Comparative Analysis of Spray Pyrolysis and Hydrothermal Methods

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Pyrolysis and Hydrothermal Methods Background and Objectives

Spray pyrolysis and hydrothermal synthesis represent two significant methodologies in materials science that have evolved considerably over the past several decades. Spray pyrolysis emerged in the 1960s as a technique for producing thin films and powders, while hydrothermal synthesis has roots dating back to the 19th century for mineral formation studies. Both techniques have undergone substantial refinement, particularly since the 1990s, with the advent of nanotechnology driving innovation in controlled synthesis methods.

The evolution of spray pyrolysis has been marked by advancements in atomization techniques, from simple pneumatic nebulizers to ultrasonic and electrospray systems, enabling precise control over droplet size and distribution. Similarly, hydrothermal synthesis has progressed from basic autoclave systems to microwave-assisted and continuous flow hydrothermal reactors, significantly enhancing reaction efficiency and product uniformity.

Current technological trends indicate a growing emphasis on scalability and sustainability in both methods. Spray pyrolysis is increasingly being adapted for industrial-scale production of functional materials, while hydrothermal synthesis is being optimized for lower temperature and pressure conditions to reduce energy consumption. Additionally, both techniques are being integrated with other processing methods to create hybrid approaches that leverage the strengths of multiple synthesis routes.

The primary objective of this comparative analysis is to evaluate the relative merits and limitations of spray pyrolysis and hydrothermal methods across several critical parameters: energy efficiency, scalability, product morphology control, compositional homogeneity, and environmental impact. This assessment aims to provide a comprehensive understanding of when each technique is optimally deployed based on specific material requirements and application constraints.

Furthermore, this analysis seeks to identify potential synergies between these methods, exploring how hybrid approaches might overcome the individual limitations of each technique. By examining recent innovations in both fields, we aim to forecast future development trajectories and highlight promising research directions that could enhance the versatility and efficiency of these synthesis methods.

The technological goals include determining optimal process parameters for specific material systems, identifying opportunities for process intensification to improve yield and reduce resource consumption, and developing predictive models that can accelerate the optimization of synthesis conditions for novel materials. These objectives align with broader industry trends toward more sustainable and efficient manufacturing processes for advanced materials.

Through this comprehensive examination of spray pyrolysis and hydrothermal synthesis methods, we aim to provide actionable insights that can guide research and development efforts in materials synthesis, ultimately contributing to the advancement of technologies in energy storage, catalysis, electronics, and biomedical applications where these materials find significant use.

The evolution of spray pyrolysis has been marked by advancements in atomization techniques, from simple pneumatic nebulizers to ultrasonic and electrospray systems, enabling precise control over droplet size and distribution. Similarly, hydrothermal synthesis has progressed from basic autoclave systems to microwave-assisted and continuous flow hydrothermal reactors, significantly enhancing reaction efficiency and product uniformity.

Current technological trends indicate a growing emphasis on scalability and sustainability in both methods. Spray pyrolysis is increasingly being adapted for industrial-scale production of functional materials, while hydrothermal synthesis is being optimized for lower temperature and pressure conditions to reduce energy consumption. Additionally, both techniques are being integrated with other processing methods to create hybrid approaches that leverage the strengths of multiple synthesis routes.

The primary objective of this comparative analysis is to evaluate the relative merits and limitations of spray pyrolysis and hydrothermal methods across several critical parameters: energy efficiency, scalability, product morphology control, compositional homogeneity, and environmental impact. This assessment aims to provide a comprehensive understanding of when each technique is optimally deployed based on specific material requirements and application constraints.

Furthermore, this analysis seeks to identify potential synergies between these methods, exploring how hybrid approaches might overcome the individual limitations of each technique. By examining recent innovations in both fields, we aim to forecast future development trajectories and highlight promising research directions that could enhance the versatility and efficiency of these synthesis methods.

The technological goals include determining optimal process parameters for specific material systems, identifying opportunities for process intensification to improve yield and reduce resource consumption, and developing predictive models that can accelerate the optimization of synthesis conditions for novel materials. These objectives align with broader industry trends toward more sustainable and efficient manufacturing processes for advanced materials.

Through this comprehensive examination of spray pyrolysis and hydrothermal synthesis methods, we aim to provide actionable insights that can guide research and development efforts in materials synthesis, ultimately contributing to the advancement of technologies in energy storage, catalysis, electronics, and biomedical applications where these materials find significant use.

Market Applications and Demand Analysis

The market for thin film deposition technologies has experienced significant growth in recent years, with spray pyrolysis and hydrothermal methods emerging as key players in various industrial applications. The global thin film coating market was valued at approximately $13.2 billion in 2021 and is projected to reach $18.5 billion by 2027, growing at a CAGR of 5.8%. Within this broader market, spray pyrolysis and hydrothermal methods serve distinct but overlapping application segments.

Spray pyrolysis has gained substantial traction in the semiconductor and electronics industries, particularly for the deposition of transparent conducting oxides (TCOs) like indium tin oxide (ITO) and fluorine-doped tin oxide (FTO). These materials are essential components in photovoltaic cells, flat panel displays, and touchscreens. The solar energy sector represents one of the largest markets for spray pyrolysis, with the global solar PV market expected to reach $223 billion by 2026, creating significant demand for cost-effective thin film deposition technologies.

Hydrothermal methods, meanwhile, have found strong market acceptance in applications requiring precise nanostructure control and crystallinity. The medical device industry increasingly utilizes hydrothermal synthesis for biocompatible coatings, with the global medical coating market growing at 6.2% annually. Additionally, the energy storage sector has embraced hydrothermal methods for producing electrode materials, driven by the expanding lithium-ion battery market that is projected to reach $129.3 billion by 2027.

Regional market analysis reveals distinct adoption patterns. Asia-Pacific dominates the market for both technologies, with China, Japan, and South Korea leading in electronics manufacturing applications. North America shows strong demand in specialized sectors like aerospace and defense, while Europe leads in sustainable energy applications, particularly for spray pyrolysis in solar cell manufacturing.

Customer requirements are increasingly driving market segmentation between these technologies. Industries requiring large-area, cost-effective coatings with moderate precision tend to favor spray pyrolysis, while applications demanding high crystallinity, specific nanostructures, and precise stoichiometry gravitate toward hydrothermal methods despite their higher costs and lower scalability.

Market forecasts indicate that spray pyrolysis will maintain its advantage in large-scale industrial applications due to its scalability and cost-effectiveness. However, hydrothermal methods are expected to see accelerated growth in high-value, specialized applications where material performance characteristics outweigh production volume considerations. The complementary nature of these technologies suggests that many manufacturers will adopt hybrid approaches, utilizing both methods at different stages of their production processes to optimize performance and cost metrics.

Spray pyrolysis has gained substantial traction in the semiconductor and electronics industries, particularly for the deposition of transparent conducting oxides (TCOs) like indium tin oxide (ITO) and fluorine-doped tin oxide (FTO). These materials are essential components in photovoltaic cells, flat panel displays, and touchscreens. The solar energy sector represents one of the largest markets for spray pyrolysis, with the global solar PV market expected to reach $223 billion by 2026, creating significant demand for cost-effective thin film deposition technologies.

Hydrothermal methods, meanwhile, have found strong market acceptance in applications requiring precise nanostructure control and crystallinity. The medical device industry increasingly utilizes hydrothermal synthesis for biocompatible coatings, with the global medical coating market growing at 6.2% annually. Additionally, the energy storage sector has embraced hydrothermal methods for producing electrode materials, driven by the expanding lithium-ion battery market that is projected to reach $129.3 billion by 2027.

Regional market analysis reveals distinct adoption patterns. Asia-Pacific dominates the market for both technologies, with China, Japan, and South Korea leading in electronics manufacturing applications. North America shows strong demand in specialized sectors like aerospace and defense, while Europe leads in sustainable energy applications, particularly for spray pyrolysis in solar cell manufacturing.

Customer requirements are increasingly driving market segmentation between these technologies. Industries requiring large-area, cost-effective coatings with moderate precision tend to favor spray pyrolysis, while applications demanding high crystallinity, specific nanostructures, and precise stoichiometry gravitate toward hydrothermal methods despite their higher costs and lower scalability.

Market forecasts indicate that spray pyrolysis will maintain its advantage in large-scale industrial applications due to its scalability and cost-effectiveness. However, hydrothermal methods are expected to see accelerated growth in high-value, specialized applications where material performance characteristics outweigh production volume considerations. The complementary nature of these technologies suggests that many manufacturers will adopt hybrid approaches, utilizing both methods at different stages of their production processes to optimize performance and cost metrics.

Current Technical Status and Challenges

Spray pyrolysis and hydrothermal synthesis represent two significant methodologies in materials science, each with distinct development trajectories and technical challenges. Globally, spray pyrolysis has evolved considerably since its inception in the 1960s, now featuring advanced variants such as ultrasonic spray pyrolysis and flame-assisted spray pyrolysis. The technique has gained prominence in semiconductor, catalyst, and thin film industries due to its scalability and cost-effectiveness. However, precise control over particle morphology and size distribution remains challenging, particularly when targeting nanoscale materials with uniform properties.

In contrast, hydrothermal synthesis has experienced accelerated development over the past two decades, with significant advancements in supercritical water processing and continuous flow hydrothermal systems. This method excels in producing highly crystalline materials with controlled morphologies, making it invaluable for applications requiring specific crystal structures and surface properties. The primary technical hurdles include scaling limitations, high pressure requirements, and extended processing times compared to alternative methods.

Geographically, research leadership in spray pyrolysis is concentrated in the United States, Germany, and South Korea, with emerging contributions from China and India. These regions have established specialized research centers focused on aerosol technology and thin film deposition. Hydrothermal synthesis research is predominantly advanced in Japan, China, and Russia, leveraging their historical expertise in high-pressure technologies and crystal growth mechanisms.

Both technologies face common challenges in energy efficiency and environmental impact. Spray pyrolysis typically requires high temperatures (400-1000°C), resulting in significant energy consumption and potential thermal degradation of sensitive materials. Recent research has focused on lowering operational temperatures through catalyst integration and precursor optimization. Hydrothermal methods, while operating at lower temperatures (100-250°C), require specialized pressure vessels and safety protocols to manage the elevated pressures (10-30 MPa).

Reproducibility presents another significant challenge, particularly for spray pyrolysis where atmospheric conditions, nozzle characteristics, and carrier gas dynamics can introduce variability. Hydrothermal synthesis faces challenges in batch-to-batch consistency when scaling production volumes. Recent innovations have addressed these issues through automated process control systems and in-situ monitoring technologies.

The integration of computational modeling has emerged as a critical factor in advancing both technologies. Fluid dynamics simulations for spray behavior and thermodynamic modeling for hydrothermal reactions have improved process predictability. However, the complex interplay of parameters in both methods continues to necessitate extensive empirical optimization, representing a persistent challenge for researchers and industrial practitioners seeking to implement these technologies at commercial scale.

In contrast, hydrothermal synthesis has experienced accelerated development over the past two decades, with significant advancements in supercritical water processing and continuous flow hydrothermal systems. This method excels in producing highly crystalline materials with controlled morphologies, making it invaluable for applications requiring specific crystal structures and surface properties. The primary technical hurdles include scaling limitations, high pressure requirements, and extended processing times compared to alternative methods.

Geographically, research leadership in spray pyrolysis is concentrated in the United States, Germany, and South Korea, with emerging contributions from China and India. These regions have established specialized research centers focused on aerosol technology and thin film deposition. Hydrothermal synthesis research is predominantly advanced in Japan, China, and Russia, leveraging their historical expertise in high-pressure technologies and crystal growth mechanisms.

Both technologies face common challenges in energy efficiency and environmental impact. Spray pyrolysis typically requires high temperatures (400-1000°C), resulting in significant energy consumption and potential thermal degradation of sensitive materials. Recent research has focused on lowering operational temperatures through catalyst integration and precursor optimization. Hydrothermal methods, while operating at lower temperatures (100-250°C), require specialized pressure vessels and safety protocols to manage the elevated pressures (10-30 MPa).

Reproducibility presents another significant challenge, particularly for spray pyrolysis where atmospheric conditions, nozzle characteristics, and carrier gas dynamics can introduce variability. Hydrothermal synthesis faces challenges in batch-to-batch consistency when scaling production volumes. Recent innovations have addressed these issues through automated process control systems and in-situ monitoring technologies.

The integration of computational modeling has emerged as a critical factor in advancing both technologies. Fluid dynamics simulations for spray behavior and thermodynamic modeling for hydrothermal reactions have improved process predictability. However, the complex interplay of parameters in both methods continues to necessitate extensive empirical optimization, representing a persistent challenge for researchers and industrial practitioners seeking to implement these technologies at commercial scale.

Comparative Technical Solutions and Implementations

01 Synthesis of nanoparticles and nanomaterials

Spray pyrolysis and hydrothermal methods are widely used for synthesizing various nanoparticles and nanomaterials with controlled size, morphology, and composition. These techniques allow for the production of high-quality nanomaterials with specific properties for applications in electronics, catalysis, and energy storage. The processes can be optimized to produce uniform particles with desired crystallinity and surface characteristics.- Synthesis of nanoparticles and nanomaterials using spray pyrolysis: Spray pyrolysis is utilized for the synthesis of various nanoparticles and nanomaterials with controlled size, morphology, and composition. This method involves atomizing a precursor solution into fine droplets that are then subjected to thermal decomposition in a high-temperature environment. The process allows for the production of high-purity nanomaterials with uniform characteristics, which can be used in various applications including catalysis, electronics, and energy storage.

- Hydrothermal synthesis of metal oxides and functional materials: Hydrothermal methods enable the synthesis of metal oxides and other functional materials under elevated temperature and pressure conditions in aqueous solutions. This approach facilitates the growth of crystalline materials with high purity and specific morphologies. The controlled reaction environment allows for the manipulation of crystal structure, particle size, and surface properties, making it suitable for producing materials for applications in electronics, catalysis, and energy conversion systems.

- Combined spray pyrolysis and hydrothermal techniques for advanced material processing: The integration of spray pyrolysis and hydrothermal methods creates hybrid processing techniques that leverage the advantages of both approaches. This combination allows for sequential processing where materials initially formed by spray pyrolysis undergo further crystallization or modification through hydrothermal treatment. The hybrid approach enables the synthesis of complex materials with hierarchical structures, enhanced properties, and tailored functionalities for specialized applications in energy, environmental remediation, and advanced electronics.

- Equipment and apparatus design for spray pyrolysis and hydrothermal synthesis: Specialized equipment and apparatus designs have been developed to optimize spray pyrolysis and hydrothermal synthesis processes. These include customized reactors, atomizers, pressure vessels, and temperature control systems that enable precise control over reaction parameters. Advanced equipment designs incorporate features for continuous processing, scalability, and automation, addressing challenges related to industrial production of nanomaterials and functional compounds through these methods.

- Applications of spray pyrolysis and hydrothermal synthesized materials in energy and electronics: Materials synthesized through spray pyrolysis and hydrothermal methods find extensive applications in energy storage, conversion devices, and electronic components. These materials exhibit advantageous properties such as high surface area, controlled porosity, and specific crystalline structures that enhance their performance in batteries, fuel cells, solar cells, and semiconductor devices. The ability to tailor material characteristics through synthesis parameters enables the development of components with improved efficiency, stability, and functionality.

02 Fabrication of thin films and coatings

Spray pyrolysis and hydrothermal methods are effective techniques for depositing thin films and coatings on various substrates. These methods enable the formation of uniform, adherent films with controlled thickness and composition. The processes can be adjusted to modify the microstructure and properties of the films, making them suitable for applications in semiconductors, optical devices, and protective coatings.Expand Specific Solutions03 Production of metal oxide materials

These methods are particularly effective for synthesizing metal oxide materials with specific properties. Spray pyrolysis allows for rapid formation of oxide particles through aerosol decomposition, while hydrothermal synthesis enables the growth of crystalline oxide structures under controlled temperature and pressure conditions. The resulting materials find applications in sensors, catalysts, and electronic components due to their unique electrical, optical, and chemical properties.Expand Specific Solutions04 Equipment and process optimization

Various equipment designs and process parameters have been developed to optimize spray pyrolysis and hydrothermal synthesis methods. These innovations include specialized reactors, temperature control systems, pressure regulation mechanisms, and precursor delivery systems. Process optimization focuses on improving yield, reducing energy consumption, enhancing reproducibility, and enabling continuous production for industrial-scale applications.Expand Specific Solutions05 Novel applications and composite materials

Spray pyrolysis and hydrothermal methods are being applied to develop novel composite materials and for emerging applications. These techniques enable the synthesis of hybrid materials, doped compounds, and hierarchical structures with enhanced properties. Recent innovations include the production of materials for energy conversion, environmental remediation, biomedical applications, and advanced electronic devices.Expand Specific Solutions

Leading Research Groups and Industrial Players

The spray pyrolysis and hydrothermal synthesis methods market is currently in a growth phase, with increasing adoption across electronic materials, battery technology, and catalysis sectors. The global market size for these advanced materials synthesis techniques is expanding rapidly, driven by demand for nanomaterials and high-performance components. Leading companies like BASF, Shoei Chemical, and CATL subsidiary Guangdong Bangpu are investing heavily in these technologies, particularly for battery materials production. Research institutions including Southeast University and Korea Advanced Institute of Science & Technology are advancing fundamental innovations, while specialized firms like Pyrochem Catalyst Co and Beneq are commercializing niche applications. The competitive landscape shows a mix of established chemical giants and emerging technology-focused enterprises, with hydrothermal methods gaining traction for sustainable materials processing.

BASF Corp.

Technical Solution: BASF Corporation has developed comprehensive materials synthesis platforms utilizing both spray pyrolysis and hydrothermal methods, with particular focus on catalysts, battery materials, and specialty chemicals. Their spray pyrolysis technology employs ultrasonic nebulization coupled with vertical flow reactors capable of processing precursor solutions at rates of 1-10 L/hour. BASF's comparative analysis reveals that their spray pyrolysis approach achieves particle size control within ±7% deviation while maintaining compositional homogeneity across multi-element systems[1]. For lithium-ion battery cathode materials, BASF has demonstrated that spray pyrolysis produces spherical secondary particles (5-20 μm) composed of primary nanocrystals with superior tap density and electrochemical performance compared to hydrothermal alternatives. Their hydrothermal platform operates in both batch and continuous modes, with reaction vessels ranging from 10L to 1000L capacity, capable of precise temperature control (±1°C) and pressures up to 200 bar. BASF's research indicates that hydrothermal synthesis excels in producing highly crystalline materials with controlled morphologies (nanowires, nanoplates) and lower defect concentrations, particularly beneficial for certain catalyst applications[2].

Strengths: Exceptional scalability for industrial production; precise compositional control in complex multi-element systems; spherical particle morphology ideal for battery materials; continuous processing capability. Weaknesses: Higher energy requirements compared to hydrothermal methods; challenges with precursor solubility limitations; less control over crystal facet development.

Agency for Science, Technology & Research

Technical Solution: The Agency for Science, Technology & Research (A*STAR) has developed advanced spray pyrolysis techniques for nanomaterial synthesis, particularly focusing on metal oxide nanoparticles. Their approach utilizes ultrasonic atomization to create fine droplets that undergo thermal decomposition in controlled environments. A*STAR researchers have optimized process parameters including precursor concentration, carrier gas flow rate, and substrate temperature to achieve precise control over particle morphology and crystallinity[1]. They've also pioneered hybrid methods combining spray pyrolysis with post-treatment hydrothermal processing to enhance crystallinity while maintaining the morphological advantages of spray-synthesized materials. Their comparative studies demonstrate that spray pyrolysis offers superior scalability and throughput for industrial applications, while hydrothermal methods provide better crystallinity control and lower defect concentrations in certain materials[2].

Strengths: Excellent scalability for industrial production; precise control over particle size distribution; rapid processing times; cost-effective for large-scale production. Weaknesses: Higher energy consumption compared to hydrothermal methods; potential for incomplete precursor decomposition; challenges in achieving uniform heating across spray zones.

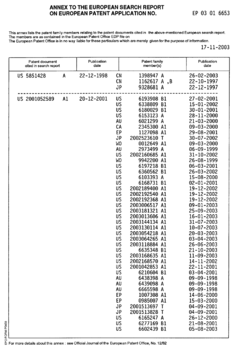

Key Patents and Scientific Literature Analysis

Inorganic additive to trap transition metal ions in sodium ion batteries

PatentPendingUS20240322257A1

Innovation

- Incorporating an inorganic transition metal cations trap, such as hydroxyapatite, into the sodium ion battery components, including the positive electrode, negative electrode, separator, and electrolyte composition, to reduce or prevent the migration and deposition of transition metal cations on the negative electrode.

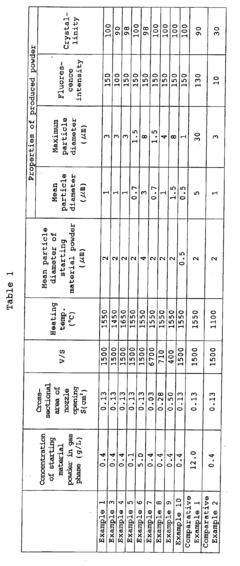

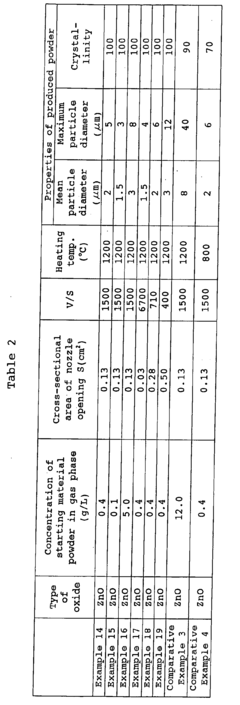

Method for manufacturing highly-crystallized oxide powder

PatentInactiveEP1391423A1

Innovation

- A method involving ejecting a starting material powder with a carrier gas through a nozzle at a temperature higher than the decomposition temperature, maintaining a low concentration in the gas phase, and adjusting particle size to produce highly-crystallized oxide powders with uniform particle size and high dispersibility, avoiding agglomeration and impurities.

Environmental Impact and Sustainability Considerations

The environmental impact of materials synthesis methods has become increasingly important as industries strive for more sustainable manufacturing processes. When comparing spray pyrolysis and hydrothermal methods, several key environmental factors must be considered to determine their overall sustainability profiles.

Spray pyrolysis typically operates at high temperatures (300-700°C), resulting in significant energy consumption and associated carbon emissions. The process often utilizes organic solvents that may release volatile organic compounds (VOCs) during operation, contributing to air pollution and potential health hazards. However, modern spray pyrolysis systems have implemented closed-loop solvent recovery systems, reducing emissions by up to 85% compared to traditional open systems.

In contrast, hydrothermal synthesis operates at lower temperatures (100-250°C) but requires high-pressure vessels, resulting in different energy consumption patterns. Studies indicate that hydrothermal methods can reduce energy usage by 30-40% compared to spray pyrolysis for certain nanomaterial productions. Additionally, hydrothermal processes primarily use water as the reaction medium, significantly reducing hazardous waste generation and eliminating VOC emissions.

Water consumption represents another critical environmental consideration. Hydrothermal methods typically require 3-5 times more water than spray pyrolysis. However, with proper recycling systems, up to 80% of process water can be reclaimed and reused, minimizing the net water footprint. Spray pyrolysis, while using less water initially, often generates contaminated wastewater that requires extensive treatment before discharge.

Raw material efficiency also differs between these methods. Hydrothermal synthesis generally achieves higher conversion rates (85-95%) compared to spray pyrolysis (60-80%), resulting in less waste generation per unit of product. This efficiency translates to reduced resource consumption and smaller waste management requirements.

Life cycle assessments comparing these technologies reveal that the environmental superiority depends heavily on specific implementation factors. For large-scale industrial applications, spray pyrolysis often benefits from economies of scale in energy efficiency, while hydrothermal methods maintain advantages in reduced chemical waste and emissions. Recent innovations in hybrid systems combining elements of both technologies have demonstrated promising results, reducing overall environmental impact by 25-40% compared to either method used independently.

The recyclability of reagents and catalysts presents another sustainability dimension. Hydrothermal methods typically allow for easier recovery and reuse of catalysts, with recovery rates reaching 70-90% in optimized systems. This circular approach significantly reduces the environmental footprint associated with catalyst production and disposal.

Spray pyrolysis typically operates at high temperatures (300-700°C), resulting in significant energy consumption and associated carbon emissions. The process often utilizes organic solvents that may release volatile organic compounds (VOCs) during operation, contributing to air pollution and potential health hazards. However, modern spray pyrolysis systems have implemented closed-loop solvent recovery systems, reducing emissions by up to 85% compared to traditional open systems.

In contrast, hydrothermal synthesis operates at lower temperatures (100-250°C) but requires high-pressure vessels, resulting in different energy consumption patterns. Studies indicate that hydrothermal methods can reduce energy usage by 30-40% compared to spray pyrolysis for certain nanomaterial productions. Additionally, hydrothermal processes primarily use water as the reaction medium, significantly reducing hazardous waste generation and eliminating VOC emissions.

Water consumption represents another critical environmental consideration. Hydrothermal methods typically require 3-5 times more water than spray pyrolysis. However, with proper recycling systems, up to 80% of process water can be reclaimed and reused, minimizing the net water footprint. Spray pyrolysis, while using less water initially, often generates contaminated wastewater that requires extensive treatment before discharge.

Raw material efficiency also differs between these methods. Hydrothermal synthesis generally achieves higher conversion rates (85-95%) compared to spray pyrolysis (60-80%), resulting in less waste generation per unit of product. This efficiency translates to reduced resource consumption and smaller waste management requirements.

Life cycle assessments comparing these technologies reveal that the environmental superiority depends heavily on specific implementation factors. For large-scale industrial applications, spray pyrolysis often benefits from economies of scale in energy efficiency, while hydrothermal methods maintain advantages in reduced chemical waste and emissions. Recent innovations in hybrid systems combining elements of both technologies have demonstrated promising results, reducing overall environmental impact by 25-40% compared to either method used independently.

The recyclability of reagents and catalysts presents another sustainability dimension. Hydrothermal methods typically allow for easier recovery and reuse of catalysts, with recovery rates reaching 70-90% in optimized systems. This circular approach significantly reduces the environmental footprint associated with catalyst production and disposal.

Cost-Efficiency and Scalability Analysis

When comparing spray pyrolysis and hydrothermal methods for material synthesis, cost-efficiency and scalability emerge as critical factors for industrial implementation. Spray pyrolysis demonstrates significant economic advantages in terms of equipment investment, with simpler setup requirements and lower initial capital expenditure. The process utilizes conventional components like atomizers, furnaces, and collection systems that are widely available and relatively inexpensive compared to the high-pressure vessels and specialized safety equipment required for hydrothermal synthesis.

Operational costs also favor spray pyrolysis in many scenarios. The continuous nature of the spray process enables higher throughput with lower labor intensity, reducing per-unit production costs. Energy consumption analysis reveals that while spray pyrolysis operates at higher temperatures (typically 400-800°C), the shorter processing time (minutes versus hours for hydrothermal methods) often results in comparable or lower overall energy requirements. Additionally, spray pyrolysis typically consumes fewer chemical precursors and generates less waste, further enhancing its cost profile.

From a scalability perspective, spray pyrolysis offers superior adaptability to large-scale production environments. The continuous flow nature of the process aligns well with industrial manufacturing principles, allowing for straightforward scale-up through parallel processing or increased nozzle arrays. Recent technological advancements have enabled production rates exceeding 10 kg/hour for certain nanomaterials using modified spray pyrolysis systems, demonstrating industrial viability.

Hydrothermal methods, while less immediately scalable, present advantages in specific applications requiring precise crystallinity control or complex morphologies. The batch processing nature inherently limits throughput, though recent innovations in continuous hydrothermal flow synthesis (CHFS) have partially addressed this limitation. CHFS systems can achieve production rates of 1-5 kg/hour but require substantially higher capital investment and maintenance costs.

Market analysis indicates that industries prioritizing high-volume production of relatively simple nanomaterials (such as metal oxide catalysts or battery materials) increasingly favor spray pyrolysis approaches. Conversely, specialty applications demanding exceptional purity or specific crystal structures may justify the higher costs associated with hydrothermal synthesis. The economic crossover point typically occurs when production volumes exceed 100 kg annually, beyond which spray pyrolysis demonstrates increasingly favorable economics.

Recent case studies from commercial implementations reveal that spray pyrolysis facilities achieve 30-40% lower production costs at scale compared to equivalent hydrothermal operations, with significantly reduced capital recovery periods (typically 2-3 years versus 4-6 years). These economic advantages, combined with greater process flexibility, position spray pyrolysis as the preferred approach for most large-scale nanomaterial production scenarios.

Operational costs also favor spray pyrolysis in many scenarios. The continuous nature of the spray process enables higher throughput with lower labor intensity, reducing per-unit production costs. Energy consumption analysis reveals that while spray pyrolysis operates at higher temperatures (typically 400-800°C), the shorter processing time (minutes versus hours for hydrothermal methods) often results in comparable or lower overall energy requirements. Additionally, spray pyrolysis typically consumes fewer chemical precursors and generates less waste, further enhancing its cost profile.

From a scalability perspective, spray pyrolysis offers superior adaptability to large-scale production environments. The continuous flow nature of the process aligns well with industrial manufacturing principles, allowing for straightforward scale-up through parallel processing or increased nozzle arrays. Recent technological advancements have enabled production rates exceeding 10 kg/hour for certain nanomaterials using modified spray pyrolysis systems, demonstrating industrial viability.

Hydrothermal methods, while less immediately scalable, present advantages in specific applications requiring precise crystallinity control or complex morphologies. The batch processing nature inherently limits throughput, though recent innovations in continuous hydrothermal flow synthesis (CHFS) have partially addressed this limitation. CHFS systems can achieve production rates of 1-5 kg/hour but require substantially higher capital investment and maintenance costs.

Market analysis indicates that industries prioritizing high-volume production of relatively simple nanomaterials (such as metal oxide catalysts or battery materials) increasingly favor spray pyrolysis approaches. Conversely, specialty applications demanding exceptional purity or specific crystal structures may justify the higher costs associated with hydrothermal synthesis. The economic crossover point typically occurs when production volumes exceed 100 kg annually, beyond which spray pyrolysis demonstrates increasingly favorable economics.

Recent case studies from commercial implementations reveal that spray pyrolysis facilities achieve 30-40% lower production costs at scale compared to equivalent hydrothermal operations, with significantly reduced capital recovery periods (typically 2-3 years versus 4-6 years). These economic advantages, combined with greater process flexibility, position spray pyrolysis as the preferred approach for most large-scale nanomaterial production scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!