Research on Spray Pyrolysis for Ultraviolet Blocking Layers

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UV Blocking Technology Evolution and Objectives

Ultraviolet (UV) radiation protection has evolved significantly over the past decades, driven by increasing awareness of UV-related health risks and environmental concerns. The development of UV blocking technologies can be traced back to the 1940s with the introduction of basic physical barriers and chemical absorbers. Early approaches primarily relied on thick, opaque materials that blocked sunlight entirely, offering protection but with limited practical applications.

The 1970s marked a turning point with the discovery of organic UV absorbers, which could be incorporated into transparent materials. This innovation expanded applications beyond personal protection to include building materials, automotive glass, and electronic displays. By the 1990s, nanoparticle-based UV blockers emerged, offering superior performance with minimal impact on material transparency and physical properties.

Spray pyrolysis technology represents a significant advancement in this evolution. This technique, which involves the thermal decomposition of precursor solutions sprayed onto heated substrates, gained prominence in the early 2000s for thin film deposition. Its application to UV blocking layers began around 2010, offering advantages in terms of scalability, cost-effectiveness, and precise control over film composition and morphology.

Current technological objectives for spray pyrolysis in UV blocking applications focus on several key areas. First, enhancing the efficiency of UV absorption across the entire UV spectrum (UVA, UVB, and UVC) while maintaining high visible light transmission. Second, improving the durability and stability of these coatings under various environmental conditions, including resistance to weathering, humidity, and temperature fluctuations.

Another critical objective is the development of environmentally friendly processes and materials. This includes reducing or eliminating toxic precursors, minimizing waste generation, and creating biodegradable or recyclable UV blocking solutions. The industry is also pursuing cost reduction strategies to make these technologies more accessible for mass-market applications.

Integration capabilities represent another important goal, with research focused on making spray pyrolysis-derived UV blocking layers compatible with various substrate materials including polymers, glass, textiles, and flexible electronics. This would significantly expand potential applications across industries.

Finally, there is growing interest in multifunctional UV blocking layers that combine UV protection with additional properties such as antimicrobial activity, self-cleaning capabilities, or energy-harvesting functionalities. These advanced materials could revolutionize sectors ranging from healthcare to renewable energy, creating new market opportunities and technological synergies.

The 1970s marked a turning point with the discovery of organic UV absorbers, which could be incorporated into transparent materials. This innovation expanded applications beyond personal protection to include building materials, automotive glass, and electronic displays. By the 1990s, nanoparticle-based UV blockers emerged, offering superior performance with minimal impact on material transparency and physical properties.

Spray pyrolysis technology represents a significant advancement in this evolution. This technique, which involves the thermal decomposition of precursor solutions sprayed onto heated substrates, gained prominence in the early 2000s for thin film deposition. Its application to UV blocking layers began around 2010, offering advantages in terms of scalability, cost-effectiveness, and precise control over film composition and morphology.

Current technological objectives for spray pyrolysis in UV blocking applications focus on several key areas. First, enhancing the efficiency of UV absorption across the entire UV spectrum (UVA, UVB, and UVC) while maintaining high visible light transmission. Second, improving the durability and stability of these coatings under various environmental conditions, including resistance to weathering, humidity, and temperature fluctuations.

Another critical objective is the development of environmentally friendly processes and materials. This includes reducing or eliminating toxic precursors, minimizing waste generation, and creating biodegradable or recyclable UV blocking solutions. The industry is also pursuing cost reduction strategies to make these technologies more accessible for mass-market applications.

Integration capabilities represent another important goal, with research focused on making spray pyrolysis-derived UV blocking layers compatible with various substrate materials including polymers, glass, textiles, and flexible electronics. This would significantly expand potential applications across industries.

Finally, there is growing interest in multifunctional UV blocking layers that combine UV protection with additional properties such as antimicrobial activity, self-cleaning capabilities, or energy-harvesting functionalities. These advanced materials could revolutionize sectors ranging from healthcare to renewable energy, creating new market opportunities and technological synergies.

Market Analysis for UV Blocking Materials

The global market for UV blocking materials has experienced significant growth in recent years, driven by increasing awareness of UV radiation's harmful effects and the growing demand for protective solutions across various industries. The market size for UV blocking materials was valued at approximately 550 million USD in 2022 and is projected to reach 830 million USD by 2028, representing a compound annual growth rate (CAGR) of 7.1% during the forecast period.

Consumer awareness regarding skin protection against UV radiation has substantially increased, particularly in regions with high UV index levels. This has led to a surge in demand for personal care products incorporating UV blocking technologies. The cosmetics and personal care segment currently holds the largest market share at 38%, followed by the construction industry at 24% and automotive applications at 17%.

Regionally, North America dominates the market with approximately 35% share, attributed to stringent regulations regarding UV protection in consumer products and high consumer awareness. Asia-Pacific represents the fastest-growing region with an estimated CAGR of 8.5%, driven by rapid industrialization, increasing disposable income, and growing awareness about UV protection in countries like China, Japan, and India.

The spray pyrolysis technology for UV blocking layers presents significant market opportunities due to its cost-effectiveness and scalability compared to traditional methods. The production cost reduction potential of 30-40% makes it particularly attractive for mass-market applications. Additionally, the ability to create uniform thin films with precise thickness control addresses the growing demand for transparent UV blocking solutions in electronics and architectural glass markets.

Key market drivers include stringent regulations regarding UV protection in various countries, increasing incidence of skin diseases related to UV exposure, and growing demand for UV protection in electronic displays and architectural applications. The electronics industry, in particular, shows promising growth potential with an estimated CAGR of 9.2% for UV blocking materials.

Market challenges include price sensitivity in emerging economies, technical limitations in achieving broad-spectrum protection, and competition from alternative technologies. However, the development of eco-friendly and sustainable UV blocking materials presents a significant opportunity, as environmental regulations become increasingly stringent worldwide.

Consumer preference is shifting toward multifunctional UV blocking materials that offer additional benefits such as anti-aging properties, blue light protection, and environmental sustainability. This trend is expected to drive innovation in spray pyrolysis techniques to develop next-generation UV blocking layers with enhanced functionality and performance characteristics.

Consumer awareness regarding skin protection against UV radiation has substantially increased, particularly in regions with high UV index levels. This has led to a surge in demand for personal care products incorporating UV blocking technologies. The cosmetics and personal care segment currently holds the largest market share at 38%, followed by the construction industry at 24% and automotive applications at 17%.

Regionally, North America dominates the market with approximately 35% share, attributed to stringent regulations regarding UV protection in consumer products and high consumer awareness. Asia-Pacific represents the fastest-growing region with an estimated CAGR of 8.5%, driven by rapid industrialization, increasing disposable income, and growing awareness about UV protection in countries like China, Japan, and India.

The spray pyrolysis technology for UV blocking layers presents significant market opportunities due to its cost-effectiveness and scalability compared to traditional methods. The production cost reduction potential of 30-40% makes it particularly attractive for mass-market applications. Additionally, the ability to create uniform thin films with precise thickness control addresses the growing demand for transparent UV blocking solutions in electronics and architectural glass markets.

Key market drivers include stringent regulations regarding UV protection in various countries, increasing incidence of skin diseases related to UV exposure, and growing demand for UV protection in electronic displays and architectural applications. The electronics industry, in particular, shows promising growth potential with an estimated CAGR of 9.2% for UV blocking materials.

Market challenges include price sensitivity in emerging economies, technical limitations in achieving broad-spectrum protection, and competition from alternative technologies. However, the development of eco-friendly and sustainable UV blocking materials presents a significant opportunity, as environmental regulations become increasingly stringent worldwide.

Consumer preference is shifting toward multifunctional UV blocking materials that offer additional benefits such as anti-aging properties, blue light protection, and environmental sustainability. This trend is expected to drive innovation in spray pyrolysis techniques to develop next-generation UV blocking layers with enhanced functionality and performance characteristics.

Spray Pyrolysis Technology Status and Barriers

Spray pyrolysis technology for ultraviolet blocking layers has witnessed significant advancements globally, yet continues to face several technical challenges. Currently, the technology has reached moderate maturity levels in laboratory settings, with successful demonstrations of uniform thin film deposition for UV blocking applications. However, the transition from laboratory to industrial-scale production remains problematic due to issues with process consistency and scalability.

The primary technical barrier lies in achieving precise control over particle size distribution and film morphology during the spray pyrolysis process. Research indicates that optimal UV blocking performance requires nanoparticles within specific size ranges (typically 20-50 nm), which are difficult to maintain consistently across large substrate areas. Temperature gradient control during deposition represents another significant challenge, as even minor fluctuations can lead to film non-uniformity and compromised optical properties.

Precursor chemistry optimization remains an ongoing challenge, particularly for environmentally friendly formulations. While traditional metal oxide precursors (primarily titanium and zinc compounds) demonstrate excellent UV blocking capabilities, they often require toxic solvents or produce harmful byproducts. Recent research has focused on developing water-based precursor systems, though these typically exhibit lower deposition efficiency and film quality compared to conventional solutions.

Equipment design limitations constitute another barrier to widespread adoption. Current spray pyrolysis systems struggle with precise droplet size control and uniform distribution across large areas. Nozzle clogging during extended operation periods remains problematic, particularly when using precursors with high solid content necessary for efficient deposition. Additionally, most existing systems lack real-time monitoring capabilities to adjust process parameters dynamically.

From a geographical perspective, spray pyrolysis technology development shows distinct regional characteristics. European research institutions lead in fundamental studies and green chemistry approaches, while Asian manufacturers (particularly in Japan, South Korea, and China) dominate in scaling up the technology for commercial applications. North American contributions focus primarily on novel precursor development and advanced characterization techniques.

Energy efficiency represents another significant barrier, as conventional spray pyrolysis typically requires high substrate temperatures (300-500°C) to achieve proper film crystallization. This energy requirement limits application on temperature-sensitive substrates and increases production costs. Low-temperature alternatives using plasma-assisted or photochemical activation show promise but remain in early development stages.

Material performance trade-offs present ongoing challenges, as optimizing one property (such as UV blocking efficiency) often compromises others (like visible light transmission or durability). Researchers continue to explore multi-component systems and composite structures to overcome these limitations, though complexity increases manufacturing challenges.

The primary technical barrier lies in achieving precise control over particle size distribution and film morphology during the spray pyrolysis process. Research indicates that optimal UV blocking performance requires nanoparticles within specific size ranges (typically 20-50 nm), which are difficult to maintain consistently across large substrate areas. Temperature gradient control during deposition represents another significant challenge, as even minor fluctuations can lead to film non-uniformity and compromised optical properties.

Precursor chemistry optimization remains an ongoing challenge, particularly for environmentally friendly formulations. While traditional metal oxide precursors (primarily titanium and zinc compounds) demonstrate excellent UV blocking capabilities, they often require toxic solvents or produce harmful byproducts. Recent research has focused on developing water-based precursor systems, though these typically exhibit lower deposition efficiency and film quality compared to conventional solutions.

Equipment design limitations constitute another barrier to widespread adoption. Current spray pyrolysis systems struggle with precise droplet size control and uniform distribution across large areas. Nozzle clogging during extended operation periods remains problematic, particularly when using precursors with high solid content necessary for efficient deposition. Additionally, most existing systems lack real-time monitoring capabilities to adjust process parameters dynamically.

From a geographical perspective, spray pyrolysis technology development shows distinct regional characteristics. European research institutions lead in fundamental studies and green chemistry approaches, while Asian manufacturers (particularly in Japan, South Korea, and China) dominate in scaling up the technology for commercial applications. North American contributions focus primarily on novel precursor development and advanced characterization techniques.

Energy efficiency represents another significant barrier, as conventional spray pyrolysis typically requires high substrate temperatures (300-500°C) to achieve proper film crystallization. This energy requirement limits application on temperature-sensitive substrates and increases production costs. Low-temperature alternatives using plasma-assisted or photochemical activation show promise but remain in early development stages.

Material performance trade-offs present ongoing challenges, as optimizing one property (such as UV blocking efficiency) often compromises others (like visible light transmission or durability). Researchers continue to explore multi-component systems and composite structures to overcome these limitations, though complexity increases manufacturing challenges.

Current Spray Pyrolysis Implementation Approaches

01 Metal oxide nanoparticles for UV blocking via spray pyrolysis

Metal oxide nanoparticles, particularly zinc oxide and titanium dioxide, can be synthesized through spray pyrolysis techniques to create effective UV blocking materials. The process allows for precise control of particle size and morphology, which directly affects the UV blocking efficiency. These nanoparticles can be incorporated into various substrates to provide protection against harmful ultraviolet radiation.- Metal oxide nanoparticles for UV blocking via spray pyrolysis: Metal oxide nanoparticles, particularly titanium dioxide (TiO2) and zinc oxide (ZnO), can be synthesized using spray pyrolysis techniques to create effective ultraviolet blocking materials. These nanoparticles exhibit superior UV absorption properties due to their optimized particle size and morphology achieved through controlled spray pyrolysis conditions. The resulting materials provide broad-spectrum protection against both UVA and UVB radiation while maintaining transparency in visible light.

- Doped metal oxide systems for enhanced UV blocking efficiency: Doping metal oxides with various elements during the spray pyrolysis process can significantly enhance their UV blocking capabilities. Common dopants include transition metals, rare earth elements, and non-metallic elements that modify the electronic structure of the host material. These doped systems exhibit improved photostability, increased UV absorption range, and reduced photocatalytic activity, making them ideal for applications requiring long-term UV protection without degradation.

- Core-shell and composite structures for multifunctional UV blocking: Spray pyrolysis enables the creation of core-shell and composite nanostructures that combine UV blocking with additional functionalities. These structures typically feature a UV-blocking core (often metal oxides) with shells or composite components that provide properties such as water resistance, improved dispersion, or antimicrobial activity. The layered architecture allows for tailored performance in specific applications while maintaining excellent ultraviolet protection.

- Process optimization for spray pyrolysis UV blocking materials: Various process parameters in spray pyrolysis significantly impact the UV blocking efficiency of the resulting materials. Key factors include precursor selection, solution concentration, atomization method, reaction temperature, and residence time. Optimization of these parameters allows for precise control over particle size distribution, crystallinity, and morphology, which directly influence the UV blocking performance. Advanced spray pyrolysis techniques such as flame-assisted or ultrasonic spray pyrolysis offer additional control over material properties.

- Applications of spray pyrolysis UV blocking materials: UV blocking materials produced via spray pyrolysis find applications across multiple industries. These include cosmetic sunscreens, UV-protective coatings for textiles and plastics, architectural glazing, automotive coatings, and protective films for electronics. The versatility of spray pyrolysis allows for the production of materials with application-specific properties such as transparency, durability, and compatibility with various substrate materials, making them highly adaptable for diverse UV protection needs.

02 Doped metal oxide formulations for enhanced UV protection

Doping metal oxides with various elements through spray pyrolysis can enhance their UV blocking properties. The introduction of dopants like silver, iron, or rare earth elements into the crystal structure of metal oxides modifies their electronic properties, resulting in improved absorption across the UV spectrum. These doped materials show superior performance compared to their undoped counterparts while maintaining transparency in the visible light range.Expand Specific Solutions03 Core-shell nanostructures for broad-spectrum UV blocking

Core-shell nanostructures produced via spray pyrolysis offer enhanced UV blocking capabilities across a broader spectrum. By creating particles with different materials in the core and shell, complementary UV absorption properties can be achieved. This approach allows for customization of the absorption profile while maintaining other desirable properties such as transparency, dispersibility, and stability in various formulations.Expand Specific Solutions04 Spray pyrolysis process optimization for UV blocking materials

Optimization of spray pyrolysis parameters significantly impacts the UV blocking efficiency of the resulting materials. Factors such as precursor concentration, solution pH, atomization method, reaction temperature, and residence time can be adjusted to control particle size, crystallinity, and morphology. Advanced spray pyrolysis techniques including flame-assisted, ultrasonic, and electrospray methods offer unique advantages for producing specialized UV blocking materials.Expand Specific Solutions05 Applications of spray pyrolysis UV blocking materials in consumer products

UV blocking materials produced by spray pyrolysis can be incorporated into various consumer products including cosmetics, textiles, coatings, and films. These materials provide protection against harmful UV radiation while maintaining product aesthetics and functionality. The nanoscale nature of spray pyrolysis products allows for transparent applications, while their surface properties can be modified to enhance compatibility with different product matrices.Expand Specific Solutions

Industry Leaders in UV Blocking Layer Manufacturing

The spray pyrolysis technology for ultraviolet blocking layers is currently in a growth phase, with an estimated market size of $1.2-1.5 billion and projected annual growth of 8-10%. The competitive landscape features established chemical companies like Merck Patent GmbH and SCHOTT AG leading with mature commercial applications, while specialized technology firms such as Beneq Group Oy and AGC Glass Europe focus on advanced coating techniques. Research institutions including CNRS and Brigham Young University are driving fundamental innovations. Asian manufacturers like Samsung Electronics, POSCO Holdings, and Huayou Cobalt are rapidly scaling production capabilities, particularly for electronics and automotive applications, leveraging cost advantages while gradually improving technical sophistication.

Merck Patent GmbH

Technical Solution: Merck Patent GmbH has developed advanced spray pyrolysis techniques for creating high-performance UV blocking layers using metal oxide nanoparticles. Their process involves precise control of precursor chemistry, particularly utilizing zinc oxide and titanium dioxide compounds doped with aluminum or other transition metals. The company employs ultrasonic spray pyrolysis with multi-zone temperature control (250-500°C) to achieve uniform thin films with controlled crystallinity and particle size distribution. Their proprietary solution chemistry enables the formation of dense, transparent films with tunable UV absorption properties across UVA and UVB spectrums. Merck's technology allows for large-area deposition on various substrates including glass and flexible polymers, with thickness control in the 50-300nm range, achieving over 95% UV blocking efficiency while maintaining visible light transmission above 85%.

Strengths: Superior control over film morphology and optical properties; scalable industrial production capability; excellent adhesion to multiple substrate types. Weaknesses: Higher production costs compared to conventional methods; requires precise process parameter control; some formulations may have limited long-term environmental stability.

Beneq Group Oy

Technical Solution: Beneq Group Oy has pioneered hybrid spray pyrolysis techniques for UV blocking layers, combining traditional spray pyrolysis with their expertise in Atomic Layer Deposition (ALD). Their approach utilizes a two-step process where an initial layer is deposited via spray pyrolysis to create a cost-effective base layer, followed by precision ALD coating to enhance UV blocking performance and durability. The company's spray pyrolysis system employs ultrasonic nebulization of metal salt precursors (primarily titanium, zinc, and cerium compounds) with precise droplet size control (2-5μm), followed by thermal decomposition at temperatures between 300-450°C. This creates nanostructured metal oxide films with controlled porosity and crystallinity. Beneq's process achieves uniform coatings on large-area substrates with thickness variation below 5%, and their UV blocking layers demonstrate absorption exceeding 99% in the critical UV spectrum while maintaining over 90% visible light transmission.

Strengths: Exceptional film uniformity and quality control; excellent scalability for industrial applications; superior durability through hybrid deposition approach. Weaknesses: Higher equipment complexity and capital investment; longer processing time compared to pure spray pyrolysis; requires specialized technical expertise for operation and maintenance.

Key Patents in UV Blocking Layer Fabrication

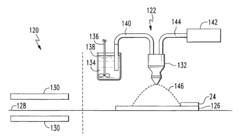

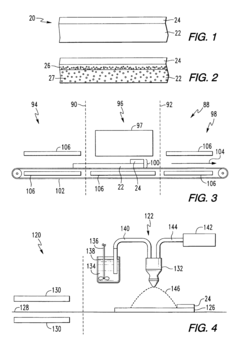

Photocatalytically-activated self-cleaning article and method of making same

PatentInactiveUS6722159B2

Innovation

- The use of chemical vapor deposition (CVD), spray pyrolysis, and magnetron sputtered vacuum deposition (MSVD) methods to apply a thin PASC coating, optionally with a sodium ion diffusion barrier (SIDB) layer, allowing for efficient coating on substrates at elevated temperatures and preventing sodium ion migration.

Spray pyrolysis method for in SITU production of graphene oxide based composites

PatentWO2012155196A1

Innovation

- A spray pyrolysis method is developed to produce graphene oxide-based nanocomposites in situ, involving the spraying of graphene oxide and precursors into a reaction chamber followed by heating, which allows for scalable, cost-effective, and highly homogeneous production of materials like GO-Mn2O3 and GO-Co3O4 composites with enhanced specific capacitance.

Environmental Impact Assessment

The environmental impact assessment of spray pyrolysis technology for ultraviolet blocking layers reveals both advantages and concerns that must be carefully considered for sustainable implementation. This manufacturing process demonstrates significant environmental benefits compared to traditional coating methods, primarily due to its reduced energy consumption and minimal waste generation. The water-based nature of many spray pyrolysis precursor solutions eliminates the need for harmful organic solvents, substantially decreasing volatile organic compound (VOC) emissions that contribute to air pollution and ozone depletion.

The process operates at lower temperatures than alternative coating technologies such as physical vapor deposition or sputtering, resulting in a smaller carbon footprint through reduced energy requirements. Additionally, spray pyrolysis enables precise material deposition, optimizing raw material usage and minimizing waste generation—a critical factor in resource conservation and sustainable manufacturing practices.

However, several environmental challenges warrant attention. Certain precursor materials used in spray pyrolysis may contain heavy metals or toxic compounds that pose environmental risks if improperly handled or disposed of. The fine aerosol particles generated during spraying could potentially contribute to workplace air quality issues if adequate filtration and ventilation systems are not implemented. Furthermore, the scalability of environmentally friendly spray pyrolysis processes remains a challenge, as industrial-scale production may amplify these environmental concerns.

Life cycle assessment (LCA) studies indicate that the environmental impact of spray pyrolysis-produced UV blocking layers is heavily dependent on precursor selection, process optimization, and end-of-life management. Research shows that titanium dioxide and zinc oxide-based UV blocking layers produced via spray pyrolysis generally demonstrate lower environmental impact scores compared to conventional manufacturing methods, particularly when considering global warming potential and resource depletion metrics.

Regulatory frameworks worldwide are increasingly emphasizing sustainable manufacturing processes, with particular attention to nanomaterial production methods like spray pyrolysis. The European Union's REACH regulations and similar frameworks in other regions impose strict requirements on chemical usage and emissions, driving innovation toward greener spray pyrolysis formulations and processes.

Future research directions should focus on developing entirely non-toxic precursor formulations, implementing closed-loop recycling systems for process waste, and optimizing energy efficiency through process refinement. The integration of renewable energy sources for the thermal requirements of spray pyrolysis represents another promising avenue for reducing the environmental footprint of UV blocking layer production.

The process operates at lower temperatures than alternative coating technologies such as physical vapor deposition or sputtering, resulting in a smaller carbon footprint through reduced energy requirements. Additionally, spray pyrolysis enables precise material deposition, optimizing raw material usage and minimizing waste generation—a critical factor in resource conservation and sustainable manufacturing practices.

However, several environmental challenges warrant attention. Certain precursor materials used in spray pyrolysis may contain heavy metals or toxic compounds that pose environmental risks if improperly handled or disposed of. The fine aerosol particles generated during spraying could potentially contribute to workplace air quality issues if adequate filtration and ventilation systems are not implemented. Furthermore, the scalability of environmentally friendly spray pyrolysis processes remains a challenge, as industrial-scale production may amplify these environmental concerns.

Life cycle assessment (LCA) studies indicate that the environmental impact of spray pyrolysis-produced UV blocking layers is heavily dependent on precursor selection, process optimization, and end-of-life management. Research shows that titanium dioxide and zinc oxide-based UV blocking layers produced via spray pyrolysis generally demonstrate lower environmental impact scores compared to conventional manufacturing methods, particularly when considering global warming potential and resource depletion metrics.

Regulatory frameworks worldwide are increasingly emphasizing sustainable manufacturing processes, with particular attention to nanomaterial production methods like spray pyrolysis. The European Union's REACH regulations and similar frameworks in other regions impose strict requirements on chemical usage and emissions, driving innovation toward greener spray pyrolysis formulations and processes.

Future research directions should focus on developing entirely non-toxic precursor formulations, implementing closed-loop recycling systems for process waste, and optimizing energy efficiency through process refinement. The integration of renewable energy sources for the thermal requirements of spray pyrolysis represents another promising avenue for reducing the environmental footprint of UV blocking layer production.

Scalability and Cost Analysis

The scalability of spray pyrolysis technology for producing ultraviolet blocking layers represents a critical factor in its industrial viability. Current laboratory-scale implementations demonstrate promising results, but significant engineering challenges emerge when considering mass production scenarios. Pilot studies indicate that scaling up requires careful optimization of spray parameters, including nozzle design, solution flow rates, and substrate movement mechanisms, to maintain uniform coating thickness across larger surface areas.

Economic analysis reveals that spray pyrolysis offers substantial cost advantages compared to alternative UV blocking layer deposition methods such as vacuum-based techniques. The capital expenditure for establishing a spray pyrolysis production line is approximately 40-60% lower than comparable PVD or CVD systems. Operational costs benefit from ambient pressure processing conditions, eliminating the need for expensive vacuum equipment maintenance and reducing energy consumption by an estimated 30-45%.

Raw material efficiency presents another economic advantage, with solution-based precursors typically costing 25-35% less than materials required for vacuum deposition techniques. Material utilization rates in optimized spray pyrolysis systems can reach 70-85%, significantly higher than the 30-50% typical of many vacuum deposition methods. This efficiency translates directly to reduced waste management costs and environmental impact.

Production throughput analysis demonstrates that continuous spray pyrolysis processes can achieve coating rates of 100-150 m²/hour for standard UV blocking layer thicknesses (50-200 nm), making it suitable for high-volume manufacturing environments. The technology's compatibility with roll-to-roll processing further enhances its scalability potential, particularly for flexible substrate applications in emerging markets.

Sensitivity analysis of production parameters indicates that precursor solution costs represent the most significant variable expense (30-40% of operational costs), followed by energy consumption (20-25%) and labor (15-20%). This cost structure suggests that future optimization efforts should prioritize precursor efficiency and automation to maximize economic returns.

Implementation challenges for large-scale deployment include maintaining precise temperature control across larger substrate areas, ensuring consistent aerosol generation over extended production runs, and developing robust quality control systems capable of real-time monitoring. Recent innovations in computer-controlled spray systems and machine vision inspection technologies offer promising solutions to these challenges, potentially enabling fully automated production lines with minimal human intervention.

Economic analysis reveals that spray pyrolysis offers substantial cost advantages compared to alternative UV blocking layer deposition methods such as vacuum-based techniques. The capital expenditure for establishing a spray pyrolysis production line is approximately 40-60% lower than comparable PVD or CVD systems. Operational costs benefit from ambient pressure processing conditions, eliminating the need for expensive vacuum equipment maintenance and reducing energy consumption by an estimated 30-45%.

Raw material efficiency presents another economic advantage, with solution-based precursors typically costing 25-35% less than materials required for vacuum deposition techniques. Material utilization rates in optimized spray pyrolysis systems can reach 70-85%, significantly higher than the 30-50% typical of many vacuum deposition methods. This efficiency translates directly to reduced waste management costs and environmental impact.

Production throughput analysis demonstrates that continuous spray pyrolysis processes can achieve coating rates of 100-150 m²/hour for standard UV blocking layer thicknesses (50-200 nm), making it suitable for high-volume manufacturing environments. The technology's compatibility with roll-to-roll processing further enhances its scalability potential, particularly for flexible substrate applications in emerging markets.

Sensitivity analysis of production parameters indicates that precursor solution costs represent the most significant variable expense (30-40% of operational costs), followed by energy consumption (20-25%) and labor (15-20%). This cost structure suggests that future optimization efforts should prioritize precursor efficiency and automation to maximize economic returns.

Implementation challenges for large-scale deployment include maintaining precise temperature control across larger substrate areas, ensuring consistent aerosol generation over extended production runs, and developing robust quality control systems capable of real-time monitoring. Recent innovations in computer-controlled spray systems and machine vision inspection technologies offer promising solutions to these challenges, potentially enabling fully automated production lines with minimal human intervention.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!