superelasticity and shape recovery properties of these alloys allow for minimally invasive procedures and devices that can adapt to body temperature. These materials can be designed to activate at body temperature, making them ideal for various medical interventions and implants.

- Actuators and mechanical systems using shape memory alloys: Shape memory alloys are utilized in actuator systems that convert thermal energy into mechanical work. These actuators can generate significant force and displacement when heated above their transformation temperature. Applications include automotive systems, aerospace components, robotics, and consumer electronics. The ability of SMAs to remember and return to a predetermined shape when heated makes them valuable in various mechanical systems requiring controlled movement or force generation.

- Advanced processing techniques for shape memory alloys: Advanced processing techniques have been developed to enhance the properties and performance of shape memory alloys. These include laser processing, additive manufacturing, surface modification, and specialized heat treatments. Such techniques allow for the creation of complex geometries, improved fatigue resistance, and tailored transformation characteristics. Researchers continue to develop new methods to optimize the microstructure and functional properties of these materials for specific applications.

- Smart materials and composite systems incorporating shape memory alloys: Shape memory alloys are integrated into smart material systems and composites to create adaptive structures with self-healing or self-adjusting capabilities. These systems combine SMAs with other materials such as polymers, ceramics, or conventional metals to achieve multifunctional properties. Applications include vibration damping, structural health monitoring, deployable structures, and temperature-responsive devices. The integration of SMAs into composite systems enables the development of materials with programmable responses to environmental stimuli.

02 Applications in medical devices and implants

Shape memory alloys are widely used in medical applications due to their biocompatibility and unique mechanical properties. These materials are particularly valuable for minimally invasive surgical devices, stents, orthodontic wires, and implantable devices. The superelasticity and shape recovery properties allow medical devices to be compressed for insertion and then expand to a predetermined shape once inside the body. These characteristics enable the development of sophisticated medical technologies that can adapt to physiological conditions.Expand Specific Solutions03 Actuator and sensor applications

Shape memory alloys function effectively as actuators and sensors in various engineering systems. When used as actuators, they can generate significant force and displacement in response to temperature changes or electrical stimulation. In sensing applications, these materials can detect environmental changes and respond accordingly. The combination of sensing and actuating capabilities makes them suitable for smart systems in aerospace, automotive, and robotics industries where compact, reliable mechanical components are required.Expand Specific Solutions04 Thermal processing and heat treatment techniques

The performance of shape memory alloys is highly dependent on proper thermal processing and heat treatment. Specific annealing protocols, aging treatments, and thermomechanical processing methods are employed to optimize the shape memory effect and superelastic properties. These processes control the crystallographic structure and transformation behavior of the alloys. Advanced heat treatment techniques can tailor the transformation temperatures, hysteresis, and fatigue resistance of the materials for specific applications.Expand Specific Solutions05 Smart materials and adaptive structures

Shape memory alloys are integral components in smart materials and adaptive structures that can respond to environmental stimuli. These materials enable the development of self-healing structures, morphing surfaces, and reconfigurable systems. By incorporating shape memory alloys into composite materials or structural elements, engineers can create structures that adapt their shape, stiffness, or damping characteristics in response to external conditions. This capability is particularly valuable in aerospace, civil engineering, and automotive applications where adaptive performance is desired.Expand Specific Solutions

Key Industry Players in SMA Safety Applications

The regulatory landscape for Shape Memory Alloys (SMAs) in safety applications is evolving within a growing market characterized by increasing technical maturity. Currently in the growth phase, the global SMA market demonstrates significant expansion potential across aerospace, automotive, and medical sectors. Leading players like SAES Getters SpA, Actuator Solutions GmbH, and Toyota Motor Corp. have established advanced regulatory compliance frameworks, while research institutions such as MIT and Caltech drive innovation in safety standards. Companies including QinetiQ Ltd. and Honeywell International Technologies are developing certification protocols specifically for high-reliability applications. The competitive landscape features both specialized SMA manufacturers and large industrial conglomerates, with regulatory expertise becoming a key differentiator as applications in critical safety systems expand.

SAES Getters SpA

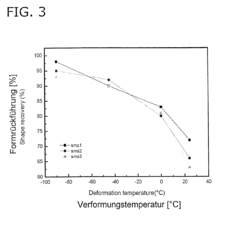

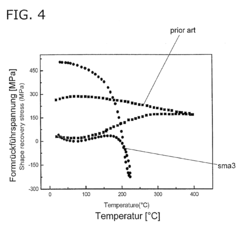

Technical Solution: SAES Getters has developed a specialized regulatory compliance framework for Nitinol-based shape memory alloys in medical and industrial safety applications. Their approach centers on a material master file system that maintains complete traceability from raw material production through final component testing, addressing FDA 21 CFR Part 820 requirements for medical applications. The company's technical solution includes proprietary surface treatment processes that enhance corrosion resistance while maintaining transformation characteristics, critical for implantable safety devices[4]. SAES has established specific validation protocols for SMA actuators in fail-safe applications, with documented testing under extreme environmental conditions (temperature ranges from -40°C to +125°C) to ensure reliable operation in safety-critical systems. Their regulatory strategy incorporates accelerated aging studies correlated with real-world performance data spanning over 15 years, providing statistical reliability models that satisfy both medical device (ISO 13485) and industrial safety standards (IEC 61508)[5]. The company maintains a dedicated regulatory affairs team that actively participates in international standards development for SMA materials.

Strengths: Extensive experience with medical-grade Nitinol regulatory requirements; comprehensive material traceability system. Weaknesses: Higher production costs associated with stringent quality control may limit competitiveness in price-sensitive applications.

Smarter Alloys, Inc.

Technical Solution: Smarter Alloys has pioneered a regulatory approach specifically addressing the unique challenges of multiple memory shape memory alloys (MM-SMAs) in safety applications. Their technical solution centers on their patented Multiple Memory Material™ technology, which enables programming different transformation behaviors into a single piece of material. This innovation has required development of novel testing protocols that go beyond traditional SMA regulatory frameworks to address the complexity of multiple transformation zones[6]. The company has established a comprehensive validation system that includes high-precision differential scanning calorimetry (DSC) mapping of transformation temperatures across components, ensuring predictable behavior in safety-critical applications. Their regulatory documentation includes detailed material characterization across multiple transformation cycles (>10,000) with statistical analysis of performance degradation, addressing key concerns from regulatory bodies about long-term reliability. Smarter Alloys has developed specific protocols for automotive safety applications that align with ISO 26262 functional safety requirements while maintaining compliance with material biocompatibility standards where human contact is possible[7]. Their approach includes real-time monitoring systems that can detect deviations from expected transformation behavior.

Strengths: Unique expertise in multiple memory materials provides competitive advantage in complex safety applications; innovative testing protocols. Weaknesses: Relatively new technology with limited long-term field data compared to conventional SMAs, potentially requiring more extensive validation for conservative regulatory bodies.

Critical SMA Patents and Technical Literature Review

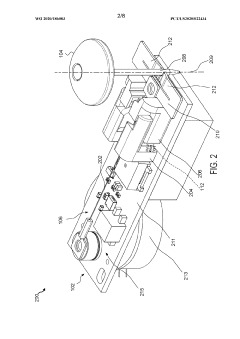

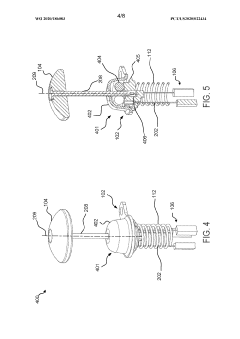

Security tag including thermally actuated detachment mechanism

PatentWO2020186083A1

Innovation

- A security tag with a thermally actuated detachment mechanism using a shape memory alloy (SMA) element that transitions from a locked to an unlocked state upon heating, allowing for self-detachment without external force, powered by an energy harvesting device and electrical circuit, enabling easy and efficient release from attached articles.

Shape memory alloys based on iron, manganese and silicon

PatentActiveEP2141251A1

Innovation

- A shape memory alloy composition of 17-20% manganese, 4-6% silicon, 8-10% chromium, and 4-7% nickel with a high iron mass fraction, along with vanadium, nitrogen, and/or carbon, forming vanadium nitride and carbide nanoparticles, which eliminates the need for thermomechanical training and narrows the austenite transition temperature range, allowing for lower transition temperatures and enhanced shape memory properties.

International Regulatory Framework for SMA Implementation

The global implementation of Shape Memory Alloys (SMAs) in safety-critical applications necessitates adherence to a complex web of international regulatory frameworks. Currently, no unified global standard specifically addresses SMAs, requiring manufacturers to navigate multiple regulatory systems across different jurisdictions.

In the United States, the Food and Drug Administration (FDA) regulates medical applications of SMAs through the 510(k) premarket notification process for devices incorporating Nitinol. The FDA has established specific testing protocols for SMA-based implants, focusing on fatigue resistance, corrosion behavior, and biocompatibility. Meanwhile, the Federal Aviation Administration (FAA) has developed specialized certification pathways for SMA actuators in aircraft systems through Advisory Circulars AC 23.1309-1E and AC 25.1309-1A.

The European Union approaches SMA regulation through the Medical Device Regulation (MDR 2017/745) for healthcare applications and the European Aviation Safety Agency (EASA) CS-25 certification specifications for aerospace implementations. The EU's approach emphasizes risk classification systems that determine the level of regulatory scrutiny applied to SMA components based on their failure consequences.

In Asia, Japan's Pharmaceuticals and Medical Devices Agency (PMDA) has pioneered specific guidelines for SMA medical devices, while China's National Medical Products Administration (NMPA) has recently introduced accelerated approval pathways for innovative SMA technologies with demonstrated safety profiles.

International standards organizations play a crucial harmonizing role across these regional frameworks. ISO 15674:2016 addresses the testing of shape memory alloys for mechanical properties, while ASTM F2063-18 specifically covers wrought nickel-titanium shape memory alloys for medical devices and surgical implants. The International Electrotechnical Commission (IEC) has developed IEC 60601-1 standards that include provisions for SMA-based electrical medical equipment.

Emerging regulatory trends indicate movement toward performance-based rather than prescriptive requirements, allowing greater innovation while maintaining safety standards. Regulatory bodies increasingly adopt risk-based approaches that scale compliance requirements according to application criticality. Additionally, international harmonization efforts are accelerating, with the International Medical Device Regulators Forum (IMDRF) working to develop globally recognized SMA testing methodologies and safety parameters.

For manufacturers, successful navigation of this regulatory landscape requires early engagement with authorities, comprehensive documentation of material characterization, and robust validation protocols that address the unique properties of SMAs, particularly their fatigue behavior under cyclic transformation.

In the United States, the Food and Drug Administration (FDA) regulates medical applications of SMAs through the 510(k) premarket notification process for devices incorporating Nitinol. The FDA has established specific testing protocols for SMA-based implants, focusing on fatigue resistance, corrosion behavior, and biocompatibility. Meanwhile, the Federal Aviation Administration (FAA) has developed specialized certification pathways for SMA actuators in aircraft systems through Advisory Circulars AC 23.1309-1E and AC 25.1309-1A.

The European Union approaches SMA regulation through the Medical Device Regulation (MDR 2017/745) for healthcare applications and the European Aviation Safety Agency (EASA) CS-25 certification specifications for aerospace implementations. The EU's approach emphasizes risk classification systems that determine the level of regulatory scrutiny applied to SMA components based on their failure consequences.

In Asia, Japan's Pharmaceuticals and Medical Devices Agency (PMDA) has pioneered specific guidelines for SMA medical devices, while China's National Medical Products Administration (NMPA) has recently introduced accelerated approval pathways for innovative SMA technologies with demonstrated safety profiles.

International standards organizations play a crucial harmonizing role across these regional frameworks. ISO 15674:2016 addresses the testing of shape memory alloys for mechanical properties, while ASTM F2063-18 specifically covers wrought nickel-titanium shape memory alloys for medical devices and surgical implants. The International Electrotechnical Commission (IEC) has developed IEC 60601-1 standards that include provisions for SMA-based electrical medical equipment.

Emerging regulatory trends indicate movement toward performance-based rather than prescriptive requirements, allowing greater innovation while maintaining safety standards. Regulatory bodies increasingly adopt risk-based approaches that scale compliance requirements according to application criticality. Additionally, international harmonization efforts are accelerating, with the International Medical Device Regulators Forum (IMDRF) working to develop globally recognized SMA testing methodologies and safety parameters.

For manufacturers, successful navigation of this regulatory landscape requires early engagement with authorities, comprehensive documentation of material characterization, and robust validation protocols that address the unique properties of SMAs, particularly their fatigue behavior under cyclic transformation.

Risk Assessment Methodologies for SMA Safety Systems

Risk assessment for Shape Memory Alloy (SMA) safety systems requires specialized methodologies that account for the unique properties and behaviors of these materials. Traditional risk assessment frameworks often prove inadequate when applied to SMA applications due to the material's temperature-dependent behavior, fatigue characteristics, and potential for unexpected shape recovery. Comprehensive risk assessment for SMA safety systems typically employs a multi-tiered approach combining both qualitative and quantitative methods.

Failure Mode and Effects Analysis (FMEA) has been adapted specifically for SMA applications, with particular attention to transformation temperature shifts under varying load conditions. This modified FMEA incorporates additional parameters such as thermomechanical cycling effects and environmental exposure factors that can significantly alter SMA performance characteristics. Statistical reliability models have also been developed to predict SMA component lifespans under various operational scenarios, utilizing Weibull distribution analysis calibrated with accelerated life testing data.

Probabilistic Risk Assessment (PRA) methodologies for SMA safety systems incorporate Monte Carlo simulations to account for the inherent variability in material properties and transformation behaviors. These simulations typically model thousands of operational scenarios to identify potential failure modes that might not be apparent through deterministic approaches. Bayesian network models have proven particularly effective in capturing the complex interdependencies between thermal, mechanical, and environmental factors affecting SMA performance.

Real-time monitoring protocols form an essential component of dynamic risk assessment frameworks for SMA safety systems. These protocols typically involve continuous measurement of critical parameters such as temperature, strain, and electrical resistance to detect early warning signs of potential failures. Machine learning algorithms have been successfully implemented to analyze these data streams and identify anomalous behavior patterns that may indicate impending system failures.

Regulatory compliance assessment methodologies have been developed specifically for SMA safety applications in critical sectors such as aerospace, medical devices, and automotive systems. These methodologies incorporate industry-specific standards and testing protocols, such as those outlined in ASTM F2063 for medical-grade Nitinol. The assessment process typically includes verification of material composition, transformation temperatures, mechanical properties, and corrosion resistance through standardized testing procedures.

Human factors analysis has emerged as a crucial component of comprehensive risk assessment for SMA safety systems, particularly in applications where human interaction may influence system performance. This analysis examines potential user errors, misunderstandings of system limitations, and improper maintenance procedures that could compromise safety margins. Scenario-based testing with actual users has proven effective in identifying previously unforeseen risk factors in human-SMA system interactions.

Failure Mode and Effects Analysis (FMEA) has been adapted specifically for SMA applications, with particular attention to transformation temperature shifts under varying load conditions. This modified FMEA incorporates additional parameters such as thermomechanical cycling effects and environmental exposure factors that can significantly alter SMA performance characteristics. Statistical reliability models have also been developed to predict SMA component lifespans under various operational scenarios, utilizing Weibull distribution analysis calibrated with accelerated life testing data.

Probabilistic Risk Assessment (PRA) methodologies for SMA safety systems incorporate Monte Carlo simulations to account for the inherent variability in material properties and transformation behaviors. These simulations typically model thousands of operational scenarios to identify potential failure modes that might not be apparent through deterministic approaches. Bayesian network models have proven particularly effective in capturing the complex interdependencies between thermal, mechanical, and environmental factors affecting SMA performance.

Real-time monitoring protocols form an essential component of dynamic risk assessment frameworks for SMA safety systems. These protocols typically involve continuous measurement of critical parameters such as temperature, strain, and electrical resistance to detect early warning signs of potential failures. Machine learning algorithms have been successfully implemented to analyze these data streams and identify anomalous behavior patterns that may indicate impending system failures.

Regulatory compliance assessment methodologies have been developed specifically for SMA safety applications in critical sectors such as aerospace, medical devices, and automotive systems. These methodologies incorporate industry-specific standards and testing protocols, such as those outlined in ASTM F2063 for medical-grade Nitinol. The assessment process typically includes verification of material composition, transformation temperatures, mechanical properties, and corrosion resistance through standardized testing procedures.

Human factors analysis has emerged as a crucial component of comprehensive risk assessment for SMA safety systems, particularly in applications where human interaction may influence system performance. This analysis examines potential user errors, misunderstandings of system limitations, and improper maintenance procedures that could compromise safety margins. Scenario-based testing with actual users has proven effective in identifying previously unforeseen risk factors in human-SMA system interactions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!