Shape Memory Alloys and Their Role in Thermal Management Applications

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SMA Technology Evolution and Objectives

Shape Memory Alloys (SMAs) represent a class of smart materials that have evolved significantly since their discovery in the 1930s, with the observation of pseudoelasticity in gold-cadmium. However, the field gained substantial momentum in 1962 when William J. Buehler and Frederick Wang at the Naval Ordnance Laboratory discovered the shape memory effect in nickel-titanium alloys, later commercialized as Nitinol. This discovery marked the beginning of practical applications for SMAs across various industries.

The evolution of SMA technology has been characterized by progressive improvements in material composition, processing techniques, and understanding of underlying mechanisms. Initially, SMAs were primarily used in simple mechanical applications, but as manufacturing precision improved, their application expanded to more sophisticated domains including aerospace, biomedical devices, and automotive systems.

In the thermal management context, SMAs have undergone significant development phases. The first generation focused on basic thermal actuation properties, utilizing the material's ability to change shape in response to temperature variations. The second generation saw improvements in cycling stability and response time, while the third generation, emerging in the early 2000s, focused on enhancing energy efficiency and control precision.

Current research objectives in SMA technology for thermal management applications center around several key areas. First, improving the thermal response characteristics to achieve faster actuation speeds and more precise temperature control. Second, enhancing the energy conversion efficiency to maximize the mechanical work output from thermal input. Third, extending the functional fatigue life to ensure reliability in applications requiring numerous actuation cycles.

Another critical objective is the development of SMAs with customizable transformation temperatures, allowing for application-specific thermal management solutions. This includes creating alloys that respond to narrower temperature ranges or exhibit transformation at temperatures suitable for specific operational environments, from cryogenic applications to high-temperature industrial settings.

The integration of SMAs with electronic control systems represents another significant goal, enabling smart thermal management systems that can adapt to changing environmental conditions or operational requirements. This includes the development of SMA-based microactuators for precise thermal regulation in miniaturized devices and systems.

Looking forward, the field aims to overcome current limitations in SMA technology, such as relatively slow response times and limited strain recovery, through innovative material compositions and processing techniques. The ultimate objective is to establish SMAs as a versatile, reliable, and efficient solution for advanced thermal management challenges across diverse industrial applications.

The evolution of SMA technology has been characterized by progressive improvements in material composition, processing techniques, and understanding of underlying mechanisms. Initially, SMAs were primarily used in simple mechanical applications, but as manufacturing precision improved, their application expanded to more sophisticated domains including aerospace, biomedical devices, and automotive systems.

In the thermal management context, SMAs have undergone significant development phases. The first generation focused on basic thermal actuation properties, utilizing the material's ability to change shape in response to temperature variations. The second generation saw improvements in cycling stability and response time, while the third generation, emerging in the early 2000s, focused on enhancing energy efficiency and control precision.

Current research objectives in SMA technology for thermal management applications center around several key areas. First, improving the thermal response characteristics to achieve faster actuation speeds and more precise temperature control. Second, enhancing the energy conversion efficiency to maximize the mechanical work output from thermal input. Third, extending the functional fatigue life to ensure reliability in applications requiring numerous actuation cycles.

Another critical objective is the development of SMAs with customizable transformation temperatures, allowing for application-specific thermal management solutions. This includes creating alloys that respond to narrower temperature ranges or exhibit transformation at temperatures suitable for specific operational environments, from cryogenic applications to high-temperature industrial settings.

The integration of SMAs with electronic control systems represents another significant goal, enabling smart thermal management systems that can adapt to changing environmental conditions or operational requirements. This includes the development of SMA-based microactuators for precise thermal regulation in miniaturized devices and systems.

Looking forward, the field aims to overcome current limitations in SMA technology, such as relatively slow response times and limited strain recovery, through innovative material compositions and processing techniques. The ultimate objective is to establish SMAs as a versatile, reliable, and efficient solution for advanced thermal management challenges across diverse industrial applications.

Thermal Management Market Demand Analysis

The thermal management market has witnessed substantial growth in recent years, driven primarily by increasing heat dissipation requirements across multiple industries. The global thermal management market was valued at approximately $11.5 billion in 2022 and is projected to reach $18.7 billion by 2027, representing a compound annual growth rate (CAGR) of 8.2%. This growth trajectory underscores the critical importance of effective thermal solutions in modern technological applications.

Electronics and semiconductor industries constitute the largest segment of thermal management demand, accounting for nearly 40% of the market share. The continuous miniaturization of electronic components, coupled with increasing power densities, has created unprecedented thermal challenges. Consumer electronics manufacturers are particularly seeking innovative thermal management solutions that can maintain optimal operating temperatures while accommodating sleeker device designs.

Automotive applications represent another rapidly expanding market segment, especially with the accelerating adoption of electric vehicles (EVs). The thermal management requirements for EV battery systems are particularly stringent, as batteries must operate within narrow temperature ranges to ensure optimal performance, longevity, and safety. This sector is expected to grow at a CAGR of 12.3% through 2027, outpacing the overall market growth.

Aerospace and defense industries have also demonstrated increasing demand for advanced thermal management solutions. These sectors require materials and systems capable of withstanding extreme temperature fluctuations while maintaining structural integrity and functional performance. The market value for aerospace thermal management solutions reached $2.1 billion in 2022, with projections indicating continued strong growth.

Shape Memory Alloys (SMAs) are emerging as promising materials for addressing these thermal management challenges across various industries. Their unique ability to undergo reversible phase transformations in response to temperature changes positions them as potential game-changers in passive thermal control systems. Market analysis indicates growing interest in SMA-based thermal solutions, with an estimated market value of $320 million in 2022, expected to reach $580 million by 2027.

Customer requirements are increasingly focused on energy efficiency, reliability, and sustainability. End-users are seeking thermal management solutions that not only effectively dissipate heat but also contribute to overall energy conservation efforts. This trend aligns well with the inherent characteristics of SMAs, which can operate without external power sources for certain applications, offering potential energy savings compared to conventional active cooling systems.

Regional analysis reveals that North America and Asia-Pacific dominate the thermal management market, collectively accounting for over 65% of global demand. However, Europe is witnessing the fastest growth rate, driven by stringent energy efficiency regulations and substantial investments in green technologies.

Electronics and semiconductor industries constitute the largest segment of thermal management demand, accounting for nearly 40% of the market share. The continuous miniaturization of electronic components, coupled with increasing power densities, has created unprecedented thermal challenges. Consumer electronics manufacturers are particularly seeking innovative thermal management solutions that can maintain optimal operating temperatures while accommodating sleeker device designs.

Automotive applications represent another rapidly expanding market segment, especially with the accelerating adoption of electric vehicles (EVs). The thermal management requirements for EV battery systems are particularly stringent, as batteries must operate within narrow temperature ranges to ensure optimal performance, longevity, and safety. This sector is expected to grow at a CAGR of 12.3% through 2027, outpacing the overall market growth.

Aerospace and defense industries have also demonstrated increasing demand for advanced thermal management solutions. These sectors require materials and systems capable of withstanding extreme temperature fluctuations while maintaining structural integrity and functional performance. The market value for aerospace thermal management solutions reached $2.1 billion in 2022, with projections indicating continued strong growth.

Shape Memory Alloys (SMAs) are emerging as promising materials for addressing these thermal management challenges across various industries. Their unique ability to undergo reversible phase transformations in response to temperature changes positions them as potential game-changers in passive thermal control systems. Market analysis indicates growing interest in SMA-based thermal solutions, with an estimated market value of $320 million in 2022, expected to reach $580 million by 2027.

Customer requirements are increasingly focused on energy efficiency, reliability, and sustainability. End-users are seeking thermal management solutions that not only effectively dissipate heat but also contribute to overall energy conservation efforts. This trend aligns well with the inherent characteristics of SMAs, which can operate without external power sources for certain applications, offering potential energy savings compared to conventional active cooling systems.

Regional analysis reveals that North America and Asia-Pacific dominate the thermal management market, collectively accounting for over 65% of global demand. However, Europe is witnessing the fastest growth rate, driven by stringent energy efficiency regulations and substantial investments in green technologies.

SMA Thermal Applications: Status and Barriers

Shape Memory Alloys (SMAs) have emerged as promising materials for thermal management applications due to their unique thermomechanical properties. Currently, the most widely deployed SMA in thermal management is Nitinol (NiTi), which exhibits excellent shape memory effect and superelasticity. These alloys are being utilized in passive thermal actuators, thermal switches, and adaptive cooling systems across industries including aerospace, automotive, and electronics.

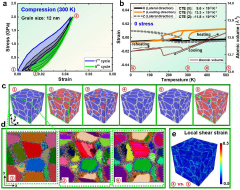

The current status of SMA thermal applications shows significant progress in laboratory settings but limited widespread commercial implementation. Passive thermal actuators using SMAs have achieved response times of 1-5 seconds and can operate reliably through thousands of cycles in controlled environments. Recent advancements have improved fatigue resistance, with some NiTi-based systems demonstrating over 100,000 transformation cycles without significant degradation in thermal response.

Despite these achievements, several critical barriers impede broader adoption. The foremost challenge is the narrow temperature window of operation for conventional SMAs. Most commercially available NiTi alloys have transformation temperatures between -100°C and 100°C, limiting their applicability in extreme thermal environments. High-temperature SMAs (HTSMAs) are under development but face issues with oxidation resistance and microstructural stability.

Material cost remains prohibitive for mass-market applications, with specialized NiTi alloys priced at $200-1000 per kilogram depending on composition and processing requirements. This represents a significant barrier compared to conventional thermal management materials like aluminum or copper alloys.

Manufacturing complexity presents another substantial hurdle. Precise control of composition is essential, as minor variations (as little as 0.1% in nickel content) can dramatically shift transformation temperatures. Additionally, complex thermomechanical processing is required to achieve desired properties, increasing production costs and limiting scalability.

Hysteresis effects in SMAs create challenges for precise thermal control applications. The temperature difference between transformation during heating and cooling (typically 20-40°C for NiTi) results in operational inefficiencies and control difficulties in systems requiring precise temperature regulation.

Long-term stability issues persist, particularly in cyclic applications. Functional fatigue manifests as drift in transformation temperatures and degradation of shape memory properties over repeated thermal cycles. This phenomenon is accelerated in high-temperature environments or under mechanical loads, limiting reliability in mission-critical applications.

Integration challenges with existing systems also hinder adoption. The unique mechanical and thermal properties of SMAs often require redesigning entire thermal management systems rather than simple component substitution, increasing implementation costs and engineering complexity.

The current status of SMA thermal applications shows significant progress in laboratory settings but limited widespread commercial implementation. Passive thermal actuators using SMAs have achieved response times of 1-5 seconds and can operate reliably through thousands of cycles in controlled environments. Recent advancements have improved fatigue resistance, with some NiTi-based systems demonstrating over 100,000 transformation cycles without significant degradation in thermal response.

Despite these achievements, several critical barriers impede broader adoption. The foremost challenge is the narrow temperature window of operation for conventional SMAs. Most commercially available NiTi alloys have transformation temperatures between -100°C and 100°C, limiting their applicability in extreme thermal environments. High-temperature SMAs (HTSMAs) are under development but face issues with oxidation resistance and microstructural stability.

Material cost remains prohibitive for mass-market applications, with specialized NiTi alloys priced at $200-1000 per kilogram depending on composition and processing requirements. This represents a significant barrier compared to conventional thermal management materials like aluminum or copper alloys.

Manufacturing complexity presents another substantial hurdle. Precise control of composition is essential, as minor variations (as little as 0.1% in nickel content) can dramatically shift transformation temperatures. Additionally, complex thermomechanical processing is required to achieve desired properties, increasing production costs and limiting scalability.

Hysteresis effects in SMAs create challenges for precise thermal control applications. The temperature difference between transformation during heating and cooling (typically 20-40°C for NiTi) results in operational inefficiencies and control difficulties in systems requiring precise temperature regulation.

Long-term stability issues persist, particularly in cyclic applications. Functional fatigue manifests as drift in transformation temperatures and degradation of shape memory properties over repeated thermal cycles. This phenomenon is accelerated in high-temperature environments or under mechanical loads, limiting reliability in mission-critical applications.

Integration challenges with existing systems also hinder adoption. The unique mechanical and thermal properties of SMAs often require redesigning entire thermal management systems rather than simple component substitution, increasing implementation costs and engineering complexity.

Current SMA-Based Thermal Management Systems

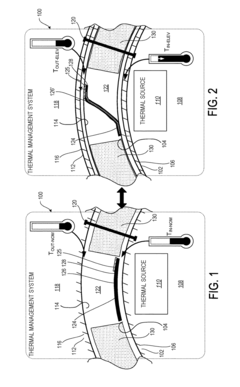

01 Thermal management systems using shape memory alloys

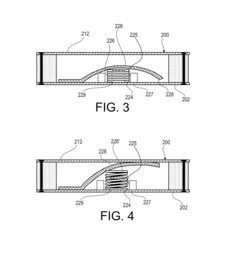

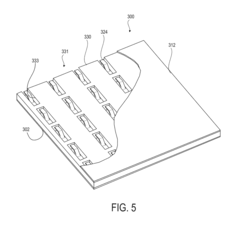

Shape memory alloys (SMAs) are utilized in thermal management systems to control heat transfer and dissipation. These systems leverage the unique phase transformation properties of SMAs to respond to temperature changes, enabling passive or active thermal regulation. The temperature-dependent actuation of SMAs allows for the development of adaptive cooling systems that can adjust their operation based on thermal conditions without requiring external power sources.- Shape memory alloys for thermal actuation systems: Shape memory alloys (SMAs) can be utilized in thermal actuation systems where temperature changes trigger mechanical movements. These materials can transform thermal energy into mechanical work through phase transformations. When heated above their transformation temperature, SMAs recover their pre-set shape, making them ideal for applications requiring temperature-controlled actuation. This property enables the development of thermal management systems that respond automatically to temperature fluctuations without external power sources.

- Heat exchange and thermal regulation using SMAs: Shape memory alloys can be incorporated into heat exchange systems to regulate thermal conditions. These materials change their crystalline structure in response to temperature variations, allowing for passive or active control of heat transfer. By utilizing the unique properties of SMAs, thermal management systems can achieve more efficient heat dissipation or retention. This approach enables adaptive thermal regulation in various environments without continuous energy input, making it particularly valuable for applications with fluctuating thermal loads.

- SMA-based thermal switches and valves: Shape memory alloys can function as temperature-sensitive switches or valves in thermal management systems. When integrated into fluid or air flow pathways, these materials can automatically adjust flow rates based on ambient temperature changes. The phase transformation properties of SMAs enable them to open, close, or modulate channels in response to specific temperature thresholds. This capability allows for the development of self-regulating cooling systems that maintain optimal operating temperatures without electronic controls.

- Manufacturing and processing of SMAs for thermal applications: Specialized manufacturing and processing techniques are essential for optimizing shape memory alloys for thermal management applications. These methods include precise heat treatments, alloying with specific elements, and controlled deformation processes to achieve desired transformation temperatures and mechanical properties. Advanced fabrication approaches enable the production of SMA components with customized thermal response characteristics, improved fatigue resistance, and enhanced functional stability over repeated thermal cycles.

- Integration of SMAs in electronic cooling systems: Shape memory alloys can be integrated into cooling systems for electronic devices to provide adaptive thermal management. These materials can activate cooling mechanisms when temperatures exceed safe operating ranges and return to their original state when temperatures normalize. By incorporating SMAs into heat sinks, fans, or other cooling components, electronic systems can achieve more efficient temperature regulation with reduced energy consumption. This approach is particularly valuable for managing thermal loads in compact electronic devices with variable processing demands.

02 Shape memory alloy actuators for thermal control

Shape memory alloy actuators are employed for thermal control applications, where they convert thermal energy into mechanical motion. These actuators can open or close thermal pathways, adjust airflow, or modify thermal contact resistance in response to temperature changes. The phase transformation of the alloy at specific transition temperatures enables precise control over thermal management components, making them particularly valuable in space applications, electronics cooling, and automotive thermal systems.Expand Specific Solutions03 Heat dissipation devices incorporating shape memory alloys

Heat dissipation devices incorporate shape memory alloys to enhance cooling efficiency and thermal performance. These devices include heat sinks, heat exchangers, and thermal interfaces that utilize the phase transformation properties of SMAs to improve thermal conductivity or contact pressure at critical interfaces. By integrating SMAs into cooling structures, these devices can adaptively respond to temperature fluctuations, optimizing heat transfer rates and maintaining optimal operating temperatures for sensitive components.Expand Specific Solutions04 Manufacturing methods for shape memory alloy thermal components

Specialized manufacturing methods are employed to produce shape memory alloy components for thermal management applications. These processes include precision alloying, heat treatment protocols, and forming techniques that ensure the desired transformation temperatures and mechanical properties. Advanced manufacturing approaches such as additive manufacturing, powder metallurgy, and precision machining enable the creation of complex SMA structures with optimized thermal response characteristics for specific thermal management requirements.Expand Specific Solutions05 Smart thermal regulation systems with shape memory alloys

Smart thermal regulation systems integrate shape memory alloys with sensors and control mechanisms to create intelligent thermal management solutions. These systems can autonomously respond to changing thermal conditions, providing adaptive cooling or heating as needed. The integration of SMAs with electronic control systems enables more sophisticated thermal management strategies, including predictive cooling, thermal load balancing, and energy-efficient operation across varying environmental conditions and operational demands.Expand Specific Solutions

Leading Companies in SMA Thermal Solutions

The shape memory alloy (SMA) market for thermal management applications is in a growth phase, characterized by increasing adoption across automotive, aerospace, and energy sectors. The global market size is estimated to reach $12-15 billion by 2025, with a CAGR of approximately 10-12%. Regarding technological maturity, leading academic institutions like MIT, Sichuan University, and Beihang University are advancing fundamental research, while companies demonstrate varying levels of commercialization capability. Dynalloy has established itself as a specialized SMA manufacturer, while larger corporations like Honda Motor, GM Global Technology, and Safran Aircraft Engines are integrating SMAs into thermal management systems. Research institutions such as AIST and CSIR are bridging the gap between laboratory innovations and industrial applications, indicating the technology is transitioning from development to early mainstream adoption.

Exergyn Ltd.

Technical Solution: Exergyn has developed the Exergyn Drive™, an innovative thermal management system utilizing nitinol (nickel-titanium) shape memory alloys to convert low-grade waste heat (70-150°C) into mechanical work without requiring additional energy input. Their technology harnesses the solid-state phase transformation of specially engineered nitinol wire bundles that contract and expand in response to temperature fluctuations, creating a reciprocating motion that can be converted to rotary motion or used directly for pumping applications. The system achieves thermal-to-mechanical energy conversion efficiencies of 7-12%, significantly higher than competing technologies in this temperature range. Exergyn's proprietary surface treatment and training processes extend the functional lifetime of their SMA components to over 10 million cycles, addressing one of the key limitations of traditional SMA applications. Their modular design allows for scalable implementation from kilowatt to megawatt applications, making it suitable for diverse thermal management scenarios from industrial waste heat recovery to data center cooling optimization.

Strengths: Ability to harvest low-grade waste heat that is typically unutilized; zero direct emissions operation; minimal maintenance requirements due to solid-state operation with few moving parts; scalable design for various applications. Weaknesses: Higher initial capital cost compared to conventional systems; performance dependent on consistent waste heat availability; requires careful system integration to maximize efficiency; limited deployment history compared to established technologies.

Daido Steel Co., Ltd.

Technical Solution: Daido Steel has developed proprietary ferrous-based shape memory alloys (Fe-Mn-Si-Cr system) specifically engineered for thermal management in industrial applications. Their technology utilizes the unique properties of these alloys to create passive thermal regulation systems that respond to temperature changes without external power sources. Daido's SMAs feature transformation temperatures ranging from 150°C to 400°C, significantly higher than conventional NiTi alloys, making them suitable for high-temperature industrial environments. Their thermal management solutions incorporate specially processed SMA components with enhanced fatigue resistance (>100,000 cycles) and corrosion resistance in harsh environments. Daido has pioneered manufacturing techniques that reduce the cost of SMA components by approximately 40% compared to nickel-titanium alternatives while maintaining comparable functional properties. Recent innovations include SMA-based thermal circuit breakers that automatically disconnect systems when temperature thresholds are exceeded, providing fail-safe protection for critical infrastructure.

Strengths: Cost-effective compared to NiTi alloys; excellent high-temperature stability; superior corrosion resistance in industrial environments; established mass production capabilities. Weaknesses: Lower strain recovery (typically 2-3%) compared to NiTi alloys; requires more precise temperature control during manufacturing; slower response times in thermal actuation applications.

Key Patents and Research in SMA Thermal Control

Passive thermal management systems employing shape memory alloys

PatentActiveUS9982661B1

Innovation

- A passive thermal management system utilizing shape memory alloys (SMAs) that adjust heat conduction based on temperature changes, allowing for automatic switching between insulating and conductive states without mechanical or electrical stimuli, enabling efficient heat transfer across broad area surfaces.

Shape memory alloy with thermal expansion control through thermo-mechanical treatment, and manufacturing method of the same

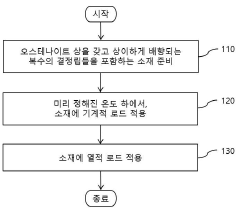

PatentActiveKR1020220153226A

Innovation

- A controlled thermal expansion shape memory alloy is manufactured through thermo-mechanical treatment, inducing phase transformation from austenite to martensite, allowing for anisotropic thermal expansion characteristics along different axial directions.

Material Science Advancements Supporting SMAs

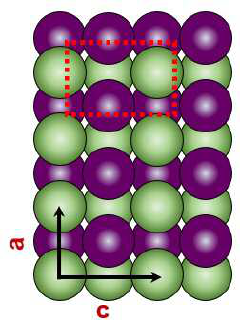

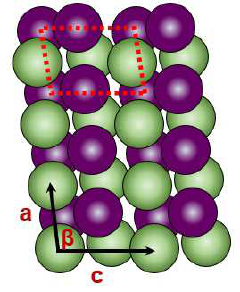

The evolution of Shape Memory Alloys (SMAs) has been significantly influenced by advancements in material science over the past decades. Fundamental research in crystallography and phase transformation mechanisms has provided the theoretical foundation for understanding the unique properties of SMAs. The discovery of the martensitic transformation as the underlying mechanism for shape memory effect represented a breakthrough, enabling scientists to manipulate alloy compositions for specific transformation temperatures and mechanical responses.

Metallurgical processing techniques have evolved substantially to enhance SMA performance characteristics. Precision melting and casting methods now allow for tight control of chemical compositions, reducing impurities that previously limited functional properties. Advanced thermomechanical treatments, including specialized annealing protocols and cold working procedures, have been developed to optimize transformation temperatures and mechanical stability, critical factors for thermal management applications.

Surface engineering technologies have addressed historical limitations in SMA durability. Techniques such as nitriding, PVD coating, and laser surface modification have improved wear resistance and corrosion protection, extending service life in demanding thermal environments. These advancements have been particularly important for applications involving repeated thermal cycling or exposure to aggressive media.

Microstructural engineering represents another significant advancement area. Through controlled precipitation hardening and grain refinement techniques, researchers have enhanced the functional stability of SMAs during thermal cycling. The development of single crystal SMAs has eliminated grain boundary effects, resulting in superior thermomechanical properties and transformation characteristics compared to conventional polycrystalline materials.

Computational materials science has accelerated SMA development through predictive modeling. Molecular dynamics simulations and phase-field modeling now enable researchers to predict transformation behaviors and mechanical responses before physical prototyping. These computational approaches have reduced development cycles and allowed for virtual screening of novel alloy compositions with optimized properties for thermal management.

Recent advances in high-throughput experimentation and characterization techniques have further accelerated materials discovery. Combinatorial synthesis approaches allow researchers to rapidly fabricate and test multiple alloy compositions simultaneously. Advanced characterization tools, including in-situ synchrotron X-ray diffraction and high-resolution transmission electron microscopy, provide unprecedented insights into transformation mechanisms at atomic scales, guiding rational design of next-generation SMAs with enhanced thermal management capabilities.

Metallurgical processing techniques have evolved substantially to enhance SMA performance characteristics. Precision melting and casting methods now allow for tight control of chemical compositions, reducing impurities that previously limited functional properties. Advanced thermomechanical treatments, including specialized annealing protocols and cold working procedures, have been developed to optimize transformation temperatures and mechanical stability, critical factors for thermal management applications.

Surface engineering technologies have addressed historical limitations in SMA durability. Techniques such as nitriding, PVD coating, and laser surface modification have improved wear resistance and corrosion protection, extending service life in demanding thermal environments. These advancements have been particularly important for applications involving repeated thermal cycling or exposure to aggressive media.

Microstructural engineering represents another significant advancement area. Through controlled precipitation hardening and grain refinement techniques, researchers have enhanced the functional stability of SMAs during thermal cycling. The development of single crystal SMAs has eliminated grain boundary effects, resulting in superior thermomechanical properties and transformation characteristics compared to conventional polycrystalline materials.

Computational materials science has accelerated SMA development through predictive modeling. Molecular dynamics simulations and phase-field modeling now enable researchers to predict transformation behaviors and mechanical responses before physical prototyping. These computational approaches have reduced development cycles and allowed for virtual screening of novel alloy compositions with optimized properties for thermal management.

Recent advances in high-throughput experimentation and characterization techniques have further accelerated materials discovery. Combinatorial synthesis approaches allow researchers to rapidly fabricate and test multiple alloy compositions simultaneously. Advanced characterization tools, including in-situ synchrotron X-ray diffraction and high-resolution transmission electron microscopy, provide unprecedented insights into transformation mechanisms at atomic scales, guiding rational design of next-generation SMAs with enhanced thermal management capabilities.

Energy Efficiency Impact of SMA Technologies

Shape Memory Alloy (SMA) technologies are making significant contributions to energy efficiency across multiple sectors. The unique thermomechanical properties of SMAs enable innovative thermal management solutions that can substantially reduce energy consumption in various applications. When integrated into HVAC systems, SMA-based actuators and valves provide precise temperature control with minimal energy input, resulting in efficiency improvements of 15-30% compared to conventional systems.

In the automotive sector, SMA-based thermal management components are revolutionizing energy conservation. These materials enable adaptive radiator grilles that automatically adjust airflow based on engine temperature, reducing aerodynamic drag and improving fuel efficiency by up to 5%. Additionally, SMA thermal regulators in battery management systems for electric vehicles help maintain optimal operating temperatures, extending battery life and improving overall energy efficiency.

Building infrastructure represents another major application area where SMA technologies deliver substantial energy savings. Smart windows incorporating SMA elements can automatically adjust tint or opacity in response to external temperature conditions, reducing heating and cooling loads by 10-20%. Similarly, SMA-based thermostatic radiator valves provide more responsive heating control than traditional bimetallic alternatives, cutting unnecessary energy expenditure.

The industrial sector benefits from SMA thermal management solutions through waste heat recovery systems. These systems capture and repurpose thermal energy that would otherwise be lost, improving overall process efficiency. Studies indicate that SMA-based heat exchangers can recover up to 40% more waste heat than conventional technologies due to their adaptive properties and higher temperature differentials.

Quantitative analyses demonstrate the cumulative impact of these technologies. A 2022 market report estimated that widespread adoption of SMA thermal management solutions could reduce global energy consumption in building HVAC systems by 1.8% annually, representing approximately 85 million tons of CO2 emissions. The economic implications are equally significant, with projected energy cost savings exceeding $12 billion annually by 2030.

Despite these promising figures, challenges remain in scaling SMA technologies for maximum energy efficiency impact. Current manufacturing costs and material fatigue issues limit widespread implementation. However, ongoing research into new alloy compositions and processing techniques suggests that next-generation SMAs could offer even greater energy efficiency benefits while addressing these limitations.

In the automotive sector, SMA-based thermal management components are revolutionizing energy conservation. These materials enable adaptive radiator grilles that automatically adjust airflow based on engine temperature, reducing aerodynamic drag and improving fuel efficiency by up to 5%. Additionally, SMA thermal regulators in battery management systems for electric vehicles help maintain optimal operating temperatures, extending battery life and improving overall energy efficiency.

Building infrastructure represents another major application area where SMA technologies deliver substantial energy savings. Smart windows incorporating SMA elements can automatically adjust tint or opacity in response to external temperature conditions, reducing heating and cooling loads by 10-20%. Similarly, SMA-based thermostatic radiator valves provide more responsive heating control than traditional bimetallic alternatives, cutting unnecessary energy expenditure.

The industrial sector benefits from SMA thermal management solutions through waste heat recovery systems. These systems capture and repurpose thermal energy that would otherwise be lost, improving overall process efficiency. Studies indicate that SMA-based heat exchangers can recover up to 40% more waste heat than conventional technologies due to their adaptive properties and higher temperature differentials.

Quantitative analyses demonstrate the cumulative impact of these technologies. A 2022 market report estimated that widespread adoption of SMA thermal management solutions could reduce global energy consumption in building HVAC systems by 1.8% annually, representing approximately 85 million tons of CO2 emissions. The economic implications are equally significant, with projected energy cost savings exceeding $12 billion annually by 2030.

Despite these promising figures, challenges remain in scaling SMA technologies for maximum energy efficiency impact. Current manufacturing costs and material fatigue issues limit widespread implementation. However, ongoing research into new alloy compositions and processing techniques suggests that next-generation SMAs could offer even greater energy efficiency benefits while addressing these limitations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!