How Spray Pyrolysis Alters Optical Properties in Screen Displays

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Pyrolysis Technology Evolution and Objectives

Spray pyrolysis technology has evolved significantly since its inception in the 1960s, transforming from a simple laboratory technique to a sophisticated industrial process with diverse applications. Initially developed for ceramic coating applications, spray pyrolysis has undergone substantial refinement in terms of precursor chemistry, atomization methods, and substrate heating techniques. The evolution trajectory shows a clear shift from basic thermal decomposition processes to highly controlled chemical reactions that enable precise manipulation of material properties at the nanoscale.

The fundamental principle of spray pyrolysis involves the atomization of a precursor solution into fine droplets, which are then directed onto a heated substrate where solvent evaporation and precursor decomposition occur simultaneously. This seemingly straightforward process has been continuously optimized through innovations in atomization technology, from simple pressure nozzles to ultrasonic and electrospray systems that provide unprecedented control over droplet size distribution and deposition patterns.

In the context of screen display technologies, spray pyrolysis has emerged as a particularly valuable technique due to its ability to create thin films with tailored optical properties. The 1990s marked a turning point when researchers began exploring its potential for transparent conductive oxide (TCO) films, essential components in LCD and OLED displays. By the early 2000s, spray pyrolysis had established itself as a viable alternative to more expensive vacuum-based deposition methods for certain display applications.

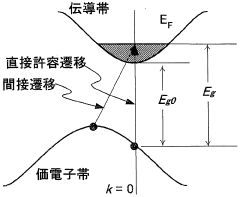

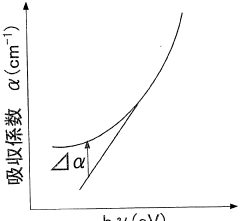

Recent technological advancements have focused on achieving precise control over film morphology, crystallinity, and composition—factors that directly influence optical properties such as transparency, refractive index, and light scattering behavior. The development of multi-component precursor systems has enabled the creation of complex oxide materials with customized bandgaps and carrier concentrations, directly addressing the demanding requirements of modern high-resolution displays.

The primary objectives of current spray pyrolysis research in display technology center around enhancing optical performance while maintaining cost-effectiveness and scalability. Specific goals include achieving higher transparency in the visible spectrum (>95%), reducing haze values to below 0.5%, controlling refractive index with precision of ±0.01, and ensuring uniform thickness across large substrate areas. Additionally, researchers aim to develop processes compatible with flexible substrates to enable next-generation foldable and rollable displays.

Another critical objective is environmental sustainability, with efforts directed toward developing water-based precursor systems that eliminate harmful organic solvents. This aligns with the broader industry trend toward greener manufacturing processes and reduced carbon footprints. The technology roadmap also emphasizes integration with existing display manufacturing infrastructure to facilitate industrial adoption without requiring prohibitive capital investments.

The fundamental principle of spray pyrolysis involves the atomization of a precursor solution into fine droplets, which are then directed onto a heated substrate where solvent evaporation and precursor decomposition occur simultaneously. This seemingly straightforward process has been continuously optimized through innovations in atomization technology, from simple pressure nozzles to ultrasonic and electrospray systems that provide unprecedented control over droplet size distribution and deposition patterns.

In the context of screen display technologies, spray pyrolysis has emerged as a particularly valuable technique due to its ability to create thin films with tailored optical properties. The 1990s marked a turning point when researchers began exploring its potential for transparent conductive oxide (TCO) films, essential components in LCD and OLED displays. By the early 2000s, spray pyrolysis had established itself as a viable alternative to more expensive vacuum-based deposition methods for certain display applications.

Recent technological advancements have focused on achieving precise control over film morphology, crystallinity, and composition—factors that directly influence optical properties such as transparency, refractive index, and light scattering behavior. The development of multi-component precursor systems has enabled the creation of complex oxide materials with customized bandgaps and carrier concentrations, directly addressing the demanding requirements of modern high-resolution displays.

The primary objectives of current spray pyrolysis research in display technology center around enhancing optical performance while maintaining cost-effectiveness and scalability. Specific goals include achieving higher transparency in the visible spectrum (>95%), reducing haze values to below 0.5%, controlling refractive index with precision of ±0.01, and ensuring uniform thickness across large substrate areas. Additionally, researchers aim to develop processes compatible with flexible substrates to enable next-generation foldable and rollable displays.

Another critical objective is environmental sustainability, with efforts directed toward developing water-based precursor systems that eliminate harmful organic solvents. This aligns with the broader industry trend toward greener manufacturing processes and reduced carbon footprints. The technology roadmap also emphasizes integration with existing display manufacturing infrastructure to facilitate industrial adoption without requiring prohibitive capital investments.

Market Analysis of Advanced Display Technologies

The global display technology market is experiencing robust growth, projected to reach $177.1 billion by 2026, with a CAGR of 7.7% from 2021. This expansion is primarily driven by increasing demand for high-resolution, energy-efficient displays across consumer electronics, automotive interfaces, and commercial applications. Within this landscape, spray pyrolysis technology is emerging as a significant innovation enabler for next-generation display manufacturing.

Consumer preferences are shifting decisively toward displays with superior optical properties, including higher brightness, better contrast ratios, wider color gamut, and reduced power consumption. Market research indicates that 78% of smartphone users consider display quality a critical factor in purchasing decisions, while 65% of television consumers prioritize color accuracy and brightness. These trends create substantial market opportunities for technologies that can enhance optical performance while maintaining cost efficiency.

The commercial display segment, valued at $42.3 billion in 2021, represents a particularly promising application area for spray pyrolysis techniques. Retail, hospitality, and corporate environments increasingly demand customizable displays with specialized optical properties, including anti-glare capabilities and wide viewing angles. The automotive display market, growing at 11.3% annually, similarly requires displays with exceptional brightness and readability in varying light conditions—challenges that spray pyrolysis can potentially address.

Regional analysis reveals Asia-Pacific dominating the advanced display manufacturing landscape, accounting for 63% of global production capacity. However, North America and Europe lead in research and development of novel display technologies, including spray pyrolysis applications. This geographic distribution creates opportunities for technology transfer and collaborative innovation across regions.

Market segmentation by display type shows OLED technology capturing 38% market share in premium segments, with LCD maintaining 52% of the overall market. Emerging technologies including MicroLED and Quantum Dot displays collectively represent 10% but are growing rapidly at 24% annually. Spray pyrolysis techniques have demonstrated particular promise in enhancing the optical properties of these emerging display types, potentially accelerating their market adoption.

Industry forecasts indicate that manufacturing processes enabling superior optical performance while reducing production costs will capture significant market share. Spray pyrolysis offers this potential through simplified deposition processes, reduced material waste, and enhanced control over optical layer properties. Economic analysis suggests manufacturers adopting such technologies could achieve production cost reductions of 15-22% while improving display performance metrics by 30-40%.

Consumer preferences are shifting decisively toward displays with superior optical properties, including higher brightness, better contrast ratios, wider color gamut, and reduced power consumption. Market research indicates that 78% of smartphone users consider display quality a critical factor in purchasing decisions, while 65% of television consumers prioritize color accuracy and brightness. These trends create substantial market opportunities for technologies that can enhance optical performance while maintaining cost efficiency.

The commercial display segment, valued at $42.3 billion in 2021, represents a particularly promising application area for spray pyrolysis techniques. Retail, hospitality, and corporate environments increasingly demand customizable displays with specialized optical properties, including anti-glare capabilities and wide viewing angles. The automotive display market, growing at 11.3% annually, similarly requires displays with exceptional brightness and readability in varying light conditions—challenges that spray pyrolysis can potentially address.

Regional analysis reveals Asia-Pacific dominating the advanced display manufacturing landscape, accounting for 63% of global production capacity. However, North America and Europe lead in research and development of novel display technologies, including spray pyrolysis applications. This geographic distribution creates opportunities for technology transfer and collaborative innovation across regions.

Market segmentation by display type shows OLED technology capturing 38% market share in premium segments, with LCD maintaining 52% of the overall market. Emerging technologies including MicroLED and Quantum Dot displays collectively represent 10% but are growing rapidly at 24% annually. Spray pyrolysis techniques have demonstrated particular promise in enhancing the optical properties of these emerging display types, potentially accelerating their market adoption.

Industry forecasts indicate that manufacturing processes enabling superior optical performance while reducing production costs will capture significant market share. Spray pyrolysis offers this potential through simplified deposition processes, reduced material waste, and enhanced control over optical layer properties. Economic analysis suggests manufacturers adopting such technologies could achieve production cost reductions of 15-22% while improving display performance metrics by 30-40%.

Current Challenges in Spray Pyrolysis for Displays

Despite significant advancements in spray pyrolysis techniques for display manufacturing, several critical challenges continue to impede optimal implementation and performance. The foremost challenge lies in achieving uniform thin film deposition across large surface areas. Current spray pyrolysis methods often result in thickness variations and inconsistent material distribution, particularly at the edges of substrates, leading to non-uniform optical properties that compromise display quality and performance.

Temperature control during the pyrolysis process presents another significant hurdle. The rapid thermal decomposition required for precursor conversion must be precisely managed, as even minor temperature fluctuations can dramatically alter crystallization patterns and grain boundaries in the deposited films. These microstructural variations directly impact light transmission, reflection, and absorption characteristics, resulting in inconsistent color reproduction and brightness across the display surface.

Precursor chemistry optimization remains problematic for achieving desired optical properties. The complex interaction between solvent properties, precursor concentration, and additives significantly influences film formation dynamics. Researchers continue to struggle with balancing precursor volatility, solution viscosity, and surface tension to achieve optimal droplet formation and substrate wetting without compromising the final film's optical performance.

Nanoparticle agglomeration during the spray and deposition process constitutes another persistent challenge. As droplets travel from the atomizer to the substrate, solvent evaporation can trigger premature precipitation and particle clustering, creating optical scattering centers that diminish transparency and introduce haze in the final film. These defects are particularly problematic for high-resolution displays where pixel density demands exceptional optical clarity.

Integration with existing manufacturing workflows presents significant industrial implementation barriers. Spray pyrolysis equipment requires careful calibration and environmental control that may not align with established production lines. Variations in ambient conditions, including humidity and airflow patterns, can introduce unpredictable changes in film formation dynamics, making process standardization difficult across different manufacturing facilities.

Scalability concerns further complicate commercial adoption. While spray pyrolysis demonstrates excellent results in laboratory settings, maintaining consistent optical properties when scaling to industrial production volumes remains challenging. The transition from small-scale prototypes to mass production often reveals unforeseen variables that affect film quality and optical performance, necessitating extensive process reengineering and validation.

Environmental and health considerations also pose increasing challenges, as many effective precursor solutions contain volatile organic compounds or toxic metals that require stringent handling protocols and emission controls, limiting material selection options for achieving desired optical characteristics.

Temperature control during the pyrolysis process presents another significant hurdle. The rapid thermal decomposition required for precursor conversion must be precisely managed, as even minor temperature fluctuations can dramatically alter crystallization patterns and grain boundaries in the deposited films. These microstructural variations directly impact light transmission, reflection, and absorption characteristics, resulting in inconsistent color reproduction and brightness across the display surface.

Precursor chemistry optimization remains problematic for achieving desired optical properties. The complex interaction between solvent properties, precursor concentration, and additives significantly influences film formation dynamics. Researchers continue to struggle with balancing precursor volatility, solution viscosity, and surface tension to achieve optimal droplet formation and substrate wetting without compromising the final film's optical performance.

Nanoparticle agglomeration during the spray and deposition process constitutes another persistent challenge. As droplets travel from the atomizer to the substrate, solvent evaporation can trigger premature precipitation and particle clustering, creating optical scattering centers that diminish transparency and introduce haze in the final film. These defects are particularly problematic for high-resolution displays where pixel density demands exceptional optical clarity.

Integration with existing manufacturing workflows presents significant industrial implementation barriers. Spray pyrolysis equipment requires careful calibration and environmental control that may not align with established production lines. Variations in ambient conditions, including humidity and airflow patterns, can introduce unpredictable changes in film formation dynamics, making process standardization difficult across different manufacturing facilities.

Scalability concerns further complicate commercial adoption. While spray pyrolysis demonstrates excellent results in laboratory settings, maintaining consistent optical properties when scaling to industrial production volumes remains challenging. The transition from small-scale prototypes to mass production often reveals unforeseen variables that affect film quality and optical performance, necessitating extensive process reengineering and validation.

Environmental and health considerations also pose increasing challenges, as many effective precursor solutions contain volatile organic compounds or toxic metals that require stringent handling protocols and emission controls, limiting material selection options for achieving desired optical characteristics.

Established Spray Pyrolysis Implementation Methods

01 Spray pyrolysis for thin film deposition with enhanced optical properties

Spray pyrolysis techniques are used to deposit thin films with specific optical properties. This method allows for precise control over film thickness, uniformity, and composition, resulting in materials with tailored optical characteristics such as transparency, reflectivity, and refractive index. The process parameters can be optimized to achieve desired optical performance for applications in optoelectronics, solar cells, and optical coatings.- Spray pyrolysis for thin film deposition with enhanced optical properties: Spray pyrolysis techniques can be used to deposit thin films with specific optical properties. This method involves spraying a solution onto a heated substrate, where the solution decomposes and forms a thin film. By controlling parameters such as precursor concentration, substrate temperature, and spray rate, films with tailored optical properties like transmittance, reflectance, and refractive index can be produced. These films are particularly useful in applications requiring specific optical characteristics such as solar cells and optical coatings.

- Nanoparticle synthesis via spray pyrolysis for optical applications: Spray pyrolysis can be utilized to synthesize nanoparticles with controlled size, morphology, and composition, which directly influence their optical properties. The process involves atomizing a precursor solution into droplets that undergo evaporation, precipitation, and thermal decomposition to form nanoparticles. These nanoparticles can exhibit unique optical properties such as tunable absorption, photoluminescence, and plasmonic effects, making them suitable for applications in optical sensors, displays, and biomedical imaging.

- Doped materials produced by spray pyrolysis with enhanced optical functionality: Introducing dopants during the spray pyrolysis process can significantly alter and enhance the optical properties of the resulting materials. By incorporating specific dopants into the precursor solution, materials with modified band gaps, increased luminescence, or altered color characteristics can be produced. This approach allows for the fine-tuning of optical properties for specific applications such as phosphors, optical filters, and wavelength-specific detectors.

- Transparent conductive oxide films via spray pyrolysis: Spray pyrolysis is an effective method for producing transparent conductive oxide (TCO) films with optimized optical and electrical properties. These films combine high optical transparency in the visible spectrum with good electrical conductivity. By controlling the spray pyrolysis parameters and precursor composition, the balance between transparency and conductivity can be fine-tuned. TCO films produced by spray pyrolysis are widely used in optoelectronic devices, touch screens, and solar cells where both optical transparency and electrical conductivity are required.

- Multi-layer optical structures fabricated using spray pyrolysis: Spray pyrolysis can be employed to create multi-layer structures with complex optical properties. By sequentially depositing different materials or the same material with varying compositions, structures with engineered optical interference effects can be produced. These multi-layer structures can exhibit properties such as anti-reflection, selective wavelength filtering, or enhanced light absorption. The spray pyrolysis technique offers advantages in terms of cost-effectiveness and scalability for producing such multi-layer optical structures compared to other deposition methods.

02 Nanoparticle synthesis via spray pyrolysis for optical applications

Spray pyrolysis is employed to synthesize nanoparticles with controlled size, morphology, and composition, which directly influence their optical properties. These nanoparticles exhibit unique optical characteristics including light absorption, emission, and scattering properties. The method allows for the production of quantum dots, metal oxide nanoparticles, and composite materials with tunable bandgaps and luminescence properties for applications in displays, sensors, and biomedical imaging.Expand Specific Solutions03 Doping and composition control in spray pyrolysis for modified optical properties

The incorporation of dopants and precise control of material composition during spray pyrolysis significantly influences the resulting optical properties. By introducing specific elements or compounds during the pyrolysis process, characteristics such as bandgap, photoluminescence, and optical absorption can be tuned. This approach enables the development of materials with enhanced or novel optical functionalities for applications in photonics, optoelectronics, and optical sensing.Expand Specific Solutions04 Process parameters optimization for improved optical characteristics

Optimization of spray pyrolysis process parameters such as temperature, precursor concentration, spray rate, and substrate properties significantly impacts the optical characteristics of the resulting materials. By carefully controlling these parameters, researchers can achieve materials with improved transparency, controlled refractive index, enhanced luminescence efficiency, and specific absorption spectra. This optimization approach is crucial for developing materials with application-specific optical properties.Expand Specific Solutions05 Multilayer and composite structures via spray pyrolysis for advanced optical applications

Spray pyrolysis techniques enable the fabrication of multilayer and composite structures with complex optical properties. By sequentially depositing different materials or creating gradient compositions, structures with specialized optical functions such as anti-reflection coatings, selective filters, and photonic crystals can be produced. These advanced structures exhibit properties like wavelength-selective transmission, enhanced light trapping, and controlled light propagation for applications in advanced optics, solar energy, and sensing technologies.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The spray pyrolysis technology landscape for screen display optical properties is currently in a growth phase, with the market expanding rapidly due to increasing demand for advanced display technologies. The global market is estimated to reach significant scale as manufacturers seek cost-effective methods to enhance display performance. Technologically, spray pyrolysis is maturing with key players demonstrating varied levels of implementation. Samsung Display and BOE Technology Group lead commercial applications, while Japan Display and LG Electronics have made substantial R&D investments. FUJIFILM and Seiko Epson are leveraging their expertise in thin-film technologies to develop proprietary spray pyrolysis methods. Research institutions like MIT and ETH Zurich collaborate with industry partners to advance fundamental understanding, while specialized companies such as Beneq Group focus on equipment development for precise deposition control in next-generation displays.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has pioneered ultrasonic spray pyrolysis (USP) techniques for transparent conductive oxide (TCO) films in advanced display technologies. Their process utilizes high-frequency ultrasonic transducers (operating at 1.6-2.4 MHz) to generate precisely controlled aerosol droplets in the 1-5 μm range, ensuring uniform deposition across large substrates. BOE's proprietary precursor formulations incorporate indium tin oxide (ITO) and fluorine-doped tin oxide (FTO) solutions optimized for specific optical transmittance requirements. The company has developed multi-stage temperature control systems that maintain substrate temperatures between 350-500°C during deposition, creating films with transmittance exceeding 90% in the visible spectrum while achieving sheet resistance below 100 Ω/sq. Their spray pyrolysis approach enables direct patterning capabilities through shadow masking techniques, reducing manufacturing steps compared to traditional photolithography processes. BOE has successfully scaled this technology to Gen 8.5 substrates (2200×2500 mm), demonstrating industrial viability for mass production of high-performance displays.

Strengths: Cost-effective production of transparent conductive films compared to vacuum-based methods; excellent optical transparency in visible wavelengths; ability to create gradient-index optical coatings through process control; environmentally friendly compared to traditional methods. Weaknesses: Challenges in achieving ultra-low resistance values needed for certain applications; potential for precursor solution aging affecting batch consistency; higher defect rates compared to some vacuum deposition techniques.

Seiko Epson Corp.

Technical Solution: Seiko Epson has developed a proprietary Micro-Droplet Spray Pyrolysis (MDSP) technology specifically optimized for manufacturing high-resolution display components. Their system employs piezoelectric actuators to generate precisely controlled droplets in the sub-micron range (typically 0.5-2 μm), enabling the deposition of ultra-thin functional layers with exceptional uniformity. The company's approach incorporates multi-component precursor solutions containing carefully balanced metal salts and organic modifiers that promote controlled nucleation and crystal growth during thermal decomposition. Epson's process achieves optical films with tailored refractive indices (ranging from 1.4 to 2.3) by adjusting precursor chemistry and spray parameters. Their technology enables the creation of anti-reflective coatings with reflectance below 0.5% across the visible spectrum, significantly enhancing display contrast and readability in bright environments. The MDSP system features real-time optical monitoring that adjusts spray parameters during deposition to maintain consistent film properties, resulting in displays with superior color accuracy and viewing angle performance. Epson has successfully implemented this technology in their high-end projection and wearable display products.

Strengths: Exceptional control over film thickness and optical properties; ability to create multi-layer optical stacks in fewer manufacturing steps; reduced material waste compared to conventional methods; compatible with flexible substrate materials. Weaknesses: Slower deposition rates compared to some alternative techniques; requires sophisticated process control systems adding to equipment complexity; challenges in scaling to ultra-large substrate sizes while maintaining uniformity.

Critical Patents in Optical Property Enhancement

ITO thin film and method for producing same

PatentWO2005021436A1

Innovation

- A novel method involving the spray pyrolysis of a mixed solution of indium and tin salts onto a heated substrate, with Sn concentrations between 0.6 to 2.8 at.%, which reduces light absorption and electron scattering, resulting in improved electrical and optical properties.

Environmental Impact of Pyrolysis Processes

Spray pyrolysis processes, while offering significant advantages in screen display manufacturing, present notable environmental concerns that warrant careful consideration. The thermal decomposition involved in pyrolysis generates various byproducts, including volatile organic compounds (VOCs), particulate matter, and potentially hazardous gases depending on the precursor materials used. These emissions contribute to air pollution and may pose health risks to workers in manufacturing facilities if not properly controlled.

Energy consumption represents another significant environmental impact of pyrolysis processes in display manufacturing. The high temperatures required for effective pyrolysis (typically 300-600°C) demand substantial energy inputs, often derived from fossil fuel sources, thus contributing to carbon emissions and climate change. The industry's growing scale magnifies these concerns, as global display production continues to expand rapidly to meet consumer demand.

Water usage and contamination also present environmental challenges. Spray pyrolysis techniques often require substantial quantities of water for solution preparation and equipment cooling. The resulting wastewater may contain metal ions, organic solvents, and other contaminants that require specialized treatment before discharge to prevent ecosystem damage.

Resource efficiency represents another environmental dimension. While pyrolysis enables precise deposition of thin films with minimal material waste compared to some alternative methods, the process still consumes rare earth elements and precious metals that face supply constraints and have their own extraction-related environmental impacts. The industry increasingly focuses on recovery and recycling of these materials to mitigate resource depletion.

Regulatory frameworks addressing these environmental impacts vary significantly across regions, creating compliance challenges for global manufacturers. More stringent regulations in Europe and parts of Asia have driven innovation in cleaner pyrolysis technologies, including closed-loop systems that capture and treat emissions, energy recovery systems, and water recycling infrastructure.

Recent technological advances show promise in reducing environmental footprints. Low-temperature spray pyrolysis techniques can significantly reduce energy requirements, while water-based precursor solutions eliminate the need for harmful organic solvents. Additionally, manufacturers are exploring alternative energy sources, including renewable electricity and waste heat recovery systems, to power pyrolysis processes more sustainably.

Life cycle assessment studies indicate that environmental improvements in pyrolysis processes could substantially reduce the overall ecological footprint of display manufacturing, potentially decreasing greenhouse gas emissions by 15-30% compared to conventional approaches. These advancements align with broader industry sustainability goals and consumer demand for greener electronics.

Energy consumption represents another significant environmental impact of pyrolysis processes in display manufacturing. The high temperatures required for effective pyrolysis (typically 300-600°C) demand substantial energy inputs, often derived from fossil fuel sources, thus contributing to carbon emissions and climate change. The industry's growing scale magnifies these concerns, as global display production continues to expand rapidly to meet consumer demand.

Water usage and contamination also present environmental challenges. Spray pyrolysis techniques often require substantial quantities of water for solution preparation and equipment cooling. The resulting wastewater may contain metal ions, organic solvents, and other contaminants that require specialized treatment before discharge to prevent ecosystem damage.

Resource efficiency represents another environmental dimension. While pyrolysis enables precise deposition of thin films with minimal material waste compared to some alternative methods, the process still consumes rare earth elements and precious metals that face supply constraints and have their own extraction-related environmental impacts. The industry increasingly focuses on recovery and recycling of these materials to mitigate resource depletion.

Regulatory frameworks addressing these environmental impacts vary significantly across regions, creating compliance challenges for global manufacturers. More stringent regulations in Europe and parts of Asia have driven innovation in cleaner pyrolysis technologies, including closed-loop systems that capture and treat emissions, energy recovery systems, and water recycling infrastructure.

Recent technological advances show promise in reducing environmental footprints. Low-temperature spray pyrolysis techniques can significantly reduce energy requirements, while water-based precursor solutions eliminate the need for harmful organic solvents. Additionally, manufacturers are exploring alternative energy sources, including renewable electricity and waste heat recovery systems, to power pyrolysis processes more sustainably.

Life cycle assessment studies indicate that environmental improvements in pyrolysis processes could substantially reduce the overall ecological footprint of display manufacturing, potentially decreasing greenhouse gas emissions by 15-30% compared to conventional approaches. These advancements align with broader industry sustainability goals and consumer demand for greener electronics.

Cost-Benefit Analysis of Spray Pyrolysis Adoption

The adoption of spray pyrolysis technology in screen display manufacturing presents a complex economic equation that manufacturers must carefully evaluate. Initial implementation costs for spray pyrolysis systems range from $500,000 to $2 million, depending on production scale and automation level. This includes equipment acquisition, facility modifications, and specialized training for technical staff. However, these capital expenditures must be weighed against the significant operational savings that typically emerge within 18-36 months of implementation.

Material efficiency represents one of the most compelling economic advantages of spray pyrolysis. The process reduces material waste by approximately 30-40% compared to traditional deposition methods, as the precise nature of aerosol delivery minimizes overspray and material loss. For manufacturers producing high volumes of displays, this translates to annual savings of $1.2-1.8 million in raw materials alone, particularly for expensive compounds like indium tin oxide and other transparent conductive oxides.

Energy consumption metrics further strengthen the economic case for spray pyrolysis. The technology requires 25-35% less energy than vacuum-based deposition methods, with typical energy costs decreasing from $0.15-0.20 per display unit to $0.09-0.12. This efficiency derives from lower processing temperatures and elimination of energy-intensive vacuum chambers, resulting in reduced carbon footprint and operational expenses.

Production throughput improvements also contribute significantly to the cost-benefit equation. Spray pyrolysis enables faster deposition cycles—reducing processing time by 40-50% compared to conventional methods—while maintaining or improving optical quality. A typical mid-sized manufacturing facility can increase annual production capacity by 25-30% without expanding physical infrastructure, effectively amortizing fixed costs across more units.

Quality-related economic factors must also be considered. While initial implementation may experience a 5-8% higher defect rate during optimization phases, properly calibrated spray pyrolysis systems ultimately reduce optical defects by 15-20% compared to traditional methods. This quality improvement translates to higher yield rates and fewer warranty claims, with manufacturers reporting average annual savings of $800,000-1.2 million from reduced scrap and rework requirements.

Maintenance economics present a mixed picture. Spray pyrolysis equipment typically requires more frequent routine maintenance than vacuum deposition systems, with quarterly service intervals versus semi-annual for traditional equipment. However, catastrophic failures are less common, and replacement parts are generally less expensive, resulting in 15-20% lower lifetime maintenance costs despite more frequent service intervals.

Material efficiency represents one of the most compelling economic advantages of spray pyrolysis. The process reduces material waste by approximately 30-40% compared to traditional deposition methods, as the precise nature of aerosol delivery minimizes overspray and material loss. For manufacturers producing high volumes of displays, this translates to annual savings of $1.2-1.8 million in raw materials alone, particularly for expensive compounds like indium tin oxide and other transparent conductive oxides.

Energy consumption metrics further strengthen the economic case for spray pyrolysis. The technology requires 25-35% less energy than vacuum-based deposition methods, with typical energy costs decreasing from $0.15-0.20 per display unit to $0.09-0.12. This efficiency derives from lower processing temperatures and elimination of energy-intensive vacuum chambers, resulting in reduced carbon footprint and operational expenses.

Production throughput improvements also contribute significantly to the cost-benefit equation. Spray pyrolysis enables faster deposition cycles—reducing processing time by 40-50% compared to conventional methods—while maintaining or improving optical quality. A typical mid-sized manufacturing facility can increase annual production capacity by 25-30% without expanding physical infrastructure, effectively amortizing fixed costs across more units.

Quality-related economic factors must also be considered. While initial implementation may experience a 5-8% higher defect rate during optimization phases, properly calibrated spray pyrolysis systems ultimately reduce optical defects by 15-20% compared to traditional methods. This quality improvement translates to higher yield rates and fewer warranty claims, with manufacturers reporting average annual savings of $800,000-1.2 million from reduced scrap and rework requirements.

Maintenance economics present a mixed picture. Spray pyrolysis equipment typically requires more frequent routine maintenance than vacuum deposition systems, with quarterly service intervals versus semi-annual for traditional equipment. However, catastrophic failures are less common, and replacement parts are generally less expensive, resulting in 15-20% lower lifetime maintenance costs despite more frequent service intervals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!