Application of Spray Pyrolysis in Large-Scale Thin Film Production

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Pyrolysis Technology Evolution and Objectives

Spray pyrolysis has evolved significantly since its inception in the 1960s as a simple laboratory technique for producing thin films. Initially limited to academic research, this technology has progressively transformed into a viable industrial process for large-scale thin film production. The evolution trajectory shows a clear shift from batch processing to continuous manufacturing capabilities, enabling higher throughput and consistency in film properties.

The fundamental principle of spray pyrolysis—atomizing precursor solutions onto heated substrates to form thin films through thermal decomposition—has remained unchanged. However, significant advancements have occurred in atomization techniques, precursor chemistry, and process control systems. Early systems utilized simple pneumatic atomizers, while modern configurations employ ultrasonic or electrospray atomization that provides superior control over droplet size distribution and deposition uniformity.

A critical milestone in spray pyrolysis development was the introduction of computer-controlled systems in the 1990s, which dramatically improved process repeatability and enabled real-time adjustments based on in-situ monitoring. This advancement facilitated the scaling of substrate dimensions from laboratory-scale samples to industrially relevant sizes exceeding one square meter.

The technology has demonstrated remarkable versatility across various applications, initially focusing on transparent conducting oxides for solar cells and later expanding to functional ceramics, semiconductor materials, and most recently, perovskite films for next-generation photovoltaics. Each application domain has driven specific optimizations in the spray pyrolysis process, contributing to its overall technological maturity.

Current technological objectives for spray pyrolysis in large-scale thin film production center on several key areas. First, enhancing deposition uniformity across large substrate areas remains paramount for industrial viability. Second, increasing material utilization efficiency addresses both economic and environmental concerns. Third, developing multi-layer deposition capabilities without intermediate handling steps would significantly improve manufacturing throughput and reduce contamination risks.

Additionally, the integration of spray pyrolysis with complementary thin film technologies in hybrid manufacturing lines represents an emerging objective. This approach leverages the strengths of multiple deposition techniques within a single production system. Finally, adapting spray pyrolysis for flexible and roll-to-roll substrates aligns with the growing demand for flexible electronics and photovoltaics.

The technology roadmap anticipates continued refinement of process parameters through computational fluid dynamics modeling and machine learning algorithms, potentially enabling predictive process control that could revolutionize quality assurance methodologies in thin film manufacturing.

The fundamental principle of spray pyrolysis—atomizing precursor solutions onto heated substrates to form thin films through thermal decomposition—has remained unchanged. However, significant advancements have occurred in atomization techniques, precursor chemistry, and process control systems. Early systems utilized simple pneumatic atomizers, while modern configurations employ ultrasonic or electrospray atomization that provides superior control over droplet size distribution and deposition uniformity.

A critical milestone in spray pyrolysis development was the introduction of computer-controlled systems in the 1990s, which dramatically improved process repeatability and enabled real-time adjustments based on in-situ monitoring. This advancement facilitated the scaling of substrate dimensions from laboratory-scale samples to industrially relevant sizes exceeding one square meter.

The technology has demonstrated remarkable versatility across various applications, initially focusing on transparent conducting oxides for solar cells and later expanding to functional ceramics, semiconductor materials, and most recently, perovskite films for next-generation photovoltaics. Each application domain has driven specific optimizations in the spray pyrolysis process, contributing to its overall technological maturity.

Current technological objectives for spray pyrolysis in large-scale thin film production center on several key areas. First, enhancing deposition uniformity across large substrate areas remains paramount for industrial viability. Second, increasing material utilization efficiency addresses both economic and environmental concerns. Third, developing multi-layer deposition capabilities without intermediate handling steps would significantly improve manufacturing throughput and reduce contamination risks.

Additionally, the integration of spray pyrolysis with complementary thin film technologies in hybrid manufacturing lines represents an emerging objective. This approach leverages the strengths of multiple deposition techniques within a single production system. Finally, adapting spray pyrolysis for flexible and roll-to-roll substrates aligns with the growing demand for flexible electronics and photovoltaics.

The technology roadmap anticipates continued refinement of process parameters through computational fluid dynamics modeling and machine learning algorithms, potentially enabling predictive process control that could revolutionize quality assurance methodologies in thin film manufacturing.

Market Demand Analysis for Thin Film Applications

The global thin film market has experienced substantial growth in recent years, driven primarily by increasing demand across multiple industries. The market was valued at approximately $70 billion in 2022 and is projected to reach $115 billion by 2028, representing a compound annual growth rate (CAGR) of 8.6%. This growth trajectory underscores the expanding applications and technological advancements in thin film production methodologies, particularly spray pyrolysis techniques.

Electronics and semiconductor industries remain the largest consumers of thin film technologies, accounting for nearly 40% of the total market share. The miniaturization trend in electronic devices continues to fuel demand for thinner, more efficient coating solutions that spray pyrolysis can effectively deliver. Additionally, the global push toward energy efficiency has significantly boosted the solar photovoltaic sector, where thin film solar cells represent a rapidly growing segment with projected annual growth rates exceeding 12% through 2030.

Consumer electronics manufacturers are increasingly incorporating thin film technologies in displays, touchscreens, and flexible electronics. The market for OLED displays alone, which heavily relies on thin film deposition techniques, is expected to grow at 15% annually, creating substantial opportunities for large-scale spray pyrolysis applications. The automotive industry has also emerged as a significant market, with thin films being utilized in smart windows, displays, and various sensor applications.

Healthcare and biomedical applications represent another expanding market segment, with thin films being used in biosensors, medical implants, and drug delivery systems. This sector is projected to grow at 9.5% annually through 2028, driven by increasing healthcare expenditure and technological advancements in medical devices.

Regionally, Asia-Pacific dominates the thin film market, accounting for approximately 45% of global demand, followed by North America and Europe. China, Japan, South Korea, and Taiwan are particularly significant markets due to their robust electronics manufacturing ecosystems. However, emerging economies in Southeast Asia and India are showing the fastest growth rates, presenting new market opportunities for large-scale thin film production technologies.

The transition toward sustainable manufacturing processes has created additional market pull for spray pyrolysis techniques, which offer relatively lower environmental impact compared to some alternative deposition methods. Industries are increasingly valuing production techniques that minimize waste generation and energy consumption while maintaining high-quality output, aligning well with the capabilities of advanced spray pyrolysis systems.

Customer requirements are evolving toward higher precision, greater uniformity, and increased production throughput, particularly for applications in next-generation electronics and renewable energy technologies. This trend necessitates continuous innovation in spray pyrolysis equipment and methodologies to meet these demanding specifications at industrial scales.

Electronics and semiconductor industries remain the largest consumers of thin film technologies, accounting for nearly 40% of the total market share. The miniaturization trend in electronic devices continues to fuel demand for thinner, more efficient coating solutions that spray pyrolysis can effectively deliver. Additionally, the global push toward energy efficiency has significantly boosted the solar photovoltaic sector, where thin film solar cells represent a rapidly growing segment with projected annual growth rates exceeding 12% through 2030.

Consumer electronics manufacturers are increasingly incorporating thin film technologies in displays, touchscreens, and flexible electronics. The market for OLED displays alone, which heavily relies on thin film deposition techniques, is expected to grow at 15% annually, creating substantial opportunities for large-scale spray pyrolysis applications. The automotive industry has also emerged as a significant market, with thin films being utilized in smart windows, displays, and various sensor applications.

Healthcare and biomedical applications represent another expanding market segment, with thin films being used in biosensors, medical implants, and drug delivery systems. This sector is projected to grow at 9.5% annually through 2028, driven by increasing healthcare expenditure and technological advancements in medical devices.

Regionally, Asia-Pacific dominates the thin film market, accounting for approximately 45% of global demand, followed by North America and Europe. China, Japan, South Korea, and Taiwan are particularly significant markets due to their robust electronics manufacturing ecosystems. However, emerging economies in Southeast Asia and India are showing the fastest growth rates, presenting new market opportunities for large-scale thin film production technologies.

The transition toward sustainable manufacturing processes has created additional market pull for spray pyrolysis techniques, which offer relatively lower environmental impact compared to some alternative deposition methods. Industries are increasingly valuing production techniques that minimize waste generation and energy consumption while maintaining high-quality output, aligning well with the capabilities of advanced spray pyrolysis systems.

Customer requirements are evolving toward higher precision, greater uniformity, and increased production throughput, particularly for applications in next-generation electronics and renewable energy technologies. This trend necessitates continuous innovation in spray pyrolysis equipment and methodologies to meet these demanding specifications at industrial scales.

Current State and Challenges in Spray Pyrolysis Scaling

Spray pyrolysis technology has evolved significantly over the past decades, transitioning from laboratory-scale experiments to pilot production facilities. Currently, the technology demonstrates promising capabilities for thin film deposition across various applications including solar cells, sensors, and protective coatings. Global research institutions and industrial entities have achieved notable success in implementing spray pyrolysis for medium-scale production, particularly in developing countries where cost-effective manufacturing solutions are prioritized.

Despite these advancements, the scaling of spray pyrolysis to truly industrial levels faces several critical challenges. Uniformity control represents perhaps the most significant obstacle, as maintaining consistent film thickness and composition becomes exponentially more difficult when scaling from laboratory dimensions (typically 10-100 cm²) to industrial requirements (often exceeding several square meters). The edge effects and flow dynamics that are manageable at smaller scales become dominant factors in large-area deposition.

Precursor delivery systems constitute another major limitation. Current atomization technologies struggle to maintain consistent droplet size distribution when scaled up, leading to variations in film morphology across larger substrates. The engineering of nozzle arrays that can deliver uniform spray patterns over extended areas without interference patterns remains problematic, with most existing solutions requiring complex synchronization systems that add cost and maintenance requirements.

Temperature control across large substrates presents additional complications. The thermal gradients that develop during deposition can cause significant variations in reaction kinetics, crystallization behavior, and ultimately film properties. Current heating systems lack the precision required for maintaining temperature uniformity within ±2°C across industrial-scale substrates, which is often necessary for high-performance electronic materials.

Process reproducibility also deteriorates with scale. Minor variations in ambient conditions, precursor chemistry, or equipment performance that might be negligible in laboratory settings can propagate into significant quality issues in continuous production environments. The lack of standardized in-line monitoring techniques for spray pyrolysis further complicates quality control efforts.

Environmental and safety considerations become more pronounced at industrial scales. The aerosolization of chemical precursors creates potential exposure risks that require sophisticated extraction and filtration systems. Additionally, the solvent volumes required for large-scale production raise concerns regarding volatile organic compound (VOC) emissions and fire safety, necessitating significant investment in environmental control systems.

Economic viability remains questionable for certain applications. While spray pyrolysis offers cost advantages for some materials, the capital expenditure required for scaling up specialized equipment, combined with higher material utilization inefficiencies at larger scales, creates barriers to widespread industrial adoption. Current estimates suggest material utilization rates rarely exceed 40% in scaled systems, compared to 60-70% achievable in optimized laboratory setups.

Despite these advancements, the scaling of spray pyrolysis to truly industrial levels faces several critical challenges. Uniformity control represents perhaps the most significant obstacle, as maintaining consistent film thickness and composition becomes exponentially more difficult when scaling from laboratory dimensions (typically 10-100 cm²) to industrial requirements (often exceeding several square meters). The edge effects and flow dynamics that are manageable at smaller scales become dominant factors in large-area deposition.

Precursor delivery systems constitute another major limitation. Current atomization technologies struggle to maintain consistent droplet size distribution when scaled up, leading to variations in film morphology across larger substrates. The engineering of nozzle arrays that can deliver uniform spray patterns over extended areas without interference patterns remains problematic, with most existing solutions requiring complex synchronization systems that add cost and maintenance requirements.

Temperature control across large substrates presents additional complications. The thermal gradients that develop during deposition can cause significant variations in reaction kinetics, crystallization behavior, and ultimately film properties. Current heating systems lack the precision required for maintaining temperature uniformity within ±2°C across industrial-scale substrates, which is often necessary for high-performance electronic materials.

Process reproducibility also deteriorates with scale. Minor variations in ambient conditions, precursor chemistry, or equipment performance that might be negligible in laboratory settings can propagate into significant quality issues in continuous production environments. The lack of standardized in-line monitoring techniques for spray pyrolysis further complicates quality control efforts.

Environmental and safety considerations become more pronounced at industrial scales. The aerosolization of chemical precursors creates potential exposure risks that require sophisticated extraction and filtration systems. Additionally, the solvent volumes required for large-scale production raise concerns regarding volatile organic compound (VOC) emissions and fire safety, necessitating significant investment in environmental control systems.

Economic viability remains questionable for certain applications. While spray pyrolysis offers cost advantages for some materials, the capital expenditure required for scaling up specialized equipment, combined with higher material utilization inefficiencies at larger scales, creates barriers to widespread industrial adoption. Current estimates suggest material utilization rates rarely exceed 40% in scaled systems, compared to 60-70% achievable in optimized laboratory setups.

Current Industrial-Scale Spray Pyrolysis Implementation Methods

01 Spray pyrolysis for nanoparticle synthesis

Spray pyrolysis is widely used for the synthesis of nanoparticles with controlled size, morphology, and composition. This technique involves atomizing a precursor solution into fine droplets that undergo thermal decomposition in a high-temperature environment, resulting in the formation of nanoparticles. The process allows for precise control over particle characteristics by adjusting parameters such as precursor concentration, temperature, and residence time.- Spray pyrolysis for nanoparticle synthesis: Spray pyrolysis is used for the synthesis of various nanoparticles with controlled size, morphology, and composition. This technique involves atomizing a precursor solution into fine droplets that undergo thermal decomposition in a heated zone, resulting in the formation of nanoparticles. The process allows for continuous production of high-purity nanomaterials with uniform characteristics, which can be used in various applications including catalysis, electronics, and energy storage.

- Thin film deposition via spray pyrolysis: Spray pyrolysis is employed for the deposition of thin films on various substrates. In this process, a precursor solution is atomized and sprayed onto a heated substrate where thermal decomposition occurs, resulting in the formation of a solid film. This technique offers advantages such as simplicity, cost-effectiveness, and the ability to deposit films on large areas and complex geometries. It is widely used for producing semiconductor, oxide, and conductive films for electronic devices, solar cells, and sensors.

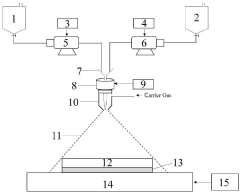

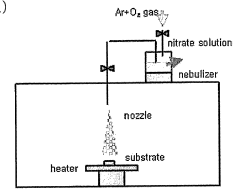

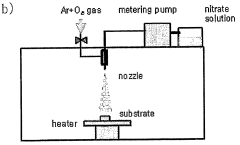

- Equipment and apparatus for spray pyrolysis: Various specialized equipment and apparatus have been developed for spray pyrolysis processes. These include atomizers, spray nozzles, heated chambers, and collection systems designed to optimize the spray pyrolysis process for specific applications. Advanced systems may incorporate features such as ultrasonic or pneumatic atomization, temperature control zones, and automated precursor delivery systems to enhance process control and reproducibility. These technological improvements enable more efficient production of nanomaterials and thin films with precise characteristics.

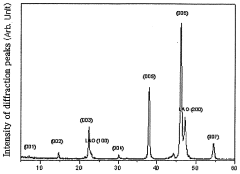

- Superconductor material production using spray pyrolysis: Spray pyrolysis is utilized for the synthesis of superconductor materials with high critical temperatures and current densities. The process allows for precise control of stoichiometry and phase formation, which are crucial for superconducting properties. By atomizing solutions containing metal precursors and subjecting them to controlled thermal treatment, high-quality superconducting materials can be produced in the form of powders or films. This approach offers advantages in terms of homogeneity and scalability compared to conventional solid-state synthesis methods.

- Functional ceramic materials via spray pyrolysis: Spray pyrolysis enables the production of functional ceramic materials with tailored properties for various applications. This technique allows for the synthesis of complex oxide ceramics, doped materials, and composite structures with controlled composition and microstructure. The process involves the thermal decomposition of atomized precursor solutions, resulting in ceramic particles or films with specific functional properties. Applications include catalysts, sensors, solid oxide fuel cells, and electronic components where precise control of material characteristics is essential for performance.

02 Thin film deposition via spray pyrolysis

Spray pyrolysis is an effective method for depositing thin films on various substrates. In this process, a precursor solution is atomized and sprayed onto a heated substrate where thermal decomposition occurs, resulting in the formation of a solid film. This technique is valued for its simplicity, cost-effectiveness, and ability to produce uniform coatings with good adhesion. It is particularly useful for creating functional thin films for electronic, optical, and energy applications.Expand Specific Solutions03 Equipment and apparatus for spray pyrolysis

Specialized equipment and apparatus have been developed to optimize the spray pyrolysis process. These systems typically include components for solution preparation, atomization mechanisms (such as ultrasonic or pressure nozzles), temperature-controlled reaction chambers, and collection systems. Advanced designs incorporate features for precise control of spray parameters, heating profiles, and gas flow dynamics to enhance process efficiency and product quality.Expand Specific Solutions04 Superconductor and ceramic material production

Spray pyrolysis is employed for the synthesis of high-quality superconducting and ceramic materials. The technique allows for the production of complex oxide materials with controlled stoichiometry and phase purity. By carefully selecting precursor solutions and controlling reaction conditions, materials with specific electrical, magnetic, and structural properties can be produced for applications in energy storage, electronics, and high-field magnets.Expand Specific Solutions05 Catalytic materials and functional coatings

Spray pyrolysis enables the production of catalytic materials and functional coatings with enhanced performance characteristics. The process can create materials with high surface area, controlled porosity, and specific active sites for catalytic applications. These materials find use in environmental remediation, chemical processing, and energy conversion systems. The technique also allows for doping and compositional modifications to tailor the properties for specific applications.Expand Specific Solutions

Leading Companies and Research Institutions in Thin Film Production

The spray pyrolysis thin film production market is currently in a growth phase, with increasing adoption across semiconductor, solar, and electronics industries. The global market size is estimated to reach $3.5 billion by 2025, driven by demand for cost-effective large-scale manufacturing solutions. Technologically, the field shows varying maturity levels, with companies like TSMC and GlobalFoundries leading commercial implementation in semiconductor applications, while Sharp Corp. and Suntech Power demonstrate advanced capabilities in solar applications. Research institutions including MIT, Swiss Federal Institute of Technology, and Chinese Academy of Science are advancing fundamental innovations. Emerging players like Alion Energy and CTF Solar are developing specialized applications, while established materials companies such as Cabot Corp. and Shoei Chemical provide essential precursor materials, creating a competitive ecosystem balancing industrial implementation with ongoing research advancements.

Swiss Federal Institute of Technology

Technical Solution: The Swiss Federal Institute of Technology (ETH Zurich) has developed an innovative spray pyrolysis system for large-scale thin film production that combines precision fluid dynamics with advanced thermal management. Their approach utilizes a computer-controlled array of ultrasonic nozzles that generate precisely sized droplets (2-10μm) with narrow size distribution. The system incorporates a unique substrate motion mechanism that ensures uniform coverage across large areas while maintaining optimal spray-to-substrate distance. ETH researchers have pioneered a multi-zone heating approach that creates carefully controlled temperature gradients across the substrate, enabling manipulation of film growth dynamics and crystallization behavior. Their process has demonstrated exceptional results for transparent conducting oxides (particularly ITO and AZO films) with sheet resistances below 10 Ω/sq and optical transparency exceeding 85%. The system incorporates real-time monitoring of film properties using spectroscopic ellipsometry, allowing for dynamic adjustment of spray parameters to maintain consistent film quality. ETH has also developed specialized precursor formulations that improve solution stability and decomposition characteristics, resulting in films with enhanced electrical and optical properties.

Strengths: Exceptional control over film microstructure and electrical properties; ability to create films with complex compositional gradients; highly reproducible process with minimal run-to-run variation. Weaknesses: Relatively slower deposition rates compared to some industrial techniques; challenges with scaling to ultra-high throughput manufacturing; higher technical expertise required for system operation and maintenance.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed a proprietary spray pyrolysis technology for large-scale production of high-quality thin films used in semiconductor manufacturing. Their system employs a precision-engineered array of piezoelectric atomizers that generate uniform microdroplets (1-3μm diameter) of precursor solutions. These droplets are delivered to heated silicon wafers through a laminar flow system that minimizes turbulence and ensures uniform deposition. TSMC's innovation includes a multi-stage thermal processing approach where initial low-temperature deposition is followed by controlled ramping to higher temperatures, enabling precise control of film crystallization and densification. Their process achieves exceptional thickness uniformity (<±2% variation) across 300mm wafers. The company has successfully implemented this technology for depositing dielectric layers, passivation films, and specialized functional oxides with thicknesses ranging from 10nm to several hundred nanometers. TSMC's spray pyrolysis system incorporates advanced automation with feedback control based on in-line metrology, allowing for continuous process optimization during high-volume manufacturing.

Strengths: Exceptional thickness uniformity and film quality suitable for advanced semiconductor applications; highly automated process with minimal operator intervention; excellent reproducibility between production runs. Weaknesses: Limited to smaller substrate sizes compared to other industries; higher production costs due to precision equipment requirements; challenges with certain material systems requiring extremely precise stoichiometry control.

Key Patents and Technical Innovations in Spray Pyrolysis

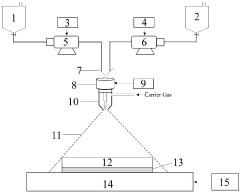

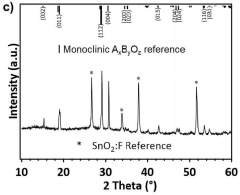

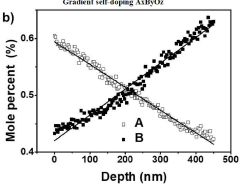

Spray pyrolysis preparation method of gradient self-doping multi metal oxide semiconductor thin film

PatentActiveAU2021100535A4

Innovation

- A spray pyrolysis method that precisely controls the liquid feeding flow rate of precursor solutions for metal ions A and B, creating a controllable A/B ratio gradient from the bottom to the top of the thin film without relying on thermal diffusion, allowing for the preparation of multi metal oxide semiconductor thin films with varying thicknesses and avoiding phase separation.

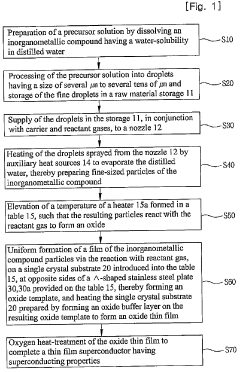

Method and apparatus for fabrication of thin film superconductor by spray pyrolysis chemical vapor deposition method

PatentWO2008038856A1

Innovation

- A method utilizing inexpensive inorganometallic compounds like nitrates, chlorides, and sulfates dissolved in distilled water for spray pyrolysis chemical vapor deposition, forming a precursor solution that is processed into fine droplets, sprayed onto a substrate, and reacted with gases to form a superconducting thin film of REBa2Cu3O7-x with a specific cation ratio, using a Λ shaped stainless steel plate and oxygen heat-treatment to achieve epitaxial deposition.

Cost-Benefit Analysis of Large-Scale Implementation

The implementation of spray pyrolysis technology for large-scale thin film production requires careful economic evaluation to determine its viability in industrial settings. Initial capital expenditure for spray pyrolysis equipment is significantly lower than competing technologies such as chemical vapor deposition (CVD) or sputtering systems, with estimates suggesting 40-60% cost savings in equipment acquisition. A medium-scale spray pyrolysis production line typically costs between $500,000 to $2 million, compared to $1.5-5 million for equivalent CVD systems.

Operational expenses also demonstrate favorable economics, with spray pyrolysis consuming approximately 30% less energy than vacuum-based deposition methods. Material utilization efficiency ranges from 70-85% for optimized spray systems, reducing waste and associated costs. Additionally, the ambient pressure operation eliminates expensive vacuum maintenance requirements, reducing annual maintenance costs by an estimated 25-35%.

Production throughput analysis indicates that modern automated spray pyrolysis systems can achieve deposition rates of 100-300 nm/min across large areas, enabling the processing of 50-100 m²/hour depending on film thickness requirements. This translates to competitive production costs of $3-8 per square meter for typical metal oxide films, positioning spray pyrolysis favorably against other industrial coating technologies.

Return on investment calculations based on industry case studies suggest payback periods of 18-36 months for facilities transitioning from other deposition methods to spray pyrolysis. Companies implementing large-scale spray pyrolysis for solar cell manufacturing have reported manufacturing cost reductions of 15-25% for the deposition process step.

Environmental compliance costs must also be factored into the economic analysis. While spray pyrolysis generates less hazardous waste than many competing technologies, proper ventilation and solvent recovery systems represent necessary investments, typically adding 5-10% to initial capital costs but reducing long-term regulatory compliance expenses.

Scalability economics reveal that spray pyrolysis demonstrates favorable cost scaling, with per-unit production costs decreasing approximately 15-20% when doubling production capacity. This positive economy of scale makes the technology particularly attractive for high-volume manufacturing applications in solar energy, display technology, and functional coatings markets.

Labor requirements for spray pyrolysis operations are moderate, with a typical large-scale production line requiring 3-5 skilled operators per shift, compared to 4-7 for equivalent PVD or CVD operations. This translates to approximately 12-18% savings in direct labor costs over competing technologies.

Operational expenses also demonstrate favorable economics, with spray pyrolysis consuming approximately 30% less energy than vacuum-based deposition methods. Material utilization efficiency ranges from 70-85% for optimized spray systems, reducing waste and associated costs. Additionally, the ambient pressure operation eliminates expensive vacuum maintenance requirements, reducing annual maintenance costs by an estimated 25-35%.

Production throughput analysis indicates that modern automated spray pyrolysis systems can achieve deposition rates of 100-300 nm/min across large areas, enabling the processing of 50-100 m²/hour depending on film thickness requirements. This translates to competitive production costs of $3-8 per square meter for typical metal oxide films, positioning spray pyrolysis favorably against other industrial coating technologies.

Return on investment calculations based on industry case studies suggest payback periods of 18-36 months for facilities transitioning from other deposition methods to spray pyrolysis. Companies implementing large-scale spray pyrolysis for solar cell manufacturing have reported manufacturing cost reductions of 15-25% for the deposition process step.

Environmental compliance costs must also be factored into the economic analysis. While spray pyrolysis generates less hazardous waste than many competing technologies, proper ventilation and solvent recovery systems represent necessary investments, typically adding 5-10% to initial capital costs but reducing long-term regulatory compliance expenses.

Scalability economics reveal that spray pyrolysis demonstrates favorable cost scaling, with per-unit production costs decreasing approximately 15-20% when doubling production capacity. This positive economy of scale makes the technology particularly attractive for high-volume manufacturing applications in solar energy, display technology, and functional coatings markets.

Labor requirements for spray pyrolysis operations are moderate, with a typical large-scale production line requiring 3-5 skilled operators per shift, compared to 4-7 for equivalent PVD or CVD operations. This translates to approximately 12-18% savings in direct labor costs over competing technologies.

Environmental Impact and Sustainability Considerations

The environmental impact of spray pyrolysis in large-scale thin film production deserves critical examination as this technology transitions from laboratory to industrial applications. Compared to conventional thin film deposition methods such as physical vapor deposition or chemical vapor deposition, spray pyrolysis typically operates at lower temperatures and atmospheric pressure, resulting in significantly reduced energy consumption. This energy efficiency translates to lower carbon emissions when implemented at industrial scale, positioning spray pyrolysis as a potentially more environmentally friendly manufacturing process.

Material utilization represents another key sustainability advantage of spray pyrolysis. The direct deposition mechanism allows for precise control over precursor delivery, minimizing waste generation compared to alternative techniques. Studies indicate that properly optimized spray pyrolysis systems can achieve material utilization rates exceeding 80%, substantially higher than many competing technologies. This efficiency reduces both raw material consumption and waste management requirements, contributing to more sustainable manufacturing practices.

Water usage in spray pyrolysis processes presents both challenges and opportunities. While aqueous-based precursor solutions are common, the technology allows for the exploration of green solvents and water-based systems that minimize environmental impact. Recent research has demonstrated successful implementation of bio-derived solvents and recycling systems that can reduce freshwater consumption by up to 60% in continuous production environments.

Airborne emissions during spray pyrolysis operations require careful management, particularly when scaling to industrial production. The atomization process can generate aerosols containing precursor chemicals that necessitate appropriate filtration and scrubbing systems. Modern spray pyrolysis facilities incorporate closed-loop ventilation designs with multi-stage filtration that can capture over 99% of particulate emissions, ensuring minimal environmental release of potentially harmful substances.

End-of-life considerations for thin films produced via spray pyrolysis also factor into sustainability assessments. The technique's compatibility with a wide range of substrate materials, including recyclable options, enhances the potential for circular economy integration. Additionally, the relatively simple chemical composition of many spray pyrolysis-derived films facilitates material recovery and recycling compared to more complex multi-layer structures produced by alternative methods.

Regulatory compliance represents an increasingly important aspect of spray pyrolysis implementation. As environmental regulations tighten globally, the relatively benign nature of many spray pyrolysis processes offers compliance advantages. The technology's adaptability allows manufacturers to proactively substitute hazardous precursors with environmentally friendly alternatives while maintaining performance specifications, positioning spray pyrolysis as a forward-compatible technology in an evolving regulatory landscape.

Material utilization represents another key sustainability advantage of spray pyrolysis. The direct deposition mechanism allows for precise control over precursor delivery, minimizing waste generation compared to alternative techniques. Studies indicate that properly optimized spray pyrolysis systems can achieve material utilization rates exceeding 80%, substantially higher than many competing technologies. This efficiency reduces both raw material consumption and waste management requirements, contributing to more sustainable manufacturing practices.

Water usage in spray pyrolysis processes presents both challenges and opportunities. While aqueous-based precursor solutions are common, the technology allows for the exploration of green solvents and water-based systems that minimize environmental impact. Recent research has demonstrated successful implementation of bio-derived solvents and recycling systems that can reduce freshwater consumption by up to 60% in continuous production environments.

Airborne emissions during spray pyrolysis operations require careful management, particularly when scaling to industrial production. The atomization process can generate aerosols containing precursor chemicals that necessitate appropriate filtration and scrubbing systems. Modern spray pyrolysis facilities incorporate closed-loop ventilation designs with multi-stage filtration that can capture over 99% of particulate emissions, ensuring minimal environmental release of potentially harmful substances.

End-of-life considerations for thin films produced via spray pyrolysis also factor into sustainability assessments. The technique's compatibility with a wide range of substrate materials, including recyclable options, enhances the potential for circular economy integration. Additionally, the relatively simple chemical composition of many spray pyrolysis-derived films facilitates material recovery and recycling compared to more complex multi-layer structures produced by alternative methods.

Regulatory compliance represents an increasingly important aspect of spray pyrolysis implementation. As environmental regulations tighten globally, the relatively benign nature of many spray pyrolysis processes offers compliance advantages. The technology's adaptability allows manufacturers to proactively substitute hazardous precursors with environmentally friendly alternatives while maintaining performance specifications, positioning spray pyrolysis as a forward-compatible technology in an evolving regulatory landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!